- Manuals

- Brands

- Isuzu Manuals

- Engine

- 4HK-1

- Manual

-

Bookmarks

Quick Links

Isuzu

4HK-1 and 6HK-1

ENGINE

FUEL SYSTEM

CE APPLICATIONS

Revised 8/29/06

Form Number 5137

1

Related Manuals for Isuzu 4HK-1

Summary of Contents for Isuzu 4HK-1

-

Page 1

Isuzu 4HK-1 and 6HK-1 ENGINE FUEL SYSTEM CE APPLICATIONS Revised 8/29/06 Form Number 5137… -

Page 2

Table Of Contents… -

Page 3

These engines also use an air to air aftercooling intake air system. The air to air intake system ports pressurized air flow between the turbocharger and the intake manifold through an air to air heat exchanger in front of the radiator. The 4HK-1 model has a displacement of 317 cubic inches (in ) or 5193 cubic centimeters (cc). -

Page 4

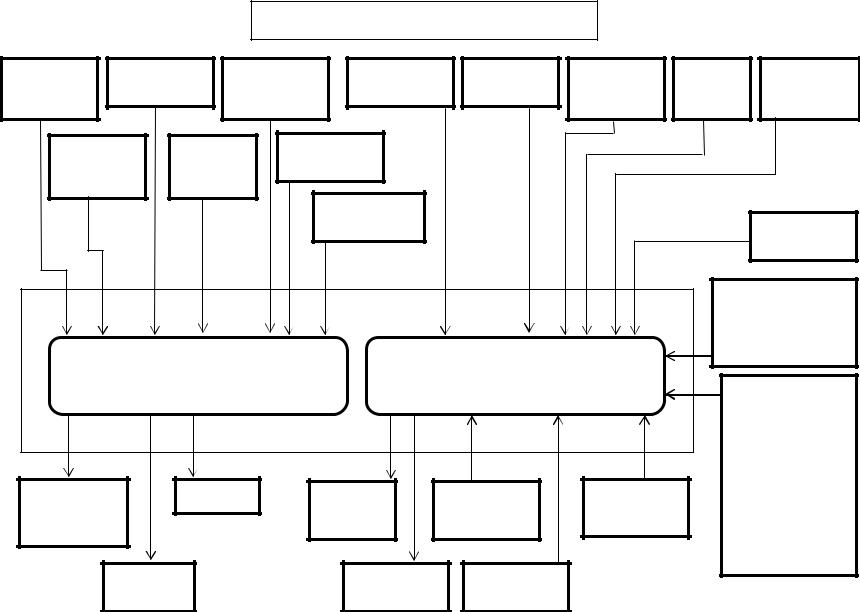

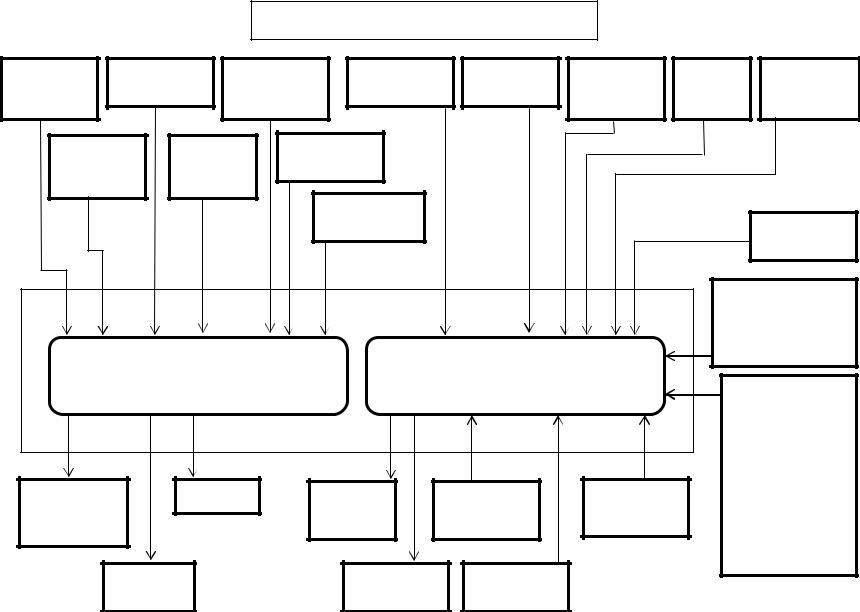

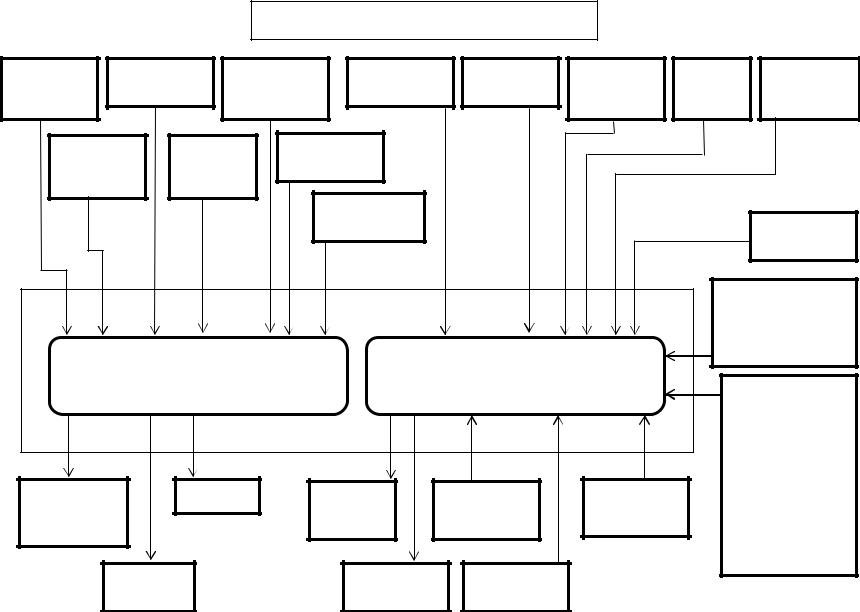

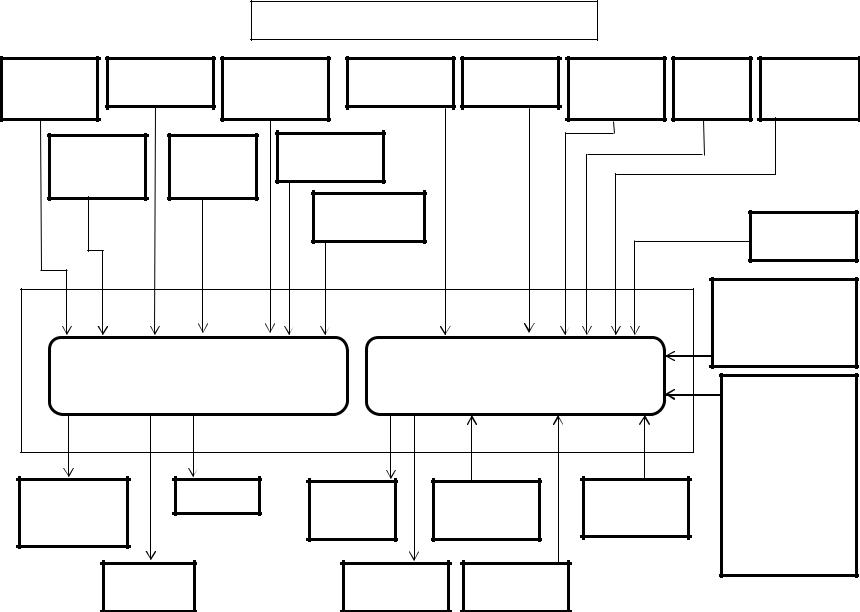

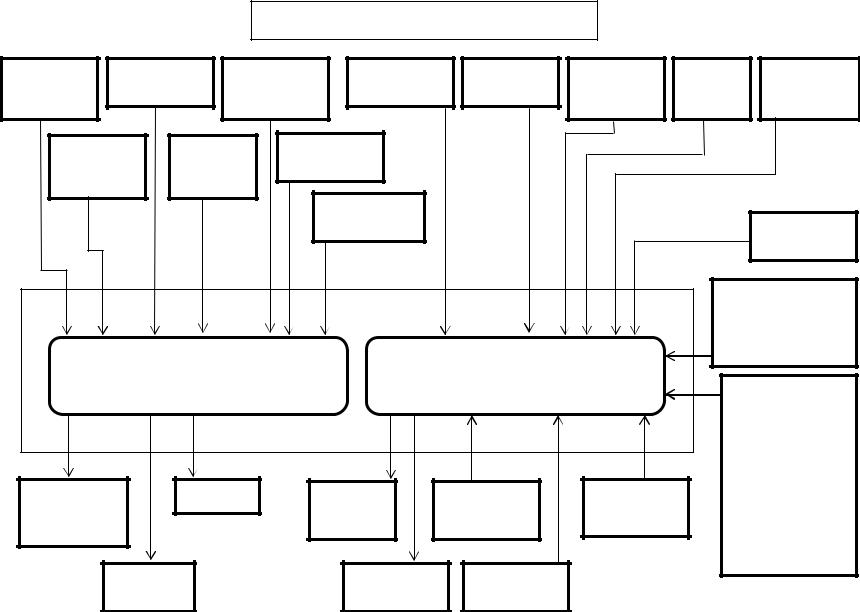

Isuzu 4HK-1 and 6HK-1 Engine Overview The electronic control system for the Isuzu 4HK-1 and 6HK-1 Engines use input information from a number of sensors and from the Excavator controller to determine the quantity and timing of the fuel delivery to the engine. -

Page 5

Isuzu 6HK1 Common Rail Engine Fuel System Common Fuel Temp Coolant Intake Air Boost Temp Barometric ENG Oil Engine Stop Rail Fuel PSI Sensor Temperature Temp. Sensor Sensor AMB PSI Switch Sensor Sensor Sensor Sensor Boost PSI Crankshaft Camshaft Sensor… -

Page 6

90° on the gear and one reference hole) on the camshaft gear flange surface on the 4HK-1 Engine. Seven through holes (six holes arranged equally every 60° on the gear and one reference hole) on the camshaft gear flange surface on the 6HK-1 Engine. -

Page 7

Isuzu 6HK1 Common Rail Engine Fuel System Common Fuel Temp Coolant Intake Air Boost Temp Barometric ENG Oil Engine Stop Rail Fuel PSI Sensor Temperature Temp. Sensor Sensor AMB PSI Switch Sensor Sensor Sensor Sensor Boost PSI Crankshaft Camshaft Sensor… -

Page 8

Isuzu 4HK-1 and 6HK-1 Engine Overview (continued) Inputs to 81 pin engine harness connector: • The 2 wire intake air temperature (IAT) sensor is installed on intake air tube and detects the temperature of intake air for optimum fuel injection control. -

