- Manuals

- Brands

- GE Manuals

- Measuring Instruments

- 3300

- Installation manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Installation Manual

Bently Nevada™ Asset Condition Monitoring

3300 System Installation

Part Number 80172-01

Rev. N (08/07)

Related Manuals for GE Bently Nevada 3300

Summary of Contents for GE Bently Nevada 3300

-

Page 1

Installation Manual Bently Nevada™ Asset Condition Monitoring 3300 System Installation Part Number 80172-01 Rev. N (08/07) -

Page 2

Bently Nevada Keyphasor, Proximitor Contact Information The following ways of contacting Bently Nevada are provided for those times when you cannot contact your local representative: Mailing Address 1631 Bently Parkway South Minden, Nevada USA 89423 Telephone 1.775.782.3611 1.800.227.5514 1.775.215.2873 Internet www.ge-energy.com/bently… -

Page 3

Additional Information Notice: This manual does not contain all the information required to operate and maintain the product. Refer to the following manuals for other required information. 3300 System Overview (Part Number 80171-01) 3300 System Troubleshooting (Part Number 80173-01) The above two documents and 80172 are available as Part Number 80170-01 or -02. 3300/12 AC Power Supply (Part Number 89602-01) 3300/14 DC Power Supply (Part Number 101256-01) 3300/03 System Monitor (Part Number 89604-01) -

Page 4: Table Of Contents

3300 System Installation Manual Contents RECEIVING INSPECTION ……………………..1 HANDLING & STORING CONSIDERATIONS………………2 RACK ASSEMBLY OPTIONS……………………3 RACK INSTALLATION [PANEL MOUNT]………………..4 RACK INSTALLATION [19-INCH EIA] ………………… 5 PANEL CUTOUT DIMENSIONS……………………. 6 WEATHERPROOF HOUSING INSTALLATION ………………7 POWER SUPPLY INSTALLATION ………………….13 SYSTEM MONITOR INSTALLATION ………………….15 MONITOR INSTALLATION [TYPICAL] ………………..16 POWER INPUT MODULE……………………17…

-

Page 5: Receiving Inspection

Section 1 — RECEIVING INSPECTION 1. RECEIVING INSPECTION 1. Visually inspect the exterior of rack assembly and components for obvious shipping damage. 2. Inspect interior of monitors and power supply. Loosen screws to pull each monitor and power supply out from rack. DAMAGE CLAIMS If shipping damage is apparent, file a claim with the carrier and…

-

Page 6: Handling & Storing Considerations

3300 System Installation Manual 2. HANDLING & STORING CONSIDERATIONS Handling and storing of printed circuit boards is extremely critical. Circuit boards contain devices that are susceptible to damage when exposed to electrostatic charges. Damage caused by obvious mishandling of the board will void the warranty. To avoid damage, observe the following precautions in the order given.

-

Page 7: Rack Assembly Options

Section 3 — RACK ASSEMBLY OPTIONS 3. RACK ASSEMBLY OPTIONS EXTERNAL DIMENSIONS 01,11,21,31 = 4 POSITIONS 11.00 IN. (279.4 mm) 8.00 IN. (203.2 mm) 02,12,22,32 = 6 POSITIONS 15.00 IN. (381.0 mm) 12.00 IN. (304.8 mm) 03,13,23,33 = 8 POSITIONS 19.00 IN.

-

Page 8: Rack Installation [Panel Mount]

3300 System Installation Manual 4. RACK INSTALLATION [PANEL MOUNT] Slide rack through panel cutout.

-

Page 9: Rack Installation [19-Inch Eia]

Section 5 — RACK INSTALLATION [19-INCH EIA] 5. RACK INSTALLATION [19-INCH EIA]…

-

Page 10: Panel Cutout Dimensions

3300 System Installation Manual 6. PANEL CUTOUT DIMENSIONS OPTIONS RACK SIZE 01,11,21,31 4 POSITIONS 8.56 IN. (217.5 mm) 01.12.22.32 6 POSITIONS 12.57 IN (319.3mm) 03,13,23,33 8 POSITIONS 16.57 IN. (420.8mm) 04,14,24,34 10 POSITIONS 20.58 IN (522.7 mm) 05,15,25,35 12 POSITIONS 24.58 IN (624.3 mm) 06,16,26,36 14 POSITIONS…

-

Page 11: Weatherproof Housing Installation

Section 7 — WEATHERPROOF HOUSING INSTALLATION 7. WEATHERPROOF HOUSING INSTALLATION The next 5 pages contain the weatherproof housing installation drawing, 330006.

-

Page 12

3300 System Installation Manual… -

Page 13

Section 7 — WEATHERPROOF HOUSING INSTALLATION… -

Page 14

3300 System Installation Manual… -

Page 15

Section 7 — WEATHERPROOF HOUSING INSTALLATION… -

Page 16

3300 System Installation Manual… -

Page 17: Power Supply Installation

Section 8 — POWER SUPPLY INSTALLATION 8. POWER SUPPLY INSTALLATION For systems with the AC Power Supply, perform the following steps. For systems with the DC Power Supply, perform the steps on the following page. WARNING High voltage present could cause shock, burns, or death.

-

Page 18

3300 System Installation Manual For systems with the DC Power Supply, perform the following steps. WARNING High voltage present could cause shock, burns, or death. Do not touch exposed wires or terminals. 1. Slide Power Supply into rack and fasten two screws. -

Page 19: System Monitor Installation

Section 9 — SYSTEM MONITOR INSTALLATION 9. SYSTEM MONITOR INSTALLATION 1. Slide System Monitor panel to the right before inserting monitor. Slide System Monitor board into rack to engage connector on backplane. 2. Slide front panel to the left and fasten two screws.

-

Page 20: Monitor Installation [Typical]

3300 System Installation Manual 10. MONITOR INSTALLATION [TYPICAL] 1. Slide monitor front panel to the right before inserting monitor. Slide monitor circuit board into rack to engage connector on backplane. If the monitor is a dual width monitor with two separate circuit boards, line the lower edges of both boards up with the slots in the rack and slide the boards in simultaneously.

-

Page 21: Power Input Module

Section 11 — POWER INPUT MODULE 11. POWER INPUT MODULE For grounding technique see Section 15.

-

Page 22: Signal Input Relay Modules

3300 System Installation Manual 12. SIGNAL INPUT RELAY MODULES WARNING CAUTION High voltage present The following information is not could cause shock, applicable to the Velomitor. Refer to burns, or death. the 3300/55 Maintenance Manual for jumper configuration of the Do not touch exposed Velomitor Relay Module.

-

Page 23

Section 12 — SIGNAL INPUT RELAY MODULES WARNING CAUTION High voltage present The following information is not applicable to the Velomitor. could cause shock, Refer to the 3300/55 burns, or death. Maintenance Manual for jumper Do not touch exposed configuration of the Velomitor wires or terminals. -

Page 24

3300 System Installation Manual SIGNAL INPUT/QUAD RELAY CARD OPTION * RELAY OPTIONS INSTALL REMOVE ALERT RELAYS W2,3C W3A,4C NORMALLY W3D,4D DE-ENERGIZED ALERT RELAYS W3A,4C W2,3C NORMALLY W3D,4D ENERGIZED DANGER RELAYS W1,3B W4B,4F NORMALLY W4A,4E DE-ENERGIZED DANGER RELAYS W4B,4F W1,3B NORMALLY W4A,4E ENERGIZED * For more information on relay configuration refer to… -

Page 25

Section 12 — SIGNAL INPUT RELAY MODULES WARNING CAUTION High voltage present The following information is not applicable to the could cause shock Velomitor. Refer to the burns or death 3300/55 Maintenance Manual for jumper Do not touch exposed configuration of the wires or terminals Velomitor Relay Module. -

Page 26

3300 System Installation Manual JUMPER RELAY OPTIONS INSTALL REMOVE ALERT RELAYS W4,W9 NORMALLY DE-ENERGIZED ALERT RELAYS W4,W9 NORMALLY ENERGIZED DANGER RELAYS W1,W10 NORMALLY DE-ENERGIZED DANGER RELAYS W1,10 NORMALLY ENERGIZED… -

Page 27: Alert Relay Actuation Circuits

Section 13 — ALERT RELAY ACTUATION CIRCUITS 13. ALERT RELAY ACTUATION CIRCUITS The following diagram shows the functional concept of jumper configurations for Alert relay bus actuation for the Dual Relay Module. For more detail refer to schematics in the applicable monitor manuals.

-

Page 28

3300 System Installation Manual FUNCTION JUMPER INSTALL REMOVE Set Alert relay for normally energized operation* W4,W11 Set Alert relay for normally de-energized operation* W4,W11 Select Alert bus 1 Select Alert bus 2 * REFER TO SECTION 12 FOR JUMPER CONFIGURATION OF RELAYS IN A SYSTEM WITH INTERNAL BARRIERS. -

Page 29

Section 13 — ALERT RELAY ACTUATION CIRCUITS The following diagram shows the functional concept of jumper configurations for Alert relay actuation for the Quad Relay Module. Note: The jumper configuration shown is not applicable to the Velomitor Signal Input Relay Module. Refer to the Dual Velocity Monitor Maintenance Manual. -

Page 30: Danger Relay Actuation Circuits

3300 System Installation Manual 14. DANGER RELAY ACTUATION CIRCUITS The following diagram shows the functional concept of jumper configurations for Danger relay bus actuation for the Dual Relay Module. Note: The jumper configuration shown is not applicable to the Velomitor Signal Input Relay Module.

-

Page 31

Section 14 — DANGER RELAY ACTUATION CIRCUITS The following diagram shows the functional concept of jumper configurations for Danger Relay actuation for the Quad Relay Module. Note: The jumper configuration shown is not applicable to the Velomitor Signal Input Relay Module. For more details refer to schematics in the applicable monitor manuals. -

Page 32: Field Grounding Technique

3300 System Installation Manual 15. FIELD GROUNDING TECHNIQUE 1. Refer to the applicable monitor manual for monitor connections. 2. For single point ground on typical system installations, install a jumper wire between the terminals labeled «Single Point Ground» on the Power Input Module. For systems with external safety barriers, refer to the field wiring diagrams in the appropriate monitor maintenance manuals for grounding requirements.

