Add to collection(s)

Add to saved

- Engineering & Technology

- Computer Science

advertisement

advertisement

Is the category for this document correct?

- Engineering & Technology

- Computer Science

Thank you for your participation!

Related documents

Proceed to the SFC Application

SFC minutes 4.28.14 — Baltimore City Public School System

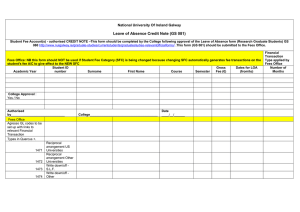

Leave of Absence Credit Note (GS 081)

SFC minutes 5.19.14

000 — SFC — Brochure — PRINT.indd

al_eng_TTY_15ab_slaidi_alg_c_

C Hegarty, S Katz, A Minenko, C Niewoehner, J… P Southern, D Wangensteen, K Watson, T Weinhaus, M Woods

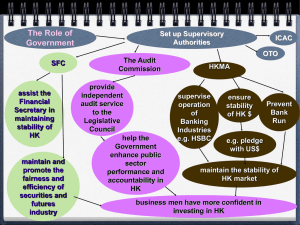

The Role of Government

Service Function Chaining Use Cases

Abstract — Compressed fluid technologies

Download

advertisement

Add this document to collection(s)

You can add this document to your study collection(s)

Sign in

Available only to authorized users

Title

Description

(optional)

Visible to

Everyone

Just me

Add this document to saved

You can add this document to your saved list

Sign in

Available only to authorized users

-

Cat. No. W446-E1-12

SYSMAC

OPERATION MANUAL

CX-Programmer Ver. [email protected]@@C-V4/[email protected]@D-V4

-

SYSMAC CX-Programmer Ver. [email protected] [email protected]@C-V4/[email protected]@D-V4 Operation

Manual Revised July 2010 -

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (ii)

About this Manual (W446): This manual describes the operation of

the CX-Programmer and consists of the following three parts.Part 1: CX-Programmer This part describes the CX-Programmer

software that is a PLC Programming Device, and also provides the

overall precautions and the version upgrades information.Part 2: CX-Server PLC Tools This part describes the CX-Server

PLC Tools software, which is a collection of the following

components: PLC Memory, IO Table, PLC Setup, Data Trace/Time Chart

Monitor, PLC Error, Memory Card, PLC-Clock, and CX-Net Network

Configuration (including Data Link Editor and Routing Table).Part 3: CX-Server Runtime This part describes the CX-Server

software that is a communications middleware.Note: References within each part are references to the pages or

chapters within that part.Related Manual For details on the function block functions and

ST programming, refer to the CX-Programmer Operation Manual

Function Blocks and Structured Text (Cat. No. W447).For details on the SFC programming functions, refer to the

CX-Programmer Operation Manual SFC (Cat. No. W469).For details on procedures for installing the CX-Programmer from

the CX-One FA Integrated Tool Package, refer to the CX-One Setup

Manual provided with CX-One.Cat. No. Model Manual name Contents

W463 [email protected]@C-V4/ [email protected]@D-V4

CX-One Setup Manual Installation and overview of CX-One FA

Integrated Tool Package.WARNING: Failure to read and understand the information provided

in this manual mayresult in personal injury or death, damage to the product, or

product failure. Please read each chapter in its entirety and be

sure you understand the information provided in the chapter and

related chapters before attempting any of the procedures or

operations given. -

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (iv)

Read and Understand this Manual Please read and understand this

manual before using the product. Please consult your OMRON

representative if you have any questions or comments.Warranty and Limitations of Liability WARRANTY

(1) The warranty period for the Software is one year from either

the date of purchase or the date on which the Software is delivered

to the specified location.(2) If the User discovers a defect in the Software (i.e.,

substantial non-conformity with the manual), and returns it to

OMRON within the above warranty period, OMRON will replace the

Software without charge by offering media or downloading services

from the Internet. And if the User discovers a defect in the media

which is attributable to OMRON and returns the Software to OMRON

within the above warranty period, OMRON will replace the defective

media without charge. If OMRON is unable to replace the defective

media or correct the Software, the liability of OMRON and the Users

remedy shall be limited to a refund of the license fee paid to

OMRON for the Software.LIMITATIONS OF LIABILITY (1) THE ABOVE WARRANTY SHALL CONSTITUTE

THE USERS SOLE AND EXCLUSIVE REMEDIESAGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT WILL OMRON BE

LIABLE FOR ANY LOST PROFITS OR OTHER INDIRECT, INCIDENTAL, SPECIAL,

OR CONSEQUENTIAL DAMAGES ARISING OUT OF USE OF THE SOFTWARE.(2) OMRON SHALL ASSUME NO LIABILITY FOR DEFECTS IN THE SOFTWARE

BASED ON MODIFICATION OR ALTERATION OF THE SOFTWARE BY THE USER OR

ANY THIRD PARTY.(3) OMRON SHALL ASSUME NO LIABILITY FOR SOFTWARE DEVELOPED BY

THE USER OR ANY THIRD PARTY BASED ON THE SOFTWARE OR ANY

CONSEQUENCE THEREOF. -

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (v)

Application Considerations SUITABILITY FOR USE

THE USER SHALL NOT USE THE SOFTWARE FOR A PURPOSE THAT IS NOT

DESCRIBED IN THE ATTACHED USER MANUAL. -

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (vi)

Disclaimers CHANGE IN SPECIFICATIONS

The software specifications and accessories may be changed at

any time based on improvements or for other reasons.EXTENT OF SERVICE The license fee of the Software does not

include service costs, such as dispatching technical staff.ERRORS AND OMISSIONS The information in this manual has been

carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or

proofreading errors, or omissions. -

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (vii)

Precautions

Intended Audience

This manual is intended for the following personnel, who must

also have knowledge of electrical systems (an electrical engineer

or the equivalent). Personnel in charge of installing FA systems.

Personnel in charge of designing FA systems. Personnel in charge of

managing FA systems and facilities.General Precautions

The user must operate the product according to the performance

specifications described in the operation manuals. Before using the

product under conditions which are not described in the manual or

applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment,

amusement machines, safety equipment, and other systems, machines,

and equipment that may have a serious influence on lives and

property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the

product are sufficient for the systems, machines, and equipment,

and be sure to provide the systems, machines, and equipment with

double safety mechanisms. This manual provides information for

programming and operating the Unit. Be sure to read this manual

before attempting to use the Unit and keep this manual close at

hand for reference during operation.WARNING It is extremely important that a PLC and all PLC Units

be used for the specified purpose and under the specified

conditions, especially in applications that can directly or

indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned

applications.Safety Precautions

WARNING Confirm safety sufficiently before transferring I/O

memory area status from the CX-Programmer to the PLC. The devices

connected to Output Units may malfunction, regardless of the

operating mode of the CPU Unit. Caution is required in respect to

the following functions. Transferring from the CX-Programmer to

real I/O (CIO Area) in the CPUUnit using the PLC Memory window. Transferring from file memory

to real I/O (CIO Area) in the CPU Unitusing the Memory Card window.

-

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (viii)

WARNING Observe the following precautions when using the PLC

Backup Tool. Sufficiently check the data that is selected for

restoring before performingthe next step. If the correct data is not restored, unexpected

operation may occur in the controlled system after the data is

restored.Some Special I/O Units and CPU Bus Units operate with parameters

that are stored in the CPU Unit. If one of these Units is selected

for backup, restrictions will be displayed in the Comments Area of

the Backup from PLC Dialog Box. Confirm the restrictions, and

always select the Special I/O Unit or CPU Bus Unit together with

the CPU Unit when backing up or restoring data. If the data from

both Units is not backed up or restored together, unexpected

operation may occur in the controlled system.If there are any backup restrictions for the Units to which data

is being restored, the restrictions will be displayed in the

Comments Area of the Backup from PLC Dialog Box. Confirm the

restrictions, and always take the required measures. If required

measures are not taken, unexpected operation may occur in the

controlled system after the data is restored.Forced status can be backed up, but it cannot be restored. If

you restored data that contained forced status, use the

CX-Programmer after restoring the data to force-set or force-reset

bits as required. If required bits are not force-set or

force-reset, differences in the forced status in memory may cause

unexpected operation of the controlled system.Confirm that stopping PLC operation will not create any problems

before restoring data during PLC operation. If the PLC stops at an

unanticipated time, unexpected operation may occur in the

controlled system.Always turn the power supply to the PLC OFF and then ON after

restoring data. If the power supply is not turned OFF and then ON,

memory in the PLC may not be updated to the restored data, which

may cause unexpected operation of the controlled system.Caution Observe the following precaution when specifying a

symbol or word address for an array variable index in a ladder

program or when specifying a symbol for an array variable index in

an ST program.When using a symbol or address to indirectly specify the element

number of an array variable, be sure that the resulting address is

not outside the memory area that contains the first word in the

array. For example, use a symbol comparison instruction or an IF

statement to ensure that processing is performed only when the

memory area is not exceeded. If an element number that exceeds the

memory area is specified, data in another memory area will be read

or written, possibly resulting in unexpected operation.Caution Observe the following precaution when specifying a

symbol or word address for an offset in a ladder program.When using a symbol or address to indirectly specify an offset

for a memory address, be sure that the resulting address is not

outside the memory area that contains original address. For

example, use a symbol comparison instruction to ensure that

processing is performed only when the memory area is not exceeded.

