- Manuals

- Brands

- SDLG Manuals

- Engine

- WP6

- Service manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Service Manual for WP6 Mechanical Pump Series Engine

Service Manual for WP6 Diesel Engine

Summary of Contents for SDLG WP6

-

Page 1

Service Manual for WP6 Mechanical Pump Series Engine Service Manual for WP6 Diesel Engine… -

Page 3

Service Manual for WP6 Diesel Engine Special Tips Operators must carefully read Diesel Engine Instruction Manual, all technical operations and maintenance regulations specified in the manual must be strictly complied with, and also pay attention to warning instructions and labels;… -

Page 4

WP6 engine, we provide you this service manual. This manual briefly introduced the technical parameters, structural features, operation and maintenance methods, and overhaul tips of WP6 mechanical pump series diesel engine, for users to refer to; provided service technologies of diesel engine to help serviceman profoundly understand disassembly and assembly methods of the engine, also laid a solid technical foundation for serviceman to do troubleshooting. -

Page 5: Table Of Contents

Service Manual for WP6 Diesel Engine CONTENTS Usage Instructions for Diesel Engine …………..1 11 External View of Diesel Engine …………….1 12 Diesel Engine Model Composition and Significance ……….3 13 Diesel Engine Main Technical Parameters …………4 14 Unseal of Diesel engine ………………5 15 Lifting of Diesel Engine ………………

-

Page 6

Service Manual for WP6 Diesel Engine Disassembly & Assembly of Diesel Engine …………22 31 Overview ………………….. 22 311 Danger Signs ………………..22 312 Safety Signs ………………..23 313 Recommended Tools ………………24 314 Notes for Health Protection …………….24 315 Environmental Protection Measures …………. -

Page 7

Service Manual for WP6 Diesel Engine 344 Disassembly, Inspection, Maintenance and Assembly of Flywheel and Ring Gear………………….. 61 345 Disassembly, Inspection, Maintenance and Assembly of Torque Vibration Damper, Crankshaft Pulley and Hub …………62 346 Disassembly, Inspection, Maintenance and Assembly of Crankshaft Bearing Shell …………………. -

Page 8

Service Manual for WP6 Diesel Engine 392 Disassembly, Inspection, Maintenance and Assembly of Engine Oil Pump ……………………90 393 Disassembly, Inspection, Maintenance and Assembly of Engine Oil Filter ……………………91 394 Disassembly, Inspection, Maintenance and Assembly of Engine Oil Cooler .. -

Page 11: Usage Instructions For Diesel Engine

Service Manual for WP6 Diesel Engine 1 Usage Instructions for Diesel Engine 11 External View of Diesel Engine Fig. 1-1 WP6 mechanical pump series diesel engine (View 1)

-

Page 12

Service Manual for WP6 Diesel Engine Fig. 1-2 WP6 mechanical pump series diesel engine (View 2) -

Page 13: Diesel Engine Model Composition And Significance

Service Manual for WP6 Diesel Engine Fig. 1-3 WP6 mechanical pump series diesel engine (View 3) 12 Diesel Engine Model Composition and Significance WP6 G XXX E2 XX Variant code Emission standard Power code Use code Product series code Fig. 1-4 Diesel Engine Model Composition and Significance…

-

Page 14: Diesel Engine Main Technical Parameters

Service Manual for WP6 Diesel Engine 13 Diesel Engine Main Technical Parameters Table 1-1 Main Technical Parameters of first-generation WP6 mechanical pump series diesel engine Items Unit Type WP6 mechanical pump series diesel engine Engine model 4-stroke, water-cooling, in-line, direct injection, —…

-

Page 15: Unseal Of Diesel Engine

Service Manual for WP6 Diesel Engine 14 Unseal of Diesel engine After opened the engine packing container, the user should firstly check the engine and its accessories according to the packing list, check whether engine appearance is damaged and whether connections are loose, and then perform the following work: (1) Wipe up the antirust coat and anticorrosive agent on exposed surface of the engine.

-

Page 16: Lifting Of Diesel Engine

Service Manual for WP6 Diesel Engine 15 Lifting of Diesel Engine Keep the center line of engine crankshaft horizontal during lifting, tilting or unilateral lifting is strictly forbidden. Keep the lifting-up and putting-down process slowly, incorrect lifting may damage the engine.

-

Page 17: Preparation Before Starting Engine

Service Manual for WP6 Diesel Engine 17 Preparation before Starting Engine (1) Check coolant level If the engine is already installed on a vehicle or platform, you can check the coolant level through the glass window on expansion water tank at any time, if the coolant is insufficient, open the filler cap to add coolant.

-

Page 18: Run The Engine

Service Manual for WP6 Diesel Engine 19 Run the Engine After the engine is started, firstly let it run idly for 2~3min, engine oil pressure should higher than 120kPa. Do not suddenly run the engine in heavy load and high speed if coolant temperature is lower than 60 C, otherwise it may affect abrasion resistance and reliability of the engine.