Page 9

Isuzu 6HK1 Common Rail Engine Fuel System Common Fuel Temp Coolant Intake Air Boost Temp Barometric ENG Oil Engine Stop Rail Fuel PSI Sensor Temperature Temp. Sensor Sensor AMB PSI Switch Sensor Sensor Sensor Sensor Boost PSI Crankshaft Camshaft Sensor… -

Page 10

Isuzu 4HK-1 and 6HK-1 Engine Overview (continued) Inputs to 81 pin engine harness connector: (continued) • The CAN (Controller Area Network) Data Bus Connector transmits communication between the engine controller and the Excavator controller. This connector transmits throttle, idle up/down, work mode, breaker mode, tachometer, instrumentation and fault code information. -

Page 11

Isuzu 6HK1 Common Rail Engine Fuel System Common Fuel Temp Coolant Intake Air Boost Temp Barometric ENG Oil Engine Stop Rail Fuel PSI Sensor Temperature Temp. Sensor Sensor AMB PSI Switch Sensor Sensor Sensor Sensor Boost PSI Crankshaft Camshaft Sensor… -

Page 12

Isuzu 4HK-1 and 6HK-1 Engine Overview (continued) Outputs from 40 pin engine harness connector: (continued) • The injectors are controlled by the engine control module (ECM). The ECM sends a common power supply to injectors 1, 3 and 5. The ECM also sends a common power supply to injectors 2, 4 and 6. -

Page 13

Isuzu 6HK1 Common Rail Engine Fuel System Common Fuel Temp Coolant Intake Air Boost Temp Barometric ENG Oil Engine Stop Rail Fuel PSI Sensor Temperature Temp. Sensor Sensor AMB PSI Switch Sensor Sensor Sensor Sensor Boost PSI Crankshaft Camshaft Sensor… -

Page 14

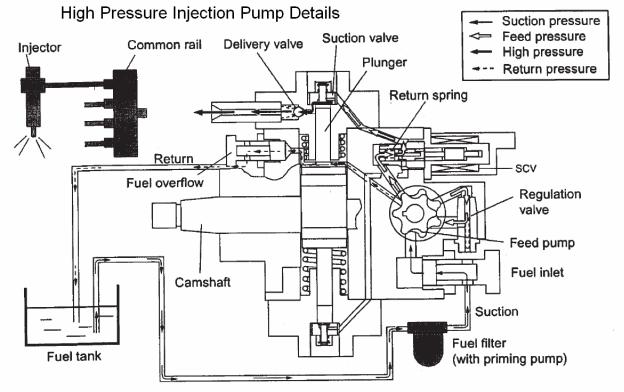

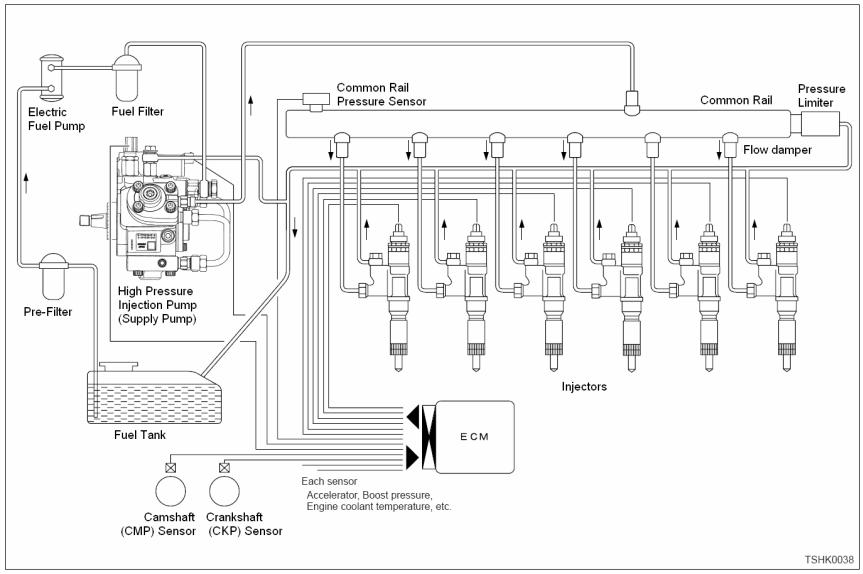

Isuzu 4HK-1 and 6HK-1 Engine Fuel Schematic Overview Fuel System Hydraulic Function Fuel comes from the tank and typically will go through a prefilter assembly. From the prefilter, the fuel then flows to an electric fuel pump, located in the hydraulic pump compartment. -

Page 16

Isuzu 4HK-1 and 6HK-1 Engine Fuel Schematic Overview The common rail system stores high pressure fuel between the supply pump and the injectors. The common rail also serves as an accumulator to dampen the fuel pulsations from the pump. Flow dampers are located at the outlet of the common rail to the lines to the injectors. -

Page 19

Isuzu 4HK-1 and 6HK-1 Engine Sensor Locations… -

Page 20

Exhaust gas Recirculation (EGR) System Exhaust Gas Recirculation system is abbreviated to EGR system. It recirculates part of exhaust gas into intake manifold to mix an inert gas with intake air. This leads to lower the combustion temperature to limit emissions of nitrogen oxide (NOx). It controls amount of EGR by opening/closing the EGR valve installed between exhaust manifold and intake manifold. -

Page 23: Engine Control System

Engine Control System 42 Installation of ECM Install the ECM in the reverse order of removal. EGR valve position learning is required after replacing the ECM. 1. Turn the key switch to “ON”. 2. Turn the key switch to “OFF”. 3.

-

Page 24

Engine Control System 56 Senser and actuator *Refer at last page.(About wiring diagrams) -

Page 25

57 Engine Control System Circuit diagram (Refer to “Wiring diagrams” for a way to read the diagram.) Main relay circuit TSWG0027… -

Page 26

Engine Control System 58 Starter for safety relay, glow circuit TSWG0068… -

Page 27

59 Engine Control System CAN, GND, DLC circuits TSHK0013… -

Page 28

Engine Control System 60 Injector circuit TSWG0031… -

Page 29

61 Engine Control System SCV circuit TSHK0016… -

Page 30

Engine Control System 62 CKP sensor, fuel temperature sensor, engine coolant temperature sensor, engine oil pressure sensor circuit TSHK0017… -

Page 31

63 Engine Control System Boost temperature sensor, boost pressure sensor circuit TSWG0034… -

Page 32

Engine Control System 64 CMP sensor, common rail pressure sensor, EGR circuit TSHK0018… -

Page 33

65 Engine Control System Memory clear switch, engine stop switch circuit TSWG0038… -

Page 34

This page Is Intentionally Left Blank. -

Page 35

67 Engine Control System TSHK0035… -

Page 36

Engine Control System 68 Terminal Terminal Number Number Boost pressure sensor GND CKP + Boost pressure sensor Vout CKP GND Boost pressure sensor Vcc E112 Terminal Number Terminal Number CMP shield Engine oil pressure sensor GND CMP GND Engine oil pressure sensor Vout CMP + Engine oil pressure sensor Vcc E113… -

Page 37

69 Engine Control System Terminal Terminal Number Number SCV−Lo CKP + SCV−Hi CKP GND Fuel temperature sensor + CKP shield ECT meter CMP + — CMP GND Overheating switch CMP shield ECT + Boost pressure sensor Vcc Terminal Engine oil pressure sensor Vcc Number Engine oil pressure sensor Vout EGR hall sensor U… -

Page 38

Engine Control System 70 Terminal Number — OS−INJ6 signal Injector power supply 2 Injector power supply 1 — OS−INJ4 signal OS−INJ2 signal — (Female connector on injector side) In cylinder head (Female connector on injector side) (Male connector on ECM side) (Male connector on ECM side) TSWG0041… -

Page 39

71 Engine Control System Connector list Connector Face Connector Face E-27 E-75 003-501 #1 injector (Silver) E-29 E-76 003-501 #2 injector (Silver) (Black) E-31 E-80 #3 injector (Silver) (Black) E-33 E-90 003-500 #4 injector (Silver) (Blue) E-35 E-93 #5 injector (Silver) (Gray) E-37 E-98… -

Page 40

Engine Control System 72 Connector Face Connector Face E-114 (Black) (Black) E-161 (Brown) (Gray) E-162 (Dark gray) (Gray) E-163 (Gray) (Black) E-164 (Black) FB-124 H-12 (Black) (Gray) FL-150 H-12 016-500 (Gray) 9 10 11 12 FL-269 H-20 13 14 15 16 17 18 19 20 020-500 003-502… -

Page 41

73 Engine Control System Connector Face Connector Face H-95 12 11 10 9 H-20 (ECM 16 15 14 13 side) 20 19 18 17 020-501 (Gray) H-95 (Injector side) (White) (Gray) H-95 (Injector side) (White) (Gray) H-94 (ECM side) (Gray) H-94 (ECM side) -

Page 42

This page Is Intentionally Left Blank. -

Page 43

103 Trouble Shooting — EXAMPLE From Service Manual Error Code: 0088 Common rail pressure is abnormally high (1st or 2nd stage). TSHK0041 Name 1. Common rail 5. Fuel tank 2. Fuel filter 6. Supply pump 3. Electromagnetic Pump 7. Injector 4. -

Page 44: Trouble Shooting 104

Trouble Shooting 104 Engine control module (ECM) CMP sensor EGR position EGR position EGR position Common rail pressure signal sensor signal sensor signal sensor signal sensor signal 99 E-56 98 E-56 E-56 E-56 E-56 E-56 E-56 E-56 E-56 E-56 E-56 E-56 E-56 H-20…

-

Page 45

105 Trouble Shooting — EXAMPLE From Service Manual Error Code set condition Back-up mode 1st step • L mode fixed. • Rail pressure is more than 185MPa for 5 seconds • Limited injection amount 3 (multi-injection stopped) or more. • Target RP upper limit (80MPa) •… -

Page 46: Trouble Shooting 106

Trouble Shooting 106 Step Action Value Check the fuel return pipe between the supply pump and the fuel tank for breakage, twist, etc. Check for clogging or twisting in the vent hose of the fuel tank. — Check for foreign matter in the fuel tank. If the trouble is detected, repair as required.

-

Page 47

107 Trouble Shooting — EXAMPLE From Service Manual About common rail pressure sensor TSWG0055 Name 1. Sensor ground 2. Sensor signal 3. Sensor power supply Characteristics of common rail pressure sensor (MPa) TSWG0201… -

Page 48

5. 380002726 EMPS/EST ECM Cable 6. 380002728 EMPS/EST RS232 Null Modem Cable Start the Engine Download Tool — Isuzu EMPS The Additional Tools screen provides a button linking the Electronic Service Tool to: • Engine Diagnostic Tool — Isuzu EMPS… -

Page 49: Process Menu

Preliminary ELECTRONIC SERVICE TOOL (EST) Engine Module Programming System (EMPS) — Summary Selecting an EMPS Process Process Menu Select an EMPS operation from the Process Menu Process Menu. • ECM Reflash — Select when the ECM control program is suspected to have ECM Reflash damaged/corrupted files.