If the final address (i.e., the original address plus the specified

offset) exceeds the memory area, data in another memory area will

be read or written, possibly resulting in unexpected operation. -

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (ix)

Caution Confirm safety at the destination node before

transferring a program to another node or changing contents of the

I/O memory area. Doing either of these without confirming safety

may result in injury.Caution Execute online edit only after confirming that no

adverse effects will be caused by extending the cycle time.

Otherwise, the input signals may not be readable.Caution If synchronous unit operation is being used, perform

online editing only after confirming that an increased synchronous

processing time will not affect the operation of the main and slave

axes.Caution Confirm safety sufficiently before monitoring power flow

and present value status in the Ladder Section window or when

monitoring present values in the Watch window. If force-set/reset

or set/reset operations are inadvertently performed by pressing

short-cut keys, the devices connected to Output Units may

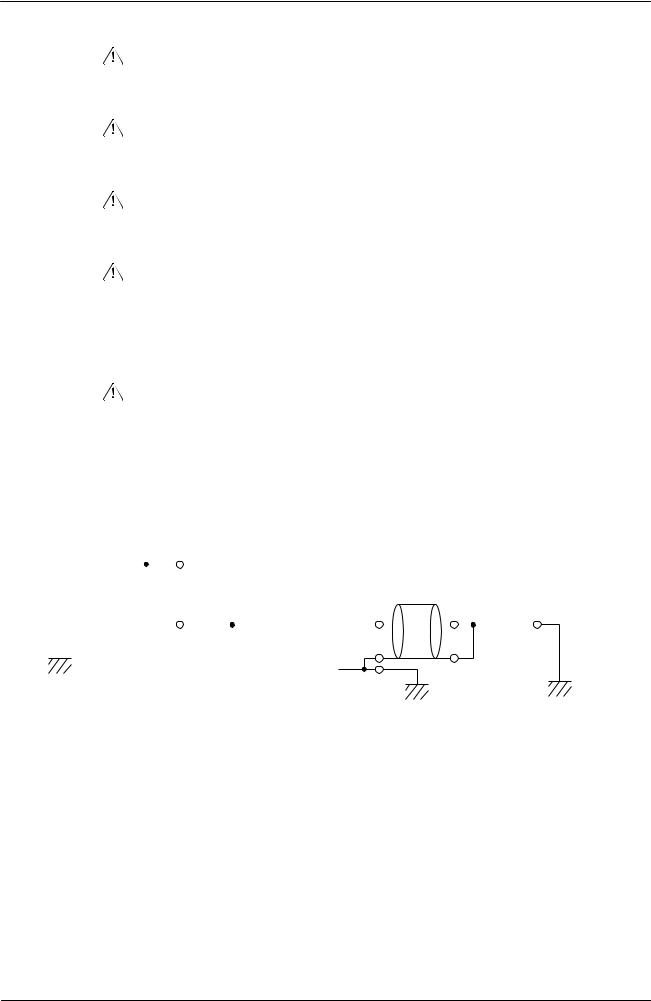

malfunction, regardless of the operating mode of the CPU Unit.Caution Caution is required when connecting peripheral devices,

such as a personal computer, to the PLC when Units with

non-isolated power supplies, such as the CS1W-CLK12/CLK52(-V1),

that are connected to an external power supply are mounted to the

PLC. If the 24-V side is grounded on the external power supply, a

short will be created if the 0-V side of the peripheral device is

grounded. When connecting peripheral devices, either ground the 0-V

side of the external power supply or do not ground the external

power supply at all.24-VDC

0-VDC 0-VDC

Non-isolated power supplies

0-VDC

Controller Link unit Peripheral devices

FG

FG

CPU unit

External powersupply

FGFG

Cable

-

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (x)

Application Precaution

Observe the following precautions when using the

CX-Programmer.Observe the following precautions before starting the

CX-Programmer. Exit all applications not directly related to the

CX-Programmer.Particularly exit any software such as screen savers, virus

checkers, email or other communications software, and schedulers or

other applications that start up periodically or automatically.Disable sharing hard disks, printers, or other devices with

other computers on any network.With some notebook computers, the RS-232C port is allocated to a

modem or an infrared port by default. Follow the instructions in

documentation for your computer and enable using the RS-232C port

as a normal serial port.With some notebook computers, the default settings for saving

energy do not supply the rated power to the RS-232C port. There may

be both Windows settings for saving energy, as well as setting for

specific computer utilities and BIOS. Following the instructions in

documentation for your computer, disable all energy saving

settings.Do not turn OFF the power supply to the PLC or disconnect the

connecting cable while the CX-Programmer is online with the PLC.

The computer may malfunction.With the CS/CJ-series PLCs, when creating an AUTOEXEC.IOM file

from the CX-Programmer to automatically transfer data at startup,

set the first write address to D20000 and be sure that the size of

data written does not exceed the size of the DM Area. When the data

file is read from the Memory Card at startup, data will be written

in the CPU Unit starting at D20000 even if another address was set

when the AUTOEXEC.IOM file was created. Also, if the DM Area is

exceeded (which is possible when the CX-Programmer is used), the

remaining data will be written to the EM Area. Refer to information

on file operations in the CS/CJ-series Programming Manual for

details.Confirm that no adverse effect will occur in the system before

attempting any of the following. Not doing so may result in an

unexpected operation.Changing the operating mode of the PLC.

Force-setting/force-resetting any bit in memory. Changing the

present value of any word or any set value in memory. Check the

user program for proper execution before actually running iton the Unit. Not checking the program may result in an

unexpected operation.Precaution on Using Indirect DM and EM Addresses in Comparison

Instructions: When indirect DM or EM addresses are used as operands

in comparison instructions, the top portion of the comparison

instruction will be displayed in yellow when it is being monitored.

At that time the power flow will not be monitored to the right of

such comparison instructions. The contact and coil status, and

present values of operands in special instructions will be

displayed normally. -

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (xi)

The user program and parameter area data in CS1-H CPU Units is

backed up in the built-in flash memory. The BKUP indicator will

light on the front of the CPU Unit when the backup operation is in

progress. Do not turn OFF the power supply to the CPU Unit when the

BKUP indicator is lit. The data will not be backed up if power is

turned OFF. To display the status of writing to flash memory on the

CX-Programmer, place a checkmark by Display dialog to show PLC

Memory Backup Status on the PLC properties and then select Windows

| PLC Memory Backup Status from the Windows menu.Precaution in Changing the PLC Type

On the CX-Programmer, you can change the PLC (device) type or

CPU type. When these are changed, however, only the data for the

ladder program and the symbol tables are changed. The following

data will be initialized and must be reset. PLC Setup Expansion

instructions I/O tables PLC memory Particularly the PLC Setup has a

large impact on PLC system operation. Be careful to reset all

require settings after changing the PLC type. If expansion

instruction allocations are not reset, program errors could occur,

preventing the PLC from running. Always restore the expansion

instruction allocates to the previous settings after changing the

PLC type. -

OMRON CX-Programmer Operation Manual

CX-Programmer_Page (xii)

Observe the following precautions when using the CX-Net.

Do not change the operating mode of the CPU Unit without first

confirming that operation of the controlled system will not be

affect.Do not run the user program on the PLC until its operation has

been checked sufficiently.The data link mode (manual setting or automatic setting) and

data link method are determined according to the data link setting

in the startup node. In the startup node, set a data link table in

the case of manual setting and data link automatic setting

parameters in the case of automatic setting. If the settings are

incorrect, the data link will not start.Check the following items before starting data links. If

incorrect data link tables or parameters are set, injury may result

due to unexpected operation of the system. Even if the correct data

link tables and parameters have been set, do not start or stop data

links before verifying that there will be no adverse influence on

the system.(1) Manually Set Data Links

Check the data link tables in each node participating in the

data link to see that they are correct. Be sure that data link

tables are deleted from nodes that are not participating in the

data links.(2) Automatically Set Data Links

Be sure that the correct DM parameters have been set in the data

link startup node.CPU Bus Units will be automatically restarted when routing

tables are transferred from a Programming Device to the CPU Unit.

Resetting is required to use the new tables. Confirm that

restarting the CPU Bus Units will not adversely affect system

operation before transferring routing tables.When Special I/O Unit or CPU Unit settings are performed in the

I/O Table Window and then transferred from the PLC Memory Window,

the following warning will be displayed if the allocated DM

Area/CIO Area addresses set for Special I/O Units or CPU Bus Units

in the I/O Table Window on the computer overlap with the PLC data

table addresses.Unless the CPU Bus Unit or Special I/O Unit settings have been

previously transferred to the CPU Unit and the allocated DM

Area/CIO Area data in the PLC data table for Special I/O Units or

CPU Bus Units is to be overwritten, always click the No Button,

shift the address, and repeat the transfer procedure.CPU Bus Unit and Special I/O Unit settings are not checked for

logical consistency. Be very careful of the logical consisting of

the overall settings when making any setting that affects other

settings, e.g., settings that enable or disable other settings.