-

Page 19

Service Manual for WP6 Diesel Engine different proportion based on ambient temperature. (4) Starting: Use starting aid to start the engine in winter. Load and speed up the engine only after oil pressure and water temperature get normal. (5) Storage battery: Be sure to check electrolyte level, viscosity and unit voltage before winter comes. -

Page 20: Maintenance Guidelines For Diesel Engine

Service Manual for WP6 Diesel Engine 2 Maintenance Guidelines for Diesel Engine 21 Fuel Oil, Engine oil, Coolant and Auxiliary Materials 211 Fuel Oil Summer: 0# diesel fuel (GB252) Winter: -10# diesel fuel is generally used, choose -20# diesel fuel if ambient temperature lower than C, and choose -35# diesel fuel if ambient temperature lower than -30 The chosen fuel should meet requirements in appendix C.6 of GB17691-2005 (Revised in June…

-

Page 21: Lubrication Of Tensioning Wheel

Service Manual for WP6 Diesel Engine 213 Lubrication of Tensioning Wheel Apply general purpose lithium lubricating grease for lubrication of tensioning wheel (refer to GB/T5671-1995) 214 Antifreeze Additive in Engine Cooling System The adopted antifreeze additive is ethylene glycol, and it is allowed to replace it with domestic long-acting antifreeze additive with reliable quality, refer to related description for specific application method.

-

Page 22: Auxiliary Materials

Service Manual for WP6 Diesel Engine We can get that required antifreeze additive for -20 C is 13.5L Difference value between -30 C and -20 C is 4L For the difference value 4L, another 50% of that is required and necessary, because of before adding antifreeze additive, a part of coolant must be drained out, and antifreeze additive in this part of coolant will be drained out too.

-

Page 23: Daily Maintenance

Service Manual for WP6 Diesel Engine Used for the seal Loctite 277 between core and Other bowl type plugs hole Used to seal top end Pushrod bush Loctite 270 face of cylinder Cylinder cover cover Fitting surface between cylinder block and…

-

Page 24: Check Engine Oil Level

Service Manual for WP6 Diesel Engine Expansion water tank Fig. 2-4 Expansion water tank NOTICE: Coolant level must be checked before starting the engine every time. 222 Check Engine Oil Level Check whether engine oil level is between the bottom scale and top scale on oil dipstick. Under no circumstances should the engine be started if the oil level is lower than the bottom scale or higher than the top scale.

-

Page 25: Check Fuel Level

Service Manual for WP6 Diesel Engine 223 Check Fuel Level Check fuel level gauge on instrument panel and add fuel timely. The fuel in use should meet the specifications. Pay attention to cleanliness of fuel and it is recommended that fuel should be subsided for more than 72 hours before adding.

-

Page 26: Check Whether Running Sound Is Normal

Service Manual for WP6 Diesel Engine Fig. 2-7 Check exhaust gas 228 Check Whether Running Sound is Normal 229 Check Whether Rotating Speed and Vibration are Normal 23 Periodic Maintenance Replace engine oil Set the engine horizontal and put a container under the engine to recycle engine oil, screw off oil drain plug 2 on the bottom of oil sump to drain all engine oil out and then screw on the plug;…

-

Page 27

Service Manual for WP6 Diesel Engine Replace engine oil filter and filter element Follow the steps below to replace engine oil filter: (1) Screw off the old engine oil filter with a dedicated wrench; (2) Fill up the new filter with engine oil;… -

Page 28

(3) Measure the clearance between rocker and valve rod head with feeler gauge 1. Required intake valve clearance for WP6 mechanical pump diesel engine is 0.2mm; while that for exhaust valve is 0.3mm. If the clearance is too large or too small, you can loosen locking nut 2, and then turn adjusting screw 3 to change the clearance. -

Page 29: Replace Fuel Filter Element

Service Manual for WP6 Diesel Engine Table 2-6 Cylinder 1 Cylinder 2 Cylinder 3 Cylinder 4 Cylinder 5 Cylinder 5 Intake and Cylinder 1 in Intake Exhaust Intake Exhaust Cannot be exhaust compression stroke valve valve valve valve adjusted valve…

-

Page 30

Service Manual for WP6 Diesel Engine Fasten or replace some parts when necessary, in order to ensure good sealing performance of intake system. Check air filter element Maximum allowed intake resistance for the engine is 6kPa, maximum intake resistance must be… -

Page 31: Maintenance For Long-Term Storage

Service Manual for WP6 Diesel Engine 24 Maintenance for Long-Term Storage 241 Cleaning Before putting the engine in storage, all rusty areas must be removed in a proper way, and all parts that have been processed with protective agent (lubricant circuit, fuel system, turbocharger etc.) must be cleaned thoroughly.

-

Page 32: Disassembly & Assembly Of Diesel Engine

Service Manual for WP6 Diesel Engine 3 Disassembly & Assembly of Diesel Engine 31 Overview Please comply with instructions in this manual strictly to disassemble and assemble the engine and pay special attention to operations which danger signs and safety signs are involved in this manual, in order to ensure personal safety and avoid accidents.

-

Page 33: Safety Signs

Service Manual for WP6 Diesel Engine This manual provides all kind of notes and warning information to help the user correctly operate and safely use our engine. However, simply read these notes are not enough to avoid all kinds of potential danger, the user should correctly understand them. Safety information described in this manual cannot include all of the safety precautions, if the procedures or actions that are not recommended in this manual are used, you must ensure the safety of the operator and machine.

-

Page 34: Recommended Tools

Service Manual for WP6 Diesel Engine 313 Recommended Tools Signs Information 2.5mm hexagon wrench 5mm hexagon wrench 8mm socket Slotted screw driver Dedicated tool 10mm slotted hexagon wrench If the methods or tools that are not recommended in this manual are used, you must ensure safety to avoid life risk to yourself or other people, in the meantime make sure the operating, maintenance and repair methods wouldn’t bring damage to the engine or potential safety hazard.