-

Page 33

Section 15 — FIELD GROUNDING TECHNIQUE…

3300 XL NSv Proximity Transducer System

Datasheet

|

BentlyNevadaMachineryCondition Monitoring |

147385Rev. K |

Description

The3300XL NSvProximity Transducer system is intended for usewith centrifugalair compressors, refrigeration compressors, process gas compressors and other machines with tight installation requirements. The3300XL NSvProximity Transducer System consists of:

•a 3300NSvprobe

•a 3300NSvextension cable

•a 3300XL NSvProximitor Sensor(1)

Theprimary uses for the3300XL NSvTransducer System are for areas wherecounter bore, sideview or rearview restrictions limit theuseofstandard Bently Nevada 3300and 3300XL 5 and 8mm Transducer Systems. It is also idealfor smalltarget applications, such as measuring radialvibration on shafts smaller than 51mm (2 in) or axialposition on flat targets smaller than 15mm (0.6in). It is primarily used in the following applications on fluid-filmed bearing machines wherea smallshaft or reduced side-view is present:

•Radialvibration and radialposition measurements

•Axial(thrust) position measurements

•Tachometer and zero speed measurements

•Phasereference(Keyphasor signals)

The3300XL NSvTransducer System design allows it to replace both the3300RAMTransducer Systems and the3000-series or 7000-series 190Transducer System. Upgrades from the 3300RAMsystem to the3300XL NSvsystem may usethe existing probe, extension cable, and monitoring system with 3300XL NSvProximitor Sensor. Upgrades from the3000-series or 7000-series Transducer System must replacetheprobe, extension cableand Proximitor Sensor with NSvcomponents.

|

3300XL NSv Proximity TransducerSystem |

|

|

Datasheet |

147385Rev. K |

The3300XL NSvTransducer System has an AverageScaleFactor of7.87V/mm (200 mV/mil), which is themost common output for eddy current transducers. Its enhanced sideview and smalltarget characteristics giveit a shorter linear rangethan theBently Nevada 3300XL-series 5and 8mm Transducer System. With The1.5mm (60mils) oflinear range exceeds thelinear rangeofthe3000-series 190 Transducer System.

Although theterminals and connector on theProximitor Sensor have protection against electrostatic discharge, takereasonableprecautions to avoid electrostatic dischargeduring handling.

Proximitor Sensor

The3300XL NSvProximitor Sensor has similar features to thosefound in the3300XL 8mm Proximitor Sensor. Its thin design allows the user to mount it in either a high-density DIN-rail installation or a moretraditionalpanelmount configuration. Improved RFI/EMIimmunity allows the3300XL NSvProximitor Sensor to achieveEuropean CE mark approvals without any specialmounting considerations. This RFI immunity also prevents nearby high frequency radio signals from adversely affecting the transducer system. SpringLoc terminalstrips on theProximitor Sensor requireno special installation tools and facilitatefaster, highly robust field wiring connections.

Proximity Probe and Extension Cable

The3300NSvprobeand extension cableare mechanically and electrically compatibleand interchangeablewith Bently Nevada’s previous 3300RAMproximity probeand extension cable. TheNSvprobehas increased chemical resistancecompared to the3300RAMprobe, which allows its usein many process compressor applications. Theside-view characteristics ofthe3300NSvprobearealso superior to thoseofthe3000-series 190probe when gapping the3300NSvprobeat thesame distancefrom theprobetarget.

The3300NSvprobecomes in varying probe caseconfigurations, including armored and unarmored ¼ -28, 3⁄8-24, M8X1and M10X1 probethreads. Thereversemount 3300NSv probecomes standard with either 3⁄8-24or M10X1threads. Allcomponents ofthe transducer system havegold-plated brass ClickLocconnectors. ClickLoc connectors lock into placeand prevent theconnection from loosening. Thepatented TipLocmolding method provides a robust bond between the probetip and theprobebody. Bently Nevada’s patented CableLocdesign provides 220N(50 lb) ofpullstrength and securely attaches the probecableto theprobetip. Connector protectors arerecommended for useon the probe-to-extension cableconnection, as well as on thecable-to-Proximitor Sensor connection. Connector protectors prevent most liquids from entering into theClickLoc connectors and adversely affecting the electricalsignal(2).

Notes:

(1)ProximitorSensors aresupplied by default from thefactory calibrated to AISI4140steel. Calibration to other target materials is available upon request.

(2)Siliconetapeis also provided with each 3300NSvextension cableand can beused instead ofconnector protectors. Siliconetape is not recommended in applications wherethe probe-to-extension cableconnection willbe exposed to turbineoil.