Transfer the Special I/O Unit or CPU Bus Unit settings to the PLC

and then start operation, being aware that any logical

inconsistencies may produce unexpected operation.For example, if one setting selects either user settings or

default settings and is set to use the default settings, it will

not automatically change to enable user settings even if the

related user settings are made. To use the user settings, they will

have to be enabled manually and specifically in the setting that

selects either user settings or default settings. -

CX-Programmer_Page (xiii)

Unit Versions of CS/CJ/CP-series CPU Units Unit Versions

A unit version has been introduced to manage CPU Units in the

CS/CJ/CP Series according to differences in functionality

accompanying Unit upgrades. This applies to the CJ2H, CJ2M, CS1-H,

CJ1-H, CJ1M, CS1D, CP1H, CP1L, and CP1E CPU Units.Notation of Unit Versions on Products The unit version is given

to the right of the lot number on the nameplate of the products for

which unit versions are being managed, as shown below.Unit versionExample for unit version 3.0

CS1H-CPU67H

CPU UNIT

Lot No. 040715 0000 Ver.3.0

OMRON Corporation MADE IN JAPAN

Produce nameplateCS/CJ/CP-series CPU Unit

Lot No.

CS1-H, CJ1-H, and CJ1M CPU Units (except for low-end models)

manufactured on or before November 4, 2003 do not have a unit

version given on the CPU Unit (i.e., the location for the unit

version shown above is blank).The unit version of the CJ1-H-R CPU Units begins at version 4.0.

The unit version of the CS1-H, CJ1-H, and CJ1M CPU Units, as well

as theCS1D CPU Units for Single-CPU Systems, begins at version 2.0.

The unit version of the CS1D CPU Units for Duplex-CPU Systems

beginsat version 1.1. The unit version of the CP1H/CP1L/CP1E CPU Units

begins at version 1.0,except for the [email protected]@@@[email protected], for which the unit version begins

at version 1.1.CPU Units for which a unit version is not given are called

Pre-Ver. @[email protected] CPU Units, such as Pre-Ver. 2.0 CPU Units and Pre-Ver.

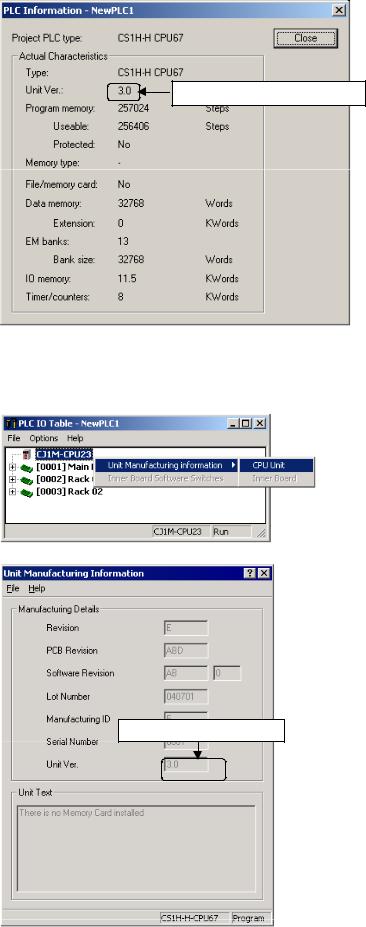

1.1 CPU Units.Confirming Unit Versions with Support Software

CX-Programmer version 4.0 can be used to confirm the unit

version using one of the following two methods. Using the PLC

Information Using the Unit Manufacturing Information (This method

can be used forSpecial I/O Units and CPU Bus Units as well.) Note CX-Programmer

version 3.3 or lower cannot be used to confirm unit versions.PLC Information If you know the device type and CPU type, select

them in the Change PLCDialog Box, go online, and select PLC — Edit — Information from

the menus.If you dont know the device type and CPU type, but are connected

directly to the CPU Unit on a serial line, select PLC — Auto Online

to go online, and then select PLC — Edit — Information from the

menus.In either case, the following PLC Information Dialog Box will be

displayed. -

CX-Programmer_Page (xiv)

Unit version

Use the above display to confirm the unit version of the CPU

Unit.Unit Manufacturing Information In the IO Table Window,

right-click and select Unit Manufacturing information — CPU

Unit.The following Unit Manufacturing information Dialog Box will be

displayedUnit version

Use the above display to confirm the unit version of the CPU

Unit connected online. -

CX-Programmer_Page (xv)

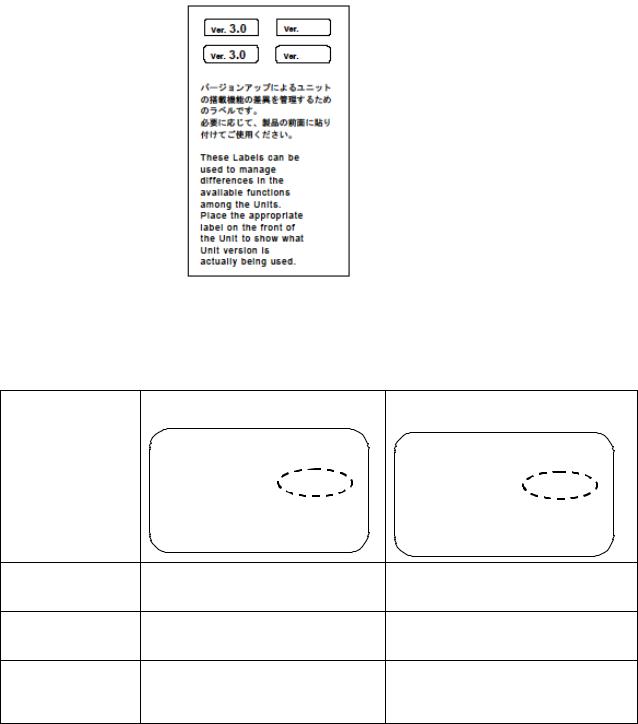

Using the Unit Version Labels The following unit version labels

are provided with the CPU Unit.These labels can be attached to the front of previous CPU Units

to differentiate between CPU Units of different unit versions.Unit Version Notation In this manual, the unit version of a CPU

Unit is given as shown in the following table.Product nameplate

Meaning

CPU Units on which no unit version is given

Lot No. XXXXXX XXXX

OMRON Corporation MADE IN JAPAN

Units on which a version is given (Ver. @[email protected])

Lot No. XXXXXX XXXX [email protected]@

Designating individual CPU Units (e.g., the CS1H-CPU67H)

Pre-Ver. 2.0 CS1-H CPU Units CS1H-CPU67H CPU Unit Ver. @[email protected]

Designating groups of CPU Units (e.g., the CS1-H CPU Units)

Pre-Ver. 2.0 CS1-H CPU Units CS1-H CPU Units Ver. @[email protected]

Designating an entire series of CPU Units (e.g., the CS-series

CPU Units)Pre-Ver. 2.0 CS-series CPU Units CS-series CPU Units Ver.

@[email protected] -

CX-Programmer_Page (xvi)

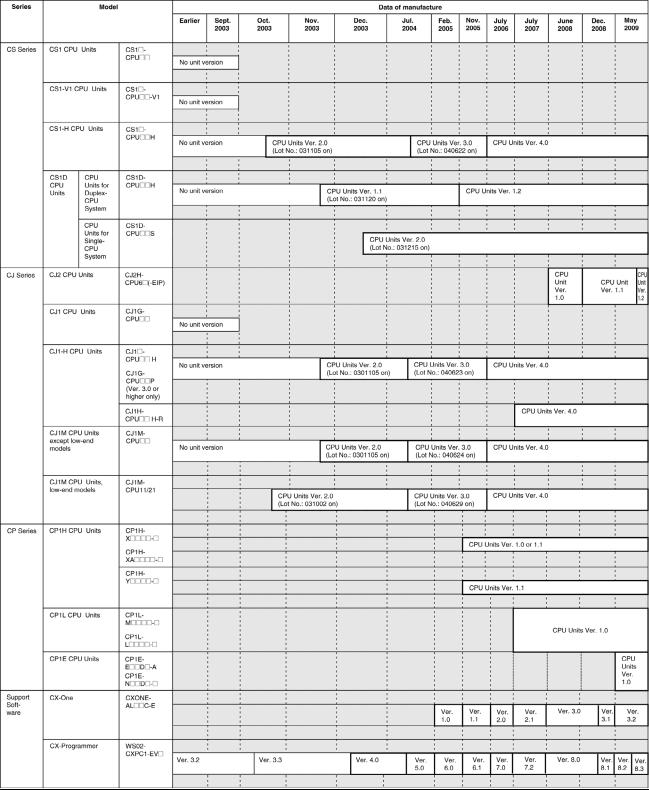

Unit Versions and Lot Numbers

Dec. 2009

Feb 2010

Series Model

CS1 CPU Units

CS1-V1 CPU Units

CS1-H CPU Units

CS Series

Earlier

[email protected]@@

No unit version

[email protected]@@-V1

[email protected]@@H

Oct. 2003

Nov. 2003

Data of manufacture

Dec. 2003

Jul. 2004

Feb. 2005

Nov. 2005

July 2006

July 2007

June 2008

Dec. 2008

May 2009

CPU Units Ver. 4.0 CPU Units Ver. 3.0 (Lot No.: 040622 on)