-

Page 35: Environmental Protection Measures

Any violation of instructions in this manual may result in serious accident, even death. SDLG cannot foresee all potential danger. Similarly, the rules and instructions in this manual cannot cover everything.

-

Page 36: Cylinder Cover Assembly

Service Manual for WP6 Diesel Engine 32 Cylinder Cover Assembly 321 Disassembly and Assembly of Cylinder Cover Assembly 3211 Exploded View of Cylinder Cover Assembly Cylinder Connecting cover shield Thermostat bolt Lifting eye bolt Water Intake pipe outlet pipe Turbocharger…

-

Page 37

Service Manual for WP6 Diesel Engine (5) Remove exhaust pipe, refer to disassembly of air intake and exhaust system for details; (6) Remove intake pipe, refer to disassembly of air intake and exhaust system for details; (7) Remove cylinder cover shields and its gaskets;… -

Page 38: Disassembly, Inspection, Maintenance And Assembly Of Cylinder Cover Shield

Service Manual for WP6 Diesel Engine 322 Disassembly, Inspection, Maintenance and Assembly of Cylinder Cover Shield 3221 Exploded View of Cylinder Cover Shield Cylinder cover shield bolt Cmpound gasket Cylinder cover shield Cylinder cover shield gasket Fig. 3-2 Exploded view of cylinder cover shield 3222 Steps to Disassemble Cylinder Cover Shield (1) Screw off cylinder cover shield bolts orderly;…

-

Page 39

Service Manual for WP6 Diesel Engine gaskets should be replaced; (3) Cylinder cover shield gaskets are disposable, and should be replaced during maintenance. 3224 Steps to Assemble Cylinder Cover Shield (1) Check whether there is manufacturing defect, usage defect or damage on cylinder cover shield gaskets and cylinder cover before assembling;… -

Page 40: Disassembly, Inspection, Maintenance And Assembly Of Cylinder Cover

Service Manual for WP6 Diesel Engine 323 Disassembly, Inspection, Maintenance and Assembly of Cylinder Cover 3231 Exploded View of Cylinder Cover Cylinder cover shield Cylinder cover shield gasket Rocker seat module Pipe joint module Cylinder cover bolt Cylinder cover Bowl shape plug…

-

Page 41

Service Manual for WP6 Diesel Engine prevent the cover crashing the injectors during removal), do not waggle the cover during removal, otherwise remnant coolant may outflow. If cylinder cover gasket is attached on the removed cylinder cover, take it down and put it back on engine block;… -

Page 42

Service Manual for WP6 Diesel Engine Reference table for valve recession requirements: Required value of valve recession (mm) Intake valve 1.0~1.45 Exhaust valve 1.0~1.45 If valve recession exceeds allowed range, the cylinder cover must be replaced to ensure reliability of diesel engine. If valve recession doesn’t exceed allowed range, disassemble the valve to check the sealing surface between valve and valve seat for obvious wear and abnormal damage. -

Page 43

Service Manual for WP6 Diesel Engine 120° ± 4° , and 120° ± 4° again. (6) Refer to Fig. 3-6 for pre-tightening and tightening order. Fig. 3-6 cylinder cover bolts tightening order… -

Page 44: Disassembly, Inspection, Maintenance And Assembly Of Water Outlet Pipe

Service Manual for WP6 Diesel Engine 324 Disassembly, Inspection, Maintenance and Assembly of Water Outlet Pipe 3241 Exploded View of Cylinder Cover Thermostat Cooling water Pipe joint Minor cycle rubber hose pipe module fitting Pipe adapter (outlet) (hose) water pump assembly…

-

Page 45

WP6 engine water outlet pipe is of integral-type welded structure, the whole pipe should be replaced even if only one pipe joint is damaged or leaking. -

Page 46: Disassembly, Inspection, Maintenance And Assembly Of Oil-Gas Separator

Service Manual for WP6 Diesel Engine 325 Disassembly, Inspection, Maintenance and Assembly of Oil-Gas Separator 3251 Exploded View of Oil-Gas Separator Support Oil connecting hose Clamp Oil-gas separator module Spring Hose Hose clamp Breather O-shape Sealing Hexagon seal ring gasket bolt Fig.

-

Page 47: Disassembly, Inspection, Maintenance And Assembly Of Lifting Eyes

Service Manual for WP6 Diesel Engine (3) Check whether there is oil leakage trace on each joint, tighten the joint if so. 3254 Steps to Assemble Oil-Gas Separator Assembling steps are contrary to disassembling ones. 326 Disassembly, Inspection, Maintenance and Assembly of Lifting Eyes…

-

Page 48

Service Manual for WP6 Diesel Engine 3262 Steps to Disassemble Lifting Eye After removing parts that used to cover lifting eye screw, screw off the screw. 3263 Inspection and Maintenance of Lifting Eye Check whether there is crack on lifting eye screw and the threaded hole, replace the cracked parts. -

Page 49: Engine Block Assembly

Service Manual for WP6 Diesel Engine 33 Engine Block Assembly 331 Disassembly, Inspection, Maintenance and Assembly of Engine Block Assembly 3311 Exploded View of Engine Block Assembly Fig. 3-10 Exploded view of engine block assembly…

-

Page 50

Service Manual for WP6 Diesel Engine Name Name Name Combination seal Engine block module Stud gasket Cylinder sleeve Cap shape nut Flat gasket O-shape seal ring Dead plate 2-type hexagon nut O-shape seal ring Welded elbow Cylinder cover bolt Plug… -