-

Page 50

This page Is Intentionally Left Blank.

This manual is also suitable for:

6hk-1

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

URL:http://www.hitachi-c-m.com

PRINTED IN JAPAN (K) 2015, 06

PART NO.

EWDCY-EN-00

Engine Manual

Workshop Manual

4HK1

GB3

EXHAUST EMISSION

STANDARDS

Service Manual consists of the following sections.

Technical Manual (Operational Principle)

Technical Manual (Troubleshooting)

Workshop Manual

Engine Manual

Related Manuals for Hitachi 4HK1

Summary of Contents for Hitachi 4HK1

-

Page 1

PART NO. EWDCY-EN-00 Engine Manual Workshop Manual 4HK1 EXHAUST EMISSION STANDARDS URL:http://www.hitachi-c-m.com Service Manual consists of the following sections. Technical Manual (Operational Principle) Technical Manual (Troubleshooting) Workshop Manual PRINTED IN JAPAN (K) 2015, 06 Engine Manual… -

Page 2

Find manuals at https://best-manuals.com Find manuals at https://best-manuals.com… -

Page 3

FOREWORD FOREWORD This manual describes the service procedures for the 4HK1 diesel engine (GB 3). The contents of this manual are current at the date of issue, but may differ slightly from your engine due to specification changes This manual describes the service procedures for the 4HK1 diesel engine (GB 3). or other modifications made thereafter. The contents of this manual are current at the date of issue, but may differ slightly from your engine due to specification changes or other modifications made thereafter. The engine specification and description, which is not installed in the machine, may be explained on this manual. This manual consists of the following sub-sections. This manual consists of the following sub-sections. Publication No. Publication Name Sub-sections IDE-2820 ENGINE Introduction Publication No. Publication Name Sub-sections Service Information Guide IDE-2820 ENGINE Introduction Maintenance Information… -

Page 4

Find manuals at https://best-manuals.com Find manuals at https://best-manuals.com… -

Page 5

Introduction (All) 0-1 Introduction Introduction (All) Table of Contents Introduction…………….0-2 safety information…………0-2 Find manuals at https://best-manuals.com Find manuals at https://best-manuals.com… -

Page 6

0-2 Introduction (All) Introduction safety information while paying sufficient attention to the handling precautions. Repair work safety information Furthermore, for work besides this, carry out work while wearing safety clothes and equipment. When the engine is unloaded from the machine, use the engine stand. -

Page 7: Table Of Contents

Service Information Guide (All) 14A-1 Description General Information Service Information Guide (All) Table of Contents Contents included in service information…..14A-2 Plastic gauge…………..14A-4 Recommended liquid gasket………14A-6 Thread locking adhesive agent……..14A-8 Term…………….14A-9 Abbreviations ………….14A-10 Standard bolts…………..14A-13 Find manuals at https://best-manuals.com Find manuals at https://best-manuals.com…

-

Page 8: Contents Included In Service Information

14A-2 Service Information Guide (All) Contents included in service information Contents included in service information Connection Includes the connection procedures for wiring, piping, Removal etc. Includes the removal procedure when repairing parts, devices, etc. Writing Includes the writing procedure necessary when replacing Installation the ECM or supply pump.

-

Page 9

Service Information Guide (All) 14A-3 1. Forward 9. Gas or warm air 2. Upward 10. Mixing of outside air and gas or mixing of cold 3. Operating section or operating direction air and warm air 4. Detail of a particular part 11. -

Page 10: Plastic Gauge

14A-4 Service Information Guide (All) Plastic gauge Using the plasti-gauge Type Measurable range : 0.025 to 0.076 mm { 0.00098 PG-1 (Green) to 0.00299 in } : 0.051 to 0.152 mm { 0.00201 PR-1 (Red) to 0.00598 in } : 0.102 to 0.229 mm { 0.00402 PB-1 (Blue) to 0.00902 in } Method for measuring clearance between the connecting…

-

Page 11

Service Information Guide (All) 14A-5… -

Page 12: Recommended Liquid Gasket

14A-6 Service Information Guide (All) Recommended liquid gasket Using the thread liquid gasket Type Product name Manufacturer Location of use (Reference) Silicon type ThreeBond 1207B ThreeBond Engine oil seal retainer (Room- ThreeBond 1207C ThreeBond Engine oil pan temperature ThreeBond 1215 ThreeBond Timing gear case vulcanized)

-

Page 13

Service Information Guide (All) 14A-7 Caution: ・ If the workshop manual specifies an application method, follow that method. -

Page 14: Thread Locking Adhesive Agent

14A-8 Service Information Guide (All) Thread locking adhesive agent Using the thread locking adhesive agent Type Color Loctite 242 Blue Loctite 262 Loctite 271 Caution: ・ Thoroughly remove grime, moisture, oil, and grease from the bolts, bolt holes, and screw thread portion of the nuts to which thread locking adhesive agent will be applied.

-

Page 15: Term

Service Information Guide (All) 14A-9 Term Term Nominal dimension Refers to standard values during production. Specified value Refers to specified values for inspection, adjustment, assembly, and installation. Limit Refers to maximum or minimum values that should not be exceeded during maintenance. Parts exceeding these values must be repaired or replaced.

-

Page 16: Abbreviations

14A-10 Service Information Guide (All) Abbreviations Abbreviations Abbreviation Description A- E Analog/Digital ABDC After bottom dead center Alternating current Accessory Alternating current generator Actuator American Petroleum Institute Assembly ATDC After top dead center Automatic transmission fluid Battery + terminal Battery BBDC Before bottom dead center Bracket…

-

Page 17

Service Information Guide (All) 14A-11 Abbreviation Description F — N Feedback Fuel cut Fusible link Fusible link wire Front Fuel temperature Forward Generator Ground Hydrocarbon HO2S Superheat O2 sensor Idle air control Intake air temperature Integrated circuit ID Plate Name plate IDSS ISUZU Diagnostic Service System Intake manifold temperature… -

Page 18

14A-12 Service Information Guide (All) Abbreviation Description O — W O2 sensor On-board diagnosis Original equipment manufacturer Option Oil temperature Pilot light Pump control valve / Positive crankcase ventilation Proportion-integration Particulate matter Power take-off Pulse width modulation wave Quick on start system Quick warming up system Right side Relay… -

Page 19: Standard Bolts

Service Information Guide (All) 14A-13 Standard bolts List of standard bolt and nut tightening torques Note: ・ Those indicated with an asterisk (*) are used The tightening torque values in the following table apply for the internal threaded portion of soft to locations where no tightening torque is specified.

-

Page 20

14A-14 Service Information Guide (All) Strength category Bolt head shape Hex bolt Flange bolt Hex bolt Flange bolt M18 — M24 : 151.0 to 225.6 N・m : 195.2 to 293.2 N・m M18 x 1.5 { 15.4 to 23.0 kgf・m / ―… -

Page 21

Service Information Guide (All) 14A-15 Strength category Bolt head shape Hex bolt Flange bolt Hex bolt Flange bolt M6 — M16 : 5.6 to 11.2 N・m { 0.6 : 6.6 to 12.2 N・m { 0.7 M6 x 1 to 1.1 kgf・m / 50 to 99 to 1.2 kgf・m / 58 to 108 ―… -

Page 22

14A-16 Service Information Guide (All) Strength category Bolt head shape Hex bolt Flange bolt Hex bolt Flange bolt M18 — M24 : 222.5 to 334.3 N・m : 229.5 to 345.2 N・m M18 x 1.5 { 22.7 to 34.1 kgf・m / ―… -

Page 23

Service Information Guide (All) 14A-17 1. Hex bolt (4.8, 4T) 10. Hex bolt (Non-thermally refined 8.8) 2. Hex bolt (4.8, 4T) 11. Flange bolt (8.8) 3. Flange bolt (4.8, 4T) 12. Flange bolt (8.8) 4. Flange bolt (4.8, 4T) 13. Hex bolt (9.8, 9T) 5. -

Page 24

14A-18 Service Information Guide (All) Connector (Brass tapered screws) Screw size PT(R)1/8 PT(R)1/4 PT(R)3/8 PT(R)1/12 : 2.0 to 14.7 N・m : 4.9 to 15.7 N・m : 9.8 to 16.7 N・m : 9.8 to 17.7 N・m ― { 0.20 to 1.50 kgf・m / { 0.5 to 1.6 kgf・m / 43 { 1.0 to 1.7 kgf・m / 87 { 1.0 to 1.8 kgf・m / 87… -

Page 25

Mechanical (4HK1) 1B-1 Engine Mechanical (4HK1) Table of Contents Cylinder head cover…………1B-2 installation……………1B-256 removal……………1B-2 Flywheel…………..1B-262 installation…………..1B-3 removal…………..1B-262 Cylinder head assembly………..1B-4 inspection…………..1B-264 removal……………1B-4 installation……………1B-265 disassembly……………1B-13 Crankshaft front oil seal……….1B-267 inspection…………..1B-19 removal…………..1B-267 reassembly…………..1B-25 installation……………1B-269 installation…………..1B-34 Crankshaft rear oil seal……….1B-272 Idle gear……………..1B-49 removal…………..1B-272 removal…………..1B-49… -

Page 26: Cylinder Head Cover

1B-2 Mechanical (4HK1) Cylinder head cover removal Ventilation hose disconnect Remove the air leak pipe from the EGR cooler and bracket. Note: ・ The existence or nonexistence of the equipment varies depending on the machine manufacturer. Remove the bracket from the cylinder head cover.

-

Page 27: Installation

Mechanical (4HK1) 1B-3 installation Connect the oil level gauge guide tube to the cylinder head cover. Cylinder head cover installation tightening torque: 19 N・m { 1.9 kgf・m / 14 lb・ft } Align the head cover gasket to the cylinder head Install the bracket to the cylinder head cover.

-

Page 28: Cylinder Head Assembly

1B-4 Mechanical (4HK1) Cylinder head assembly removal Turbocharger assembly removal Remove the exhaust pipe from the turbocharger Battery ground cable disconnect assembly. Disconnect the battery ground cable from the battery. Remove the air cleaner duct from the air cleaner Caution:…

-

Page 29

Mechanical (4HK1) 1B-5 Disconnect the water return pipe from the 13. Remove the turbocharger assembly from the exhaust turbocharger assembly. manifold. Remove the water return pipe from the water pump. Note: ・ The turbocharger specification varies Note: depending on the machine manufacturer. -

Page 30

1B-6 Mechanical (4HK1) Caution: Disconnect the harness connector from the EGR valve. ・ After removing the EGR pipe, seal to prevent intrusions of foreign material. Remove the EGR valve from EGR pipe C. Caution: ・ After removing the EGR valve, seal to prevent intrusions of foreign material. -

Page 31: Inlet Cover

Mechanical (4HK1) 1B-7 3. Fan guide bracket 2. Gasket 3. Inlet pipe Disconnect the radiator upper hose from the water 4. Boost pressure/boost temperature sensor outlet pipe. 10. Oil level gauge guide tube removal Remove the EGR cooler water pipe from the engine assembly.