CPU Units Ver. 2.0 (Lot No.: 031105 on)

Support Soft- ware

[email protected]@C-E

CX-One

CP1E CPU Units

CP1L CPU Units

CP Series CP1H CPU Units [email protected]@@@[email protected]

[email protected]@@@[email protected]

[email protected]@@@[email protected]

[email protected]@@@[email protected]

[email protected]@@@[email protected]

[email protected]@[email protected] [email protected]@[email protected]@

CJ1M CPU Units, low-end models

CJ1M CPU Units except low-end models

CJ1-H CPU Units

CJ1M-CPU11/21

[email protected]@

[email protected]@ H-R

[email protected]@@ H

CJ1G- [email protected]@P (Ver. 3.0 or higher only)

CJ1 CPU Units

CJ Series CJ2 CPU Units

[email protected]@

[email protected](-EIP)

CS1D CPU Units

CPU Units for Duplex-CPU System

CPU Units for Single-CPU System

[email protected]@H

[email protected]@S

CJ2M CPU Units [email protected]@ CPU Unit

Ver. 1.0

July 2010

Ver. 4.0

CPU Unit Ver. 2.0

CPU Unit Ver. 1.2

CPU Unit Ver. 1.0

CPU Unit Ver. 1.1

CPU Unit Ver. 1.3

CPU Units Ver. 2.0 (Lot No.: 031215 on)

CPU Units Ver. 1.1 (Lot No.: 031120 on)

CPU Units Ver. 1.2 No unit version

CPU Units Ver. 4.0

CPU Units Ver. 4.0 CPU Units Ver. 2.0 (Lot No.: 0301105 on)

CPU Units Ver. 3.0 (Lot No.: 040623 on)

No unit version

CPU Units Ver. 4.0 CPU Units Ver. 3.0 (Lot No.: 040624 on)

CPU Units Ver. 2.0 (Lot No.: 0301105 on)

No unit version

No unit version

No unit version

No unit version

CPU Units Ver. 4.0 CPU Units Ver. 2.0 (Lot No.: 031002 on)

CPU Units Ver. 3.0 (Lot No.: 040629 on)

CPU Units Ver. 1.0 or 1.1

CPU Units Ver. 1.1

CPU Units Ver. 1.0

CPU Units Ver. 1.0

Ver. 3.0 Ver. 1.1

Ver. 1.0

Ver. 3.2

Ver. 3.1

Ver. 2.1

Ver. 2.0

-

CX-Programmer_Page (xvii)

Function Support by Unit Version

CS1-H CPU Units ([email protected]@@H) Unit version Function

Pre-Ver. 2.0 CPU Units

CPU Units Ver. 2.0 or later

Downloading and Uploading Individual Tasks — OK

Improved Read Protection Using Passwords — OK

Write Protection from FINS Commands Sent to CPU Units via

Networks— OK

Online Network Connections without I/O Tables — OK

Communications through a Maximum of 8 Network Levels — OK

Connecting Online to PLCs via NS-series PTs OK from lot number

030201OK

Setting First Slot Words OK for up to 8 groups OK for up to 64

groupsAutomatic Transfers at Power ON without a Parameter File —

OKAutomatic Detection of I/O Allocation Method for Automatic

Transfer at Power ON— —

Operation Start/End Times — OK

MILH, MILR, MILC — OK

=DT, DT, =DT — OK

BCMP2 — OK

GRY OK from lot number 030201

OK

TPO — OK

DSW, TKY, HKY, MTR, 7SEG — OK

EXPLT, EGATR, ESATR, ECHRD, ECHWR — OK

Reading/Writing CPU Bus Units with IORD/IOWR OK from lot number

030418OK

New Application Instructions

PRV2 — —

-

CX-Programmer_Page (xviii)

CS1D CPU Units

CS1D CPU Units for Duplex-CPU Systems ([email protected]@H)

CS1D CPU Units for Single-CPU

Systems ([email protected]@S)

Function

Pre-Ver. 1.1 CPU Units

CPU Unit Ver. 1.1 CPU Unit Ver. 2.0 or later

Duplex CPU Units OK OK — Online Unit Replacement OK OK OK

Duplex Power Supply Units OK OK OK Duplex Controller Link Units OK

OK OKFunctions unique to CS1D CPU Units

Duplex Ethernet Units — OK OK

Downloading and Uploading Individual Tasks — — OK

Improved Read Protection Using Passwords — — OK

Write Protection from FINS Commands Sent to CPU Units via

Networks— — OK

Online Network Connections without I/O Tables

— — OK

Communications through a Maximum of 8 Network Levels

— — OK

Connecting Online to PLCs via NS-series PTs

— — OK

Setting First Slot Words — — OK for up to 64 groups

Automatic Transfers at Power ON without a Parameter File

— — OK

Automatic Detection of I/O Allocation Method for Automatic

Transfer at Power ON— — —

Operation Start/End Times — OK OK

MILH, MILR, MILC — — OK

=DT, DT, =DT

— — OK

BCMP2 — — OK

GRY — — OK

TPO — — OK

DSW, TKY, HKY, MTR, 7SEG — — OK

EXPLT, EGATR, ESATR, ECHRD, ECHWR

— — OK

Reading/Writing CPU Bus Units with IORD/IOWR

— — OK

New Application Instructions

PRV2 — — —

-

CX-Programmer_Page (xix)

CJ1-H/CJ1M CPU Units CJ1-H CPU Units CJ1M CPU Units

([email protected]@H-R) ([email protected]@@H) ([email protected]@P)

CJ1M-CPU12/13/22/23 CJ1M-CPU11/21

Function

Pre-Ver. 2.0 CPU Units

CPU Units Ver. 2.0

Pre-Ver. 2.0 CPU Units

CPU Units Ver. 2.0

CPU Units Ver. 2.0 or

later Downloading and Uploading Individual Tasks

— OK — OK OK

Improved Read Protection Using Passwords

— OK — OK OK

Write Protection from FINS Commands Sent to CPU Units via

Networks— OK — OK OK

Online Network Connections without I/O Tables

OK, but only if I/O table allocation at power ON is set

OK OK, but only if I/O table allocation at power ON is set

OK OK

Communications through a Maximum of 8 Network Levels

OK for up to 8 groups

OK for up to 64 groups

OK for up to 8 groups

OK for up to 64 groups

OK for up to 64 groups

Connecting Online to PLCs via NS-series PTs

OK from lot number 030201

OK OK from lot number 030201

OK OK

Setting First Slot Words — OK — OK OK

Automatic Transfers at Power ON without a Parameter File

— OK — OK OK

Automatic Detection of I/O Allocation Method for Automatic

Transfer at Power ON— OK — OK OK

Operation Start/End Times — OK — OK OK

MILH, MILR, MILC

— OK — OK OK

=DT, DT, =DT

— OK — OK OK

BCMP2 — OK OK OK OK

GRY OK from lot number 030201

OK OK from lot number 030201

OK OK

TPO — OK — OK OK

DSW, TKY, HKY, MTR, 7SEG

— OK — OK OK

EXPLT, EGATR, ESATR, ECHRD, ECHWR

— OK — OK OK

Reading/Writing CPU Bus Units with IORD/IOWR

— OK — OK OK

New Application Instructions

PRV2 — — — OK, but only for models with built-in I/O

OK, but only for models with built-in I/O

-

CX-Programmer_Page (xx)

Functions Supported by Unit Version 3.0 or Later

CS1-H CPU Units ([email protected]@@H) Unit version Function

Pre-Ver. 2.0, Ver. 2.0

Ver. 3.0 Ver. 4.0 (See note.)

Function blocks (supported for CX-Programmer Ver. 5.0 or

higher)— OK OK

Serial Gateway (converting FINS commands to CompoWay/F commands

at the built-in serial port)— OK OK

Comment memory (in internal flash memory) — OK OK Expanded

simple backup data — OK OKTXDU(256), RXDU(255) (support no-protocol communications with

Serial Communications Units with unit version 1.2 or later)— OK OK

Model conversion instructions: XFERC(565), DISTC(566),

COLLC(567), MOVBC(568), BCNTC(621)— OK OK

New application instructions

Special function block instructions: GETID(286)

— OK OK

Additional instruction functions

TXD(235) and RXD(236) instructions (support no-protocol

communications with Serial Communications Boards with unit version

1.2 or later)— OK OK

New application instructions

ASCII conversion instructions (NUMBER-TO-ASCII and ASCII-TO-

NUMBER) Text File Write (TWRIT)— — OK

Online editing of function blocks — — OK Input-output

variables are supported. (Input-output variables can be specified

in arrays.)— — OK Improved function block (FB) functions

The STRING data type and text-string processing functions are

supported in ST language.— — OK

Using ST language programming in tasks — — OK with

CX-Programmer Ver. 7.2 or higherUsing SFC programming in tasks — — OK with CX-Programmer

Ver. 7.2 or higherNote: CX-Programmer version 7.0 or higher is required to use

functions added for unit version 4.0. Additional functions are

supported if CX-Programmer version 7.2 or higher is used.CS1D CPU Units Unit version 3.0 (Ver. 3.0) is not supported.