2/30

|

3300XL NSv Proximity TransducerSystem |

|||

|

Datasheet |

147385Rev. K |

||

|

(1,000 feet)between the3300 XL |

|||

|

NSv ProximitorSensorand the |

|||

|

monitor. Seethefrequency |

|||

|

Unless otherwisenoted, thefollowing |

responsegraphs Figure16 and |

||

|

Figure17 forsignal rolloff at high |

|||

|

specifications arefor a 3300XL NSvProximitor |

frequencies when using longerfield |

||

|

Sensor, extension cableand probebetween 0°C |

wiring lengths. |

||

|

and +45°C(+32°F to +113°F), with a -24Vdc |

1.5 mm (60 mils). Linearrange |

||

|

power supply, a 10kΩload, a Bently Nevada |

begins at approximately 0.25 mm |

||

|

supplied AISI4140steeltarget that is 31mm (1.2 |

LinearRange |

(10 mils)from target and is from |

|

|

in) diameter or larger, and a probegap of1.0 |

0.25 to 1.75 mm (10 to 70 mils) |

||

|

mm (40mils). Thesystem accuracy and |

(approximately -1 to -13 Vdc). |

||

|

interchangeability specifications do not apply |

Recommended |

1.0 mm (40 mils) |

|

|

when using a transducer system calibrated to |

Gap Setting |

||

|

any target other than a Bently Nevada AISI4140 |

System performance over ambient temperature |

||

|

steeltarget. |

range (0°C to 45°C) |

Electrical

|

Proximitor |

Accepts onenon-contacting 3300 |

|

|

RAM or3300 NSv Proximity Probe |

||

|

SensorInput |

||

|

and Extension Cable. |

||

|

Requires -17.5 Vdc to -26 Vdc |

||

|

without barriers at 12 mA maximum |

||

|

Power |

consumption, -23 Vdc to -26 Vdc |

|

|

with barriers. Operation at a more |

||

|

positivevoltagethan -23.5 Vdc can |

||

|

result in reduced linearrange. |

||

|

Supply |

Less than 2 mV changein output |

|

|

voltagepervolt changein input |

||

|

Sensitivity |

||

|

voltage. |

||

|

Output |

50 Ω |

|

|

resistance |

||

|

Probe dc Resistance |

|

ProbeLength |

Resistancefrom theCenter |

|

Conductorto theOuterConductor |

|

|

(m) |

(RPROBE)(ohms) |

0.54.0 ± 0.5

1.04.2 ± 0.5

5.05.3 ± 0.7

7.05.9 ± 0.9

|

Extension |

Centerconductor: 0.220 Ω/m |

|

|

(0.067 Ω/ft) |

||

|

cabledc |

||

|

resistance |

Shield:0.066 Ω/m (0.020 Ω/ft) |

|

|

Extension |

69.9 pF/m (21.3 pF/ft)typical |

|

|

cable |

||

|

capacitance |

||

|

2 |

||

|

0.2 to 1.5 mm (16 to 24 AWG) [0.25 |

||

|

2 |

||

|

to 0.75 mm (18 to 23 AWG)with |

||

|

Field Wiring |

ferrules]. Recommend using three- |

|

|

conductorshielded triad cable. |

||

|

Maximum length of 305 metres |

|

Incremental |

7.87 V/mm (200 mV/mil)+12.5%/- |

|

|

20% including interchangeability |

||

|

ScaleFactor |

errorwhen measured in increments |

|

|

(ISF) |

of 0.25 mm (10 mils)overthe1.5 |

|

|

mm (60 mil)linearrange. |

||

|

Deviation from |

Less than ±0.06 mm (±2.3 mils). |

|

|

best fit straight |

||

|

line(DSL) |

||

|

Frequency |

0 to 10 kHz: +0, -3 dB typical, with up |

|

|

to 305 metres (1000 feet)of field |

||

|

Response |

||

|

wiring. |

||

|

Minimum: 8.9 mm (0.35 in) |

||

|

diameter |

||

|

Recommended minimum: 13 mm |

||

|

(0.5 in)diameter |

||

|

Target Size(flat |

Axial position measurements on |

|

|

target) |

shaft diameters smallerthan 13mm |

|

|

(0.5 in)will generally result in a |

||

|

changein scalefactor. Reducing |

||

|

thegap between theprobeand |

||

|

target will help limit thechangein |

||

|

scalefactor. SeeFigure12 for |

||

|

additional information. |

||

|

Minimum (standard X-Y probe |

||

|

configuration): 30 mm (1.2 in) |

||

|

Minimum (X-Y proximity probes |

||

|

offset axially by 23 mm (0.9 in)): 20 |

||

|

mm (0.8 in) |

||

|

Shaft Diameter |

Measurements on shaft diameters |

|

|

smallerthan 30 mm (1.2 in)usually |

||

|

requireclosespacing of radial |

||

|

vibration oraxial position |

||

|

transducers. This creates the |

||

|

potential fortheirelectromagnetic |

||

|

emitted fields to interact with one |

||

3/30

|

3300XL NSv Proximity TransducerSystem |

|||||||||||||||

|

Datasheet |

147385Rev. K |

||||||||||||||

|

another(cross-talk), resulting in |

Extension |

75 Ωcoaxial, fluoroethylene |

|||||||||||||

|

erroneous readings. To prevent |

Cable |

||||||||||||||

|

propylene(FEP)insulated. |

|||||||||||||||

|

cross-talk, maintain minimum |

Material |

||||||||||||||

|

separation of m transducertips of |

|||||||||||||||

|

Proximitor |

|||||||||||||||

|

at least 25 mm (1.0 in)foraxial |

|||||||||||||||

|

Sensor |

A380 aluminum |

||||||||||||||

|

position measurements or23 mm |

|||||||||||||||

|

Material |

|||||||||||||||

|

(0.9 in)forradial vibration |

|||||||||||||||

|

System |

5 or7 metres including extension |

||||||||||||||

|

measurements. ProbeCross-talk |

|||||||||||||||

|

with Probes Mounted in Parallel and |

Length |

cable |

|||||||||||||

|

ProbeCross-talk with Probes |

Extension |

FlexibleAISI 302 SSTwith/without FEP |

|||||||||||||

|

Mounted in X-Y Configuration |

CableArmor |

||||||||||||||

|

Radial vibration orradial position |

(optional) |

outerjacket. |

|||||||||||||

|

measurements on shaft diameters |

|||||||||||||||

|

220 N(50 lb)probecaseto probe |

|||||||||||||||

|

smallerthan 20 mm (0.8 in)will |

Tensile |

||||||||||||||

|

lead. 220 N(50 lb)at probelead to |

|||||||||||||||

|

generally result in greaterthan a |

Strength |

||||||||||||||

|

extension cableconnectors. 220 N |

|||||||||||||||

|

10% changein AverageScaleFactor |

(maximum |

||||||||||||||

|

(50 lb)probecaseto stainless steel |

|||||||||||||||

|

(ASF). SeeFigure13 foradditional |

rated) |

||||||||||||||

|

armor. |

|||||||||||||||

|

information. |

|||||||||||||||

|

Connector |

|||||||||||||||

|

Minimum: 9.5 mm (0.375 in) |

Gold-plated brass |

||||||||||||||

|

material |

|||||||||||||||

|

Recommended minimum: 13 mm |

|||||||||||||||

|

Recommended |

case hole and tap size for 1/4-28 |

||||||||||||||

|

(0.5 in) |

case |

||||||||||||||

|

Counterbores smallerthan 13 mm |

Drill Size |

0.213 in |

|||||||||||||

|

Counterbore |

(0.5 in)generally result in a change |

HoleSize |

0.218 to 0.222 in |

||||||||||||

|

in scalefactorat fargaps. |

|||||||||||||||

|

HoleDepth |

0.376 to 0.750 in |

||||||||||||||

|

Reducing thegap between the |

|||||||||||||||

|

Tap Drill Size |

#3 |

||||||||||||||

|

probeand thetarget will allow the |

|||||||||||||||

|

transducersystem to maintain its |

Recommended |

case hole and tap size for M8x1 |

|||||||||||||

|

AverageScaleFactor(ASF)overa |

case |

||||||||||||||

|

reduced linearrange. SeeFigure9 |

|||||||||||||||

|

Drill Size |

7.4mm |

||||||||||||||

|

foradditional information. |

|||||||||||||||

|

HoleSize |

7.511 to 7.622 mm |

||||||||||||||

|

Effects of 60 Hz Magnetic Fields Up to 300 Gauss |

|||||||||||||||

|

HoleDepth |

12 to 24 mm |

||||||||||||||

|

(5 metre system) |

|||||||||||||||

|

Tap Drill Size |

L |

||||||||||||||

|

Output voltagein mil pp/gauss |

|||||||||||||||

|

Recommended case hole and tap size for 3/8-24 |

|||||||||||||||

|

Gap |

Proximitor |

Probe |

Ext. Cable |

case |

|||||||||||

|

Sensor |

|||||||||||||||

|

Drill Size |

0.332 in |

||||||||||||||

|

0.25 mm |

0.006 |

0.001 |

0.001 |

||||||||||||

|

HoleSize |

0.338 to 0.343 in |

||||||||||||||

|

(10 mils) |

|||||||||||||||

|

HoleDepth |

0.562 to 0.xxx1.125 in |

||||||||||||||

|

1.0 mm (40 |

0.007 |

0.002 |

0.001 |

||||||||||||

|

Tap Drill Size |

Q |

||||||||||||||

|

mils) |

|||||||||||||||

|

1.75 mm (70 |

|||||||||||||||

|

0.008 |

0.002 |

0.003 |

Recommended |

case hole and tap size for M10x1 |

|||||||||||

|

mils) |

case |

||||||||||||||

|

Mechanical |

Drill Size |

9.4mm |

|||||||||||||

|

HoleSize |

9.541 to 9.662 mm |

||||||||||||||

|

ProbeTip |

Polyphenylenesulfide(PPS). |

HoleDepth |

15 to 30 mm |

||||||||||||

|

Material |

|||||||||||||||

|

Tap Drill Size |

U |

||||||||||||||

|

ProbeCase |

AISI 304 stainless steel (SST). |

||||||||||||||

|

Material |

Connector-to-connector Torque |

||||||||||||||

|

75 Ωcoaxial, fluoroethylene |

|||||||||||||||

|

ProbeCase |

Maximum Rated |

Recommended |

|||||||||||||

|

ProbeCable |

propylene(FEP)insulated probe |

||||||||||||||

|

Torque |

|||||||||||||||

|

Specifications |

cablein thefollowing total probe |

||||||||||||||

|

¼ -28 orM8x1 |

|||||||||||||||

|

lengths: 0.5, 1, 5, or7 metres. |

7.3 N•m |

5.1 N•m |

|||||||||||||

|

probecases |

|||||||||||||||

4/30

|

3300XL NSv Proximity TransducerSystem |

|||||||||||||||

|

Datasheet |

147385Rev. K |

||||||||||||||

|

Connector-to-connector Torque |

Storage |

-52°C to +105°C (-62°F to +221°F) |

|||||||||||||

|

Temperature |

|||||||||||||||

|

(65 in•lb) |

(45 in•lb) |

||||||||||||||

|

100% condensing, non-submersible |

|||||||||||||||

|

3/8-24 orM10x1 |

33.9 N•m |

11.3 N•m |

Relative |

||||||||||||

|

when connectors areprotected. |

|||||||||||||||

|

probecases |

(300 in•lb) |

(100 in•lb) |

Humidity |

Tested to IEC 68-2-3 damp heat. |

|||||||||||

|

3300 NSv probes aredesigned to seal |

|||||||||||||||

|

3/8-24 orM10x1 |

22.6 N•m |

7.5 N•m |

|||||||||||||

|

probecases – |

differential pressurebetween the |

||||||||||||||

|

first three |

(200 in•lb) |

(66 in•lb) |

probetip and case. Theprobe |

||||||||||||

|

threads |

Probe |

sealing material consists of a Viton |

|||||||||||||

|

O-ring. Probes arenot pressure |

|||||||||||||||

|

Reversemount |

22.6 N•m |

7.5 N•m |

Pressure |

||||||||||||

|

tested priorto shipment. Contact our |

|||||||||||||||

|

probes |

(200 in•lb) |

(66 in•lb) |

custom design department if you |

||||||||||||

|

requirea test of thepressureseal for |

|||||||||||||||

|

yourapplication |

|||||||||||||||

|

Recommended |

Fingertight |

||||||||||||||

|

It is theresponsibility of thecustomeroruser |

|||||||||||||||

|

torque |

|||||||||||||||

|

Maximum |

0.56 N• m (5 in• lb) |

to ensurethat all liquids and gases are |

|||||||||||||

|

torque |

contained and safely controlled should |

||||||||||||||

|

leakageoccurfrom a proximity probe. In |

|||||||||||||||

|

Minimum Bend |

|||||||||||||||

|

addition, solutions with high orlow pH |

|||||||||||||||

|

Radius (with or |

25.4 mm (1.0 in) |

||||||||||||||

|

values may erodethetip assembly of the |

|||||||||||||||

|

without sst |

probecausing media leakageinto |

||||||||||||||

|

armor) |

|||||||||||||||

|

surrounding areas. Bently Nevada will not |

|||||||||||||||

|

System Weight (typical) |

beheld responsibleforany damages |

||||||||||||||

|

Probe |

Approximately 14 to 150 g (0.5 to |

resulting from leaking 3300 NSv Proximity |

|||||||||||||

|

5.3 oz) |

Probes. In addition, 3300 NSv Proximity |

||||||||||||||

|

Probes will not bereplaced undertheservice |

|||||||||||||||

|

Extension |

|||||||||||||||

|

45 g/m (0.5 oz/ft) |

plan dueto probeleakage. |

||||||||||||||

|

Cable |

|||||||||||||||

|

Armored |

Field Wiring Limitations |

||||||||||||||

|

Extension |

64 g/m (0.7 oz/ft) |

||||||||||||||

|

Cable |

Type |

Gas |

Capicitance |

Inductance |

L/R Ratio |

||||||||||

|

Approval |

Group |

(μF) |

(mH) |

(μH/Ω) |

|||||||||||

|

Proximitor |

255 g (9 oz) |

||||||||||||||

|

IIC |

0.078 |

0.99 |

29.2 |

||||||||||||

|

Sensor |

ATEX and |

||||||||||||||

|

IEC Zone |

IIB |

0.645 |

7.41 |

117.0 |

|||||||||||

|

Environmental Limits |

|||||||||||||||

|

0/1 |

|||||||||||||||

|

IIA |

2.144 |

15.6 |

234.0 |

||||||||||||

|

A & B |

0.070 |

1.0 |

29.2 |

||||||||||||

|

ProbeTemperatureRange |

|||||||||||||||

|

CSA Div 1 |

C |

0.600 |

5.0 |

117.0 |

|||||||||||

|

Operating |

-52°C to +177°C (-62°F to +351°F) |

||||||||||||||

|

D |

2.09 |

11.0 |

234.0 |

||||||||||||

|

Temperature |

|||||||||||||||

|

CSA Div 2 |

All |

0.460 |

100.0 |

N/A |

|||||||||||

|

-52°C to +177°C (-62°F to +351°F) |

|||||||||||||||

|

Storage |

Exposing theprobeto |

||||||||||||||

|

temperatures below -34°C (- |

|||||||||||||||

|

Temperature |

30°F)fora sustained period |

||||||||||||||

|

of timemay causepremature |

|||||||||||||||

|

failureof thepressureseal. |

|||||||||||||||

Extension Cable Temperature Range

Operating

and Storage -52°C to +177°C (-62°F to +351°F) Temperature

Proximitor Sensor Temperature Range

|

Operating |

-52°C to +100°C (-62°F to +212°F) |

|

Temperature |

5/30

orwhen installed with galvanic isolators.

|

3300XL NSv Proximity TransducerSystem |

|

|

Datasheet |

147385Rev. K |

Compliance and

Certifications

FCC

This devicecomplies with part 15ofthe FCCRules. Operation is subject to the following two conditions:

•This devicemay not causeharmful interference.

