-

7/25/2019 cnc kad user manual

1/50

cncKad

Cutting Tutorial

-

7/25/2019 cnc kad user manual

2/50

LaserTutEng.2006.85.001

-

7/25/2019 cnc kad user manual

3/50

Laser Cutting Tutorial

iii

Copyright 2006

Metalix CAD/CAM.

All Rights Reserved

Limited Warranty

Metalix CAD/CAMWarrants the software will perform substantially

in accordance with theaccompanying printed materials. Metalix

CAD/CAMdoes not warrant that the functionscontained in the software

will meet your requirements or that the operation of the

softwarewill be uninterrupted or error-free.Limitation of Liabilities

In no event willMetalix CAD/CAMor its suppliers be liable for

direct, indirect, special,incidental, contingent, consequential or similar damages of any

kind resulting from any defectin the software or documentation,

including without limitation, any lost profits or savings.Metalix CAD/CAM LTD.

Koranit

D.N. Misgav 20181

ISRAEL

Tel: (972) 4-9998436

Fax: (972) 4-9998519

E-mail: [email protected]

Copyright 2006

-

7/25/2019 cnc kad user manual

4/50

cncKad

iv

-

7/25/2019 cnc kad user manual

5/50

Laser Cutting Tutorial

v

Table of Contents

Laser Cutting Tutorial

……………………………………………………………………………………….

7Laser Tutorial Overview and

Aims…………………………………………………………………..7How to use this

Tutorial………………………………………………………………………………7A brief explanation about

Clicking………………………………………………………………..

71 Exercise 1 Basic Drafting and Cutting

………………………………………………………..

91.1

Overview………………………………………………………………………………………………

91.1.1 What you will learn in this exercise:

…………………………………………………… 91.1.2 Tips

……………………………………………………………………………………………….

91.2 Creating a New Part

…………………………………………………………………………….101.3 Selecting the Active Machine

Model……………………………………………………….111.4 Positioning Holes with Help Lines

………………………………………………………….121.5 Creating the Inner

Rectangle…………………………………………………………………131.6 Filleting

Contours…………………………………………………………………………………

161.7 Geometry

Checks………………………………………………………………………………..161.8 Saving the Part

……………………………………………………………………………………

171.9 Cutting the

Part……………………………………………………………………………………171.10Defining the Sheet Size

………………………………………………………………………..191.11Generating the NC Code

………………………………………………………………………221.12Simulating the NC

Program…………………………………………………………………..231.12.1Running the

Simulation…………………………………………………………………..

231.13Summary

……………………………………………………………………………………………242 Exercise 2 Setting Cuts Manually

…………………………………………………………….

252.1

Overview…………………………………………………………………………………………….252.1.1 What you will learn in this exercise:

………………………………………………….252.2 Saving a File Under a New Name

………………………………………………………….

252.3 Adding a Dimension

…………………………………………………………………………….

252.4 Stretching the

Part……………………………………………………………………………….262.5 Deleting Existing Cuts on the

Part………………………………………………………….272.6 Setting Auto Cut

Definitions…………………………………………………………………..282.7 Setting Individual

Cuts………………………………………………………………………….282.8 Summary

……………………………………………………………………………………………303 Exercise 3 Advanced Drafting

…………………………………………………………………313.1

Overview…………………………………………………………………………………………….313.1.1 What you will learn in this exercise:

………………………………………………….313.2

Creating Notches and Bend Relief

…………………………………………………………313.3 Trimming Lines

……………………………………………………………………………………

343.4 Adding a Rectangular

Hole……………………………………………………………………

353.5 Chamfering a Corner

……………………………………………………………………………

363.6 Filleting Corners and

Contour………………………………………………………………..363.7 Creating a Circular Array

………………………………………………………………………

373.8 Creating Rectangular Arrays

…………………………………………………………………

39 -

7/25/2019 cnc kad user manual

6/50

cncKad

vi

3.9 Adding a Marking Point

………………………………………………………………………..

403.10Summary

……………………………………………………………………………………………414 Exercise 4 — Advanced Cutting

Definitions……………………………………………………424.1

Overview…………………………………………………………………………………………….424.1.1 What you will learn in this exercise:

………………………………………………….424.2 Cutting a Previously Cut Part

………………………………………………………………..424.2.1

Deleting Cuts

………………………………………………………………………………..424.2.2 Replacing Cutting Definitions with Auto

Cut……………………………………….424.3 What Are Cutting Tables

………………………………………………………………………424.3.1 Cutting Tables

Example………………………………………………………………….434.4 Corner Treatment

………………………………………………………………………………..

454.4.1 Max Angle

…………………………………………………………………………………….

454.5 The Global Cut Tab

……………………………………………………………………………..

454.6 Rounding Corners

……………………………………………………………………………….454.7 Slowing

………………………………………………………………………………………………

474.8 Using

Loops………………………………………………………………………………………..474.8.1

Editing Corner Parameters

……………………………………………………………..484.8.2 Setting Corner Parameters

……………………………………………………………..484.9 Point

Marking………………………………………………………………………………………484.9.1 Options for

Marking………………………………………………………………………..484.10Summary

……………………………………………………………………………………………495 Index

………………………………………………………………………………………………………

50 -

7/25/2019 cnc kad user manual

7/50

Laser Cutting Tutorial

7

Laser Cutting Tutorial

Laser Tutorial Overview and AimsThis Tutorial is designed to

give the newcomer to cncKada quick and easy start withthe program,

while teaching the use of some of the most common commands. Theexercises are set out so that the user may work with the program

in conjunction withthis book.The exercises are of varying difficulty, each one designed to

teach the new user adifferent aspect of the program — various

drafting techniques as well as utilizing lasercutting technology.

Each exercise is accompanied by detailed steps that allow a newuser

to create and learn everything from the easiest to the most

complicatedprocedures within the program.Having completed the exercises in this book you will be able to

successfully drawand cut your own sheet metal parts, using many of

the commands in cncKad. Youwill be able to take the geometry and

cuts and create a working NC program that canbe sent to your

machine.This Tutorial should be used in conjunction with the cncKad

Drafting & NestingManualand the cncKad Laser Manual. Working

with these manuals will give you theultimate reference and teaching

tool.How to use this Tutorial

The first page of each chapter shows the part we will create

during the exercise.Throughout the exercise you will find tips that

will help you create the draft and thencut it. These tips will be

denoted by the sign, e.g.:The Shapescommands are quick and easy methods for building

different contours that are typical to the sheet metal

industries.You may want to try creating these parts before looking at the

following pages for thedetailed explanation and part creation

steps.This book is written for work in conjunction with version 8 of

cncKad. If you have theDOS version of cncKad please refer to the appropriate books.If

you have a different version of cncKad Windows, while most of the

exercises andcommands are compatible, you may find slight

discrepancies between thecommands and the procedures as listed here

and your software. If such a case,please consult the user manual

that came with your copy of the program or theupdate pamphlet.A brief explanation about Cl icking

When working with cncKad, it is important to remember that the

basic unit of draftingis the Entity.An Entity can be a Line, an Arc, a Circle or a Point.

As you create parts, you will often need to choose a specific

Entity or processingdefinition for manipulation.When you click your mouse to choose

a specific Entity, it is imperative you rememberthat cncKad uses

the following rules to interpret your action:1. Which Entity has been chosen?