-

CX-Programmer_Page (xxi)

CJ1-H/CJ1M CPU Units ([email protected]@@H, [email protected]@) Unit version

FunctionPre-Ver. 2.0, Ver. 2.0

Ver. 3.0 Ver. 4.0 (See note.)

Function blocks (supported for CX-Programmer Ver. 5.0 or

higher)— OK OK

Serial Gateway (converting FINS commands to CompoWay/F commands

at the built-in serial port)— OK OK

Comment memory (in internal flash memory) — OK OK Expanded

simple backup data — OK OK Additional instruction functionsPRV(881) and PRV2(883) instructions: Added high-frequency

calculation methods for calculating pulse frequency. (CJ1M CPU

Units only)— OK OK

TXDU(256), RXDU(255) (support no-protocol communications with

Serial Communications Units with unit version 1.2 or later)— OK OK

Model conversion instructions: XFERC(565), DISTC(566),

COLLC(567), MOVBC(568), BCNTC(621)— OK OK

New application instructions

Special function block instructions: GETID(286)

— OK OK

Additional instruction functions

TXD(235) and RXD(236) instructions (support no-protocol

communications with Serial Communications Boards with unit version

1.2 or later)— OK OK

New application instructions

ASCII conversion instructions (NUMBER-To-ASCII and ASCII-TO

NUMBER)— — OK

Online editing of function blocks — — OK Input-output

variables are supported. (Input-output variables can be specified

in arrays.)— — OK Improved function block (FB) functions

The STRING data type and text-string processing functions are

supported in ST language.— — OK

Using ST language programming in tasks — — OK with

CX-Programmer Ver. 7.2 or higherUsing SFC programming in tasks — — OK with CX-Programmer

Ver. 7.2 or higherNote: CX-Programmer version 7.0 or higher is required to use

functions added for unit version 4.0. Additional functions are

supported if CX-Programmer version 7.2 or higher is used. -

CX-Programmer_Page (xxii)

Functions Supported by Unit Version for CJ2 CPU Units

([email protected], [email protected]) Functions Added for Unit Version

1.3CX-Programmer version 9.1 or higher is required to use functions

added for unit version 1.3. CPU Units CJ2H CPU Units Models

[email protected][email protected] Unit version

Function Unit version 1.3

CJ1W-NC281/NC481/NC881 Position Control Units: PCU HIGH-SPEED

POSITIONING (NCDMV(218))Supported. Special instructions for specific CPU Bus Units

CJ1W-NC281/NC481/NC881 Position Control Units: PCU POSITIONING

TRIGGER (NCDTR(219))Supported.

SIGNED AREA RANGE COMPARE (ZCPS(117))

Supported. New special instructions

DOUBLE SIGNED AREA RANGE COMPARE (ZCPSL(118))

Supported.

Unit Version 1.2 or Later CX-Programmer version 8.3 or higher

must be used to enable using the functions added for unit version

1.2. Unit CJ2H CPU Unit Model [email protected][email protected] Unit version

Item Unit version 1.2

EM Area force-setting/resetting Supported.

Unit Version 1.1 or Later CX-Programmer version 8.1 or higher

must be used to enable using the functions added for unit version

1.1. Unit CJ2H CPU Unit Model [email protected][email protected] Unit version

Item Unit version 1.1 Unit version 1.0

High-speed interrupt function Decreased overhead time for

interrupt tasks Minimum interval setting of 0.1 ms for Scheduled

Interrupt TaskSupported. Not supported.

Changing the minimum cycle time setting in MONITOR mode

Supported. Not supported.

Synchronous unit operation Supported. Not supported.

-

CX-Programmer_Page (xxiii)

Unit Version 1.0 All functions that are supported by unit

version 4.0 or later of the CJ1 CPU Units are supported by unit

version 1.0 of the CJ2 CPU Units. CX-Programmer version 8.0 or

higher must be used to enable using unit version 1.0 of the CJ2 CPU

Units.Functions Supported by Unit Version for CJ2M CPU Units Functions

Added for Unit Version 2.0CX-Programmer version 9.12 or higher is required to use the

following function added for unit version 2.0.Support of the CJ2M-MD211/212 Pulse I/O Modules.

Functions Added for Unit Version 1.0 The functions supported by

unit versions 1.0 to 1.3 of the CJ2H CPU Units are supported except

for the following functions from unit version 1.1.High-speed interrupt function Synchronous unit operation

-

CX-Programmer_Page (xxiv)

Functions Supported by Unit Version for CP-series CPU Units

Functions Supported by Unit Version 1.0 and 1.1Functionality is the same as that for CS/CJ-series CPU Units

with unit version 3.0. The functionality added for CS/CJ-series CPU

Unit unit version 4.0 is not supported.CP1H CPU Units CX-Programmer version 6.11 or higher is required

to use [email protected]@@@-@/[email protected]@@@[email protected] with unit version 1.1 or 1.0. CX-Programmer version

6.20 or higher is required to use [email protected]@@@-@ with unit version 1.1. CPU Unit CP1H CPU Unit Model

[email protected]@@@[email protected][email protected]@@@[email protected] (See note 1.)

[email protected]@@@[email protected](See note 2.)

Unit versionFunction

Ver. 1.1 or later

Ver. 1.0 Ver. 1.1

Allocated built-in I/O terminals

4 axes at 100 kHz

2 axes at 100 kHz 2 axes at 30 kHz

2 axes 100 kHz Pulse outputs

Special pulse output terminals

None 2 axes at 1 kHz

Note 1. The unit version for the [email protected]@@@[email protected]/[email protected]@@@[email protected] begins at

1.0.2. The unit version for the [email protected]@@@[email protected] begins at 1.1. 3.

CX-Programmer version 7.11 or higher is required to use CP1L CPU

Units with unitversion 1.0.

-

CX-Programmer_Page (xxv)

Unit Versions and Programming Devices CX-Programmer version 4.0

or higher must be used to enable using the functions added for CPU

Unit Ver. 2.0. The following tables show the relationship between

unit versions and CX-Programmer versions.Unit Versions and Programming Devices for CJ2 CPU Units Required

Programming DeviceCX-Programmer CPU Unit Functions

Ver. 7.1 or

lower

Ver. 8.0 Ver. 8.1 Ver. 8.2 Ver. 8.3 Ver. 9.0 Ver. 9.1 Ver.

9.12[email protected] Unit version 1.0

Functions for unit version 1.0

[email protected] Unit version 1.1

Functions added for unit version 1.1

[email protected] Unit version 1.1

Functions added for unit version 1.1

[email protected] Unit version 1.2

Functions added for unit version 1.2

[email protected] Unit version 1.2

Functions added for unit version 1.2

[email protected] Unit version 1.3

Functions added for unit version 1.3

[email protected] Unit version 1.3

Functions added for unit version 1.3

[email protected]@ Unit version 1.0

Functions for unit version 1.0

[email protected]@ Unit version 2.0

Functions for unit version 2.0

: Cannot be used, : Can be used except for new functions added

for unit versions, : Can be used Note 1. It is not necessary to

upgrade the version of the CX-Programmer if functionality that

wasenhanced for the upgrade of the CPU Unit will not be used. 2.

CX-Programmer version 8.1 or higher is required to use the

functions added for unitversion 1.1. The high-speed interrupt function and changing the

minimum cycle time setting in MONITOR mode, however, are also

supported by CX-Programmer version 8.02.3. A Programming Console cannot be used with a CJ2H CPU

Unit. -

CX-Programmer_Page (xxvi)

Unit Versions and Programming Devices for CPU Units Other Than

CJ2 CPU Units Required Programming DeviceCX-Programmer CPU Unit Functions

Ver. 3.3 Ver. 4.0 Ver. 5.0 Ver. 6.0

Ver. 7.0 Ver. 7.2 Ver. 8.0 or later

CS/CJ Series CPU Units, Unit Ver. 4.0

Functions added for unit version 4.0

(See note 4.)

CS/CJ Series CPU Units, Unit Ver. 3.0

Functions added for unit version 3.0

CS/CJ Series CPU Units, Unit Ver. 2.0

Functions added for unit version 2.0

CS1D CPU Units for Single-CPU Systems, Unit Ver. 2.0

Functions added for unit version 2.0

CS1D CPU Units for Duplex-CPU Systems, Unit Ver.1.1

Functions added for unit version 1.1

: Cannot be used, : Can be used except for new functions added

for unit versions, : Can be used Note 1. As shown above, there is

no need to upgrade to CX-Programmer version 4.0 as long asthe functions added for unit version 2.0 or unit version 1.1 are

not used. 2. CX-Programmer version 7.0 or higher is required to use

functions added for unit version4.0. Additional functions are supported if CX-Programmer version

7.2 or higher is used. 3. Unit version 4.2 of the [email protected] is

supported only by CX-Programmer version 8.0or higher. 4. CX-Programmer version 8.0 or higher is required to

use unit version 4.2 of the CJ1H-[email protected]

Unit Versions of CP-series CPU Units and Programming Devices

CX-Programmer version CPU Unit Model Unitversion Ver. 6.11 Ver. 6.20 Ver. 7.11 Ver. 8.2 or later

[email protected]@@@[email protected] Ver. 1.1 OK OK OK OK [email protected]@@@[email protected] Ver. 1.0 OK OK