Page 51

Service Manual for WP6 Diesel Engine 3313 Inspection and Maintenance of Engine Block Assembly Key point 1: Assembling: Apply lubricating oil on bearing surface and thread of cylinder cover bolts, and then tighten them according to following instructions: (1) Tighten the four bolts of each cylinder cover with four-axis tightening machine, follow the… -

Page 52

Service Manual for WP6 Diesel Engine to the corresponding hole on engine block, fix it on the block with dead plate, inside hexagonal bolts and spring washers. Key point 3: Inspection: (1) Measure the protrusion of cylinder sleeve (0.05mm~0.10mm is qualified). -

Page 53: Disassembly, Inspection, Maintenance And Assembly Of Engine Block Module

Service Manual for WP6 Diesel Engine 332 Disassembly, Inspection, Maintenance and Assembly of Engine Block Module 3321 Exploded View of Engine Block Module Engine block Thrust bearing cap Main bearing cap Main bearing bolt Main bearing bolt Fig. 3-12 Exploded view of engine block module 3322 Steps to Disassemble Engine Block Module (1) Remove main bearing bolts (key pint 1);…

-

Page 54

Service Manual for WP6 Diesel Engine Assembling: For 6-cylinder engine, 14 M14-10.9 main bearing bolts are used to fix the bearings. As shown in Fig 3-13, start with middle bearings, do the tightening work from middle to two ends evenly, follow the procedures below: Firstly pre-tighten each bolt to 70Nm, and tighten the bolts for further 90°… -

Page 55: Disassembly, Inspection, Maintenance And Assembly Of Engine

Service Manual for WP6 Diesel Engine 333 Disassembly, Inspection, Maintenance and Assembly of Engine Front Cover 3331 Exploded View of Engine Front Cover Plug O-shape seal ring Engine front cover Hexagon bolt Breather Hexagon bolt Hexagon bolt Radial seal ring (front oil seal)

-

Page 56

Service Manual for WP6 Diesel Engine Assembling: (1) Knock-in locating pins, as shown in Fig. 3-15; Fig. 3-15 Knock-in locating pins (2) Apply sealant on the fitting surface of engine front cover, make sure the sealant is evenly distributed and no discontinuity. -

Page 57

Service Manual for WP6 Diesel Engine Fig. 3-18 Bolt tightening Notes: Set pneumatic impact wrench to gear II for M8 bolts, and gear III for M10 bolts. Tightening order: 3-7-10-18, follow the sequence of arrows to tighten other bolts. A copper gasket should be assembled together with bolt 5, pre-tighten it with pneumatic impact wrench firstly and use 13# open-end wrench for final tightening. -

Page 58: Disassembly, Inspection, Maintenance And Assembly Of Flywheel Housing

Service Manual for WP6 Diesel Engine 334 Disassembly, Inspection, Maintenance and Assembly of Flywheel Housing 3341 Exploded View of Flywheel Housing Hexagon bolt Spring washer Monitoring Sealing gasket window cap Hexagon plug Hexagon bolt Radial seal ring Flywheel housing Fig. 3-19 Exploded view of flywheel housing 3342 Steps to Disassemble Flywheel Housing (1) Remove fixing bolts of flywheel housing (key point 1);…

-

Page 59

Service Manual for WP6 Diesel Engine Step 1: Preassemble the bolts Step 2: Follow the sequence of arrow to tighten the M10 bolts, tighten torque for M10 bolts is 80~85Nm. And then tighten the M12 bolts according to the marked order 1-2-3-4-5-6, tighten torque for M12 bolts is 140~145Nm. -

Page 60: Disassembly, Inspection, Maintenance And Assembly Of Oil Sump

Service Manual for WP6 Diesel Engine 335 Disassembly, Inspection, Maintenance and Assembly of Oil Sump 3351 Exploded View of Oil Sump Hexagon bolt Oil sump sealing gasket Gasket Oil sump Screw seat Combination gasket Magnetic screw plug assembly Fig. 3-21 Exploded view of oil sump 3352 Steps to Disassemble Oil Sump (1) Turn over the engine to keep oil sump upward (key point 1);…

-

Page 61: Disassembly, Inspection, Maintenance And Assembly Of Piston Nozzle

Service Manual for WP6 Diesel Engine Key point 2: Assembling: (1) Apply sealant on fitting surface of engine block and partially apply sealant on oil sump, place sealing gasket on the fitting surface. (2) Lift and place oil sump, be careful and avoid crashing the fitting surface.

-

Page 62: Disassembly, Inspection, Maintenance And Assembly Of Thrust Plates

Service Manual for WP6 Diesel Engine 3362 Steps to Disassemble Piston Nozzle (1) Remove the hexagon bolt (key point 1); (2) Remove nozzle module (key point 2). 3363 Inspection and Maintenance of Piston Nozzle Key point 1: Assembling: (1) Compress nozzle module tightly with bolt (with spring washer) and pressing plate;…

-

Page 63: Disassembly, Inspection, Maintenance And Assembly Of Front And Rear Oil Seals

Service Manual for WP6 Diesel Engine 3372 Steps to Disassemble Thrust Plates (1) Remove main bearing cap (refer to section 332); (2) Remove crankshaft (refer to section 344); (3) Remove thrust plates (key point 1). 3373 Inspection and Maintenance of Thrust Plates…