•This devicemust accept any interferencereceived, including interferencethat may cause undesired operation.

EMC

EN61000-6-2

EN61000-6-4

EMCDirective2014/30/EU

RoHS

RoHS Directive2011/65/EU

Maritime

ABS 2009SteelVessels Rules 1-1-4/7.7,4-8-3/1.11.1,4-9-7/13

Hazardous Area Approvals

Forthedetailed listing of country and product specific approvals, referto theApprovals Quick ReferenceGuide(108M1756)availablefrom Bently.com.

CSA/NRTL/C

3300 XL Proximitor Sensor

|

ia |

Class I, Zone0: AEx/Ex ia IIC T4/T5 |

|

|

When installed |

Ga; |

|

|

Class I, Groups A, B, C, and D, |

||

|

with |

Class II, Groups E, F and G, |

|

|

intrinsically |

Class III; |

|

|

safezener |

T5 |

@ Ta= -55°˚C to + 40°˚C. |

|

barriers per |

||

|

drawing 141092 |

T4 |

@ Ta= -55°˚C to + 80°C. |

|

Class I, Zone2: AEx/Ex nA IIC T4/T5 |

||

|

Gc; |

||

|

nA, ec |

Class I, Division 2, Groups A, B, C, |

|

|

and D; |

||

|

When installed |

Class I, Zone2: AEx/Ex ec llC T4/T5 |

|

|

without |

Gc; |

|

|

barriers per |

Class I, Division 2, Groups A, B, C, |

|

|

and D; |

||

|

drawing |

||

|

140979. |

T5 @ Ta= -55°C to + 40°C |

|

|

T4 @ Ta= -55°C to + 80°C |

||

|

3300 XL Probe |

||

|

ia |

||

|

When installed |

Class I, Zone0: AEx/Ex ia IIC T5…T1 |

|

|

with |

Ga; |

|

|

intrinsically |

Class 1, Groups A, B. C, and D, |

|

|

safezener |

Class II, Groups E, F, and G, |

|

|

barriers per |

Class III; |

|

|

drawing 141092 |

(seeTemperatureScheduletableto |

|

|

orwhen |

||

|

installed with |

follow) |

|

|

galvanic |

||

|

isolators. |

||

|

nA, ec |

Class I, Zone2: AEx/Ex nA IIC T5…T1 |

|

|

Gc; |

||

|

When installed |

Class 1, Division 2, Groups A, B, C, D; |

|

|

Class 1, Zone2: AEx/Ex ec llC T5…T1 |

||

|

without |

Gc; Class I, Division 2, Groups A, B, C, |

|

|

barriers per |

and D; |

|

|

drawing |

(seeTemperatureScheduletableto |

|

|

140979. |

||

|

follow) |

6/30

|

3300XL NSv Proximity TransducerSystem |

|

|

Datasheet |

147385Rev. K |

ATEX/IECEx

3300 XL Proximitor Sensor

|

II 1 G |

|||||

|

Ex ia IIC T4/T5 Ga |

|||||

|

Ex ia IIIC T90C/T105C Dc |

|||||

|

ForEPL Dc: |

|||||

|

T105C @ Ta = -55°C to 100°C |

|||||

|

ia |

T90C @ Ta = -55°C to +85°C |

||||

|

Ui= -28V |

Uo= -28V |

||||

|

Ii= 140mA |

Io= 140mA |

||||

|

Pi= 0.91W |

Po= 0.742W |

||||

|

Ci47nF |

Co= 1.5nF |

||||

|

Li= 1460µH |

Lo= 610µH |

||||

|

II 3 G |

|||||

|

Ex nA IIC T4/T5 Gc |

|||||

|

nA,ec |

Ex ec llC T4/T5 Gc |

||||

|

Ui= -28V |

li= 140 mA |

||||

|

T5 @ Ta= -55˚ C to + 40˚C |

|||||

|

T4 @ Ta= -55 ˚C to + 80˚C |

3300 XL Probe

Probeentity parameters aremet when used with BNextension cables and connected to BNProx.

|

II 1 G |

|||||

|

Ex ia IIC T5…T1 Ga, |

|||||

|

(seeTemperatureSchedule |

|||||

|

tableto follow) |

|||||

|

ia |

Ex ia IIIC T90°C … T280°C Dc |

||||

|

ForEPL Dc: |

|||||

|

Ui= -28V |

Ci = 1.5 nF |

||||

|

Ii = 140 mA |

Li =610 μH |

||||

|

Pi = 0.91 W |

|||||

|

nA,ec |

II 3 G |

||||

|

Ex nA IIC T5…T1 Gc, |

|||||

|

Ex ec llC T5…T1 Gc, |

|||||

|

(seeTemperatureSchedule |

|||||

|

tableto follow) |

|

Ui= -28V |

li= 140 mA |

|||

Temperature Schedule

|

Temperature |

Ambient Temperature |

|

Classification |

(Probe Only) |

|

For EPL Ga and Gc |

|

|

T1 |

-55°C to +232°C |

|

T2 |

-55°C to +177°C |

|

T3 |

-55°C to +120°C |

|

T4 |

-55°C to +80°C |

|

T5 |

-55°C to +40°C |

|

For EPL Dc |

|

|

T280°C @ Ta |

-55°C to +232°C |

|

T225°C @ Ta |

-55°C to +177°C |

|

T170°C @ Ta |

-55C to +120°C |

|

T130°C @ Ta |

-55°C to +80°C |

|

T105°C @ Ta |

-55°C to +100°C |

|

T90°C @ Ta |

-55°C to +40°C |

7/30

|

3300XL NSv Proximity TransducerSystem |

|

|

Datasheet |

147385Rev. K |

Hazardous Area Conditions of Safe Use

CSA/NRTL/C:

ia

Installper Bently Nevada drawing 141092. nA, ec

Installper Bently Nevada drawing 140979.

ATEX/IECEx:

ia

Installper Bently Nevada drawing 141092. nA, ec

TheProxmust beinstalled so as to providethe terminals with a degreeofprotection ofat least IP54.

Field Wiring Limitations

|

Type |

Gas |

Capicitance |

Inductance |

L/R |

|

|

Ratio |

|||||

|

Approval |

Group |

(μF) |

(mH) |

(μH/Ω) |

|

|

ATEXand |

IIC |

0.078 |

0.99 |

29.2 |

|

|

IEC Zone |

IIB |

0.645 |

7.41 |

117.0 |

|

|

0/1 |

|||||

|

IIA |

2.144 |

15.6 |

234.0 |

||

|

A & B |

0.070 |

1.0 |

29.2 |

||

|

CSA Div 1 |

C |

0.600 |

5.0 |

117.0 |

|

|

D |

2.09 |

11.0 |

234.0 |

||

|

CSA Div 2 |

All |

0.460 |

100.0 |

N/A |

8/30

|

3300XL NSv Proximity TransducerSystem |

||||

|

Datasheet |

147385Rev. K |

|||

|

1 2 |

Miniaturecoaxial ClickLoc connector, |

|||

Ordering Information |

FluidLoc cable |

|||

|

E: Agency Approval Option |

||||

|

Forthedetailed listing of country and product |

0 0 |

Not required |

||

|

specific approvals, referto theApprovals Quick |

||||

|

0 5 |

MultipleApprovals |

|||

|

ReferenceGuide(108M1756)availablefrom |

||||

|

Bently.com. |

3300 NSv Proximity Probes

330901 3300 NSv Probe, 1/4-28 UNF thread, without armor

330902 3300 NSv Probe, 1/4-28 UNF thread, with armor

330908 3300 NSv Probe, 3/8-24 UNF thread, without armor

330909 3300 NSv Probe, 3/8-24 UNF thread, with armor

Part Number-AA-BB-CC-DD-EE

A: Unthreaded Length Option

Unthreaded length must beat least 0.7 inch less than thecaselength.

Orderin increments of 0.1 in

Length configurations:

Maximum unthreaded length: 9.2 in

Minimum unthreaded length: 0.0 in

Example: 0 4 = 0.4 in

B: Overall Case Length Option

Orderin increments of 0.1 in

Threaded length configurations:

Maximum caselength: 9.9 in

Minimum caselength: 0.8 in

Example: 2 4 = 2.4 in

C:Total Length Option 0 5 0.5 metre(20 in) 1 0 1.0 metre(39 in)

5 0 5.0 metres (16.4 feet)

7 0 7.0 metres (23.0 feet)

D:Connector and Cable-Type Option

|

0 1 |

Miniaturecoaxial ClickLoc connectorwith |

|

|

connectorprotector, standard cable |

||

|

0 2 |

Miniaturecoaxial ClickLoc connector, |

|

|

standard cable |

||

|

1 1 |

Miniaturecoaxial ClickLoc connectorwith |

|

|

connectorprotector, FluidLoc cable |

||

3300 NSv Proximity Probes, Metric

330903 3300 NSv Probe, M8 x 1 thread, without armor

330904 3300 NSv Probe, M8 x 1 thread, with armor

330905 3300 NSv Probe, M10 x 1 thread, without armor

330910 3300 NSv Probe, M10 x 1 thread, with armor

Part Number-AA-BB-CC-DD-EE

A: Unthreaded Length Option

Unthreaded length must beat least 20 mm less than thecaselength.