OK OKCP1H CPU Units

[email protected]@@@[email protected] Ver. 1.1 — OK OK OK [email protected]@@@[email protected] CP1L CPU Units

[email protected]@@@[email protected]Ver. 1.0 — — OK OK

[email protected]@[email protected] CP1E CPU Units [email protected]@[email protected]@

Ver. 1.0 — — — OK

Note 1. Functionality of CP1H CPU Units with unit version 1.0 or

1.0 and CP1L CPU Units with unit version 1.0 is the same as that

for CS/CJ-series CPU Units with unit version 3.0. The functionality

added for CS/CJ-series CPU Unit unit version 4.0 is not

supported.2. There is no need to upgrade to CX-Programmer as long as the

upgraded functionality is not used. -

CX-Programmer_Page (xxvii)

Device Type Setting The unit version does not affect the setting

made for the device type on the CX-Programmer. Select the device

type as shown in the following table regardless of the unit version

of the CPU Unit.Series CPU Unit group CPU Unit model Device type setting on

CX-Programmer[email protected]@H CS1G-H CS1-H CPU Units [email protected]@H CS1H-H

CS1D CPU Units for Duplex-CPU Systems [email protected]@H CS1D-H (or

CS1H-H)CS Series

CS1D CPU Units for Single-CPU Systems [email protected]@S CS1D-S CJ2H

CPU Units [email protected](-EIP) CJ2H CJ2M CPU Units [email protected]@ CJ2M[email protected]@H CJ1G- [email protected]@P

CJ1-H CPU Units

[email protected]@[email protected]@H

CJ1G-H

CJ Series

CJ1M CPU Units [email protected]@ CJ1M CP1H CPU Units [email protected]@@@[email protected]

[email protected]@@@[email protected]@@@@[email protected]

CP1H

CP1L CPU Units [email protected]@@@[email protected] [email protected]@@@[email protected]

CP1L

CP Series

CP1E CPU Units [email protected]@[email protected] [email protected]@[email protected]@

CP1E

Note Device types not supported by the CX-Programmer version

that is being used will not bedisplayed on the pull-down list of the Device type Field.

-

CX-Programmer_Page (xxviii)

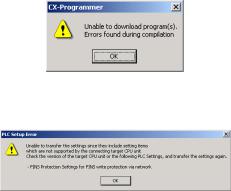

Troubleshooting Problems with Unit Versions on the CX-Programmer

Problem Cause SolutionAfter the above message is displayed, a compiling error will be

displayed on the Compile Tab Page in the Output Window.An attempt was made using CX-Programmer version 4.0 or higher to

download a program containing instructions supported only by CPU

Units Ver. 2.0 or later to a Pre-Ver. 2.0 CPU Units.Check the program or change the CPU Unit being downloaded to a

CPU Unit Ver. 2.0 or later.An attempt was made using CX-Programmer version 4.0 or higher to

download a PLC Setup containing settings supported only by CPU

Units Ver. 2.0 or later (i.e., not set to their default values) to

a Pre-Ver. 2.0 CPU Units.Check the settings in the PLC Setup or change the CPU Unit being

downloaded to a CPU Unit Ver. 2.0 or later.«????» is displayed in a program transferred from the PLC to the

CX-Programmer.CX-Programmer version 3.3 or lower was used to upload a program

containing instructions supported only by CPU Units Ver. 2.0 or

later from a CPU Unit Ver. 2.0 or later.The new instructions cannot be uploaded using CX-Programmer

version 3.3 or lower. Use CX-Programmer version 4.0 or higher. -

PART 1: CX-Programmer

-

OMRON PART 1: CX-Programmer

CX-Programmer_Page (i)

Notice OMRON products are manufactured for use according to

proper procedures by a qualified operator and only for the purposes

described in this manual.The following conventions are used to indicate and classify

precautions in this manual. Always heed the information provided in

them. Failure to heed precautions can result in injury to people or

damage to the product.DANGER Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. Additionally,

there may be severe property damage.WARNING Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury. Additionally,

there may be severe property damage.Caution Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury, or property

damage.OMRON Product References All OMRON products are capitalized in

this manual. The word Unit is also capitalized when it refers to an

OMRON product, regardless of whether or not it appears in the

proper name of the product.The abbreviation PLC means Programmable Logic Controller and is

not used as an abbreviation for anything else. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (ii)

Visual Aids The following headings appear in the left column of

the manual to help you locate different types of information.Indicates information of particular interest for efficient and

convenient operation of the product.1, 2, 3 Indicates lists of one sort or another, such as

procedures, checklists etc.Represents a shortcut on the Toolbar to one of the options

available on the menu of the same window.OMRON, 2005 All rights reserved. No part of this publication may

be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying,

recording, or otherwise, without the prior written permission of

OMRON.All copyright and trademarks acknowledged.

No patent liability is assumed with respect to the use of the

information contained herein. Moreover, because OMRON is constantly

striving to improve its high-quality products, the information

contained in this manual is subject to change without notice. Every

precaution has been taken in the preparation of this manual.

Nevertheless, OMRON assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (iii)

About this Part This part describes the CX-Programmer

application and its ability to create and maintain programs for use

with OMRON SYSMAC CS/CJ/CP, CV and C PLCs. It does not provide

detailed information concerning the PLCs themselves, for this

information the commercial manual for the device must be

consulted.This part contains the following chapters:

Precautions. This portion describes general precautions for

using the CX-Programmer (including CX-Server PLC Tools).Version Upgrade Information. This portion describes the changes

that have been made from version 3.0 to version 3.1 of the

CX-Programmer.Chapter 1 Technical Specifications. This chapter describes the

CX-Programmer software in general terms and also provides details

of the operating environment and minimum configuration necessary

for the satisfactory operation of CX-Programmer.Chapter 2 Quick Start Guide. This chapter describes the basic

features of CX-Programmer together with a simple tutorial for

familiarization purposes.Chapter 3 Project Reference. This describes the features common

to two or more parts of CX-Programmer.Chapter 4 Reference. This chapter introduces the features

contained in the Project workspace and discusses their associated

commands and features.Chapter 5 Advanced Topics. This chapter discusses the more

advanced topics in relation to CX-Programmer.Appendix A Toolbars and Keyboard Shortcuts. This appendix

summarizes the toolbar and keyboard shortcuts available from

CX-Programmer.A Glossary of Terms and Index are also provided.

-

OMRON PART 1: CX-Programmer

CX-Programmer_Page (iv)

Version 9.1 Upgrade Information

Functionality Improved from Version 9.0 to 9.1 Compatible PLC

Models*The CJ2M CPU Units with unit version 2.0 are supported. The

CJ2M-MD211/212 Pulse I/O Modules are available.Improvements on Ethernet Connections* With a CP1E-N30/40/60 or

CP1E-NA CPU Unit, Ethernet connections are made available using a

CP1W-CIF41 Ethernet Option Board with unit version 2.0.* Functionality improved in version 9.12 over version 9.10.

Compatible PLC Models The CJ2M CPU Units are supported. Select

the CJ2M as the PLC model. CJ2H CPU Units with unit version 1.3 are

supported.Improvements to Memory View Function When the CJ2M is selected

as the PLC model, function block area usage is displayed.Improvements for Host Link (SYSMAC WAY) Connections When the

CP1E is selected as the PLC model, the network type can be set to

SYSMAC WAY.Version 9.0 Upgrade Information

Functionality Improved from Version 8.3 to 9.0 Compatible PLC

ModelsThe CX-Programmer also supports CP1E-NA20 CPU Units (20-point

CPU Units). CP1E-N/E CPU Units with 10, 14, and 60 I/O points are

supported.Supported Operating Systems The CX-Programmer will run on

Windows 7.Improvements to Memory View Function When the CP1E is selected

as the PLC model, Program Area usage is displayed.Improvements for Host Link (SYSMAC WAY) Connections When the

CJ2H is selected as the PLC model, the network type can be set to

SYSMAC WAY.Data Structures Supported as Symbol Data Types Previous version

(version 8.3) New version (version 9.0)Data structures are not supported. CJ2 CPU Units now support

data structures as symbol data types.Enhanced Program Input Functions Previous version (version 8.3)

New version (version 9.0)The input mode cannot be changed. A Smart Input Mode is

supported that automatically displays suggested instructions and

addresses. The input mode can be changed from a menu or a tool

bar.When copying circuits to create similar rungs with different

addresses, the addresses must be input again.The Address Incremental Copy function can be used to easily

create copies of similar circuit structures with offset

addresses. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (v)

Enhanced User Interface for Menu and Option Settings Previous

version (version 8.3) New version (version 9.0)The display configuration for menus and options cannot be

changed.Switching to Smart Style Mode is now possible for the menu and

option setting style. Smart Style is the same type of menu and

option setting function as the one supported in CX-Programmer for

CP1E. Either the previous Classic Mode or the new Smart Style Mode

can be selected for the menus and options by selecting Tools —

Options and then setting the Menu/Options Style on the General Tab

Page.Changes to Search/Replace Dialog Boxes Previous version (version

8.3) New version (version 9.0)Searches can be performed only in the entire PLC or in the data

in the current view.«Programs» has been added to the search range.