-

Page 64

Service Manual for WP6 Diesel Engine 3382 Steps to Disassemble Front and Rear Oil Seals (1) Remove engine front cover (refer to section 333); (2) Remove front oil seal; (3) Remove rear oil seal (key point 1); 3383 Inspection and Maintenance of Front and Rear Oil Seals… -

Page 65: Crank-Rod Mechanism

Service Manual for WP6 Diesel Engine 34 Crank-Rod Mechanism 341 Disassembly and Assembly of Crank-Rod Mechanism 3411 Exploded View of Crank-Rod Mechanism Piston-rod assembly Flywheel ring gear Flywheel Crankshaft timing gear Crankshaft Torque vibration damper Crankshaft pulley Torque vibration damper…

-

Page 66: Disassembly, Inspection, Maintenance And Assembly Of Piston-Rod Assembly

Service Manual for WP6 Diesel Engine 342 Disassembly, Inspection, Maintenance and Assembly of Piston-Rod Assembly 3421 Exploded View of Piston-Rod Assembly Piston-rod assembly Engine block module Piston-rod assembly Crankshaft Fig. 3-26 Schematic diagram of piston-rod assembly First compression ring Second compression ring…

-

Page 67

Service Manual for WP6 Diesel Engine 3422 Steps to Disassemble Piston-Rod Assembly (1) Check before disassembling. Check connecting rod axial backlash, check tightening torque of connecting rod bolts; (2) Tilt and lay the engine on its side, rotate the flywheel until the to-be removed piston is in BDC, and then remove connecting rod bolts and cap;… -

Page 68

Service Manual for WP6 Diesel Engine connecting rod oblique incision and piston cooling oil gallery inlet should be in the same direction, apply proper clean lubricating oil on connecting rod small end hole and piston pin. (3) Arrange the assembled piston-rod assembly in cylinder number order, and then install oil ring, second compression ring and first compression ring into piston ring grooves orderly with piston ring plier. -

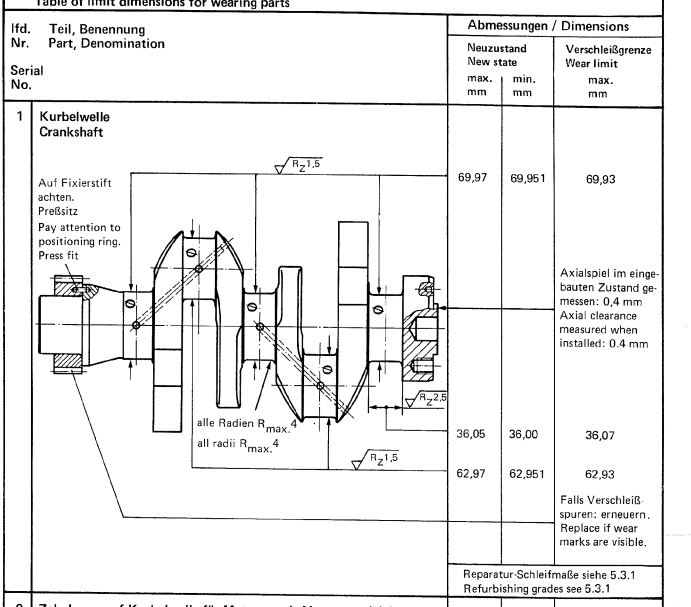

Page 69: Disassembly, Inspection, Maintenance And Assembly Of Crankshaft

Service Manual for WP6 Diesel Engine 343 Disassembly, Inspection, Maintenance and Assembly of Crankshaft 3431 Exploded View of Crankshaft Flywheel ring gear Flywheel Crankshaft timing gear Crankshaft Torque vibration damper Crankshaft pulley Torque vibration damper fastening bolt Flywheel bolt Hub fastening bolt Main bearing Fig.

-

Page 70

Service Manual for WP6 Diesel Engine 3434 Steps to Assemble Crankshaft (1) Clean up cylinder bottom holes. (2) Press main bearing upper shell into cylinder bottom holes and clean up scraped foreign matters. a) The bearing shell should be strictly inspected for bump damage before assembling, and shell with bump damage should not be reused even if repaired. -

Page 71: Disassembly, Inspection, Maintenance And Assembly Of Flywheel And Ring Gear

Service Manual for WP6 Diesel Engine 344 Disassembly, Inspection, Maintenance and Assembly of Flywheel and Ring Gear 3441 Exploded View of Flywheel and Ring Gear Flywheel Flywheel ring gear Crankshaft Flywheel bolt Locating pin Fig. 3-31 Exploded view of flywheel and ring gear 3442 Steps to Disassemble Flywheel and Ring Gear Disassembling steps are contrary to assembling ones.