-

Page 32

1B-8 Mechanical (4HK1) Remove the fuel pipe from the fuel supply pump and the common rail assembly. Note: ・ Remove the clip. Caution: ・ Do not reuse the gasket. 14. Fuel leak off pipe assembly removal Disconnect the fuel leak-off pipe from the cylinder head assembly. -

Page 33

Mechanical (4HK1) 1B-9 Disconnect the injector harness from the injector. Caution: ・ Be careful not to damage the injector side stud bolts. Remove the injector harness from the cylinder head assembly. Note: ・ Remove the bracket tightening bolts and then remove the injector harness together with the bracket. -

Page 34

1B-10 Mechanical (4HK1) SST: 5-8840-0019-0 — sliding hammer 1. Injector 2. Injector sleeve Caution: ・ Store each ID code plate on the injector head with the cylinder number tag attached to avoid a mix-up. ・ Be extremely careful not to damage the injector nozzle. -

Page 35

Mechanical (4HK1) 1B-11 Remove the camshaft bearing from the cylinder head assembly. Note: ・ Temporarily assemble the removed caps and bearings in the original position to avoid a mix- up after the bearings have been inspected. Remove the rocker arm shaft from the cylinder head assembly. -

Page 36: Cylinder Block

1B-12 Mechanical (4HK1) 22. Cylinder head assembly removal Remove the cylinder head assembly from the cylinder block. Note: ・ Loosening order of the head bolts Caution: ・ Since the idle gear C protrudes from the bottom surface of the cylinder head, be careful not to damage the gear.

-

Page 37

Mechanical (4HK1) 1B-13 disassembly Engine hanger bracket removal Remove the front engine hanger bracket from the cylinder head assembly. Remove the rear engine hanger bracket from the cylinder head assembly. 1. EGR cooler bracket 2. Bracket Inlet cover removal Remove EGR pipe C from the case. -

Page 38

1B-14 Mechanical (4HK1) Caution: 1. Distance tube 2. Washer ・ Do not forget to remove the bolts indicated by 3. Exhaust manifold the arrow in the diagram. Remove the gasket from the cylinder head assembly. Thermostat removal Remove the fan guide bracket from the water outlet pipe. -

Page 39

Mechanical (4HK1) 1B-15 1. Overheat switch Remove the idle gear C from the cylinder head 2. Engine coolant temperature sensor assembly. CMP sensor removal Remove the CMP sensor from the cylinder head assembly. 1. Idle gear C 2. Idle gear shaft 10. -

Page 40

1B-16 Mechanical (4HK1) SST: 8-9439-6862-0 — pivot ASM 13. Valve stem oil seal removal Remove the valve stem oil seal from the valve guide using the pliers. Caution: ・ Do not reuse the valve stem oil seal. Remove the valve spring seat from the cylinder head assembly. -

Page 41

This as a preview PDF file from best-manuals.com Download full PDF manual at best-manuals.com…

- Brands:

Isuzu - File Size:

3.2MB - Total Pages:

121 - File Type:

PDF

INTRODUCTION & ENGINE MECHANICAL FEATURES

The 2005 model year NPR/NQR truck, the 4HK1-TC inline 4 cylinder engine replaces the 4HE1-TC engine for advanced exhaust emission countries. The 4HK1-TC engine has been newly developed on the basis of previous 4HE1-TC engine, with additional features including the employment of four valve mechanism per a cylinder that are operated via a single camshaft, common rail fuel injection system, water-cooled exhaust gas re-circulation (EGR) system, and the change of combustion chamber form. The larger engine displacement and the common rail fuel injection system have resulted in an increase both in maximum output and torque, and met Euro 3 emission regulation standard. Most conspicuous items are listed below.

- Multi fuel injection type high-pressure common rail system and is made with Denso.

- Single overhead camshaft (OHC) with 4 valves per a cylinder.

- Electrical control EGR valve, water-cooled EGRcooler.

- Turbocharger with intercooler.

The base transmission is MYY for 4HK1-TCN low output engine, MZZ for 4HK1-TCS high output engine. The Smoother system is available for only MYY transmission.

GEAR TRAIN

To rotate the fuel supply pump with engine speed, idle gear has changed with three steps. The crankshaft gear (42 teeth) corresponds with the large diameter of idle gear A (72 teeth). The fuel supply pump gear (35 teeth) corresponds with the middle diameter of idle gear A (60 teeth). The idle gear B (61 teeth) corresponds with the small diameter of idle gear A (30 teeth).

Valve Train

To improve exhaust emission and engine output performance, four valve mechanism is newly adopted for 4HK1-TC engine. Note that the adjustment method of valve clearance has been changed from 4HK1-TC engine as following steps:

- Rotate the crankshaft to make the No.1 cylinder meet the compression top dead center (TDC). There are 2 marks stamped on the crank pulley. The mark (1) is used to bring the engine No.1 or No. 4 cylinder to TDC. The mark (2) is irrelevant. Do not use the mark (2).

- Loosen fully each adjusting screw (8) & (2) of the bridge and the rocker arm.

- Insert a 0.4mm (0.016in) thickness gauge between the tip of the rocker arm and bridge cap (5), and adjust the clearance with the adjusting screw (3) on the rocker arm, and then fix it with a lock nut (4).

- With a thickness gauge kept inserted, check that the adjusting screw (6) contacts the valve shaft end and the movement of the thickness gauge has become tight when the adjusting screw (6) on the bridge is tightened lightly.

- Check the valve shaft end on the opposite side floats or it contacts obliquely. In case of a floating or oblique contact, loosen a little the adjusting screw (6) on the bridge side and adjust so that the valve shaft ends on both sides get in contact properly. Bridge (8) & valve shaft end clearance less than 0.1 mm (0.004in).

- After the adjustment so that the end of the valves on both sides touch properly, tighten up the lock nut (7) on the bridge (8).

CYLINDER HEAD COVER & HEAD COVER CASE

Along with the employment of a common rail type fuel injection system, the head cover is split and housed in a newly introduced head cover case attached with an intermediate connector for the injector. The head cover case is so designed that it is secured individually to the cylinder head with four bolts, and further it is tightened together with the head cover with nine bolts. Accordingly, the head cover is removable individually regardless of the injector harness, thus enabling easy inspection and service including the valve clearance adjustment.

ENGINE CONTROL MODULE (ECM)

The engine control module (ECM) is located at inside of engine-side cover on the left via mounting bracket and is beside the engine. The ECM is made by Transtron. The ECM mainly controls the following:

- Fuel injection control

- Fuel timing control

- Exhaust gas recirculation (EGR) system control

- Preheating system control

- Exhaust brake control

- Power take off (PTO) control

- On-board diagnostics for engine control

The ECM constantly observes the information from various sensors. The ECM controls the systems that affect vehicle performance. The ECM performs the diagnostic function of the system. The ECM can recognize operational problems, alert the driver through the malfunction indicator lamp (MIL), and store diagnostic trouble code (DTC). DTC identify the system faults to aid the technician in making repair.

This diagnostic applies to internal microprocessor integrity conditions within the ECM. The electronically erasable programmable read only memory (EEPROM) memorize learning data and injector ID code data for engine control and communication with other control module.

Symbol “!” warns you of an electric shock hazard. To avoid shock and possible serious injury, DO NOT touch the terminals. When disconnecting the harness connector, always turn OFF the ignition switch or disconnect the battery cable.

Download or Read Online Isuzu 4HK-1 Engine Service Manual

Save PDF/Read Online

Isuzu

4HK-1 and 6HK-1

ENGINE

FUEL SYSTEM

CE APPLICATIONS

|

Revised 8/29/06 |

Form Number 5137 |

1

Isuzu 4HK-1 and 6HK-1 Engine Overview

The Tier III CX330 Excavators are equipped with an Isuzu 6HK-1 model common rail fuel system Engine. The Isuzu 4HK-1 model will be used in at least one other

Excavator model. These engines have 4 valves per cylinder, operated by a single overhead cam to optimize air flow, fuel economy and emissions. The injector is now located at the center of the piston under the valve cover. The fuel system is now totally electronically controlled. These engines use an water cooled Exhaust Gas Recirculation, (EGR) system, which allows a controlled amount of exhaust gas to return back to the intake. This EGR system is used to reduce the emissions level of the engine. These engines also use an air to air aftercooling intake air system. The air to air intake system ports pressurized air flow between the turbocharger and the intake manifold through an air to air heat exchanger in front of the radiator. The 4HK-1 model has a displacement of 317 cubic inches (in3) or 5193 cubic centimeters (cc). The 6HK-1 model has a displacement of 475 cubic inches (in3) or 7790cubic centimeters (cc).

The ECM calculates the basic injection amount based on the signals from throttle position sensor, boost pressure sensor, crank position sensor, cam position sensor, etc.

It regulates the opening/closing period of common rail pressure control valve and the electric activation of each injector according to the common rail pressure, engine coolant temperature, etc. at this time, to correct the optimum injection timing and injection amount.

At engine start (after the key switch is turned to the START position to start the engine, and until the return of the key switch to the ON position), the fuel injection quantity is controlled based on information from the start signal, engine speed, and engine coolant temperature. At low temperature, the fuel injection quantity increases. When the engine starts completely, this boosted quantity mode at starting is cancelled and normal running mode is restored.

The ECM calculates the current altitude based on the barometric pressure sensor signal. It corrects the fuel flow according to the altitude etc. at this time.

The Excavator machine controller communicates with the engine controller (ECM) via the CAN Data Bus system to control engine speed, return to idle command, activate the work modes and also to set the engine speed required for the breaker mode.

Engine Performance Needs

1.Air

2.Compression

3.Fuel

3

Isuzu 4HK-1 and 6HK-1 Engine Overview

The electronic control system for the Isuzu 4HK-1 and 6HK-1 Engines use input information from a number of sensors and from the Excavator controller to determine the quantity and timing of the fuel delivery to the engine.

The engine control module (ECM), is located on the inside rear of the cab. The ECM has two connectors, one an 81 pin and one 40 pin, for inputs and outputs. The engine control module requires downloading of control software to give it the ability to control all functions.

Inputs to 40 pin engine harness connector:

•The common rail fuel pressure sensor has 3 wires and is located on the common rail. This sensor detects the fuel pressure in the common rail, converts the pressure into a voltage signal, and sends the signal to the ECM. Higher common rail pressure provides higher fuel pressure sensor voltage while lower pressure provides lower fuel pressure sensor voltage.

•The 2 wire variable resistor fuel temperature sensor is installed on the fuel supply pump. The fuel temperature sensor measures the temperature of the drain fuel from the pump. When the fuel temperature sensor is cold, the sensor resistance is high.