The setting for the item to be searched for was very detailed

and included bit addresses, address, values (constants/numbers),

mnemonics, symbols, and I/O comments.Searched objects have been grouped into addresses, symbol names,

and all (text strings).Replacements can be performed only in the entire PLC or in the

data in the current view.«Programs» has been added to the replacement range. Also, the

selected circuits can be set as the replacement range.The setting for the item to be replaced was very detailed and

included bit addresses, address, values (constants/numbers),

mnemonics, symbols, and I/O comments.Searched objects have been grouped into addresses, symbol names,

mnemonics, and comments.Version 8.3 Upgrade Information Functionality Improved from

Version 8.2 to 8.3 Compatible PLC ModelsThe functionality improvements are supported for CJ2H CPU Units

with unit version 1.2 or later.TIMER and COUNTER Added as Symbol Data Types Previous version

(version 8.2) New version (version 8.3)When defining timer numbers and counter numbers as symbols, the

following three different symbols had to be registered in the

symbols table.1. Timer numbers and counter numbers specified in instruction

operands had to be defined as NUMBER symbols.2. Timer and Counter Completion Flags had to be defined as BOOL

symbols.3. Timer and counter present values had to be defined as CHANNEL

symbols.TIMER and COUNTER symbols are supported so that all of the

previous three types of symbols can be managed as one data type.

(TIMER and COUNTER are supported only by CJ2H CPU Units with unit

version 1.0 or later.) TIMER: Can be used for 1) the timer number,

2) the Timer Completion Flag, and 3) the timer present value.

COUNTER: Can be used for 1) the counter number, 2) the Counter

Completion Flag, and 3) the counter present value.Automatically assigning timer and counter numbers in ladder

programs was not possible.Automatic address assignment and layout are supported for TIMER

and COUNTER symbols. (TIMER and COUNTER are supported only by CJ2H

CPU Units with unit version 1.0 or later.) -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (vi)

Force-setting/resetting Bits in EM Area Previous version

(version 8.2) New version (version 8.3)Bits in the EM Area could be force-set/reset in CJ2H CPU Units

only for specific EM Area banks for which automatic address

assignment was used.With CJ2H CPU Units with unit version 1.2 or later, PLC Memory

Allocate EM Memory Settings can be used to specify the EM Area

banks for which bits can be force-set/reset. (The first bank is

specified and force-setting/resetting bits is possible in that bank

and all banks following it.) This is called the EM Area

force-setting/resetting function.Searching for Symbol Names and Displaying Usage Locations from

Cross-reference Pop-upsPrevious version (version 8.2) New version (version 8.3)

Searching from cross-reference pop-ups was possible only for

address specifications. (To search for symbols, you had to click

the Browse button and search for symbol names from the Symbol

Search Dialog Box.)Symbol names can be specified directly in cross-reference

pop-ups to display a list of locations that use the address of that

symbol. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (vii)

Version 8.2 Upgrade Information Functionality Improved from

Version 8.1 to 8.2 Connecting Online to the PLC through an

NV-series PT*Previous version (version 8.1) New version (version 8.2) It was

not possible to connect online from the CX-Programmer through an

NV-series PT to a PLC connected to the NV-series PT.It is now possible to connect online from the CX-Programmer

through an NV-series PT to a PLC connected to the NV-series PT.*Functionality improved in version 8.21 over version 8.20.

CP1E CPU Unit Supported for Connecting Online to a PLC via an

NS-series PT Previous version (version 8.1) New version (version

8.2)With a CP1E CPU Unit, it was not possible to connect online from

the CX-Programmer through an NS-series PT to a PLC connected to the

NS-series PT.With a [email protected]@[email protected]@ CPU Unit, it is now possible to connect

online from the CX-Programmer through an NS-series PT to a PLC

connected to the NS-series PT.Compatible PLC Models The functionality improvements are

supported for CP-series CP1E CPU Units with unit version 1.0.Online Connection to the PLC via an NS-series PT Previous

version (version 8.1) New version (version 8.2)An online connection from the CX-Programmer through an NS-series

PT to a PLC connected to the PT was not possible.An online connection from the CX-Programmer through an NS-series

PT to a PLC connected to the PT is possible when the PLC is

connected to the PT using a serial connection, Ethernet connection,

or Controller Link connection. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (viii)

Version 8.1 Upgrade Information Functionality Improved from

Version 8.0 to 8.1 Compatible PLC ModelsThe functionality improvements are supported for CJ-series CJ2

CPU Units ([email protected](-EIP)) with unit version 1.1.Support for Synchronous Unit Operation Support has been added

for the synchronous unit operation function for a combination of a

CJ-series CJ2 CPU Unit ([email protected] (-EIP)) with unit version 1.1

and CJ-series Position Control Units ([email protected]@4). Settings and

monitoring are now possible for synchronous unit operation.Improved Special I/O Unit and CPU Bus Unit Setup Functionality

Multiple dialog boxes can now be opened simultaneously when setting

CJ-series Position Control Unit ([email protected]@4) parameters. In

addition, the CAM Data Creation Software (WS02-MOPC2) can be used

to convert cam data in a CSV file into data that can be used by a

Position Control Unit, and the data can be imported to the PLC

memory component of the CX-Programmer.Improved CS/CJ Data Tracing Function Improved Trace Settings

With support for the synchronous unit operation function of CJ2

CPU Units with unit version 1.1, tracing can now be executed for

each synchronous cycle.Improved Bit Graph Display Bit graphs are displayed according to

screen size, and addresses are displayed beside the graphs. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (ix)

Version 8.0 Upgrade Information Functionality Improved from

Version 7.2 to 8.0 Support has been added for the following PLC

models as part of the version 7.2 to version 7.3 upgrade.

Compatible PLC ModelsNew CP-series CP1L CPU Units The CP-series CP1L CPU Units

([email protected]@ and [email protected]@) are supported.The following functions have been added or improved as part of

the upgrade from version 7.3 to 8.0.Compatible PLC Models CJ-series CJ2 CPU Units The CJ-series CJ2

CPU Units ([email protected]) are supported. EtherNet/IPConnection is possible to the [email protected] and EtherNet/IP

Units. New Ladder Programming InstructionsThe new instructions for the CJ2 CPU Units can be used,

including the Tracking Instructions and Data Search/Sort

Instructions.Improved Data Trace Function Overhaul of Data Tracing Function

for CS/CJ-series PLCs If a CJ2 CPU Unit is used, long-term

continuous data tracing is possible. Operations have been improved,

including zooming in and out of trace results graphs and adjusting

offsets. Trace results can also be printed or saved as bit

maps.PLC Backups Data from the CPU Unit, Special I/O Units, and CPU

Bus Units can be backed up as a batch from a personal computer. The

backup data can be compared or restored as a batch, or the data for

only selected Units can be restored. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (x)

Improvements in Programming Symbols in Array Variable

Subscripts.Previous version (version 7.2) New version (version 8.0) Symbols

could be used for array variable subscripts only inside function

blocks.With a CJ2 CPU Unit, symbols can be used for array variable

subscripts in ladder diagram programming in tasks.Address Offsets Previous version (version 7.2) New version

(version 8.0)With a CJ2 CPU Unit, an offset value can be input to offset a

specific bit or word address in ladder diagram programming.DM/EM Bit Addresses Previous version (version 7.2) New version

(version 8.0)Only word addresses could be used in the EM and DM Areas.

With a CJ2 CPU Unit, bit addresses can be specified in the EM

and DM Areas.Improvements to Online Functions With a CJ2 CPU Unit, you can

easily connect to a PLC on an EtherNet/IP network.Improvements to Monitoring When registering an array variable in

the Watch Window, it is now possible to register and monitor a

selected range of array elements.Improvements to Symbol Tables It is now possible to edit data

items (i.e., arrange or delete) when copying and pasting variable

table data via the clipboard from external applications. It is also

possible to set the contents of symbol table data to be copied to

the external application in advance using option settings.Other Improvements Previous version (version 7.2) New version

(version 8.0)The error log of the CPU Unit only displayed the error code.

In the error log of the CPU Unit, a code which gives more

detailed information about the error is displayed in addition to

the error code. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (xi)

Version 7.2 Upgrade Information Functionality Improved from

Version 7.0 to Version 7.2 Support has been added for the following

PLC models as part of the version 7.0 to version 7.10 upgrade.

Compatible PLC ModelsThe high-speed CJ1-H-R CPU Units ([email protected]@H-R) are

supported.Support has been added for the following PLC models as part of

the upgrade from version 7.10 to 7.11.Compatible PLC Models The CP-series CP1L CPU Units (CP1L-M and

CP1L-L) are supported.The following functions have been added or improved as part of

the upgrade from version 7.11 to 7.2.Improved IEC 61131-3 Language Support Support has been

strengthened for the ST and SFC languages, which are IEC 61131-3

languages. Ladder, ST, and SFC programs can be combined freely, so

the user program can be written in the language most appropriate

for the required processing. Using the most appropriate language

can reduce program development time and simplify programming.Support for ST Language Programming in Tasks Previous version

(version 7.0) New version (version 7.2)The ST language could be used only in function blocks.