2. Which Endpoint of the entity has been chosen? (lines and arcs

have 2Endpoints) -

7/25/2019 cnc kad user manual

8/50

cncKad

8

3. Which Side of the Entity has been chosen?1

The following example illustrates this interpretation

process:When selecting a processing definition, you must still select

the Entityassociated with this definition.

LineAhas been cut; if you wish to manipulate this processing

(e.g. change CuttingSpeed), you can click on points 1or 2, but NOT

on 3, 4or 5.1When clicking on an Entity that is in a closed Contour, your

click represents a choice ofInsideOutside for this Contour.

-

7/25/2019 cnc kad user manual

9/50

Laser Cutting Tutorial

9

1 Exercise 1 Basic Drafting and Cutting

1.1 OverviewThe aim of this first exercise is to give you the

ability to open a new file in cncKad,create a basic drawing, place

cuts on the drawing and simulate the NC code createdfrom the geometry.In this exercise we will be creating the

following part:1.1.1 What you wil l learn in this exercise:

1. Opening a new part file.

2. Selecting the active machine for a workstation.3. Placing

shapes and holes on the part.4. Creating inner rectangle.

5. Creating fillets.

6. Running geometry checks.

7. Saving a part.

8. Adding laser cuts.

9. Defining the sheet size.

10. Generating NC code.

11. Simulating the NC.

1.1.2 Tips

When the new drawing is opened a rectangle is created this will

be thebasis for drawing the part.The bottom left corner of the draft is placed at coordinate

position X=0, Y=0.You can position the shapes and circles using absolute

coordinates.You can use Help Linesto find a position on the part.

-

7/25/2019 cnc kad user manual

10/50

cncKad

10

1.2 Creating a New Part

1. Double click on the cncKadIcon to open cncKad.

2. From the Filemenu (at the top of the screen) select the New

=> New Partoption, or click the New PartButton from the Standardtoolbar.

Thefollowing dialog will be displayed.The procedure for opening new files in cncKadis the same as

foropening any new file in Windows programs — press the Ctrl+N

combination on your Keyboard.

3. In the File Namebox type Exer1 instead of Part1. You can do

this bydouble-clicking on the name «Part1» and then typing-in the

new name. Whenyou are done, click on the Savebutton.4. The following dialog will now be displayed:

-

7/25/2019 cnc kad user manual

11/50

Laser Cutting Tutorial

11

Remember that you define the size of the part when you open a

new partand not the size of the sheet.

If you make a mistake while typing the values — use the

Backspace key toerase the value and retype it, and the Tab key to move between

fields.5. This dialog allows you to define the part Size, sheet

Material and Thickness.In Part Size, set the Xsize to 300and Ysize

to 200.6. Select a material from the drop-down list and define the

thickness as 1mm.Leave all the rest of the options at their

defaults. For the time being we willnot fill out the User Data

options, so just click on the OKbutton to confirmyour part

definitions.The User Data tab allows the user to associate certain

information withthe part, for instance — Order Number, Drawing Name, Revisions,

andNotes. This information can then be inserted in the Report

File.7. A white rectangle of the defined size will appear on the

screen.1.3 Selecting the Active Machine ModelIt often happens that a

workstation supports more than one machine model, forexample one

(or more) for laser cutting and one (or more) for punching.Before beginning to draft the part, we should make sure that we

are working on alaser cutting machine.To select the machine model that will be the active one:

1. Click on the Machine button at the left side of the cncKad

window. -

7/25/2019 cnc kad user manual

12/50

cncKad

12

2. A list will open with the models that are installed on this

workstation, with theactive one marked by a check mark:3. To change the active machine, simply click on the one you

want.1.4 Positioning Holes with Help LinesIn this stage we will be

placing holes on the drawing and positioning them bysnapping them

to intersections of the Help Lines.We will place these Help Lines on the drawing in order to enable

the exactpositioning of the holes.Help Lines are always displayed as green lines that cross the

entireextent of the screen.

Any position can be located by entering the absolute coordinate,

butsometimes it is easier to use Help Lines to find the

position.1. From the Help Linestoolbar click the

Parallel Help-Line by Distance button.

2. In the dialog that appears define a distance of 50and click

on the OKbutton.3. Position the Help Line by clicking the mouse on the inner

side of the leftvertical line.4. Repeat this for the right vertical line.

5. Press the Space bar and re-define the parallel distance as

30. Click the OKbutton to close the dialog.6. Click the bottom horizontal line on its inner side, and then

click the tophorizontal line on its inner side. The result should

be as shown below:7. From the ShapesToolbar

select the Draw Circ lebutton . The following dialog box will be

displayed: -

7/25/2019 cnc kad user manual

13/50

Laser Cutting Tutorial

13

8. Define a diameter of 15and click on theApplybutton.

9. The dialog will disappear and you will be able to move the

circle with thecursor. Click on the Snap=Autobutton on the top left

side of the screen. Amenu will appear, from this menu select the

Snap Intersectionoption (orpress F7).You can define any Snap position as the default by clicking on

the Snapbutton at the top left of the screen, and selecting the Snap

position fromthe menu e.g. Endpoint, Center, and Intersection etc.

Unless defined otherwise a help line will automatically «snap»

to thenearest snap point. This can be an endpoint of a line, a center

of a circleor line and an intersection between two entities.

10. Position the cursor near the intersection of the help lines

and click the mouse.The circle will snap to the intersection. Repeat this for the

other three holes.11. From the Delete toolbar click theDelete Help-Linesbutton

.

12. The Select Optiontoolbar will open. ClicktheAbutton (or

press the letter A on your keyboard) and press Entertoconfirm the

selection.13. Press Esc and clean the screen by clicking on the Redraw

button (orpress F2). The part should appear as shown below:

1.5 Creating the Inner RectangleIn this stage we will be

creating a rectangle by using the help lines to define therectangle

corners. We will then draw a line by snapping to the intersections

of thehelp lines. There are also other methods for creating

rectangles — for instance youcould use the Shapes options. -

7/25/2019 cnc kad user manual

14/50

cncKad

14

The Shapes commands allow you to build certain shapes

parametrically,i.e. you define the dimensions and orientation of the shapes,

and to placethem on the drawing.

There are eleven types of shapes available (from the

Shapestoolbar orfrom the Draw=> Shapesmenu) —

o

RectangleoOval

oSingle-D

oDouble-D

oTrapeze (Connector)

oBolt Hole

oBanana Shape

oEllipse

oPunched Sheet

oTriangle

oPolygon

1. From the Help Lines toolbar click on the Vertical Help

Linebutton .2. Click the cursor on the bottom horizontal line, near the

middle of the line. Agreen, vertical help line will be placed

through the midpoint of this line.3. From the same toolbar click on the Horizontal Help Linebutton

.4. Now click the left vertical line near the midpoint. The part

should now besimilar to the drawing shown below.5. From the Help Lines toolbar select the Parallel Help Line by

Distancebutton. The distance dialog box will appear, enter a value of 100and

click onthe OKbutton.6. Click the vertical help line on either its left or right

side. A new help line will beplaced 100mm from the original

vertical help line.7. Click the other side of the (vertical) center help line.