When the fuel temperature increases, the sensor resistance decreases. With high sensor resistance, the ECM detects a high voltage on the signal circuit. With lower sensor resistance, the ECM detects a lower voltage on the signal circuit.

|

Fuel Temp. |

Fuel Temp. |

Ohms |

Fuel Temp. |

Fuel |

Ohms Ω |

|

|

(°C) |

(°F) |

Ω |

(°C) |

Temp. (°F) |

||

|

140 |

284 |

75 |

40 |

104 |

1,150 |

|

|

120 |

248 |

111 |

20 |

68 |

2,450 |

|

|

100 |

212 |

184 |

0 |

32 |

5,740 |

|

|

80 |

176 |

318 |

-20 |

-4 |

15,000 |

|

|

60 |

140 |

584 |

-40 |

-40 |

45,770 |

•The 2 wire engine coolant temperature sensor is located on the thermostat housing at the right front corner of the engine. The coolant sensor’s temperature detection component uses a thermistor. A 5 volt reference voltage is applied at all times to the sensor from the ECM. The ECM detects a voltage change due to a resistance value change in the sensor caused by the coolant temperature change.

|

Coolant |

Coolant |

Ohms |

Coolant |

Coolant |

Ohms Ω |

|

Temp. (°C) |

Temp. (°F) |

Ω |

Temp. (°C) |

Temp. (°F) |

|

|

140 |

284 |

76 |

40 |

104 |

1,161 |

|

120 |

248 |

118 |

20 |

68 |

2,500 |

|

100 |

212 |

190 |

0 |

32 |

5,773 |

|

80 |

176 |

325 |

-20 |

-4 |

15,216 |

|

60 |

140 |

591 |

-40 |

-40 |

47,365 |

4

Isuzu 6HK1 Common Rail Engine Fuel System

|

Common |

Fuel Temp |

Coolant |

Intake Air |

Boost Temp |

Barometric |

ENG Oil |

Engine Stop |

|||

|

Rail Fuel PSI |

Sensor |

Temperature |

Temp. Sensor |

Sensor |

AMB PSI |

PSI |

Switch |

|||

|

Sensor |

Sensor |

Sensor |

Sensor |

|||||||

|

Crankshaft |

Camshaft |

Boost PSI |

||||||||

|

Position |

Position |

Sensor |

||||||||

|

Sensor |

Sensor |

EGR Position |

||||||||

|

Sensor |

Start Signal |

|||||||||

|

(Fuel Boost) |

||||||||||

|

Power Supply |

||||||||||

|

1 Ignition Wire |

||||||||||

|

2 Positive Wires |

||||||||||

|

Engine Harness 40 Pin |

Engine Harness 81 Pin |

6 Ground Wires |

||||||||

|

Connector A1 |

||||||||||

|

Connector A0 |

CAN Data Bus |

|||||||||

|

Engine Control Module |

||||||||||

|

Connector |

||||||||||

|

Throttle, |

||||||||||

|

Idle Up/Down, |

||||||||||

|

Pump PSI |

Injectors |

Main ECM |

Diagnostic |

Memory Clear |

Work Modes, |

|||||

|

Breaker Mode, |

||||||||||

|

Control Valve |

Power |

Switch X24 |

Switch X23 |

|||||||

|

Tach, |

||||||||||

|

(SCV) |

Relay |

|||||||||

|

(Instrumentation |

||||||||||

|

EGR DC |

Glow |

Data Link |

& Faults) |

|||||||

|

Motor |

Relay |

Diag Conn X4 |

||||||||

|

5 |

Isuzu 4HK-1 and 6HK-1 Engine Overview (continued)

Inputs to 40 pin engine harness connector(continued):

•The 2 wire crankshaft position sensor (CKP) is located on the flywheel housing at the left rear corner of the engine. The CKP sensor detects 45 projections equally spaced every 7.5° around the flywheel periphery. There is also a space (equal to 3 projections) to act as a top dead center (TDC) reference signal for the engine control module (ECM). With these 45 pulses and the TDC reference signal, the ECM calculates the engine speed and exact position of the crankshaft.

•The 2 wire camshaft position sensor (CMP) is located on the cylinder head at the rear of the camshaft gear. The camshaft position sensor detects a total of the number of the cylinders in the engine plus an extra one. The extra hole indicates the top dead center position of number 1 cylinder. Five through holes (four holes arranged equally every 90° on the gear and one reference hole) on the camshaft gear flange surface on the 4HK-1 Engine. Seven through holes (six holes arranged equally every 60° on the gear and one reference hole) on the camshaft gear flange surface on the 6HK-1 Engine. The camshaft position sensor indicates the rotational position of the camshaft to the ECM. The CMP signal input, determines the crank angle and the ECM can use it to control fuel injection and calculate the engine speed. The crankshaft position sensor (CKP) typically controls these functions, however it is done by CMP sensor if the CKP sensor is faulty.

Diagnostic aid

If there is relevant Error Code to the crankshaft (CKP) sensor and Camshaft (CMP) sensor, the engine will not start until memory clear is performed.

If an intermittent trouble is suspected, the following may be the cause:

•Improper connection of harness connector

•Defective harness routing

•Worn harness cover

•Wire disconnection inside harness cover

•The 3 wire boost pressure sensor is located in the piping to the intake manifold of the engine. The sensor converts the boost pressure into the voltage signal and sends it to engine control module (ECM). The ECM should detect a higher signal voltage at a high boost pressure.

•The 4 wire Exhaust Gas Recirculation (EGR) position sensor is installed in EGR valve and detects the valve lift amount of EGR.

Note:

Do not disassemble the EGR position sensor. If it is faulty, replace it as EGR valve assembly.

6

Isuzu 6HK1 Common Rail Engine Fuel System

|

Common |

Fuel Temp |

Coolant |

Intake Air |

Boost Temp |

Barometric |

ENG Oil |

Engine Stop |

|||

|

Rail Fuel PSI |

Sensor |

Temperature |

Temp. Sensor |

Sensor |

AMB PSI |

PSI |

Switch |

|||

|

Sensor |

Sensor |

Sensor |

Sensor |

|||||||

|

Crankshaft |

Camshaft |

Boost PSI |

||||||||

|

Position |

Position |

Sensor |

||||||||

|

Sensor |

Sensor |

EGR Position |

||||||||

|

Sensor |

Start Signal |

|||||||||

|

(Fuel Boost) |

||||||||||

|

Power Supply |

||||||||||

|

1 Ignition Wire |

||||||||||

|

2 Positive Wires |

||||||||||

|

Engine Harness 40 Pin |

Engine Harness 81 Pin |

6 Ground Wires |

||||||||

|

Connector A1 |

||||||||||

|

Connector A0 |

CAN Data Bus |

|||||||||

|

Engine Control Module |

||||||||||

|

Connector |

||||||||||

|

Throttle, |

||||||||||

|

Idle Up/Down, |

||||||||||

|

Pump PSI |

Injectors |

Main ECM |

Diagnostic |

Memory Clear |

Work Modes, |

|||||

|

Breaker Mode, |

||||||||||

|

Control Valve |

Power |

Switch X24 |

Switch X23 |

|||||||

|

Tach, |

||||||||||

|

(SCV) |

Relay |

|||||||||

|

(Instrumentation |

||||||||||

|

EGR DC |

Glow |

Data Link |

& Faults) |

|||||||

|

Motor |

Relay |

Diag Conn X4 |

||||||||

|

7 |

Isuzu 4HK-1 and 6HK-1 Engine Overview (continued)

Inputs to 81 pin engine harness connector:

•The 2 wire intake air temperature (IAT) sensor is installed on intake air tube and detects the temperature of intake air for optimum fuel injection control.

•The 2 wire boost temperature sensor is installed onto the EGR valve on the upstream side of intake manifold. The sensor is a thermistor type. The resistance in the sensor changes as the temperature changes. When the intake temperature sensor is cold, the sensor resistance is high. When the intake temperature increases, the sensor resistance decreases. With high sensor resistance, the ECM detects a high voltage on the signal circuit. With lower sensor resistance, the ECM detects a lower voltage on the signal circuit.

•The 3 wire barometric pressure sensor is installed on the machine and converts the ambient barometric pressure into a voltage signal. The ECM calculates barometric pressure by this voltage signal and corrects the fuel injection amount (high-altitude correction) as the machine works at a higher elevation.

•The 3 wire engine oil pressure sensor is located on the left side of the engine just below and forward of the high pressure injection pump.

•An engine emergency stop signal is sent from the machine controller to the engine controller. The machine controller receives an engine stop signal from the stop switch located in the instrument cluster.

•As the engine is started (after the key switch is turned to the START position to start the engine, and until the return of the key switch to the ON position), optimum fuel injection quantity is delivered based on information from the starter switch signal, engine speed, and the engine coolant temperature sensor (ECT). At low temperature, the fuel injection quantity increases. As the engine starts completely, this boosted quantity mode at starting is cancelled and normal running mode is restored.

•Power Supply – Ignition power is sent to the engine control module (ECM) any time that the key switch is in the run position. When the ignition signal is present, the ECM activates the main relay. Once the Main Relay (K33 on machine schematic) is activated, battery power is fed to the ECM through the relay normally open (NO) contact to pins number 2 and 6. When the key switch is turned to the off position, the ECM continues to hold the main relay activated for a period of time to allow the ECM to power down safely. This delay is about 10 seconds. The ECM has six ground connections in total.

8

Isuzu 6HK1 Common Rail Engine Fuel System

|

Common |

Fuel Temp |

Coolant |

Intake Air |

Boost Temp |

Barometric |

ENG Oil |

Engine Stop |

|||

|

Rail Fuel PSI |

Sensor |

Temperature |

Temp. Sensor |

Sensor |

AMB PSI |

PSI |

Switch |

|||

|

Sensor |

Sensor |

Sensor |

Sensor |

|||||||

|

Crankshaft |

Camshaft |

Boost PSI |

||||||||

|

Position |

Position |

Sensor |

||||||||

|

Sensor |

Sensor |

EGR Position |

||||||||

|

Sensor |

Start Signal |

|||||||||

|

(Fuel Boost) |

||||||||||

|

Power Supply |

||||||||||

|

1 Ignition Wire |

||||||||||

|

2 Positive Wires |

||||||||||

|

Engine Harness 40 Pin |

Engine Harness 81 Pin |

6 Ground Wires |

||||||||

|

Connector A1 |

||||||||||

|

Connector A0 |

CAN Data Bus |

|||||||||

|

Engine Control Module |

||||||||||

|

Connector |

||||||||||

|

Throttle, |

||||||||||

|

Idle Up/Down, |

||||||||||

|

Pump PSI |

Injectors |

Main ECM |

Diagnostic |

Memory Clear |

Work Modes, |

|||||

|

Breaker Mode, |

||||||||||

|

Control Valve |

Power |

Switch X24 |

Switch X23 |

|||||||

|

Tach, |

||||||||||

|

(SCV) |

Relay |

|||||||||

|

(Instrumentation |

||||||||||

|

EGR DC |

Glow |

Data Link |

& Faults) |

|||||||

|

Motor |

Relay |

Diag Conn X4 |

||||||||

|

9 |

Isuzu 4HK-1 and 6HK-1 Engine Overview (continued)

Inputs to 81 pin engine harness connector: (continued)

•The CAN (Controller Area Network) Data Bus Connector transmits communication between the engine controller and the Excavator controller. This connector transmits throttle, idle up/down, work mode, breaker mode, tachometer, instrumentation and fault code information.