Orderin increments of 10 mm. Length configuration: Maximum unthreaded length: 230 mm

Minimum unthreaded length: 0 mm

Example:

0 6 = 60 mm

B: Overall Case Length Option

Orderin increments of 10 mm.

Metric thread configurations:

Maximum length: 250 mm

Minimum length: 20 mm

Example: 0 6 = 60 mm

C:Total Length Option 0 5 0.5 metre(20 in) 1 0 1.0 metre(39 in)

5 0 5.0 metres (16.4 feet)

7 0 7.0 metres (23.0 feet)

D:Connector and Cable-Type Option

|

0 1 |

Miniaturecoaxial ClickLoc connectorwith |

|

|

connectorprotector, standard cable |

||

9/30

Заказать Bently Nevada 3300 XL

- Применение

- Компоненты и заказные номера

- Взаимозаменяемость компонентов

Системы бесконтактного измерения перемещений Bently Nevada (BN) Proximitor®, основанные на технологии вихревых токов, выполняют преобразование осевого перемещения и виброперемещения в электросигнал.

Применение

Данные устройства предназначены для контроля параметров вибрации и осевых перемещений промышленного оборудования. Результаты измерений применяются в системах мониторинга, управления и защиты для предотвращения повреждений или выхода из строя оборудования и его компонентов, а также защиты персонала.

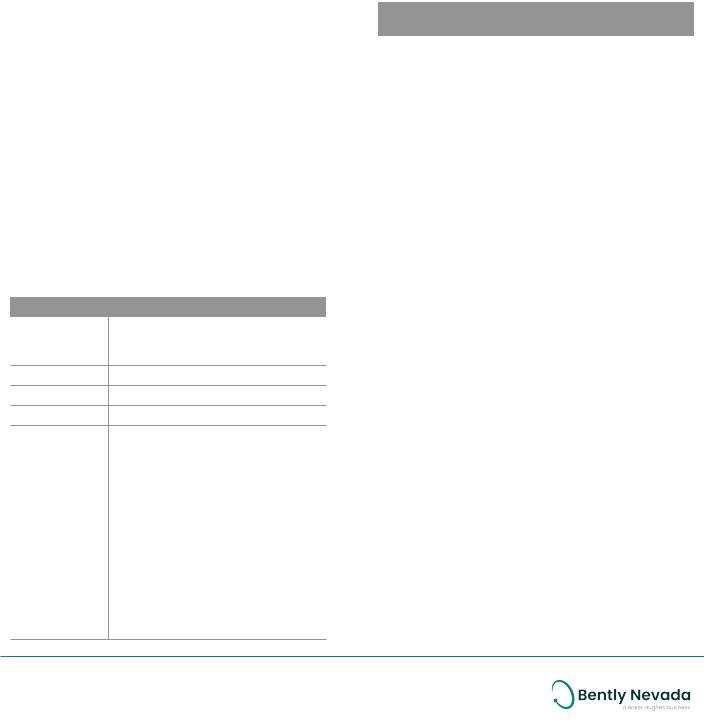

| Система | Тип измерения | Тип оборудования | |

| Bently Nevada 3300 XL | 5, 8 и 11 мм | Вибрация и смещение | Оборудование с гидродинамическими подшипника |

| 25 мм | Дифференциальное расширение | Турбогенераторы средних и больших размеров | |

| 50 мм | Дифференциальное расширение или расширение ротора | Большие паровые турбины | |

| Bently Nevada 3300 NSv | Радиальная вибрация и радиальное положение, осевое положение, скорость вращения, опорная фаза | Центробежные воздушные компрессоры, холодильные компрессоры, компрессоры технологического газа и другое оборудование со строгими требованиями к установке | |

| 7200 | 5 и 8 мм | Положение вала, вибрация | Компрессорное и вращающееся оборудование |

| 3300 | 16 мм HTPS (для температур до +350 °C) | Вибрация, осевое перемещение | Внутри горячих зон газовых, паровых турбин и другого вращающегося оборудования |

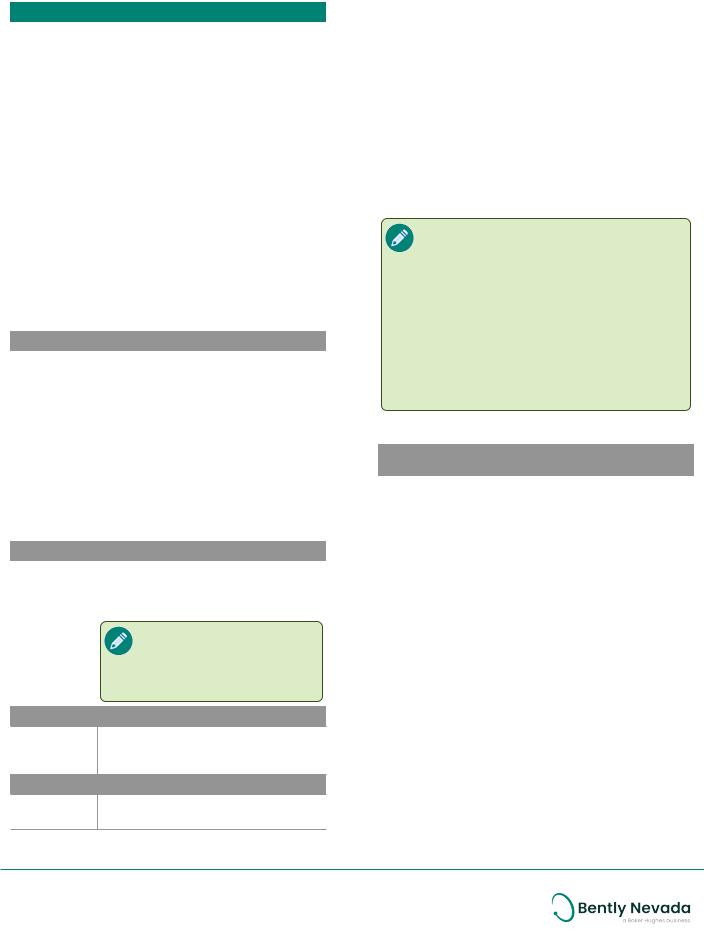

Компоненты и заказные номера

Преобразователи состоят из датчика, генератора колебаний Proximitor® и соединительного кабеля.

При изменении перемещения контролируемого объекта пропорционально меняется напряжение или ток генератора.

| Система | Датчик | Блок генератора (проксиметр Bently Nevada) | Кабель | ||

| Американская унифицированная тонкая резьба | Метрическая резьба | ||||

| Bently Nevada 3300 XL | 5 мм | 330171 и 330172 | 330173 и 330174 | Bently Nevada 330180 | 330130 |

| 8 мм | Bently Nevada 330101 и 330102 | 330103 и 330104 | |||

| 11 мм (обновление старой системы 7200 11 мм и 14 мм) | 330701, 330702, 330707, 330708 | 330703, 330704, 330709, 330710 | 330780 | 330730 | |

| 25 мм | 330851 | 330850 | 330854 | ||

| 50 мм | 330876 | 330878 | 330877 | ||

| Bently Nevada 3300 NSv | 330901, 330902, 330908, 330909 | 330903, 330904, 330905, 330910 | 330980 | 330930 | |

| 7200 | 5 мм | 21500, 21501 |

22812, 22813 |

18745 | 21747 |

| 8 мм | 21504, 21505 | 22810, 22811 | |||

| 3300 | 16 мм HTPS | 330301 и 330303 | 330302 | 330380 | 330330 |

Взаимозаменяемость компонентов

В настоящее время проксиметры Bently Nevada очень распространены на промышленных предприятиях. Они широко используются для контроля состояния и / или автоматического отключения оборудования средней или высокой критичности.

С момента, когда Дон Бентли изобрел и впервые применил вихретоковый датчик Proximitor® в конце 1960-х годов, качество, надежность и простота применения являются одними из главных приоритетов этих систем. Приверженность этим ценностям подтверждается полной взаимозаменяемостью компонентов. Под взаимозаменяемость подразумевается возможность простой замены датчиков, кабелей и генераторов Proximitor® без необходимости калибровки или специальных инструментов.

Производитель сумел обеспечивать взаимозаменяемость между основными семействами Proximitor®. Каждое семейство имеет собственную цветовую кодировку для простой идентификации.

| Система | Цвет | |

| 3300 XL | 5 и 8 мм | голубой |

| 11 мм | фиолетовый | |

| 25 мм | зеленый лаймовый | |

| 50 мм | коричневый | |

| NSv | серый | |

| 7200 | 5 и 8 мм | светло–желтый |

| 3300 | 16 мм HTPS | оранжевый |

Ассортимент продукции Bently Nevada

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Operation Manual

Bently Nevada™ Asset Condition Monitoring

3300/25 Dual Accelerometer Input

Monitor

Part Number 80181-01

Rev. AA (08/07)

Related Manuals for GE Bently Nevada 3300/25

Summary of Contents for GE Bently Nevada 3300/25

-

Page 1

Operation Manual Bently Nevada™ Asset Condition Monitoring 3300/25 Dual Accelerometer Input Monitor Part Number 80181-01 Rev. AA (08/07) -

Page 2

Transient Data Manager, Trendmaster, TrimLoc, Velomitor Contact Information The following ways of contacting Bently Nevada are provided for those times when you cannot contact your local representative: Mailing Address 1631 Bently Parkway South Minden, Nevada USA 89423 Telephone 1.775.782.3611 1.800.227.5514 1.775.215.2873 Internet www.ge-energy.com/bently… -