There should now bethree vertical help lines with a 100mm distance

between each of them.8. Click on the Parallel Help-Line by Distancebutton again and

re-enter thevalue as 50. Click the OKbutton, and click the

horizontal help line once oneach side. Now the part should be as on

the picture shown below. -

7/25/2019 cnc kad user manual

15/50

Laser Cutting Tutorial

15

9. Click the Line, Auto-Snapbutton from the Shapes Toolbar.

The Line, Auto Snapcommand automatically snaps the cursor to

thenearest Snap position. There is no need to place the cursor

exactly at thedesired position. The start and endpoint of the lines will be

placed at theclosest snapping positions.The Line, Auto Snapoption is a quick

and accurate way of snapping tointersections created by the help lines.

The user can define any snap position as the default by clicking

on theSnapbutton at the top left of the screen, and selecting the snap

positionfrom the menu i.e. Endpoint, Center, Intersectionetc.

10. With the aid of the cursor click the four intersections of

the help lines, asshown below, and then click the first one again

(to close the rectangle).11. Press the right mouse button. This is the Escapebutton and

closes thecommand.12. From the Delete Toolbar click on the Delete Help Lines

button . Click theAbutton and then Enterto delete all the help

lines.13. Click on the Redraw button from the Zoom Toolbar to clean

the screen.The screen can be redrawn any time by using the button.

Use the Zooming commands to enlarge a portion of the drawing

toenable accurate work.

-

7/25/2019 cnc kad user manual

16/50

cncKad

16

1.6 Filleting ContoursIn this stage we will be placing fillet

radii on the outer and inner contours.1. From the Edittoolbar click the Filletbutton .The following

menu will appear:The Fillet menu gives you the options of creating one single

fillet on acorner, or of creating the same fillet radius on every corner

making up aclosed contour, or of creating fillet radiuses on every corner

of the part.2. Select the second option the Contourcommand.

3. Click the inner rectangle on one of its lines. When asked if

«OK to filletselected contour «, press the Yesbutton.4. TheRadius Definit iondialog will be displayed. Define a

radius of 10andclick the OKbutton. The inner contour will be filleted on all

four corners.5. Click the outer contour. The contour will be

highlighted and you will be askedagain if this is the correct contour, click on the Yesbutton.

Define a radius of20and click on the OKbutton. The outer contour

will be filleted.6. The part should now be as shown below:

1.7 Geometry ChecksWe will now check the part for any errors or

problems.It is important to execute these checks before entering the

cutting stage, so thatcncKadwill be able to recognize the part

correctly.These checks not only verify the legality of the existing

geometry, but also repair it, ifneeded you can choose to delete

duplicate entities (e.g. Circles placed on top ofeach other), join all the breaks in the geometry, examine the

part to see if all thecontours are connected properly.1. From the Viewmenu (at the top of the screen) select the

Checkoption, orclick the Checkbutton .

2. The dialog, as shown below, will be displayed. Make sure that

the options areset as shown: -

7/25/2019 cnc kad user manual

17/50

Laser Cutting Tutorial

17

3. Press the OKbutton, to execute the checks. If there are any

gaps in contoursbigger than 1mm, the examination process will stop,

a red Xwill be placed atthat position and you will be allowed to

press Enter to continue with thechecks.Gaps in the contours that are smaller than 1mm will be

repairedautomatically. The size of the repaired gap can be set by

editing theConnect Tolerancefield.

1.8 Saving the PartIt is important to save your part after each

important change you make, so that youwill not loose a lot of work

if there is a problem. To do this, select the Savebuttonfrom the Filetoolbar.

You can also do this by pressing the Ctrl+Skey combination on

yourKeyboard.

If you want to change the parts name select Save Asfrom the

Filemenu. Thefollowing dialog will appear:Type-in a new name for the file and click the Savebutton. The

dialog will disappearand the part will be saved under the new

name.1.9 Cutting the PartThe parts drawing is now complete, and it is

time to cut it. -

7/25/2019 cnc kad user manual

18/50

cncKad

18

The cuts will be presented on the drawing as yellow lines,

placed to oneside of the contour (white) lines.

To cut the part we will use the Auto Cut option.

Click theAuto Cut button on the Commontoolbar, and the following

dialog willopen:At this point we will not go into all the options this dialog

offers — simply click the Run button.The part will be cut automatically (as you will see from the

addition of the yellowcutting lines), and the following message

will appear:Confirm by clicking OKand view your part:

-

7/25/2019 cnc kad user manual

19/50

Laser Cutting Tutorial

19

The dotted lines are the Rapid Tool Path. You can turn this

feature onand off from the Viewmenu, or by pressing the Alt+Bkeyboard

combination.

The Entry into a cut is marked with the circular

piercinggraphic:1.10 Defining the Sheet SizeWe will now define the size of the

sheet, the number of parts that fit on it and theoffsets of the

actual parts from the sheets edges.When defining a sheet size, cncKad will attempt to fit in as

many partcopies as possible. These copies are called «multiple parts».

The amountof parts that fit on the sheet is displayed in the Number of

Partsfields,below the Sheet Sizedefinition fields.1. Click the Set Sheet and Clampsbutton from the Commontoolbar

(youcan also access this dialog from the CAMmenu).2. The following dialog will appear. Go to the Sheettab and

define the SheetSizeand the Offsetsas shown below: -

7/25/2019 cnc kad user manual

20/50

cncKad

20

3. Click on the Parttab and note the Distance between

Partssection; here youcan define the distances of each part from

the next.It is important to separate the parts enough to allow for the

EntryandExitfor the cuts of the parts outer contours.

-

7/25/2019 cnc kad user manual

21/50

Laser Cutting Tutorial

21

4. Confirm the new definitions by clicking the OKbutton. Your

sheet should nowlook like this: -

7/25/2019 cnc kad user manual

22/50

cncKad

22

Remember to Saveyour work periodically.

1.11 Generating the NC CodeIt is now time to convert the parts

drawing and cutting definitions into NC code.1. Click the button in the Commontoolbar, or open the Filemenu

andselect the Post Processoption.2. The User Datadialog will open; at this point we will ignore

it. Click the Nextbutton continue.3. This dialog shows you for which machine this NC code is being

generated(which post processor is being used).4. This dialog deals with Laser Optimization. You can leave the

definitions asthey are, or set different ordering for the cuts. For

now, accept the defaultsand click the Nextbutton.5. This dialog enables you to add Tool Functionsto your cuts.

Again, click theNextbutton to skip it.6. This dialog is the Post Processor

Options. Here you can define the nameand directory for the NC file, whether or not to create a Report

file and variousother options. For now accept the defaults and

click the Finishbutton.7. The Post Processor will start and when it finishes you will

receive a summarysuch as the following: -

7/25/2019 cnc kad user manual

23/50

Laser Cutting Tutorial

23

8. Click the OKbutton and the Simulation program will open

showing yoursheet.1.12 Simulating the NC ProgramAfter the Post Processor finishes,

the Simulation program opens showing your sheet:As you can see, there are two main elements in the Simulations

screen:A graphic representation of the sheet.

The NC code generated for this sheet (on the right side).

1.12.1 Running the Simulation

The simulations running and speed are controlled by the

Executetoolbar: -

7/25/2019 cnc kad user manual

24/50

cncKad

24

To run the simulation, simply click the Run button .