•The memory clear (X23), diagnostic switch (X24) and data link (X4) connectors are not used with the Case Electronic Service Tool (EST) diagnostic system. They are required when using the Tech 2 Diagnostic Tool.

Outputs from 81 pin engine harness connector:

•When the ignition signal is present from the keyswitch, the ECM activates the main relay. Once the Main Relay (K33 on machine schematic) is activated, battery power is fed to the ECM through the relay normally open (NO) contacts to pins number 2 and 6. When the key switch is turned to the off position, the ECM continues to hold the main relay activated for a period of time to allow the ECM to power down safely. This delay is about 10 seconds.

•The glow control relay system consists of the ECM, glow relay, glow plug. When the key switch is turned ON with low engine coolant temperatures, the ECM determines the glow time and operates the glow relay (K2). After a certain time has elapsed, the ECM will turn the glow relay to “OFF”. Also, after-glow function allows to stabilize idling immediately after starting.

Outputs from 40 pin engine harness connector:

•The engine driven high pressure injection pump pressurizes fuel to feed to the common rail. The injection pump has a suction control valve (SCV), and a fuel temperature (FT) sensor. The suction control valve (SCV) is installed onto high pressure pump section and controls supply of fuel (discharge amount) to common rail. The engine control module (ECM) regulates period of electrical activation time of the SCV to regulate the fuel discharge amount.

Do not replace the SCV. If it is faulty, replace it as supply pump ASM.

•The exhaust gas recirculation (EGR) system recirculates a part of the exhaust gas to the engine intake to reduce the combustion temperature inside the cylinders to reduce NOx (nitrogen oxides) in the exhaust gas. The EGR valve opening is calculated according to the engine coolant temperature (ECT), the engine speed, and the target fuel injection quantity. The EGR motor is the brushless DC motor, and is driven by three phases. The ECM drives the EGR motor through the EGR motor drive circuits U, V, and W. The motor rotates with a combination of the threephase signals. The ECM sets the Error Code when the EGR motor drive duty is high and the difference between the target EGR position and actual EGR position is large.

10

Isuzu 6HK1 Common Rail Engine Fuel System

|

Common |

Fuel Temp |

Coolant |

Intake Air |

Boost Temp |

Barometric |

ENG Oil |

Engine Stop |

|||

|

Rail Fuel PSI |

Sensor |

Temperature |

Temp. Sensor |

Sensor |

AMB PSI |

PSI |

Switch |

|||

|

Sensor |

Sensor |

Sensor |

Sensor |

|||||||

|

Crankshaft |

Camshaft |

Boost PSI |

||||||||

|

Position |

Position |

Sensor |

||||||||

|

Sensor |

Sensor |

EGR Position |

||||||||

|

Sensor |

Start Signal |

|||||||||

|

(Fuel Boost) |

||||||||||

|

Power Supply |

||||||||||

|

1 Ignition Wire |

||||||||||

|

2 Positive Wires |

||||||||||

|

Engine Harness 40 Pin |

Engine Harness 81 Pin |

6 Ground Wires |

||||||||

|

Connector A1 |

||||||||||

|

Connector A0 |

CAN Data Bus |

|||||||||

|

Engine Control Module |

||||||||||

|

Connector |

||||||||||

|

Throttle, |

||||||||||

|

Idle Up/Down, |

||||||||||

|

Pump PSI |

Injectors |

Main ECM |

Diagnostic |

Memory Clear |

Work Modes, |

|||||

|

Breaker Mode, |

||||||||||

|

Control Valve |

Power |

Switch X24 |

Switch X23 |

|||||||

|

Tach, |

||||||||||

|

(SCV) |

Relay |

|||||||||

|

(Instrumentation |

||||||||||

|

EGR DC |

Glow |

Data Link |

& Faults) |

|||||||

|

Motor |

Relay |

Diag Conn X4 |

||||||||

|

11 |

Isuzu 4HK-1 and 6HK-1 Engine Overview (continued)

Outputs from 40 pin engine harness connector: (continued)

•The injectors are controlled by the engine control module (ECM). The ECM sends a common power supply to injectors 1, 3 and 5. The ECM also sends a common power supply to injectors 2, 4 and 6. The ECM fires the injectors by controlling the ground of the individual injectors. The ECM calculates the basic injection amount and timing based on the signals from throttle position sensor, boost pressure sensor, crankshaft (CKP) sensor, camshaft (CMP) sensor, etc. The timing of the injection is controlled by when the injector activates. The fuel quantity delivered is based upon the amount of time that the injector is open and also the pressure supplied by the common rail. To improve combustion in cylinders, the system injects a little fuel (preinjection or pilot injection) and ignites it at the beginning of the cycle. A second injection (main injection) delivers the fuel required deliver the horsepower needed.

12

Isuzu 6HK1 Common Rail Engine Fuel System

|

Common |

Fuel Temp |

Coolant |

Intake Air |

Boost Temp |

Barometric |

ENG Oil |

Engine Stop |

|||

|

Rail Fuel PSI |

Sensor |

Temperature |

Temp. Sensor |

Sensor |

AMB PSI |

PSI |

Switch |

|||

|

Sensor |

Sensor |

Sensor |

Sensor |

|||||||

|

Crankshaft |

Camshaft |

Boost PSI |

||||||||

|

Position |

Position |

Sensor |

||||||||

|

Sensor |

Sensor |

EGR Position |

||||||||

|

Sensor |

Start Signal |

|||||||||

|

(Fuel Boost) |

||||||||||

|

Power Supply |

||||||||||

|

1 Ignition Wire |

||||||||||

|

2 Positive Wires |

||||||||||

|

Engine Harness 40 Pin |

Engine Harness 81 Pin |

6 Ground Wires |

||||||||

|

Connector A1 |

||||||||||

|

Connector A0 |

CAN Data Bus |

|||||||||

|

Engine Control Module |

||||||||||

|

Connector |

||||||||||

|

Throttle, |

||||||||||

|

Idle Up/Down, |

||||||||||

|

Pump PSI |

Injectors |

Main ECM |

Diagnostic |

Memory Clear |

Work Modes, |

|||||

|

Breaker Mode, |

||||||||||

|

Control Valve |

Power |

Switch X24 |

Switch X23 |

|||||||

|

Tach, |

||||||||||

|

(SCV) |

Relay |

|||||||||

|

(Instrumentation |

||||||||||

|

EGR DC |

Glow |

Data Link |

& Faults) |

|||||||

|

Motor |

Relay |

Diag Conn X4 |

||||||||

|

13 |

Isuzu 4HK-1 and 6HK-1 Engine Fuel Schematic Overview

Fuel System Hydraulic Function

Fuel comes from the tank and typically will go through a prefilter assembly. From the prefilter, the fuel then flows to an electric fuel pump, located in the hydraulic pump compartment. The 24 volt electric fuel pump is powered directly by the battery relay, through the 65 amp fuse (F23) and the 10 amp electrical fuel pump fuse (F8) in the fuse box. The electric fuel pump then sends the fuel through the fuel filter also located hydraulic pump compartment to the inlet port of the high pressure injection pump.

The high pressure injection pump is mounted at the left rear of the engine. This pump needs to be timed to the engine. To install the pump, bring the engine to TDC and then align the mark on the pump drive gear to the mark on the front face of the high pressure pump. Once these conditions are met, install the injection pump. The high pressure injection pump has a shaft driven gerotor feed (charge) pump which provides fuel to the pump pressure control valve (Suction Control Valve SCV). The gerotor pump outlet pressure is controlled by the regulation valve to provide a constant pressure at the inlet of the high pressure pumping pistons. The high pressurepump PSI regulator (SCV), located in the injection pump, controls the flow output of the high pressure pump. The high pressure pump supplies the quantity of fuel to the common rail required to maintain the pressure dictated by the engine control unit (ECM). This assures that only the required amount of fuel is pressurized, improving energy efficiency and limiting heating of fuel in the system. The common rail pressure will range from 3625 to 29,000 PSI (25 to 200 MPa). Excess flow from the feed pump and internal leakage from the injection pump returns to the tank. The fuel temperature sensor (FT) monitors the temperature of this fuel.

14

15

Introduction

Hitachi Construction Machinery Co., Ltd

This Manual describes the structure and the troubleshooting of electronic control fuel injection system (common rail type) in 4HK1 and 6HK1 industrial engines.Use this manual sufficiently to perform service work properly and quickly.

General Contents

Control System Electronic control fuel injection system (Common rail type)

Engine Manual (1/2)

Disassemble and Assemble Engine General Information

Engine Mechanical (4HK1、6HK1)

Cooling System

Fuel System

Engine Electrical

Exhaust System and Turbocharger

General Information

GENERAL INFORMATIONGeneral Information

ContentsGeneral Information . . . . . . . . . . . . . . . . . . . . . . . 0A-2

Service Precautions . . . . . . . . . . . . . . . . . . . . . . 0A-2Reading the model . . . . . . . . . . . . . . . . . . . . . . . 0A-6General information . . . . . . . . . . . . . . . . . . . . . . 0A-7

0A-2 General Information

General Information 0A-1

0A-2 General Information

General InformationService PrecautionsIn order to carry out work safely

1. Always use an engine stand when taking theengine down from the vehicle. Do not place the engine directly onto the ground,or place in a manner that interferes with the oilpan.

2. If you are working together with others, always payattention to each other’s safety.

3. If you are repairing any part of the electricalsystem, always remove the minus side cable fromthe battery terminal before starting work. If you areremoving the battery cover, always remove thecover in a place that is away from sources of fire/heat.

4. Do not perform painting work or leave the enginerunning for long periods of time in an enclosed orbadly ventilated indoor workshop.

5. Always use the correct specialized tool indicated inthe instructions. Using the incorrect tool maycause damage to the parts or injury to the personusing the tool.

6. All regular tools, gauges and special tools shouldbe regularly inspected, and prepared beforestarting work. Do not use bent spanners, hammerswith damaged edges, chipped chisels, or any otherfaulty or damaged tools.

7. Always pay close attention to safety and handlingrequirements when using grinders, cranes,welders, and other such equipment. Moreover, always wear the correct protectivegarments and use the necessary safety tools forthe job in hand.

WSHK0190

General Information 0A-3

8. Always check that there are no fuel leaks whenperforming maintenance work on the fuel system.(It may cause a fire.)

9. Pay close attention to the risk of ignition if you arehandling parts that carry a high voltage.Furthermore, any oil or grease spilt onto rubberparts must be wiped off immediately, as it willcause deterioration of the rubber.