-

Page 72: Disassembly, Inspection, Maintenance And Assembly Of Torque Vibration Damper, Crankshaft Pulley And Hub

Service Manual for WP6 Diesel Engine 345 Disassembly, Inspection, Maintenance and Assembly of Torque Vibration Damper, Crankshaft Pulley and Hub 3451 Exploded View of Torque Vibration Damper, Crankshaft Pulley and Hub Crankshaft timing gear Crankshaft Torque vibration damper Crankshaft pulley…

-

Page 73: Disassembly, Inspection, Maintenance And Assembly Of Crankshaft Bearing Shell

Service Manual for WP6 Diesel Engine Torque vibration damper fastening bolts: Bolt specification M10-10.9 (× 6); Tightening torque: 60~70Nm; Test value: 65~80Nm. 346 Disassembly, Inspection, Maintenance and Assembly of Crankshaft Bearing Shell 3461 Exploded View of Crankshaft Bearing Shell Main bearing lower shell…

-

Page 74: Valve Mechanism

Service Manual for WP6 Diesel Engine 35 Valve Mechanism 351 Disassembly and Assembly of Valve Mechanism 3511 Exploded View of Valve Mechanism Hexagon Butterfly spring washer Rocker seat Valve lock clamp screw Circlip for shaft Hexagon nut Valve inner spring…

-

Page 75: Disassembly, Inspection, Maintenance And Assembly Of Camshaft

Service Manual for WP6 Diesel Engine 352 Disassembly, Inspection, Maintenance and Assembly of Camshaft 3521 Exploded View of Camshaft Fuel injection pump driven gear Camshaft timing gear Camshaft Hexagon socket cap screw Flange Hexagon flange bearing surface toothed bolt Hexagon flange bearing surface toothed bolt…

-

Page 76

Service Manual for WP6 Diesel Engine to assembly of tappet for details; Install camshaft, do not damage camshaft surface and engine block hole during the push-in process of camshaft and the push-in strength should be equally, the end with thread should be on engine front cover side. -

Page 77: Disassembly, Inspection, Maintenance And Assembly Of Rocker And Rocker Shaft

Service Manual for WP6 Diesel Engine 353 Disassembly, Inspection, Maintenance and Assembly of Rocker and Rocker Shaft 3531 Exploded View of Rocker and Rocker Shaft Hexagon bolt Rocker seat Butterfly spring washer Hexagon nut Rocker Circlip for shaft Adjusting screw Cylinder cover Fig.

-

Page 78

Service Manual for WP6 Diesel Engine 3534 Steps to Assemble Rocker and Rocker Shaft (1) Check whether all to-be assembled pars are clean, free of bump damage, scratch and rust; (2) Install rocker adjusting screw and lock nut, the screw should be fully screwed in, while the lock nut only needs to be screwed in for 2~3 thread pitches;… -

Page 79: Disassembly, Inspection, Maintenance And Assembly Of Valve Tappet And Pushrod

Service Manual for WP6 Diesel Engine 354 Disassembly, Inspection, Maintenance and Assembly of Valve Tappet and Pushrod 3541 Exploded View of Valve Tappet and Pushrod Cylinder cover Pushrod Engine block Tappet Fig. 3-37 Exploded view of valve tappet and pushrod 3542 Steps to Disassemble Valve Tappet and Pushrod (1) After removing rockers and rocker shafts, directly take out pushrod, place them orderly;…

-

Page 80: Disassembly, Inspection, Maintenance And Assembly Of Valve

Service Manual for WP6 Diesel Engine 3544 Steps to Assemble Valve Tappet and Pushrod (1) Check valve tappet and pushrod, replace them if necessary. Before installing the tappet, it must be cleaned with compressed air, and check whether the oil channel is smooth;…

-

Page 81

Service Manual for WP6 Diesel Engine 3552 Steps to Disassemble Valve (1) Depress valve springs with vale spring compressor or valve overhead plier or other tools, take out valve lock clamp, upper valve spring seat and lower valve spring seat and valve springs orderly;… -

Page 82: Intake And Exhaust System

Service Manual for WP6 Diesel Engine 36 Intake and Exhaust System 361 Disassembly and Assembly of Intake and Exhaust System 3611 Exploded View of Intake and Exhaust System Turbocharger oil inlet pipe Turbocharger Intake pipe Turbocharger oil outlet pipe Exhaust adapter Exhaust pipe Fig.

-

Page 83: Disassembly, Inspection, Maintenance And Assembly Of Intake Pipe

Service Manual for WP6 Diesel Engine (6) Remove intake pipe fixing bolts, take down the pipe and gaskets, refer to 362 Disassembly, Inspection, Maintenance and Assembly of Intake Pipe for details. 3613 Steps to Assemble Intake and Exhaust System Assembling steps are contrary to disassembling ones.

-

Page 84: Disassembly, Inspection, Maintenance And Assembly Of Exhaust Pipe

Service Manual for WP6 Diesel Engine 363 Disassembly, Inspection, Maintenance and Assembly of Exhaust Pipe 3631 Exploded View of Intake Pipe Lock nut Stud Exhaust adapter Exhaust pipe Exhaust pipe gasket Fig. 3-41 Exploded view of exhaust pipe 3632 Steps to Disassemble Exhaust Pipe (1) Remove lock nuts, take down exhaust adapter.

-

Page 85: Disassembly, Inspection, Maintenance And Assembly Of Turbocharger System

Service Manual for WP6 Diesel Engine 364 Disassembly, Inspection, Maintenance and Assembly of Turbocharger System 3641 Exploded View of Turbocharger System Turbocharger Gasket Stud Lock nut Fig. 3-42 Exploded view of turbocharger 3642 Steps to Disassemble Turbocharger System Disassembling steps are contrary to assembling ones.