To Pauseor Stopit, use the and buttons.

To adjust the speed, use the slider .

You can also run the NC code line after line:

1. Click the Linebutton on the left side of screen so that it

shows Line=ON.2. Click the Run button to move from one line to the next

one.To exit the simulation from the Filemenu select the

Exitoption.1.13 SummaryIn this exercise we created a simple part, used

theAuto Cut feature to process it,defined a sheet size and created

multiple parts, generated NC code for it and run thiscode in the

Simulation.You might want to create a few parts on your own and process

them to gain someconfidence before continuing to the next exercise, which will be

more advanced. -

7/25/2019 cnc kad user manual

25/50

Laser Cutting Tutorial

25

2 Exercise 2 Setting Cuts Manually

2.1 OverviewIn this exercise we will use the part we created in

Exercise 1 to see how we canmanually set the cuts on our part.2.1.1 What you wil l learn in this exercise:

1. Adding Dimensions

2. Stretching

3. Setting Auto Cut definitions

4. Editing individual cuts

2.2 Saving a File Under a New NameBecause we will now make

changes to the part, it is good procedure to save it undera new

name:1. Select Save Asfrom the Filemenu. The following dialog will

appear:2. Type-in Exer2 in the File namefield and click the

Savebutton.The dialog will close and the part will be saved under the new

name.2.3 Adding a DimensionAmong the other drafting tools,

cncKadenables you to add dimensions on your part:1. From the Dimensiontoolbar , select the

Add Dimension button .

-

7/25/2019 cnc kad user manual

26/50

cncKad

26

2. TheAdd Dimension/Text dialog will open. Define the parameters

as bellowand click OK:3. Click on the parts left side and then on its right side. A

Dimension line will bedrawn on the cursor, moving as it moves.4. Move the cursor above the part and click. The Dimension will

positioned andits size shown:2.4 Stretching the PartIt often happens that you want to re-size

a part, or a section of it:1. From the Transformtoolbar , select the

Stretchbutton .

2. The cursor will change to a cross with a Wletter. This

indicates that you needto select a window to perform the Stretch.

Click positions 1and 2as shown -

7/25/2019 cnc kad user manual

27/50

Laser Cutting Tutorial

27

below:

Entities that are entirely inside the Stretching window will be

moved, notre-sized note the two round holes.

3. This defines the Entities that will undergo the Stretching.

The Stretchdialogwill open; set dXvalue of 50and click OK:4. The part will be re-sized as below:

Note that the cutting definitions have been updated, and also

that theDimension now shows the new size.2.5 Deleting Existing Cuts on the Part

1. From the Delete toolbar, click theDelete CAMsbutton .

2. Click theAButton (or press the letter A on the Keyboard) and

press Enter.3. From the Zoomtoolbar, click the Zoom Partbutton (or press

F5).As you can see all the cuts have been removed from the part.

-

7/25/2019 cnc kad user manual

28/50

cncKad

28

2.6 Setting Auto Cut Definitions

The changes we make here are reserved for specialized cases

usuallythe standard setting should be used.

We will now add new cuts, using manual definitions.

1. Click theAuto Cut button on the Commontoolbar, and theAuto

Cut willopen.2. Un-check the Use Technology table for Entry and Exitoption,

andApproach and Exit sections will be un-grayed:3. For theApproachand the Exit, set the Geo-Typeand

Lengthparametersas above, click the Run button, and the part will

be cut with the newdefinitions.4. Using the Zoom Windowbutton zoom to the inner rectangle, to

thesection with the Entry and the Exit:Note that the Entry (marked with the piercing) is much longer

and steeperthan the Exit, as per our definitions.When you set the Auto Cut Approach/Exitdefinitions, you do it

for theentire part zoom-in to other contours on the part to see

this.2.7 Setting Individual CutsWe will now see how to change the

cutting definitions for an individual cut. -

7/25/2019 cnc kad user manual

29/50

Laser Cutting Tutorial

29

1. From the CAMtoolbar , click the Edit CAMbutton

.

You can also press the letter Eon your keyboard.

2. Click anywhere near the parts outer contour, and the Edit

Contour Cutdialog will open:3. Define the Contour Overlapas 5, and click OK. Zoom-in to note

thedifference in the cut:Before: After:

-

7/25/2019 cnc kad user manual

30/50

cncKad

30

4. Click on one of the holes and the Edit Contour Cutdialog will

open. For theExit, define the Geo-TypeasArc 90, and the Lengthas

4.5. Click OKto confirm the new definitions, and the hole should

now look like:6. Do the same for the other three holes and Saveyour part.

2.8 SummaryIn this exercise we learnt how to manually set Auto

Cut to create cuts to suit ourneeds, and how to edit individual

cuts after they have been created.You may want to play around with these features, to see the

effects of variousdefinitions. -

7/25/2019 cnc kad user manual

31/50

Laser Cutting Tutorial

31

3 Exercise 3 Advanced Drafting

3.1 OverviewIn this exercise we will create a more intricate

part, using some new commands.We will also be using commands we have used before, so some of

the explanationsare less explicit.In this exercise we will be creating the

following part:3.1.1 What you wil l learn in this exercise:1. Notching.

2. Bend Relief.

3. Trimming.

4. Filleting single corners.

5. Chamfering corners.

6. Round and Rectangular Arrays.

3.2 Creating Notches and Bend Relief1. Start a new part, name it

Exer3 and give the dimensions Xequals 250andYequals 150.

-

7/25/2019 cnc kad user manual

32/50

cncKad

32

2. From the Edittoolbar click the Notchbutton . The following

menu willappear:3. Set the parameters as above, click OK, and the part near the

bottom leftcorner.A notch can be inner or outer, depending which side of the

contour wasselected; so you need to make sure you click the right one.

4. Press the Space bar to re-open the Notch dialog, select the

OffsetRectangular Notchtab, and set the parameters as below:5. Click OK, and then click inside the bottom right corner, near

the bottom line.6. Use Zoom Window to zoom in on the corner notch you created,

andthen from the Editmenu, select the Bend Reliefoption. -

7/25/2019 cnc kad user manual

33/50

Laser Cutting Tutorial

33

7. The Bend Reliefdialog will open; enter a diameter of 2and

click OK:8. Click near the corner:

9. Redraw the part with the button to see the result, and then

do the samefor the two corners you created with the rectangular notch.10.

Re-open the Notchdialog, select the Corner Notchtab, and set

theparameters as below:

11. Click near the top right corner, closer to the top line. If

your click is nearer theside line, the Notch will not be created

correctly; remember the explanationregarding clickingat the

beginning of this Tutorial. -

7/25/2019 cnc kad user manual

34/50

cncKad

34

12. Your part should now look like this:

3.3 Trimming Lines

Trimmingmeans deleting a section of an Entity.

1. Click the Parallel Help Line by Distancebutton and set a

distance of100.2. Click just above the parts bottom-most line.

3. Press the Space bar to re-open the dialog, set a distance

of20.21, and clickjust above the existing Help Line. You should now

have:4. Click the Help-Line by Absolute Anglebutton , enter a value

of 30(degrees), and click near the intersection of the bottom Help

line with the leftside of the part.5. Click on the Vertical Help Linebutton , and click near the

intersection ofthe angular Help Line with the upper one. -

7/25/2019 cnc kad user manual

35/50

Laser Cutting Tutorial

35

6. Click the Line, Auto Snapbutton , and click the intersections

numbered1,2 and 3 as shown below:7. Delete the Help Lines (click ,Aand then press Enter).