The ST language can be used in programs other than function

blocks. (ST programs can be allocated to tasks.) Different

languages can be used in a single user program, which allows

numerical processing and string processing to be written in ST

programs, while other processing is written in ladder or SFC

programs. Note: The ST language is supported only in CS/CJ-series

CPUUnits with unit version 4.0 or later. It is not supported in

CP-series CPU Units.Support for SFC Language Programming in Tasks Previous version

(version 7.0) New version (version 7.2)The SFC language could not be used. The SFC language can be used

in programs. (SFC programs can be allocated to tasks.) Different

languages can be used in a single user program, which allows the

overall system processing to be written in SFC programs, while

other processing is written in ladder or ST programs. Note: The SFC

language is supported only in CS/CJ-series CPUUnits with unit version 4.0 or later. It is not supported in

CP-series CPU Units. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (xii)

Support for Array Variables in Ladder, ST, and SFC Programs

Previous version (version 7.0) New version (version 7.2)Array variables could be used for internal variables and

input-output variables in a function blocks algorithm, but array

variables could not be used in programs (tasks).Array variables can be specified even in programs (tasks)

written in ladder, ST, or SFC language. This feature allows

multiple variables with the same data characteristics to be managed

as a group.Comparing Function Block Definitions Previous version (version

7.0) New version (version 7.2)Function block definitions could not be compared.

Function block definitions can be compared in detail. This

feature makes it easy to check for differences between the programs

in function block definitions.Comparison of Function Block Definitions, ST Programs, and

Action Programs/Transition Programs/Subcharts in SFC ProgramsPrevious version (version 7.0) New version (version 7.2) ST

programs and SFC programs could not be compared.ST programs and SFC programs can be compared. ST programs in an

SFC program can also be compared in detail.PLC-PT Integrated Simulation The following improvements have

been made to the simultaneous interactive debugging function

(integrated simulation), which debugs operation between the

CX-Programmers ladder program and NS-series PT touch panel test

screens in the CX-Designer.Starting Integrated Simulator from the CX-Programmer Previous

version (version 7.0) New version (version 7.2)The integrated simulator could be started from the CX-Designer

only; it could not be started from the CX-Programmer.The integrated simulator can be started from the CX-Programmer

(specifying a saved CX-Designer screen file). With this feature, it

is possible to easily confirm the interaction between a ladder

program being edited in the CX-Programmer and NS-series PT touch

panel test screens.Simulating the Occurrence of PLC Errors Previous version

(version 7.0) New version (version 7.2)During simulation, it was not possible to generate PLC system

errors by manipulating the corresponding Auxiliary Area flags. (The

system error flags were write-protected.) It was necessary to

create ladder programming that generated errors using the FAL and

FALS instructions, and check operation in the simulation.PLC system errors can be generated during CX-Programmer ladder

program simulation by selecting Simulation — PLC Error Simulator

and writing the corresponding system error flags in the Auxiliary

Area. With this feature, it is not necessary to create ladder

programming to generate errors. Also, it is easy to check the

operation of the ladder program and NS-series touch panel when PLC

errors occur.Improvements to Symbol Tables Improved Interaction of the

CX-Designer with Symbol Table DataPrevious version (version 7.0) New version (version 7.2) Symbol

tables could be copied and pasted from the CX-Programmer to the

CX-Designer, but not the opposite direction. Consequently, when

NS-series touch panel test screens were being edited in the

CX-Designer and I/O comments were edited in the CX-Designer symbol

table, it was necessary to write the data in Excel and transfer it

to the CX-Programmers symbol table.Symbol tables can be copied in pasted in both directions between

the CX-Designer and CX-Programmer. This feature makes it easy to

reflect changes to the CX-Designers symbol table, such as edited

I/O comments, in the CX-Programmers symbol table. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (xiii)

Support for the STRING Data Type in Ladder Programs and ST

Programs Previous version (version 7.0) New version (version

7.2)The STRING data type could be used only in ST-language function

blocks.The STRING data type can be used in both ladder and ST

languages, in both task programs and function blocks. The STRING

data type supports ASCII characters between 1 and 255.Improved Automatic Online Connection Added Automatic Detection

of the Computers Serial PortPrevious version (version 7.0) New version (version 7.2) When

automatic online connection was performed from the computers serial

port, it was not necessary for the user to set the PLC model

because it was recognized automatically, but the serial port had to

be set in advance.It is not necessary for the user to select the computers serial

port in advance. When automatic online connection is performed, the

software automatically searches for computer serial ports that can

be used. If the software finds a serial port that can be used for

the online connection, the software automatically connects online

from the detected port, and the serial port setting is also changed

automatically.Improved Conversion of C500/C120/C**P Programs

Previous version (version 7.0) New version (version 7.2)

Programs stored in C500, C120, or C**P-series PLCs could be

uploaded and converted for use in CS/CJ/CP-series PLCs or

CVM1/CV-series PLCs, but the DM and HR Area data could not be

converted to PLC memory.DM and HR Area data can also be converted to PLC memory. After

conversion, it is now possible to select the CP1L as the PLC

model.A backup program and I/O memory (DM and HR Area data) file

(extension .c5b) could be used to restore the program to a

C500/C120/C**P-series PLC, but it could not be converted to a

CX-Programmer project.A backup program and I/O memory (DM and HR Area data) file

(extension .c5b) can be converted to a CX-Programmer project for a

CS/CJ/CP-series PLC or CVM1/CV-series PLC.A program uploaded from a C500, C120, or C**P-series PLC could

not be saved to a file in mnemonic-text format.A program uploaded from a C500, C120, or C**P-series PLC can be

saved to a file in mnemonic-text format. The saved file can be

pasted as text in the CX-Programmers Statement List (mnemonic

window), and displayed or printed in ladder format. This feature

allows the program to be checked in the CX-Programmer before

converting it to a CS/CJ/CP-series PLC or CVM1/CV-series PLC

program.Other Improvements Previous version (version 7.0) New version

(version 7.2)The CPU Units production information could be displayed from the

I/O table only.The CPU Units production information can be displayed from the

Main Menus PLC Information Dialog Box.When a CS1D Duplex System CPU Unit was being used, the CPU Units

Active/Standby status could not be displayed in the project

directory tree.When a CS1D Duplex System CPU Unit (CS1D-H) is being used, the

CPU Units Active/Standby status is displayed in the project

directory tree. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (xiv)

Version 7.0 Upgrade Information Functionality Improved from

Version 6.1 to Version 7.0 Compatible PLC ModelsThe following PLC models have been added as compatible PLCs as

part of the version 6.1 to version 7.0 upgrade.CS/CJ Series CPU Units with unit version Ver. 4.0 and higher

Ver. 4.0 and higher CS/CJ Series CPU Units are supported.CP Series CPU Units The CP Series CPU Units (CP1H-Y) are

supported.Support for NSJ-M3D Controllers The [email protected]@@@@(B)-M3D Controllers

are supported.Ladder Program to Function Block Conversion Function Previous

version (Ver. 6.1) New version (Ver. 7.0)To convert existing ladder programming to a function block, the

ladder programming was copied and pasted into a function block

definition. At that point, it was necessary to check the variables

and addresses used in the program and manually register those

variables and addresses while organizing the input variables,

internal variables, and output variables.Existing ladder program sections can be easily converted to

function blocks by selecting the program circuits to be converted

and selecting Function Block (ladder) generation. The function

block definition is created automatically and the variables are

allocated automatically based on the usage of the variables and

addresses in the program.Online Editing of Function Blocks Previous version (Ver. 6.1)

New version (Ver. 7.0)A function block definition (algorithm and variable table) could

not be edited while the PLC program was being executed. (The

instance I/O parameters could be changed.)A function block definition (algorithm and variable table) can

be edited while the PLC program is being executed. (Instances

cannot be added.) With this capability, it is possible to debug and

edit the function block definitions themselves even if the PLC must

operate 24 hours/day because there are devices that cannot be

stopped. To edit a function block, select the function block

definition in the Workspace and select FB Online Edit Begin from

the popup menu. Note: Function block instances cannot be added.

Note: This function cannot be used for simulations on the CX-

Simulator.STRING Data and Text-processing Functions Supported in

ST-language Function Blocks Previous version (Ver. 6.1) New version

(Ver. 7.0)The STRING data type could not be used in the ST language. (See

note.)The STRING data type can be used as a data type in the ST

language. With this capability, it is easy to set a variable

containing text (ASCII) in another variable with a substitution

operation (such as: a := @READ;). In this case, it is not necessary

to know the length of the ASCII text string. -

OMRON PART 1: CX-Programmer

CX-Programmer_Page (xv)

Previous version (Ver. 6.1) New version (Ver. 7.0) There were no

text-processing functions for the ST language. To process text for

message displays and no-protocol communications in the ladder

language, the user had to know the length of the ASCII string and

execute instructions such as text-processing instructions, data

conversion instructions, and serial communications instructions.

Note: The user can input text strings can inI/O memory using the CX-Programmers PLC memory function, but it

is necessary to know the data size in I/O memory.Text-processing functions (extracting text, merging, searching,

etc.) are supported for the ST language. With these functions, it

is easy to create text strings and process displayed messages using

ST language in a function block without knowing the actual ASCII

codes.Support for Input-Output Variables Previous version (Ver. 6.1)

New version (Ver. 7.0)Input-output variables were not supported in function blocks.

(Only input variables, internal variables, and output variables