Replacement parts and part numbers. 1. Always replace packing, oil seals, o-rings, caulking

lock nuts, folding lock plates, split pins and othersuch parts with brand new parts.

2. The parts numbers contained in this manual maynot represent the supply condition of the parts, andthe part numbers may be changed due torevisions. Therefore, parts should always bechecked against a parts catalogue before use.

Liquid gasket1. Each time you disassemble parts that use liquid

gasket, completely remove the old gasket residuefrom each of the parts and matching sections usinga scraper, then clean each of the parts tocompletely remove oil, water, and dirt etc. from thevarious surfaces. Using the specified type of liquidgasket, apply new liquid gasket to each of thesurfaces before reassembling the parts.

2. In order to make it easier to clean liquid gasketsurfaces, apply gasket remover liquid (Pando-391D made by Three Bond Co., Ltd.) and leavethe part to stand for approximately 10 minutes,after which the old liquid gasket residue will beeasier to remove.However, this should not be used on resincomponents or painted components.

3. Please take care not to apply too much or too littleliquid gasket. Also, you should always re-apply the liquid gasketupon itself when you start and finish application.

4. Make sure that there are no gaps when re-installing the liquid gasket parts to each other. Ifthere are gaps between the two parts, re-apply theliquid gasket. Some parts, especially the oil pan,use the same size studs as a guide to eliminate theneed for knock pin positioning etc.

5. Re-install these parts within 7 minutes of applyingthe liquid gasket.

WSHK0191 WSHK0192

0A-4 General Information

If more than 7 minutes passes, remove theprevious liquid gasket and re-apply it.

6. Please wait for at least 30 minutes since the lastpart is installed before starting the engine.

Liquid gasket

• Always use the liquid gasket products listed above,or a liquid gasket identical to the ones listed above.

• Use the correct quantity of liquid gasket. Alwaysfollow the handling instructions for each product.

Application procedure1. Wipe the contact surfaces clean of all water,

grease or oil. The contact surfaces should be dry. 2. Apply a regular bead width of liquid gasket to one

of the contact surfaces. Make sure that the beaddoes not break at this point.

Notes: If there are special regulations concerning theapplication procedure in the repair document, pleasefollow those regulations.

Work procedure1. Wipe the joint surfaces of the bolt, bolt hole, and

screw thread section clean of water, grease, andoil. The contact surfaces should be dry.

2. Apply Loctite to the top 1/3 of the screw. 3. Tighten the bolt to the correct tightening torque.

Important: After tightening the bolt, do not apply excessive torqueor try to rotate the bolt until at least one hour haspassed, and the Loctite has hardened.

Procedure for using the Plastigauge

Example: Procedure for measuring the clearancebetween the connecting rod bearing and crank pin.

• Clean the connecting rod and bearing, and installthe bearing to the rod.

• Cut the plastigauge to the same width as the crankpin, and while avoiding the oil pore of the crank pinlay the gauge parallel to the pin.

Seal section Product name Manufacturer’s name

Between cylinder block and – Flywheel housing 1207B Three Bond

Between cylinder block and – Flywheel housing and –Crankcase 1207B Three Bond

Between cylinder block and – Crank case 1207B Three Bond

Between cylinder block and – Front cover 1207B Three Bond

Cylinder block, head plug nipple, unit, switches 262 Loctite

Type Measurable range mm (in)

PG-1 (Green) 0.025 – 0.076 (0.001 – 0.003)

PR-1 (Red) 0.051 – 0.152 (0.002 – 0.006)

PB-1 (Blue) 0.102 – 0.229 (0.004 – 0.009)

General Information 0A-5

• Line up the marks on the connecting rod and capand install the crank pin, apply molybdenumdisulfide to the thread section and bearing surfaceof the fastening bolt, and rotate both cap and boltto the correct torque.

Important: Do not move the connecting rod while using theplastigauge.

• Gently remove the cap and connecting rod, andmeasure the crushed width of the plastigauge(clearance between rod and pin) using the scaleprinted on the bag.

Example: Measuring the clearance between the crankbearing and crank journal

• Clean the clamp face of the cylinder block andcrankcase bearing, and also the bearing, andinstall the cylinder block to the crankcase.

• Gently rest the crankshaft on the cylinder block,and rotate it approximately 30 degree to stabilize it.

• Cut the plastigauge to the same size as the journalwidth, and while avoiding the oil pore of the journallay the gauge parallel to the journal.

• Gently rest the crank case on the cylinder block,apply molybdenum disulfide to the thread sectionand bearing surface of the fastening bolt, andtighten in sequence to the correct torque.

Important: Do not rotate the crankshaft while using theplastigauge.

• Gently remove the crankcase, and measure thecrushed width of the plastigauge (clearancebetween bearing and journal) using the scaleprinted on the bag.

0A-6 General Information

Reading the modelEngine number stamping position4HK1

WSHK0185

General Information 0A-7

6HK1

General informationTerminology, description of abbreviations Terminology definitions

WSHK0186

Term Explanation

Maintenance standard The generic name for reference values required for maintenance, such as nominaldimension, selection of a reference point, and limit.

Nominal dimension Shows the standard value at the point of manufacture that does not include thecommon difference.

Selection of a reference point Shows the standard value after assembling, repairing, or adjusting.

Limit When this value (dimensions) is reached, it shows that the part has reached its fulllimit and must be replaced or repaired.

Front ⋅ rear, left ⋅ right, upper ⋅ lower

These show each orientations of parts installed to the vehicle when looking fromthe vehicle’s forward direction.

Unit Units written to SI conventions (mainly torque, pressure, force)[Example] Length: mm, Torque: N⋅m kgf⋅m

Warning Items that carry the warning mark pose a danger to life or threat of serious injury ifnot strictly observed.

Caution Items that carry the caution mark may cause injury or lead to accidents if not strictlyobserved.

Important Items that carry the important mark may cause the vehicle to break down, or mayprevent the guaranteed normal operation of the system or related parts if not strictlyobserved.

0A-8 General Information

Description of abbreviations

Notes Items that should receive special mention within a work procedure.

Term Explanation

Abbreviation Description

AC Alternating CurrentAlternating Current

ACC AccessoryAccessory

ACG Alternating Current GeneratorAlternating current generator

API American Petrol InstituteAmerican Petroleum Institute

ASM (Assy) AssemblyAssembly

ATDC After Top Dead CenterAfter Top Dead Center

BAT, BATT BatteryBattery

BRG, Brg BearingBearing

BKT, BRKT BracketBracket

BTDC Before Top Dead CenterBefore Top Dead Center

CO Carbon OxideCarbon Monoxide

CONN ConnectorConnector

CPU Central Processing UnitCentral processing unit

C/U Control UnitControl unit

DC Direct CurrentDirect current

DI Direct InjectionDirect injection

ECU Engine Control Unit / Electronic ControlUnitEngine control unit / control unit

ECM Engine Control ModuleEngine control module

EGR Exhaust Gas RecirculationExhaust gas recirculation

Exh, EXH ExhaustExhaust

Ft, FRT FrontFront

FWD ForwardForward

F/C Fuel CutFuel Cut

GND GroundEarth

IC Integrated CircuitIntegrated circuit

ID Plate Identification plateIdentification plate, ID plate

IN Intake, IntakeIntake

ISO International Organization forStandardizationInternational Organization forStandardization

I/PUMP Injection PumpInjection Pump

JIS Japanese Industrial StandardJapanese Industrial Standard

L/H, LH Left HandLeft hand side

M/V Magnetic ValveMagnetic valve

NOx Nitrogen OxideNitrogen Oxide

N-TDC Number — Top Dead CenterTop dead center rotational frequency

OPT OptionOption

P Pole(S)Pole

PCV Pump Control Valve/ PositiveCrankcase VentilationPump control valve/ Positive crankcaseventilation

PM Particulate MatterParticulate matter

PS Pre-StrokePre-stroke

PTO Power Take OffPower take off

QOS Quick On SystemRapid preheating system

Rr, RR RearRear

Abbreviation Description

General Information 0A-9

SI (International System of Units)With regards the conversion to SI (InternationalSystem of Units)The introduction of the SI systems aims tointernationally unify the metric system and the variousunits used by different countries (traditional weightsand measures, the foot pound method etc.), and tocurb the confusion that occurs between the differentunits (conversion calculations etc.). The new calculating method which adopted SI unitswas completely adopted in Japan in 1992, and isstandardized by JIS-Z-8203. All of the units in this manual are written in line with theInternational System of Units SI units, and conventionalunits are written in brackets.

SIFrench) Abbreviated name of Le Systeme Internationald’Unites

Connection between main SI units and conventional units

*1 Published service data may conveniently use kg forforce and mass (weight) instead of kgf. *2 Some conversion results may be rounded off to 1 or2 decimal places. Converting expressions of quantityWhen converting, prefixes such as k (kilo) or m (mili)are used.

• 200 kgf/cm2 = 19,620 kPa = 19.6 MPa• 40 mmHg = 5,332 Pa = 5.3 kPa

Conversion formulaLength

• km × 0.6214 = mile• m × 3.281 = ft• mm × 0.03937 = in

Pressure• kPa × 0.0101972 = kg/cm2

• kPa × 0.145038 = psi• MPa × 10.197162 = kg/cm2

• MPa × 145.03774 = psiTightening torque

• N⋅m × 0.101972 = kg⋅m• N⋅m × 0.737562 = lb ft

Speed• kg/h × 0.6214 = MPH

Temperature• °C × 1.8 + 32 = °F

R/H, RH Right HandRight hand side

R/L RelayRelay

STD StandardStandard

SW SwitchSwitch

TICS Timing & Injection rate Control SystemA type of injection system

VGS Turbo Variable Geometry turbochargerSystemAdjustable turbo, VGS turbo

W/L Warning LampWarning lamp

Abbreviation Description

SI Conventional Unit Item, unit conversion

Length m m Same as the conventional unit

Weight (Mass) kg kg Same as the conventional unit

Force N * kg, kgf 1 kgf = 9.80665 N

Torque N⋅m * kg⋅m, gf⋅m 1 kgf⋅m = 9.80665 N⋅m

Pressure Pa *kg/cm2, mmHg 1 kgf/cm2 = 9.80665 kPa, 1 mmHg = 133.3 Pa

Dynamic force, horsepower W PS 1 PS = 0.74 kW

Capacity, air volume displacement m3 Litle, L, cc 1 Litle = 1 dm3, 1 cc = 1mLitle = 1cm3

Fuel consumption g/(kW⋅h) g/(PS⋅h) 1 g/(PS⋅h) = 1.360 g/(kW⋅h)

M Mega 106 1,000,000

k Kilo 103 1,000

h Hecto 102 100

d Deci 10-1 0.1

c Centi 10-2 0.01

m Milli 10-3 0.001

µ Micro 10-6 0.000001

0A-10 General Information

Table of tightening torqueThe tightening torque values in the table below apply toall situations unless a special tightening torque isspecified. bolts, nuts

The * mark indicates where soft materials have been used for internal thread sections, such as castings.