Remember you can clean the screen by clicking on the

Redrawbutton.

8. From the Edittoolbar, click the Trimbutton . All the lines

will be colored alight blue.When an Entity is colored light blue it indicates it has been

selected forthe current action.9. Click the lines running from ato 1and from

ato 3in the picture above, andRedrawthe part.

10. Your part should now look like this:

3.4 Adding a Rectangular Hole1. Click the Parallel Help-Line by

Distancebutton, enter a distance of 30andclick just inside the parts top horizontal line.

2. Press the Space bar to re-open the dialog, redefine the

parallel distance as66.7, and click on the right side of the

vertical line we drew in the last stage(the line running from 2to

3in the illustration).We will use the resulting intersection to position our

rectangle. This is aneasy and precise way to positions shapes.

-

7/25/2019 cnc kad user manual

36/50

cncKad

36

3. Click the Draw Rectanglebutton and define the settings as

shownbelow:4. Click OKand then click on the intersection we made with the

Help Lines.Note that the Rectangles outline is ghosted around the cursor,

movingas you move it.5. Delete the Help Lines and Saveyour part.

3.5 Chamfering a Corner

1. From the Edittoolbar, click the Chamferbutton , and define

theparameters as below:The 1stvalue sets distance (from the corner) along the first

line wherethe chamfering line will start. The 2ndvalue is the distance

(from thecorner) along the second line where it will terminate.

2. Click the vertical line of the top right notch, and then

click the parts top-mosthorizontal line.3. Redraw the part and compare how the corner has been chamfered

with theorder in which you clicked the corners lines.

3.6 Filleting Corners and Contour

1. Click the Filletbutton and select the second option

Contour.2. Click the inner rectangle on one of its lines. When asked if

«OK to filletselected contour «, press the Yesbutton to confirm the

selection.3. TheRadius Definit iondialog will be displayed. Define a

radius of 6and clickthe OKbutton. The rectangles contour will be

filleted on all four corners. -

7/25/2019 cnc kad user manual

37/50

Laser Cutting Tutorial

37

4. Click the Filletbutton again, and this time select the first

option Single.To Fillet a single corner, you must select the two lines that

comprise it.5. Note that the Radiusis set to 6from before, and zoom-in to

the parts top leftarea:6. Click the lines marked above in the following sequence 1 then

2, 2 then 3, 3then 4. When you finish, Redrawthe part.7. Click the Filletbutton again, and again select the

Singleoption.8. Set the Radiusto 10and zoom-in to the parts top right

area:9. Click the lines marked above in the following sequence 1 then

2, 2 then 3.10. Redraw the part, and its upper section should now look like

this:Do not forget to Saveyour part periodically.

3.7 Creating a Circular Array1. Click the Parallel Help-Line by

Distancebutton, set a distance of 52.5andclick the parts bottom most horizontal line.

2. Press the Spacebarand set the value to 62.5and click the

parts left mostvertical line. You should now have two Help Lines

whose intersection marksthe center of the circular array we will

build.3. Press the Spacebar, redefine the distance as 22.5, and click

the vertical helpline on its left side.4. From the ShapesToolbar select the Draw Ovalbutton . The

Ovaldialogwill be displayed. Enter the definitions as shown below

and then click on the -

7/25/2019 cnc kad user manual

38/50

cncKad

38

OK button:

5. Click the intersection of the left Help Line with the

horizontal one and the ovalwill be positioned with its center on

the intersection.6. Zoom-in to the new oval, and from the Transformtoolbar

click theAr ray button .

7. The Selecttoolbar will open and you should click the

Windowselectionbutton , and make a window that contains the entire oval.

When using the Windowselection, the first click opens the window

andthe second sets its size.

8. Press Enterto confirm the selection and theAr ray dialog will

open. Definethe parameters as below and click OK:9. Now, you must select the center of the array; click the

intersection of the rightHelp Line with the horizontal one and the

array will be drawn around it. -

7/25/2019 cnc kad user manual

39/50

Laser Cutting Tutorial

39

10. Delete the Help Lines and Redraw your part. It should now

look like:3.8 Creating Rectangular Arrays1. Place a Parallel Help Line at

a distance of 10on the right of the left verticalside of the rectangular notch:

When you want to place the same type of Help Line and at the

samedistance setting, simply click where you want to put it you do

not haveto re-click the button

2. Place another Help Line parallel at a distance of 10from this

notchshorizontal line.3. Press Space bar to re-open the Parallel Help Line at

Distancedialog, set adistance of 15and click above the horizontal

Help Line you just placed.4. Your part should now look like this:

5. From the Shapestoolbar, click the Draw Circlebutton , set a

Diameterof 4, and click the bottom intersection of the Help

Lines.6. Click the Draw Rectanglebutton , set the Lengthand Widthto

10, andclick the top intersection of the Help Lines. -

7/25/2019 cnc kad user manual

40/50

cncKad

40

7. Click theAr ray button, click the new circle and press

Enterto confirm yourselection; set the parameters as below, and

then click OK:8. Now, use the Windowselection to select the new square,

confirm with Enter,set the parameters as below, and then click OK:

9. Delete the Help Lines.

3.9 Adding a Marking PointWe will now add a marking on the part

to help later in bending it to shape.1. Create a parallel Help Line inside the right side of the

part, at a distance of 2.2. Create another parallel Help Line at a distance of12.5,

frominside oftheparts bottom line.3. Put a Circular hole with a diameter of 0.30at the

intersection of these HelpLines.4. Delete the Help Lines and Save.

-

7/25/2019 cnc kad user manual

41/50

Laser Cutting Tutorial

41

5. Your part should now look like this:

3.10 SummaryIn this exercise we learnt new drafting techniques,

including Notching, Chamfering,Trimming and different kinds of

Arraying. -

7/25/2019 cnc kad user manual

42/50

cncKad

42

4 Exercise 4 — Advanced Cutting Definitions

4.1 OverviewIn this exercise we will go over some of the options

you can use to set the way partsare cut.4.1.1 What you wil l learn in this exercise:

1. What Cutting Tables are

2. How Cutting Tables relate to Sheet Material and Thickness

3. Corner Treatment

4. Point marking

4.2 Cutting a Previously Cut PartIn this chapter we will often

re-cut our part, to see the different treatments available.To begin with, open the part we created in the previous chapter

and run Auto Cut onit.When we want to re-cut a part, we have two options: Deleting the

previous cuts and cutting again.Running Auto Cut and thereby automatically replacing the

cuts.4.2.1 Deleting Cuts

To delete a cutting definition from an Entity, simply click the

Delete CAMsbuttonon the Deletetoolbar, and use the Selection

options to select one, some, or all thecuts on the part.4.2.2 Replacing Cutting Definitions with Auto Cut

We can also runAuto Cut and have it automatically replace

existing cuttingdefinitions.To do this, we must enable the Delete old before

runn ingoptions in the Auto Cutdialog — .