Page 3

Additional Information Notice: This manual does not contain all the information required to operate and maintain the product. Refer to the following manuals for other required information. 3300 System Overview (Part Number 80171-01) 3300 System Installation Instructions (Part Number 80172-01) 3300 System Troubleshooting (Part Number 80173-01) 3300/12 Power Supply (AC supply) (Part Number 89602-01) 3300/14 Power Supply (DC supply) (Part Number 101256-01) -

Page 4

3300/25 Dual Accelerometer Input Monitor Operation Manual In this document procedures are given only for channel A. Procedures for channel B are similar except for the obvious substitutions of corresponding switches, terminals, and indicators. NOTE: The information in this manual pertains to monitor main boards with part number 105513-xx and 79552-xx (all revisions) and filter boards with part numbers 148921-01 (all revisions), 105521-01 (all revisions and 79562-01 revision J and later. -

Page 5: Table Of Contents

Contents Dual Accelerometer Monitor System …………..1 Monitor Functions ………………..2 LED Functionality………………..6 OK LEDs ………………….6 Bypass LEDs ………………..7 Alert LEDs…………………. 8 Danger LEDs ………………..9 Read Channel Values ………………10 Read Setpoint Levels………………11 Monitor Removal and Disassembly …………..12 Monitor Disassembly ………………

-

Page 6

3300/25 Dual Accelerometer Input Monitor Operation Manual 19. Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 …54 19.1 Identify Filter Board ………………54 19.2 Filter Board Jumper Locations …………..55 19.3 Integrator/Gain Stage Flow Path…………..56 19.4 General Procedure………………57 19.5 Filter Board Options ……………….58 19.6 Integrator/Gain Stage Options …………..59 19.7… -

Page 7: Dual Accelerometer Monitor System

Section 1 — Dual Accelerometer Monitor System 1. Dual Accelerometer Monitor System Do not use this figure as a wiring diagram. Refer to 3300/25 Field Wiring Packet.

-

Page 8: Monitor Functions

3300/25 Dual Accelerometer Input Monitor Operation Manual 2. Monitor Functions DUAL ACCELEROMETER INPUT — The 3300/25 Dual Accelerometer Input Monitor provides two independent channels of on-line machine monitoring using accelerometers for the transducer inputs. Accelerometers are generally used for high frequency measurements on machines such as turbines, gear boxes, compressors, and pumps.

-

Page 9

Section 2 — Monitor Functions OK RELAY — The System OK Relay is mounted on the Power Input Module. Every channel in the rack must be OK or bypassed to energize the OK Relay. ALARM — Pressing the ALERT or DANGER switches on the monitor front panel causes the corresponding Alert (first level alarm) or Danger (second level alarm) setpoints to be displayed on the front panel meter. -

Page 10

3300/25 Dual Accelerometer Input Monitor Operation Manual transducer not OK condition. With this option, the recorder output will clamp to either +2mA or +4mA (user selectable) when a transducer is not OK. TRIP MULTIPLY — The Trip Multiply function multiplies setpoints by 2X or 3X in response to an external contact closure through terminals on the Power Input Module. -

Page 11

Section 2 — Monitor Functions… -

Page 12: Led Functionality

3300/25 Dual Accelerometer Input Monitor Operation Manual 3. LED Functionality 3.1 OK LEDs BLINK LED DISPLAY OK RELAY CONDITION DRIVE* Channel A and B are in operating range. If a channel’s OK LED goes off, that channel is not OK, has been latched not OFF** OK, or is bypassed.

-

Page 13: Bypass Leds

Section 3 — LED Functionality 3.2 Bypass LEDs BLINK LED DISPLAY CONDITION The monitor is in the Danger Bypass mode. The system is in the Power-Up mode. User invoked Self Test is in progress. BYPASS Timed OK/Channel Defeat is active. Both channels are bypassed.

-

Page 14: Alert Leds

3300/25 Dual Accelerometer Input Monitor Operation Manual 3.3 Alert LEDs BLINK ALERT LED DISPLAY CONDITION RELAY DRIVE ALERT If a channel ALERT LED comes on, that channel has exceeded its Alert setpoint ALERT level. Read Setpoint Levels, Section describes how to read alarm setpoint levels.

-

Page 15: Danger Leds

Section 3 — LED Functionality 3.4 Danger LEDs BLINK DANGER RELAY LED DISPLAY DRIVE CONDITION Voting Voting * DANGER If a channel’s DANGER LED comes on, that channel has exceeded its DANGER Danger setpoint level. Section 5 describes how to read setpoint levels.

-

Page 16: Read Channel Values

3300/25 Dual Accelerometer Input Monitor Operation Manual 4. Read Channel Values The monitor continuously indicates measured acceleration or velocity. The front panel below is indicating an acceleration of 0.9 g for channel A and 1.55 g for channel B. Note: The meter scale units must be compatible with the full scale option configured in Section…

-

Page 17: Read Setpoint Levels

Section 5 — Read Setpoint Levels 5. Read Setpoint Levels Press the ALERT switch to read Press the DANGER switch and the Alert setpoints for both read the Danger setpoints for channel A and channel B on the both channel A and channel B on meter scale.

-

Page 18: Monitor Removal And Disassembly

3300/25 Dual Accelerometer Input Monitor Operation Manual 6. Monitor Removal and Disassembly Caution Improper rack operation may occur. Power down rack or inhibit rack alarms when installing or removing a monitor. • Loosen two monitor retaining screws on the front of the monitor. •…

-

Page 19: Monitor Disassembly

Section 7 — Monitor Disassembly 7. Monitor Disassembly 7.1 Filter and Expander Board Removal Caution Component damage may result from removing the filter or expander board while power is on. Not all Dual Accelerometer Monitors contain the Expander Board. If this board does not exist, its functionality has been incorporated into the main board and connector J3 must be jumpered as shown…

-

Page 20: Filter Board Removal

3300/25 Dual Accelerometer Input Monitor Operation Manual Caution Component damage may result from removing the filter or expander board while power is on. When performing the following instructions, refer to the drawing on the previous pages. 7.1.1 Filter Board Removal 1.

-

Page 21: Front Panel Removal

Section 7 — Monitor Disassembly 7.2 Front Panel Removal 1. Disconnect J2 by pressing the connector latches outward. Caution 2. Unscrew two sliding standoffs. Component damage may result from removing the filter or expander board while power is on.

-

Page 22: Signal Input Relay Module Removal

3300/25 Dual Accelerometer Input Monitor Operation Manual 7.3 Signal Input Relay Module Removal Caution WARNING Machine protection provided by High voltage present. Contact this monitor will be lost while the could cause shock, burns, or death. Signal Input Relay Module is Do not touch exposed wires or removed from the rack.

-

Page 23: Signal Input Relay Modules (Sirm)

Section 7 — Monitor Disassembly 7.4 Signal Input Relay Modules (SIRM) A monitor can be configured with the Signal Input Relay Modules shown below. Refer to options EE & FF in Monitor Ordering Options, Section 8.2 of this manual. DUAL QUAD INTERNAL INTERNAL…

-

Page 24: No Relay And Dual Relay Sirm

3300/25 Dual Accelerometer Input Monitor Operation Manual 7.5 No Relay and Dual Relay SIRM WARNING NOTE: For relay configuration of monitors with Internal Safety Barriers, refer to High voltage present. Contact could 3300 Internal Barriers, Installation cause shock, burns, or death. Do not touch exposed wires or terminals.

-

Page 25: Quad Relay Signal Input Module Options

Section 7 — Monitor Disassembly 7.6 Quad Relay Signal Input Module Options WARNING High voltage present. Contact could cause shock, burns, or death. Do not touch exposed wires or terminals. Remove the Signal Input Relay Module from the rack before changing option jumpers. Note: AND voting logic must be done externally by wiring the contacts in series.

-

Page 26: Internal Barrier Options Sirm

3300/25 Dual Accelerometer Input Monitor Operation Manual 7.7 Internal Barrier Options SIRM For relay configuration of monitors with internal safety barriers, refer to the 3300 Internal Barriers, Installation Manual (88837) or the 3300 System Installation Instructions (80172). The Alert Relays and Danger Relays sections of the table below do not apply to the No Relay SIRM.

-

Page 27: Monitor Options

Section 8 — Monitor Options 8. Monitor Options 8.1 Field Programmable Options First Out Alert Mode Timed OK/Channel Defeat ** Enabled * Latching * Enabled * Disabled Nonlatching Disabled Alarm Delays Danger Mode Danger Relay Voting ++ 0.1 Second Latching * OR voting for relay drive * 1 Second Nonlatching…

-

Page 28: Monitor Ordering Options

3300/25 Dual Accelerometer Input Monitor Operation Manual 8.2 Monitor Ordering Options *TRANSDUCER INPUT, CHANNEL A CHANNEL B CHANNEL UNITS FULL SCALE RANGE FULL SCALE RANGE Dual accelerometer inputs; 0 to 2 g pk 0 to 2 g pk both channels indicate in acceleration units.

-

Page 29

Section 8 — Monitor Options Monitor Ordering Options (Continued) AGENCY BARRIERS ALARM TRIP APPROVAL USED RELAY MULTIPLY 00 None 00 None None None 01 CSA/NRTL/C 01 External Dual Relays, 2X trip multiply Epoxy Sealed 02 BASEEFA 02* Internal Dual Relays, 3X trip Hermetically Sealed multiply… -

Page 30: Meter Scale Replacement

3300/25 Dual Accelerometer Input Monitor Operation Manual 9. Meter Scale Replacement The monitor meter scales can be replaced for operation with different full scale ranges. The replacement meter scales are located in the back of this manual. Set the monitor full scale range. (See the Appendix A, Main Board Options.) Cut the meter scale from the back of this manual.

-

Page 31: Alarm Setpoint Adjustment

Section 10 — Alarm Setpoint Adjustment 10. Alarm Setpoint Adjustment Setpoints cannot be adjusted if trip multiply is installed and active. Trip multiply is active when the trip multiply contacts are closed. Open the front panel by loosening the two monitor retaining screws and sliding the front panel to the right.