-

Page 86

Service Manual for WP6 Diesel Engine Fig. 3-43 Rotor axial movement measuring (3) Compressor impeller radial clearance checking Press the compressor impeller radially and measure the maximum and minimum clearance between compressor impeller and compressor volute, which should be within 0.4~0.8mm, if exceeds this range, then check the bearing and eliminate the fault. -

Page 87

Service Manual for WP6 Diesel Engine (4) Check air filter, clean it timely if there is too much dust accumulated in the filter. 3644 Steps to Assemble Turbocharger System (1) Loose-fit one end of the preassembled turbocharger oil inlet pipe to engine block main oil port. -

Page 88: Fuel System

Service Manual for WP6 Diesel Engine 37 Fuel System 371 Disassembly and Assembly of Fuel System 3711 Exploded View of Fuel System Injector Injector fuel return pipe Smoke limiter High pressure fuel pipe Fine fuel filter Fine fuel filter support…

-

Page 89: Disassembly, Inspection, Maintenance And Assembly Of Fuel Injection Pump

Service Manual for WP6 Diesel Engine (8) Remove engine front cover, refer to disassembly of engine front cover for details. (9) Remove injection pump module, refer to disassembly of injection pump for details. 3713 Steps to Assemble Fuel System Assembling steps are contrary to disassembling ones.

-

Page 90: Disassembly, Inspection, Maintenance And Assembly Of High Pressure Fuel Pipe

Service Manual for WP6 Diesel Engine (6) Remove the hollow bolts that connecting fuel injection pump and lubricating pipe. (7) Remove engine front cover upper plate, refer to disassembly of engine front cover for details. (8) Screw off injection pump camshaft nuts, remove injection pump gear.

-

Page 91: Disassembly, Inspection, Maintenance And Assembly Of Fuel Injector

Service Manual for WP6 Diesel Engine 3733 Inspection and Maintenance of High Pressure Fuel Pipe (1) Check high pressure fuel pipe appearance for crack and oil leakage; if so, replace the pipe or feedback the problem to the manufacturer. (2) Check and ensure both connector conical surfaces of high pressure fuel pipe are intact.

-

Page 92: Disassembly, Inspection, Maintenance And Assembly Of Low Pressure Fuel Pipe

Service Manual for WP6 Diesel Engine 3752 Steps to Disassemble Fuel Filters (1) Remove the hollow bolts that connecting low pressure fuel pipe and coarse/fine fuel filter. (2) Remove the bolts that connecting coarse/fine fuel filter and fixed support. (3) Remove filter element and filter seat.

-

Page 93

Service Manual for WP6 Diesel Engine 3763 Inspection and Maintenance of Low pressure Fuel Pipe (1) Check low pressure fuel pipe appearance for crack and oil leakage; if so, replace the pipe or feedback the problem to the manufacturer. (2) Check the two joints of low pressure fuel pipe for oil leakage, replace hollow bolt sealing gaskets if necessary. -

Page 94: Cooling System

Service Manual for WP6 Diesel Engine 38 Cooling System 381 Disassembly and Assembly of Cooling System 3811 Exploded View of Cooling System The function of cooling system is to ensure diesel engine can continuously work at proper temperature. Forced circulation cooling offers the best guarantee to keep the engine in normal operating temperature, mainly consists of water pump, fan, expansion water tank, water tank and thermostat.

-

Page 95

Cylinder cover Water pump Engine block Fig. 3-48 Cooling route map of WP6 mechanical pump diesel engine 3812 Steps to Disassemble Cooling System As shown in Fig. 3-47: (1) Remove fan and connecting plate, refer to disassembly of fan for details. -

Page 96: Disassembly, Inspection, Maintenance And Assembly Of Fan

Service Manual for WP6 Diesel Engine 382 Disassembly, Inspection, Maintenance and Assembly of Fan 3821 Exploded View of Fan Spring Hexagon socket cap screw washer Connecting Hexagon socket cap screw plate Spring washer Water pump pulley Fig. 3-49 Exploded view of fan 3822 Steps to Disassemble Fan As shown in Fig.

-

Page 97: Disassembly, Inspection, Maintenance And Assembly Of Water Pump

Service Manual for WP6 Diesel Engine 383 Disassembly, Inspection, Maintenance and Assembly of Water Pump 3831 Exploded View of Water Pump Gasket Middle cushion block Water pump gasket Water pump Water pump pulley Spring washer Hexagon bolt Hexagon bolt Fig. 3-50 Exploded view of water pump 3832 Steps to Disassemble Water Pump As shown in Fig.

-

Page 98: Disassembly, Inspection, Maintenance And Assembly Of Thermostat

Service Manual for WP6 Diesel Engine 384 Disassembly, Inspection, Maintenance and Assembly of Thermostat 3841 Exploded View of Thermostat Cooling Thermostat water pipe Rubber hose Rubber hose Fig. 3-51 Exploded view of thermostat 3842 Steps to Disassemble Thermostat As shown in Fig. 3-51 (1) Remove clamp of upper rubber hose which connecting cooling water pipe and thermostat.