Note that there are two of these options:

In the Holessection this will affect only the holes in a

part.In the Partssection this will affect the contours of parts.

4.3 What Are Cutting TablesCutting Tables are charts that cover

all aspects of cutting a material which Gas touse, what the Feed

Rate is, the Approach and Exit definitions for different

sizedEntities, how to pierce the material and many other

parameters.These Tables are specific for both material typeand thickness

the table forAluminum 1mm is different from the one for Steel 1mm,

but also from the one forAluminum 5mm.Also, the Tables are specific for machines the Tables for Trumpf

are different thanthe ones for Amada or Bystronic.cncKad comes with standard Tables appropriate for the machine

modelyou installed, but in any case where these clash with the

definitions fromyour machines manufacturers recommendations you should

followthese recommendations.

-

7/25/2019 cnc kad user manual

43/50

Laser Cutting Tutorial

43

Because the Cutting Tables are machine-specific, we will not

give any in-depthexamples.Once you are familiar with your machine and the manufacturer

recommendations you may wish to study this matter on our

own.To view the Tables, click the Cutting Tablebutton from the Cut

toolbar —.

A dialog will open, showing data such as the following:

As discussed before these tables are machine-specific, Trumpf

6030 inthis case, so your tables may show different values.

Try changing the Thickness, and note that the parameters in the

chart at the bottomchange for each value, and the same if you

change the Gas, Heador Lens(if youhave more than one value

available for these).For now, set the Material to Steeland the Thicknessto 2, and

close the dialog.4.3.1 Cutting Tables Example

We will now see an example of how the Cutting Tables affect the

cuts placed on apart.1. Click the Set Sheet and Clampsbutton to open the dialog, go

to theSheettab and set the Material Listto 0 Steel with Sheet

Thicknessas 2(or a close value).At this point you can also set the Sheet Size.

-

7/25/2019 cnc kad user manual

44/50

cncKad

44

2. Open the Cutting Table the Cutting Tableby clicking on

thebutton , go tothe Geometrytab, and note theApproach Path Min/Max

parameters:As noted before this table is machine-specific, Trumpf 6030 in

this case.3. Close this dialog and runAuto Cut . Make sure that all the

options called UseTechnology Tableare enabled.4. If your table is close to mine, the square holes in the array

will be cut in thefollowing manner:5. The entry to the cut was made just beside the hole’s center

point (the white X,which is 5mm from the holes edge). Note in the

Table above that theApproach Path Maximum is set as4.5for the

Largecategory.6. Now, open the Set Sheet and Clampsdialog, set the Sheet

Thicknessas 6(or a close value), close this dialog and re-open the

Cutting Table.7. The Geometry table has changed, and now theApproach Path

Maximum isset as6.5for the Largecategory:8. Close this dialog and runAuto Cut . Now the square holes are

cut like this:9. You can tell from its position relative to the holes center

that the Entry is nowlonger than before, as per the parameters in

the Table.This is a simple example of the way the Cutting Tables affect

the way a part is cut. -

7/25/2019 cnc kad user manual

45/50

Laser Cutting Tutorial

45

As mentioned before, each machine manufacturer provides

differentrecommendations for these tables to allow for the machines

attributes,and unless you are sure they are inadequate you should follow

theserecommendations.

4.4 Corner Treatment

Cutting corners is often problematic they can be easily damaged

without carefulhandling, leading to scrapping the entire part.cncKad has several strategies to handle this problem, of which

we will review three.Rounding

Slowing

Loops

Before we discuss strategies, we must understand the concept of

Max Angle, andthe role of the Global Cuttab in the Set Sheet and

Clampsdialog.4.4.1 Max Angle

When we look at the corners of a part, the way we want to cut

them often dependson a corners angle an acute angle will require special

treatment, while an obtuseone can be left alone.The Max Angleparameter defines the maximum angle that a corner

can have sothat it will be subject to treatment.For example:

In our part we have two types of angles:

Straight angles —

Obtuse ones —

If we set the Max Angle as 90, only the straight (and smaller)

angles will be affected,while those with an angle greater than 90 will be left

unaffected.4.5 The Global Cut Tab

To get to this tab, click the Set Sheet and Clampsbutton .

The definitions in this tab set an overall (i.e. global) cutting

strategy for the sheet onwhich you are currently working.This means that any definitions you set for the current part

will not besaved for the next part you create.

For now, set the Max Ang leto 90, make sure all

theActivecheckboxes are notenabled, and close the dialog.4.6 Rounding CornersRunAuto Cut with the following settings:

-

7/25/2019 cnc kad user manual

46/50

cncKad

46

Make sure that in the Corner Treatmentsection, the Use

Technology Tableoptionis not enabled, and that the Delete old before running options

are indeed enabled.Now zoom-in to corners of the part, and they

should look as follows:The Bend Relief The Notch outer corners The Chamfered

cornersIf your corners look like this:

Toggle the Full Cut Tool Widthoption in the Viewmenu. You can

alsouse the keyboard shortcut Ctrl+B.

We will now add Rounding to the corners. OpenAuto Cut again, go

to the GlobalCut tab and set the parameters as follows:Max Angle 90

-

7/25/2019 cnc kad user manual

47/50

Laser Cutting Tutorial

47

Rounding,Active enabled

Rounding, Size 0.5

RunAuto Cut again, and look at the corners:

The Bend Relief The Notch outer corners The square holes

cornersNote that in each case the cutting line is an arc instead of a

straight angle.4.7 SlowingThis time we will use the Slowing strategy to process

the corners.OpenAuto Cut again, go to the Global Cuttab and set the

parameters as follows:Max Angle 90

Rounding,Active disabled

Slow,Active enabled

Slow, Distance Before Corner 8

Slow, Distance After Corner 5

Slow, Under Radius 0

RunAuto Cut again.

In order to see the difference in the speed of the cut, toggle

the Colored Tool Pathby Speedoption in the Viewmenu.After you enable the coloring, the regular speed cuts are

colored yellow, while theslow ones are orange:To see this more clearly, toggle the Full Cut Tool

Widthoption.Note that the Chamfered corners are still cut with the regular

speed.Re-openAuto Cut , go to the Global Cuttab, set the Max Angleto

160, and re-cutthe part.Now the Chamfers obtuse angles (153 and 115) are included in the

angle valuegoverning the Slow processing:4.8 Using LoopsWe will now see two ways to set individual corner

processing parameters:Selecting a corner and then setting parameters for it (click

then set).Setting parameters and then selecting one or more corners (set

then click). -

7/25/2019 cnc kad user manual

48/50

cncKad

48

The procedure we will use for using the Corner Parametersdialog

tocreate Loops can also be used for defining the other cutting

strategies forcorners Slowing, Cooling and Rounding.

4.8.1 Editing Corner Parameters

1. Click the Edit Corner Parametersbutton from the Cut

toolbar.2. Now you must select a corner. Click the bottom left

corner, and the CornerParameters dialog will open.

3. In the Loopssection, select Yesfrom theActivedrop-down menu,

set Sizeto 3 and click OK.4. Zoom-in to this corner and note the loop that was added on

it.Note that the Slow cutting definition has been removed from this

cornerno need for slowing when you are cutting the loop.