-

Page 32: Channel Bypass

3300/25 Dual Accelerometer Input Monitor Operation Manual 11. Channel Bypass Caution Machine protection provided by this monitor will be lost while Channel Bypass is on. You can use Channel Bypass to take a Not OK or unconnected channel off line. This will restore the OK Relay to the OK state.

-

Page 33: Danger Bypass

Section 12 — Danger Bypass 12. Danger Bypass Caution Machine protection provided by this monitor will be lost while Danger Bypass is on. Open the front panel by loosening the two monitor retaining screws and sliding the front panel to the right. Set DB (Danger Bypass) switch to the left (ON).

-

Page 34: Test Alarms

3300/25 Dual Accelerometer Input Monitor Operation Manual 13. Test Alarms Use this procedure to test the alarm setpoints that you set in the Alarm Setpoint Procedure Section. The test uses a function generator to exceed the setpoint levels so that you can verify that the appropriate LEDs come on. Use this procedure to test the alarms for both channels.

-

Page 35: Connect And Adjust The Test Instruments

Section 13 — Test Alarms 13.1 Connect and Adjust the Test Instruments Caution WARNING Tests will exceed alarm setpoint High voltage present. Contact could levels causing alarms to activate. cause shock, burns, or death. This could result in relay contacts Do not touch exposed wires or changing state.

-

Page 36

3300/25 Dual Accelerometer Input Monitor Operation Manual Adjust the input frequency of the function generator according to this equation: frequency f × where: = high-pass corner frequency. = low-pass corner frequency. then use these values to calculate the input If you use.. frequency low-pass filter only = 240 CPM (4 Hz) *… -

Page 37: Test The Alert Setpoint Level

Section 13 — Test Alarms 13.2 Test the Alert Setpoint Level 1. Adjust the function generator DC offset to -7.5 Vdc. 2. Wait 30 seconds for the completion of the Timed OK/Channel Defeat delay, then press the RESET switch on the System Monitor.

-

Page 38: Test The Danger Setpoint Level

3300/25 Dual Accelerometer Input Monitor Operation Manual 13.3 Test the Danger Setpoint Level 1. Adjust the function generator amplitude past the Danger setpoint level and verify that the DANGER LED comes on (flashing if the First Out option is selected). 2.

-

Page 39: Prepare To Bring The Monitor On Line

Section 13 — Test Alarms 13.4 Prepare to Bring the Monitor On Line 1. Reduce the function generator amplitude to below the alarm setpoints and observe that the ALERT and DANGER LEDs go off (if nonlatching alarm jumpers are installed). 2.

-

Page 40: Test Ok Limits

3300/25 Dual Accelerometer Input Monitor Operation Manual 14. Test OK Limits Caution WARNING Tests will exceed alarm setpoint High voltage present. Contact could levels causing alarms to activate. cause shock, burns, or death. This could result in relay contacts Do not touch exposed wires or changing state.

-

Page 41

Section 14 — Test OK Limits 3. Adjust the power supply voltage for -7.5 Vdc with respect to common. 4. Wait 30 seconds for the completion of the Timed OK/Channel Defeat delay, then press the RESET switch on the System Monitor. Verify that the channel A OK LED is 5. -

Page 42

3300/25 Dual Accelerometer Input Monitor Operation Manual Gradually increase the power supply voltage (more negative) until the OK LED goes off (upper limit). Verify that the upper OK Limit is between -11.5 Vdc and -12.0 Vdc and that the OK Relay de-energizes. Return the power supply voltage to -7.5 Vdc and verify that the OK LED comes back on and the OK Relay energizes. -

Page 43: Calibrate Channels

Section 15 — Calibrate Channels 15. Calibrate Channels Before you begin Channel Calibration, you must choose the full scale range and set the appropriate jumpers (See Section 18.6). Calibrate both channels of your monitor. To calibrate channels you will need these instruments and tools •…

-

Page 44: Set The Filter Option To No Filters

3300/25 Dual Accelerometer Input Monitor Operation Manual 15.1 Set the Filter Option to No Filters NOTE: This procedure may alter your filter configuration. Caution WARNING Tests will exceed alarm setpoint High voltage present. Contact could levels causing alarms to activate. cause shock, burns, or death.

-

Page 45: Connect And Adjust The Test Instruments

Section 15 — Calibrate Channels 15.2 Connect and Adjust the Test Instruments (Repeat for channels A and B.) Connect the function generator to the channel A terminals as shown in the figure above. (Note: For a single transducer input system, do not repeat this step for channel B.) Adjust the function generator sine wave to 307.5 ±…

-

Page 46: Calibrate The Channels

3300/25 Dual Accelerometer Input Monitor Operation Manual 15.3 Calibrate the Channels (Repeat for channels A and B) Measure the proportional signal output at TP39 (BPPLA) for Channel A and TP40 (BPPLB) for Channel B. The testpoint locations are shown in the figure below. The voltages at these testpoints should match the voltages listed in the following table.

-

Page 47: Prepare To Bring The Monitor On Line

Section 15 — Calibrate Channels 15.4 Prepare to Bring the Monitor On Line (Repeat for channels A and B) Disconnect the test equipment and reconnect the transducer wiring A to the channel A terminals. ( Field wiring is shown the 3300/25 Field Wiring Diagram Packet.) WARNING…

-

Page 48: Self Test

3300/25 Dual Accelerometer Input Monitor Operation Manual 16. Self Test The monitor has three levels of self tests: SELF TEST PERFORMED Power-up When the monitor is turned on. Continuous during monitoring Cyclic operations. When you initiate the self test by User-invoked temporarily shorting the self-test pins.

-

Page 49

Section 16 — Self Test Recall stored error codes by using the User-invoked self test. Use the following steps to run the User-invoked self test, read error codes, and clear stored error codes: Caution Machine protection provided by this monitor will be lost for the duration of the self test. -

Page 50

3300/25 Dual Accelerometer Input Monitor Operation Manual Read any other stored error codes by pressing and holding the ALERT switch for approximately one second. For example, the display to the far right contains a second stored error code — number 10. When you reach the end of the error code list, the LCD bargraph comes on at full scale range and… -

Page 51

Section 16 — Self Test When you press the RESET switch on the System Monitor, the OK LEDs will stop flashing. -

Page 52: Error Codes

3300/25 Dual Accelerometer Input Monitor Operation Manual 17. Error Codes Refer to the Monitor Functions, Section 2 and Self Test, Section 16 for more information about displaying error codes. Refer to the Self Test section for information about clearing stored errors. ERROR DESCRIPTION EXPLANATION/RECOVERY…

-

Page 53: Appendix A-Main Board Options

Section 18 — Appendix A–Main Board Options 18. Appendix A–Main Board Options 18.1 Jumper Locations for PWA 105513-xx NOTE: This drawing applies to main boards with part number 105513-xx.

-

Page 54: Shipped As Options

3300/25 Dual Accelerometer Input Monitor Operation Manual 18.2 Shipped As Options The monitor is shipped with the following configuration: OPTION SHIPPED SETTING First Out Enabled OK Mode Nonlatching Timed OK/Channel Defeat Enabled Alert Mode Latching Recorder Outputs +4 to +20 mA +4 to +20mA Recorder Disabled Not OK Output (+2 mA clamp) *…

-

Page 55: Main Board Option Settings

Section 18 — Appendix A–Main Board Options 18.3 Main Board Option Settings Use these and the tables on the following pages to configure main board options: OPTION SETTING INSTALL REMOVE Enabled* W16C None First Out Disabled None W16C Latching W20, W23** None OK Mode Nonlatching*…

-

Page 56: Recorder Options

3300/25 Dual Accelerometer Input Monitor Operation Manual 18.4 Recorder Options Use the following table to configure Main Board 105513-xx. OPTION SETTING INSTALL REMOVE W8A,B +4 to +20 mA * W11C W11A,B W12A W12B W8A,C RECORDER OUTPUTS +1 to +5 V W11B W11A,C W12B…

-

Page 57: Channel Types

Section 18 — Appendix A–Main Board Options 18.5 Channel Types TRANSDUCER INPUT, JUMPERS CHANNEL UNITS INSTALL REMOVE Dual Accelerometer, W3B,E Channel A Acceleration W6B,E Channel B Acceleration W22B W22A ** Dual Accelerometer, W3B,F Channel A Acceleration W6B,E Channel B Velocity W22B W22A ** Dual Accelerometer,…

-

Page 58: Full Scale Options

3300/25 Dual Accelerometer Input Monitor Operation Manual 18.6 Full Scale Options Caution If you change full scale options, recalibrate both channels and replace the meter scale on the front panel. MONITOR CHANNEL A JUMPERS CHANNEL B JUMPERS FULL SCALE OPTIONS INSTALL REMOVE INSTALL…

-

Page 59: Main Board Buffered Out And Filter Options

Section 18 — Appendix A–Main Board Options 18.7 Main Board Buffered Out and Filter Options BUFFERED TRANSDUCER OUTPUT CHANNEL A CHANNEL B INSTALL REMOVE INSTALL REMOVE * Buffered transducer output not filtered. W18C W18A Buffered transducer output filtered W18A W18C * Standard configuration.

-

Page 60: Appendix B-Filter Board Options Pwa 79562-01 And Pwa 105521-01

3300/25 Dual Accelerometer Input Monitor Operation Manual 19. Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 19.1 Identify Filter Board The configuration of the low pass filter is depends upon which filter board is being used. The filter board can be identified by looking at the PWA (Printed Wiring Assembly) number that is silkscreened on the component side of the board.

-

Page 61: Filter Board Jumper Locations

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 19.2 Filter Board Jumper Locations…

-

Page 62: Integrator/Gain Stage Flow Path

3300/25 Dual Accelerometer Input Monitor Operation Manual 19.3 Integrator/Gain Stage Flow Path This diagram is meant to illustrate the signal path through the Integrator/Gain Stage and the filters. It should not be used to determine jumper configurations. Follow the instructions in Section 19.4 determine the necessary jumper configuration.