N⋅m kgf⋅m

Strengthclassification

4.84T 7T

Bolt headsection shape Hexagon head bolt Flange bolt Hexagon head bolt Flange bolt

* M10 × 1.5 19.6 ~ 33.3 2.0 ~ 3.4 22.3 ~ 37.2 2.3 ~ 3.8 27.5 ~ 45.1 2.8 ~ 4.6 30.3 ~ 50.4 3.1 ~ 5.1

M12 × 1.25 49.0 ~ 73.5 5.0 ~ 7.5 54.9 ~ 82.3 5.6 ~ 8.4 60.8 ~ 91.2 6.2 ~ 9.3 68.1 ~ 102.1 6.9 ~ 10.4

* M12 × 1.75 45.1 ~ 68.6 4.6 ~ 7.0 51.0 ~ 76.5 5.2 ~ 7.8 56.9 ~ 84.3 5.8 ~ 8.6 62.7 ~ 94.0 6.4 ~ 9.6

M14 × 1.5 76.5 ~ 114.7 7.8 ~ 11.7

83.0 ~ 124.5 8.5 ~ 12.7

93.2 ~ 139.3 9.5 ~ 14.2

100.8 ~ 151.1 10.3 ~ 15.4

* M14 × 2 71.6 ~ 106.9 7.3 ~ 10.9

77.2 ~ 115.8 7.9 ~ 11.8

88.3 ~ 131.4 9.0 ~ 13.4

94.9 ~ 142.3 9.7 ~ 14.5

M16 × 1.5 104.0 ~ 157.0 10.6 ~ 16.0

115.6 ~ 173.3 11.8 ~ 17.7

135.3 ~ 204.0 13.8 ~ 20.8

150.1 ~ 225.2 15.3 ~ 23.0

* M16 × 2 100.0 ~ 149.1 10.2 ~ 15.2

109.4 ~ 164.2 11.2 ~ 16.7

129.4 ~ 194.2 13.2 ~ 19.8

142.5 ~ 213.8 14.5 ~ 21.8

M18 × 1.5 151.0 ~ 225.6 15.4 ~ 23.0 — 195.2 ~ 293.2 19.9 ~

29.9 —

* M18 × 2.5 151.0 ~ 225.6 15.4 ~ 23.0 — 196.1 ~ 294.2 20.0 ~

30.0 —

M20 × 1.5 206.0 – 310.0 21.0 ~ 31.6 — 269.7 ~ 405.0 27.5 ~

41.3 —

* M20 × 2.5 190.2 ~ 286.4 19.4 – 29.2 — 249.1 ~ 374.6 25.4 ~

38.2 —

M22 × 1.5 251.1 – 413.8 25.6 ~ 42.2 — 362.8 ~ 544.3 37.0 ~

55.5 —

* M22 × 2.5 217.7 ~ 327.5 22.2 ~ 33.4 — 338.3 ~ 507.0 34.5 ~

51.7 —

M24 × 2 358.9 ~ 539.4 36.6 ~ 55.0 — 430.5 ~ 711.0 43.9 ~

72.5 —

* M24 × 3 338.3 ~ 507.0 34.5 ~ 51.7 — 406.0 ~ 608.0 41.4 ~

62.0 —

General Information 0A-11

The * mark indicates where soft materials have been used for internal thread sections, such as castings.

N⋅m kgf⋅m

Strength classification 8.8 9.89T

Bolt head sectionshape Hexagon head bolt Flange bolt Hexagon head bolt Flange bolt

M6 × 1 5.6 ~ 11.2 0.6 ~ 1.1

6.6 ~ 12.2 0.6 ~ 1.2 — —

M8 × 1.25 13.4 ~ 25.7 1.4 ~ 2.6

15.3 ~ 28.4 1.6 ~ 2.9

16.7 ~ 30.4 1.7 ~ 3.1

18.1 ~ 33.6 1.9 ~ 3.4

M10 × 1.25 31.3 ~ 52.5 3.2 ~ 5.4

35.4 ~ 58.9 3.6 ~ 6.1

37.3 ~ 62.8 3.8 ~ 6.4

42.3 ~ 70.5 4.3 ~ 7.2

* M10 × 1.5 31.3 ~ 51.4 3.2 ~ 5.2

34.5 ~ 57.5 3.5 ~ 5.8

36.3 ~ 59.8 3.7 ~ 6.1

40.1 ~ 66.9 4.1 ~ 6.8

M12 × 1.25 69.3 ~ 104.0 7.1 ~ 10.6

77.7 ~ 116.5 7.9 ~ 11.9

75.5 ~ 113.8 7.7 ~ 11.6

85.0 ~ 127.5 8.7 ~ 13.0

* M12 × 1.75 64.8 ~ 96.1 6.6 ~ 9.8

71.4 ~ 107.2 7.3 ~ 10.9

71.6 ~ 106.9 7.3 ~ 10.9

79.5 ~ 119.2 8.1 ~ 12.2

M14 × 1.5 106.2 ~ 158.8 10.8 ~ 16.2

114.9 ~ 172.3 11.7 ~ 17.6

113.8 ~ 170.6 11.6 ~ 17.4

123.4 ~ 185.1 12.6 ~ 18.9

* M14 × 2 100.6 ~ 149.8 10.3 ~ 15.3

108.2 ~ 162.2 11.1 ~ 16.6

106.9 ~ 160.0 10.9 ~ 16.3

115.5 ~ 173.3 11.8 ~ 17.7

M16 × 1.5 154.3 ~ 232.5 15.7 ~ 23.7

171.1 ~ 256.7 17.4 ~ 26.2

160.0 ~ 240.3 16.3 ~ 24.5

176.9 ~ 265.3 18.0 ~ 27.1

* M16 × 2 147.6 ~ 221.4 15.0 ~ 22.6

162.5 ~ 243.8 16.6 ~ 24.9

153.0 ~ 229.5 15.6 ~ 23.4

168.5 ~ 252.7 17.2 ~ 25.8

M18 × 1.5 222.5 ~ 334.3 22.7 ~ 34.1 — 229.5 ~ 345.2 23.4

~ 35.2 —

* M18 × 2.5 223.6 ~ 335.4 22.8 ~ 34.2 — 230.5 ~ 346.2 23.6

~ 35.3 —

M20 × 1.5 307.4 ~ 461.7 31.4 ~ 47.1 — 316.8 ~ 475.6 32.3

~ 48.5 —

* M20 × 2.5 284.0 ~ 472.1 29.0 ~ 43.5 — 293.2 ~ 440.3 29.2

~ 44.9 —

M22 × 1.5 413.6 ~ 620.5 42.2 ~ 63.3 — 424.6 ~ 636.5 43.3

~ 64.9 —

* M22 × 2.5 385.7 ~ 578.0 39.3 ~ 58.9 — 394.2 ~ 592.3 40.0

~ 60.4 —

M24 × 2 490.8 ~ 810.5 50.0 ~ 82.7 — 554.1 ~ 830.6 56.5

~ 84.7 —

* M24 × 3 462.8 ~ 693.1 47.2 ~ 70.7 — 520.7 ~ 781.6 53.1

~ 79.7 —

0A-12 General Information

Designations for bolt heads

Legend1. Hexagon head bolt(4.8, 4T)2. Hexagon head bolt(4.8, 4T)3. Flange bolt(4.8, 4T)4. Flange bolt(4.8, 4T)5. Hexagon head bolt(7T)6. Flange bolt(7T)7. Hexagon head bolt (refined 8.8)8. Hexagon head bolt (refined 8.8)

9. Hexagon head bolt(Un-refined 8.8)10. Hexagon head bolt(Un-refined 8.8)11. Flange bolt(8.8)12. Flange bolt(8.8)13. Hexagon head bolt(9.8, 9T)14. Hexagon head bolt(9.8, 9T)15. Flange bolt(9.8, 9T)16. Flange bolt(9.8, 9T)

Flare nut

Pipe diameter tightening torque(for medium and large

size vehicles)

Flare nut 2 side width (mm)

Old New

Flare nut tightening torque (service standard value) N⋅m kgf⋅m

φ4.76 mm 12.8 ~ 18.6 1.3 ~ 1.9 14 14

φ6.35 mm 23.5 ~ 49 2.4 ~ 5.0 17 17

φ8.0 mm 23.5 ~ 49 2.4 ~ 5.0 19 17

φ10.0 mm 44.1 ~ 93.2 4.5 ~ 9.5 22 19

φ12.0 mm 58.8 ~ 137.3 6.0 ~ 14.0 27 24

φ15.0 mm 78.5 ~ 156.9 8.0 ~ 16.0 30 30

General Information 0A-13

Taper screw from connectors (brass)

Special Tool Classification

A; Essential toolServicing operation cannot be done with any other tools than the essential tool.

B; Recommended toolServicing work can be done with a general-purpose tool commercially available.However, it is advisable to use the recommended tool as much as possible for a reduced work time and an improvedsafety in work operations.

C; Available tool Although it takes a more working time, servicing operations can be made with a tool commercially available assubstitute for the available tool.

N⋅m kgf⋅m

Screw size PT(R) 1/8 PT(R) 1/4 PT(R) 3/8 PT(R) 1/12

— 2.0 ~ 14.7(0.2 ~ 1.5)

4.9 ~ 15.7(0.5 ~ 1.6)

9.8 ~ 16.7(1.0 ~ 1.7)

9.8 ~ 17.7(1.0 ~ 1.8)

0A-14 General Information

ENGINE MECHANICAL (4HK1, 6HK1)

ENGINEENGINE MECHANICAL (4HK1, 6HK1)

TABLE OF CONTENTSDIESEL ENGINE (4HK1, 6HK1) . . . . . . . . . . . . . . 1A-3

Precautions on Service Work. . . . . . . . . . . . . . . 1A-3Main Data and Specifications. . . . . . . . . . . . . . 1A-11

Cylinder Head Cover. . . . . . . . . . . . . . . . . . . . . . 1A-14Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-14Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-15Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-16Torque Specifications . . . . . . . . . . . . . . . . . . . . 1A-18

Inlet Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-20Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-20Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-21Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-22Torque Specifications . . . . . . . . . . . . . . . . . . . . 1A-24

Turbocharger and Exhaust Manifold . . . . . . . . . . 1A-25Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-25Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-26Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-27Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-28Torque Specifications . . . . . . . . . . . . . . . . . . . . 1A-31

Timing Gear Train . . . . . . . . . . . . . . . . . . . . . . . . 1A-34Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-34Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-35Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-37Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-39Torque Specifications . . . . . . . . . . . . . . . . . . . . 1A-50Special Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-51

Rocker Arm Shaft ASM . . . . . . . . . . . . . . . . . . . . 1A-52Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-52Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-52Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-53Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-55Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-56Torque Specifications . . . . . . . . . . . . . . . . . . . . 1A-58

Camshaft ASM . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-59Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-59Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-60Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-61Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-63Fixing torque . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-65Special Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-65Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-66Torque Specifications . . . . . . . . . . . . . . . . . . . . 1A-68