You can now click on a different corner and set the parameters

for it, but we will notdo this at this point.4.8.2 Setting Corner Parameters

1. Click the Set Corner Parametersbutton from the Cut

toolbar.2. The Corner Parametersdialog opens immediately; In the

Loopssection,select Yesfrom theActivedrop-down menu, set Sizeto

2and click OKandthe dialog will close.3. Click on the left corner of the rectangular notch at the

bottom, and a loop willbe added on it.4. Click on this notchs other corner, and again a loop will be

added to thecorner.4.9 Point MarkingAs you will recall, we put a 0.30hole on the

part. Zoom-in to this hole and look how ithas been cut.

As you can see, it is marked in blue. This means that it will be

engraved, instead ofbeing cut.1. The reason that this particular hole has been marked in this

way is becauseof its size: Open the Cutting Table, go to the

Geometrytab.2. Note the Min Diametervalue for the first entry. Anything

below this diameteris considered an Undersized Hole.3. Now, open theAuto Cutdialog and go to the Technologytab. Here

you willfind an item calledAction for undersized holes , with a

drop-down menu toselect the action.4.9.1 Options for Marking

By default, the undersized hole was marked with a point, but you

can define foryourself what kind of Marking will be used.Click the Set Sheet and Clampsbutton and go to the Cutting

Parameterstab,and find the section called Point Marking.Here you can select the Marking type and its size:

-

7/25/2019 cnc kad user manual

49/50

Laser Cutting Tutorial

49

4.10 SummaryIn this chapter we have gone over some of the ways

in which you can define the wayyour part will be cut. We have seen

ways to do this on three levels:For the entire workstation the Cutting Technology Table.

For an entire part from the Set Sheet and Clampsdialog.

For specific items in a part individual corner treatment.

This three-tier system is often found in cncKad, because some

definitions you wantto be permanent, some just for the current

part, and other for individual items in thecurrent part.Whenever you change a definition, it is important to be sure you

are working at thecorrect level dont change workstation definitions

when all you want is a smallcorrection on a part.

-

7/25/2019 cnc kad user manual

50/50

cncKad

5 Index

A brief explanation about ClickingLaser

…………………………………………………… 1Adding a Marking Point …………………………..34

Adding a Rectangular Hole ………………………29

Advanced Cutting Definitions…………………..36Advanced

Drafting…………………………………..25Auto Cut Definitions………………………………..22

Basic Drafting and Cutting

Laser

…………………………………………………… 3Chamfering a Corner

……………………………….30Corner

Treatment…………………………………….39Creating a Circular Array …………………………31

Creating a New

Part…………………………………..4Creating Notches and

Bend Relief …………….25Creating Rectangular Arrays …………………….33

Creating the Inner Rectangle ………………………7

Cutting a Previously Cut Part ……………………36Cutting

Tables…………………………………………36Cutting Tables Example …………………………..37

Cutting the Part ……………………………………….

11Defining the Sheet Size ……………………………13

Deleting Cuts

………………………………………….36Deleting Existing Cuts on the Part …………….21

Dimension ………………………………………………

19Editing Corner Parameters………………………..42

Filleting Contours

……………………………………10Filleting Corners and Contour…………………..30

Generating the NC Code…………………………..16Geometry

Checks…………………………………….10Global Cut

Tab………………………………………..39How to use this Tutorial

Laser…………………………………………………….1

Laser Cutting

Tutorial………………………………..1Laser Tutorial

Overview and Aims ……………..1Loops

……………………………………………………..41Max

Angle………………………………………………39Options for Marking…………………………………42

Overview………………………………… 3, 19, 25,

36Point

Marking………………………………………….42Positioning Holes with Help Lines………………6

Replacing Cutting Definitions with Auto

Cut……………………………………………………..36

Rounding Corners

……………………………………39Running the Simulation

……………………………17Saving a File Under a New Name ……………..19Saving the

Part ………………………………………..11Setting Corner Parameters ………………………..42

Setting Cuts Manually………………………………19

Setting Individual Cuts …………………………….22

Simulating the NC

Program………………………17Slowing…………………………………………………..41Stretch…………………………………………………….20Summary

………………………………. 18, 24, 35, 43Tips………………………………………………………….3

Trimming

Lines……………………………………….28What you will learn in this exercise:3, 19, 25, 36

49 тем в этом разделе

- Сортировка

-

-

3

ответа -

359

просмотров

-

3

-

-

11

ответов -

2,4k

просмотров

-

11

-

-

5

ответов -

317

просмотров

-

-

Aleksey_spb

-

6 апреля

-

5

-

Ищу постпроцессоры MAZAK

Автор:Нафаня,

22 марта-

0

ответов -

191

просмотр

-

0

-

-

1

ответ -

253

просмотра

-

1

-

-

6

ответов -

531

просмотр

-

-

Aleksey_spb

-

11 января

-

6

-

-

3

ответа -

510

просмотров

-

-

Aleksey_spb

-

10 января

-

3

-

Нужна помощь!