-

Page 63: General Procedure

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 19.4 General Procedure Follow these steps, in the order below, to program the monitor to operate with or without filters. After choosing the filter type and the location of the Integrator/Gain Stage you can check the signal flow path using figure 1 in section 19.3.

-

Page 64: Filter Board Options

3300/25 Dual Accelerometer Input Monitor Operation Manual 19.5 Filter Board Options Choose the filter type by installing and removing the jumpers on the filter board as shown in the table below. See Section 19.2 for the location of the jumpers on the Filter Board.

-

Page 65: Integrator/Gain Stage Options

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 19.6 Integrator/Gain Stage Options When measuring acceleration, configure the filter after the Integrator/Gain Stage. When measuring velocity, configure: the Low-Pass filter after the Integrator/Gain Stage and the High-Pass filter before the Integrator/Gain Stage Set the location of the Integrator/Gain Stage by installing or removing the jumpers on the main and filter boards as shown in the table below.

-

Page 66

3300/25 Dual Accelerometer Input Monitor Operation Manual Channel B Integrator/Gain Stage Location CHANNEL B Main Board Filter Board INTEGRATOR/GAIN STAGE LOCATION INSTALL REMOVE INSTALL REMOVE W41,60 *Integrator/Gain Stage with W61,85 W5B,3B W3A,3C NO Filtering W3A,3C W61,85 **Filter after the W41,60 Integrator/Gain Stage W3A,3C W41,60… -

Page 67: High Pass Filter Options

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 19.7 High Pass Filter Options Install the jumpers on the filter board as shown in this table. Select frequencies not listed in this table by using the procedure in Section 19.8.

-

Page 68

3300/25 Dual Accelerometer Input Monitor Operation Manual CHANNEL A — CHANNEL B — 10020 10560 10980 11520 12060 12480 13020 13560 14040 14520 15060 16080 16500 17040 17520 18000 18540 29760 45300 1003 60180 2006 120360 2996 179760 R = REMOVE JUMPER, I = INSTALL JUMPER Use the procedure in the following section to set a high-pass corner frequency not listed in the table. -

Page 69: Non Standard High Pass Filter Options

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 19.8 Non Standard High Pass Filter Options Follow this procedure only if the desired high-pass corner frequency is not listed in the table in the previous section. Select a high-pass corner frequency, , in the range 3.7 Hz to 3008 Hz.

-

Page 70: Example High-Pass Filter Configuration

3300/25 Dual Accelerometer Input Monitor Operation Manual 19.9 Example High-Pass Filter Configuration This example shows how to configure channel A with a high-pass filter that has a corner frequency, , of 24000 CPM (400 Hz). The High Pass Filter is located after the Integrator/Gain Stage.

-

Page 71

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 Use the formula in step 3 of Section 19.8 to obtain a value for the multiplier, D. In this case: The result is D = 33.9 Step 4 of Section 19.8 requires that you convert D to the closest 8 bit binary integer. -

Page 72: Low-Pass Freq. Configuration Table

3300/25 Dual Accelerometer Input Monitor Operation Manual 19.10 Low-Pass Freq. Configuration Table Use the tables on the next four pages to select the low-pass corner frequency . The — 3dB frequency is 1.06 x . For frequencies not listed in this table, follow the procedure in the following section.

-

Page 73

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 CHANNEL A — CHANNEL B — 1440 1980 2520 2940 3540 3960 4440 5040 5520 5880 6480 6960 7500 7980 8520 9120 9600 10080 11040 12120 12960 14160 15000 15960 17040… -

Page 74

3300/25 Dual Accelerometer Input Monitor Operation Manual CHANNEL A — CHANNEL B — 25020 27780 30000 32580 35280 37500 40560 45480 49980 55560 1000 60000 1087 65220 1163 69780 1250 75000 1351 81060 1515 90900 1667 100020 2083 124980 2500 150000 3333 199980… -

Page 75

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 CHANNEL A — CHANNEL B — 25020 27780 30000 32580 35280 37500 40560 45480 49980 55560 1000 60000 1087 65220 1163 69780 1250 75000 1351 81060 1515 90900 1667 100020 2083… -

Page 76: Non Standard Low Pass Filter Options

3300/25 Dual Accelerometer Input Monitor Operation Manual 19.11 Non Standard Low Pass Filter Options Use this procedure only if the desired low pass corner frequency is not listed in the table in the previous section. The procedure consists of these two parts: •…

-

Page 77

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 5. Convert M to the closest 8 bit binary integer M0 to M7. 6. Set the anti-aliasing filter corner frequency, Install/Remove jumpers for the multiplier value M and constant K, according to the following table. -

Page 78: Setting The Low-Pass Corner Frequency

3300/25 Dual Accelerometer Input Monitor Operation Manual 19.11.2 Setting the Low-Pass Corner Frequency Select a value for clock frequency (fCLK) from this list. We recommend that you start with 3.58 MHZ. Calculate the divider ratio D using this equation. is The clock frequency, f , (in Hz) is selected in step 1 and f is the desired low pass corner frequency (in Hz).

-

Page 79

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 Set the jumpers for the input clock frequency ( ) according to this table. R = REMOVE JUMPER, I = INSTALL JUMPER SWITCHED CAPACITOR FILTER INPUT CLOCK JUMPER TABLE CHANNEL A — CHANNEL B -… -

Page 80: Divider Ratio Table

3300/25 Dual Accelerometer Input Monitor Operation Manual 19.12 Divider Ratio Table CHANNEL CHANNEL DIVIDER DIVIDER RATIO D RATIO D 2048 R = REMOVE JUMPER, I = INSTALL JUMPER…

-

Page 81: Example Low-Pass Filter Configuration

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 19.13 Example Low-Pass Filter Configuration This example shows how to configure channel B with a low-pass filter that has a corner frequency, , of 7500 CPM (125 Hz). (The resulting -3dB point is at 1.06 x or 7950 CPM (132.5 Hz).

-

Page 82

3300/25 Dual Accelerometer Input Monitor Operation Manual Calculate the multiplier value M. In this case: Convert M to the closest 8 bit binary integer. The closest integer to 32.57 is 33, and the 8 bit binary representation is 00100001. M7 is the most significant bit (MSB), and M0 is the least significant bit (LSB). -

Page 83

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 Calculate D with = 1 MHZ. 1000000 × There is not a match for D = 200 within ±1 in the Divider Ratio Table so select = 500 kHz. Calculate D with = 500 kHz. -

Page 84: Band-Pass Filters

3300/25 Dual Accelerometer Input Monitor Operation Manual 19.14 Band-Pass Filters A band-pass filter consists of cascaded high-pass and low-pass filters. To configure the Band-Pass filter, follow the instructions for programming the high-pass and low-pass filters. The center frequency of the bandpass filter is given by: f ×…

-

Page 85: Test Filter Option

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 19.15 Test Filter Option This procedure verifies filter settings by using a function generator to simulate a signal with an amplitude equal to full scale at the -3dB frequency. Since the filter attenuates a signal with this frequency by 3dB, the monitor output should be 65% to 75% of full scale.

-

Page 86

3300/25 Dual Accelerometer Input Monitor Operation Manual Adjust the settings on the function generator according to this table: PARAMETER SETTING wave form sine wave DC offset -7.5 Vdc filter corner frequency, frequency to test high pass filters (1.06) x (f to test low pass filters amplitude See step 5… -

Page 87

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 Step 5a continued: Step 5b continued: For Full Scale Range options 01, 02, For Full Scale Range options 05, 06, 03, 04, 11, 12, 13, 14 15, 16, 17 For example, if the Full Scale Range For example if the Full Scale Range option is 11, set the amplitude to 204… -

Page 88

3300/25 Dual Accelerometer Input Monitor Operation Manual The bargraph reading may be slightly lower if you have a Low Pass Filter with a corner frequency above 13.7 kHz. The reading will be lowest when the corner frequency is at its highest setting, 22.372 kHz. -

Page 89: Test Filter Option (Alternate Procedure)

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 19.16 Test Filter Option (Alternate Procedure) This procedure should only be used when your Full Scale Range Option is 05, 06, 15, 16, or 17 (see Section 8.2) and the full scale amplitude calculated in step 5b of the main procedure…

-

Page 90

3300/25 Dual Accelerometer Input Monitor Operation Manual Configure the main board as follows to change the Gain Stage back to an Integrator Stage: Channel A: Install Remove W6B,C Channel B: Install Remove W3D,E Choose an integrator test frequency according to the following criteria: The test frequency must be within the passband of the filter. -

Page 91

Section 19 — Appendix B–Filter Board Options PWA 79562-01 and PWA 105521-01 Verify that the front panel bargraph reads 85% to 95% of full scale range. The figure below shows a monitor bargraph reading 90% of full scale. Return to step 7 of the main procedure (Section 19.15). -

Page 92: Appendix C-Filter Board Options Pwa 148921-01

3300/25 Dual Accelerometer Input Monitor Operation Manual 20. Appendix C–Filter Board Options PWA 148921-01 20.1 Identify Filter Board The configuration of the low pass filter is depends upon which filter board is being used. The filter board can be identified by looking at the PWA (Printed Wiring Assembly) number that is silkscreened on the component side of the board.

-

Page 93: Filter Board Jumper Locations

Section 20 — Appendix C–Filter Board Options PWA 148921-01 20.2 Filter Board Jumper Locations…

-

Page 94: Integrator/Gain Stage Flow Path

3300/25 Dual Accelerometer Input Monitor Operation Manual 20.3 Integrator/Gain Stage Flow Path This diagram is meant to illustrate the signal path through the Integrator/Gain Stage and the filters. It should not be used to determine jumper configurations. Follow the instructions in Section 20.4 to determine the necessary jumper configuration.

-

Page 95: General Procedure

Section 20 — Appendix C–Filter Board Options PWA 148921-01 20.4 General Procedure Follow these steps, in the order below, to program the monitor to operate with or without filters. After choosing the filter type and the location of the Integrator/Gain Stage you can check the signal flow path using Figure 1 Section…

-

Page 96: Filter Board Options