Автор:SaturN26,

9 января-

1

ответ -

299

просмотров

-

-

Aleksey_spb

-

10 января

-

1

-

Помогите разобраться

Автор:Despor,

6 декабря 2022-

1

ответ -

306

просмотров

-

1

-

-

9

ответов -

1,8k

просмотра

-

9

-

Вопросы по CncKad

Автор:Doping,

5 сентября 2014-

54

ответа -

16,5k

просмотров

-

54

-

-

0

ответов -

332

просмотра

-

-

djorudeboy.ru

-

28 июня 2022

-

0

-

-

0

ответов -

460

просмотров

-

-

Andrew Davidson

-

1 апреля 2022

-

0

-

-

6

ответов -

515

просмотров

-

6

-

не грузит нестинг

Автор:Татьяна53751,

17 ноября 2021-

0

ответов -

363

просмотра

-

0

-

trupunch и cnckad

Автор:menakev,

12 ноября 2021-

1

ответ -

418

просмотров

-

1

-

cncKad 16 не обновляет сборку

Автор:zhottuk,

1 сентября 2021-

0

ответов -

370

просмотров

-

0

-

-

6

ответов -

1k

просмотров

-

6

-

Гравёр в cncKaD v12.1.455

Автор:CJIABUK,

22 января 2021-

1

ответ -

594

просмотра

-

1

-

-

2

ответа -

1,4k

просмотра

-

2

-

Размер стола

Автор:Семен23,

4 февраля 2021-

1

ответ -

399

просмотров

-

1

-

AutoNest

Автор:Belov Alex,

11 марта 2020-

4

ответа -

2,6k

просмотров

-

4

-

Репозиция на trumpf 500

Автор:Vladislav0,

19 января 2021-

1

ответ -

538

просмотров

-

1

-

Id

Автор:Ivan1324,

4 января 2021-

0

ответов -

485

просмотров

-

0

-

-

4

ответа -

3,6k

просмотров

-

4

-

CNC KAD 12

Автор:toxany4,

30 июля 2018-

12

ответов -

3,9k

просмотров

-

12

-

инструмент колесо

Автор:zz122aaz,

1 октября 2020-

0

ответов -

524

просмотра

-

0

-

-

0

ответов -

654

просмотра

-

0

-

-

4

ответа -

1,4k

просмотров

-

4

-

Помощь по CNCKAD 16

Автор:Нафаня,

19 сентября 2019-

1

ответ -

1,4k

просмотров

-

1

-

-

1

ответ -

846

просмотров

-

1

-

export в cncKad из Solidworks

Автор:jango,

12 ноября 2019-

4

ответа -

4,5k

просмотра

-

4

-

-

3

ответа -

1,1k

просмотров

-

3

-

Обучающее пособие для cncKad 8,5

Автор:Nikolay Berliyan,

7 февраля 2013-

4

ответа -

7,5k

просмотров

-

4

-

Как обойти ключ в CncCad

Автор:Андрей13051994,

12 марта 2019-

0

ответов -

2,1k

просмотров

-

-

Андрей13051994

-

12 марта 2019

-

0

-

-

5

ответов -

7,1k

просмотров

-

5

-

-

19

ответов -

4,1k

просмотра

-

19

-

Альтернатива Cnckad

Автор:yuri-pet,

20 октября 2014-

20

ответов -

8,7k

просмотров

-

-

stim-moscow

-

2 мая 2018

-

20

-

Wilson Wheel и cncKad

Автор:HotSummer,

24 июня 2016-

8

ответов -

3,4k

просмотров

-

8

-

Вопрос по cnckad

Автор:Umka,

6 марта 2018-

1

ответ -

1,4k

просмотров

-

1

-

-

0

ответов -

2k

просмотра

-

-

Igor zatevakhin

-

22 марта 2018

-

0

-

-

3

ответа -

2,2k

просмотров

-

3

-

-

2

ответа -

1,2k

просмотра

-

2

-

-

2

ответа -

2,1k

просмотров

-

-

belkaistrelka

-

19 января 2017

-

2

-

cncKad 9.0

Автор:lionel281,

26 мая 2016-

9

ответов -

4,5k

просмотров

-

9

-

Глюк cncKad в Win7

Автор:dicty,

10 июня 2011-

8

ответов -

19,5k

просмотров

-

8

-

-

1

ответ -

4,4k

просмотров

-

1

-

-

7

ответов -

4,6k

просмотр

-

7

-

-

1

ответ -

3,2k

просмотра

-

1

cnckad16.zip

|

Имя файла: cnckad16.zip Размер файла: 2.14 GB Файл загружен: 18/11/2021 12:30:44 Файл скачали: 243 Поделиться этой ссылкой |

<a href=»https://wdfiles.ru/047b60″ target=»_blank» title=»Download from загрузить файл»>Скачать cnckad16.zip — загрузить файл</a>

[url]https://wdfiles.ru/047b60[/url]

подойдёт для вставки в документы или презентации.

Или получить файл на мобильное устройство, отсканировав QR-код программой с мобильного устройства

Приветствуем Вас на файлообменнике WdFiles.ru!

Ресурс WDfiles.RU был задуман как бесплатный файлообменник. Согласитесь, удобно с его помощью делиться файлами, или перемещать их с одного устройства на другое!

Всем спасибо за использование нашего ресурса!

Преимущества:

Прямые загрузки. Без ожидания.

Отсутствие рекламы.

Неограниченное количество загрузок.

Максимальная скорость загрузки.

Техподдержка (support@wdfiles.ru).

Неограниченная файловая зона.

Файлы в премиум-аккаунте хранятся вечно.

Загрузка файла размером свыше 10.00 GB .

Отсутствие ограничения на загрузки.

Низкая цена в сутки.

Отсутствие подписок.

Free download CncKad 16.4.325 full version standalone offline installer for Windows PC,

CncKad Overview

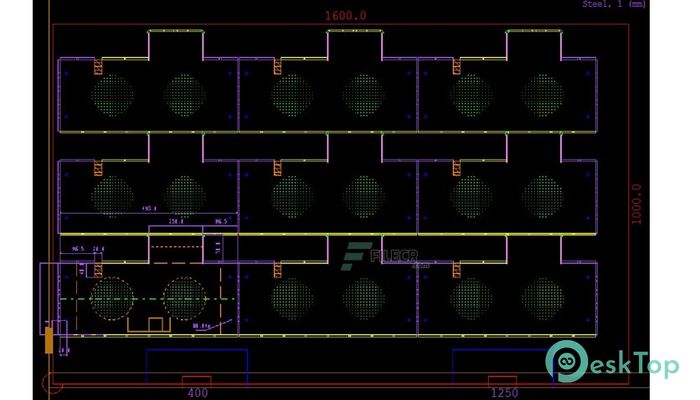

This program is the only system that combines drawing & processing functions in one module: geometry, dimensions & processing techs (punching/cutting) are completely interconnected, modules will change when change in drawing.

It offers the following capabilities: plane (2D) and volumetric (3D) modeling, AutoNest — automatic nesting of parts, generation of NC codes, visual control using graphic simulation and data transfer to the machine.

Moreover, it also has multiple language support: English, Arabic, Greek, Spanish, Italian, Chinese, Korean, German, Portuguese, Romanian, RUSSIAN, Slovak, Thai, Turkish, French, Czech, Japanese and so on.

Features of CncKad

Drafting

Importing file types including DXF and DWG

Tooling

Nesting

Part handling

Material based cutting tables

Common line cutting

WireJoint and MicroJoint positioning

Tool path optimization

Estimation data

Tube cutting, simulated in 3D

Support for laser, plasma, punch, shear, coil, busbar, water, combination machine types

System Requirements and Technical Details

Supported OS: Windows 10 / Windows 8.1 /Windows 7

Processor: Multi core Intel Series or above, Xeon or AMD equivalent

RAM: 4GB (8GB or more recommended)

Free Hard Disk Space: 4GB or more recommended

,Program download CncKad, Download CncKad, Download CncKad, Program CncKad, CncKad Full activated, crack program CncKad, program explanation CncKad

2.10 GB

Zip password: 123

Program details

-

Program language

multilanguage

-

Last updated

Before 1 Year

Download link for : : CncKad

Contact our support team on our Facebook page to solve your problem directly

go to the contact page

Сегодня мы рассмотрим еще один полезный инструмент Metalix cncKad. Представьте себе, если бы ваша CAD-система могла автоматически определять толщину детали, материал и ее количество из текста, который нанесен на эту деталь. В Metalix cncKad есть такая возможность благодаря использованию префикса.

Префикс — это некий текст, по которому Metalix cncKad определяет толщину детали, материал и ее количество. Правила форматирования очень просты. Символы которые находятся до знака равенства являются префиксом, а символы которые находятся после знака равенства явяляются значение этого префикса.

Рассмотрим пример:

Tks=1.0 Mat=Aluminium_5052 Q=100

Tks является префиксом толщины металла, Mat — префиксом материала, Q — количество деталей.

Назначается префикс в настройках импорта (вкладка «Текстовые параметры»). Префикс можно задать для материала, толщины, количества, номера чертежа, заказчика и проекта.

Один раз потратив время на настройку своей CAD-системы на включение текста с префиксами в DXF-файлы, вам не придется в последствии тратить время на назначение каждой детали толщины, материала и количества.

Это отличная возможность систематизировать базу данных деталей для максимального сокращения затрачиваемого времени на подготовку программ для лазерного раскроя. Рекомендуем использовать назначение параметров деталей в качестве правила для оформления внутренней конструкторской документации и для сторонней документации, получаемой при оказании услуг другим компаниям.