-

Page 99: Lubricating System

Service Manual for WP6 Diesel Engine 39 Lubricating System 391 Disassembly and Assembly of Lubricating System 3911 Exploded View of Lubricating System Main oil gallery pressure limiting valve Engine oil filter Engine oil cooler Engine oil filter seat Engine oil pump…

-

Page 100

Service Manual for WP6 Diesel Engine 392 Disassembly, Inspection, Maintenance and Assembly of Engine Oil Pump 3921 Exploded View of Engine Oil Pump Self-locking nut Hexagon bolt Hexagon bolt Fig. 3-53 Exploded view of engine oil pump 3922 Steps to Disassemble Engine Oil Pump Remove the two hexagon bolts and self-locking nut, take down engine oil pump, as shown in Fig. -

Page 101

Service Manual for WP6 Diesel Engine 393 Disassembly, Inspection, Maintenance and Assembly of Engine Oil Filter 3931 Exploded View of Engine Oil Filter Engine oil filter Fig. 3-54 Exploded view of engine oil filter 3932 Steps to Disassemble Engine Oil Filter Remove the filter with dedicated tool, as shown in Fig. -

Page 102: Disassembly, Inspection, Maintenance And Assembly Of Engine Oil Cooler

Service Manual for WP6 Diesel Engine 394 Disassembly, Inspection, Maintenance and Assembly of Engine Oil Cooler 3941 Exploded View of Engine Oil Cooler Engine oil cooler water inlet pipe Engine oil cooler water return pipe Connecting rubber hose Engine oil cooler…

-

Page 103: Disassembly, Inspection, Maintenance And Assembly Of Main Oil Gallery Pressure Limiting Valve

Service Manual for WP6 Diesel Engine 395 Disassembly, Inspection, Maintenance and Assembly of Main Oil Gallery Pressure Limiting Valve 3951 Exploded View of Main Oil Gallery Pressure Limiting Valve Steel ball Spring Screw Combination sealing gasket Cap nut Fig. 3-56 Exploded view of main oil gallery pressure limiting valve 3952 Steps to Disassemble Main Oil Gallery Pressure Limiting Valve Screw off main oil gallery pressure limiting valve, as shown in Fig.

-

Page 104: Disassembly, Inspection, Maintenance And Assembly Of Engine Oil Strainer

Service Manual for WP6 Diesel Engine 396 Disassembly, Inspection, Maintenance and Assembly of Engine Oil Strainer 3961 Exploded View of Engine Oil Strainer Gasket Bended plate Self-locking nut Wave spring washer Hexagon bolt 1-type hexagon nut Engine oil stainer Fig. 3-57 Exploded view of engine oil strainer…

-

Page 105: Starting System

Service Manual for WP6 Diesel Engine 310 Starting System 3101 Disassembly, Inspection, Maintenance and Assembly of Starting System 31011 Exploded View of Starting System 1 Flywheel ring gear 2 Spring washer 3 Hexagon bolt 4 Starter motor Fig. 3-58 Exploded view of starting system 31012 Steps to Disassemble Starting System (1) Remove hexagon bolt 3 and spring washer 2;…

-

Page 106: Engine Accessory System

Service Manual for WP6 Diesel Engine 311 Engine Accessory System 3111 Disassembly and Assembly of Engine Accessory System 31111 Exploded View of Engine Accessory System Draw-in bolt pad Draw-in bolt Gasket Air compressor Hexagon bolt Hexagon bolt Gasket Generator Gasket…

-

Page 107: 3112 Disassembly, Inspection, Maintenance And Assembly Of Generator

Service Manual for WP6 Diesel Engine 3112 Disassembly, Inspection, Maintenance and Assembly of Generator 31121 Exploded View of Generator Draw-in bolt pad Draw-in bolt Gasket Hexagon bolt Generator Hexagon socket Gasket Generator support Sleeve cap screw Fig. 3-60 Exploded view of generator…

-

Page 108

Service Manual for WP6 Diesel Engine 31123 Inspection and Maintenance of Generator (1) Generator fault diagnosis flow When a failure happens to the engine, firstly you should check whether it is generator failure. Instrument: test lamp. Flow chart is shown in Fig. 3-61… -

Page 109

Service Manual for WP6 Diesel Engine (2) Charging system fault diagnosis and troubleshooting a) No charging Fault 1: No charging Phenomenon Fault detection Troubleshooting a. Check whether there is voltage between (1) Turn on a. Check charging charging indicator and ground, if no starting key, indicator lamp. -

Page 110

Service Manual for WP6 Diesel Engine The brightness of indicator lamp is normal, and it goes out automatically after engine is started, generator output voltage is 27~28.5V; it means the exciting circuit has problem and needs to be repaired. -

Page 111

Service Manual for WP6 Diesel Engine of generator W/R/AC heavy load condition, then the wire or terminal (should be connector should be replaced. about half of B+ g. Oxidized lead foot and the housing that terminal voltage). used to install grounding bolts should be h. -

Page 112

Service Manual for WP6 Diesel Engine d) Unstable charging voltage Fault 4: Unstable charging voltage Phenomenon Fault detection Troubleshooting a. Generator belt and relevant pulley belts are loose. a. Tighten generator belt and When the engine is running b. Bad contact in charging relevant pulley belts. -

Page 113: 3113 Disassembly, Inspection, Maintenance And Assembly Of Air Compressor

Service Manual for WP6 Diesel Engine 3113 Disassembly, Inspection, Maintenance and Assembly of Air Compressor 31131 Exploded View of Air Compressor Air compressor Gasket Hexagon Air compressor bolt support Belt Fig. 3-62 Exploded view of air compressor 31132 Steps to Disassemble Air Compressor (1) Remove air compressor belt;…

-

Page 114

Service Manual for WP6 Diesel Engine 2) Too much carbon deposition accumulated in intake and exhaust port. Troubleshooting: 1) Check compressor relief valve module, clean and replace the invalid parts. 2) Overhaul cylinder cover, check the valve plate, replace deformed or broken valve plate. -

Page 115

Service Manual for WP6 Diesel Engine 6) Check and adjust installation direction of unloading valve (should be conform to the arrow). (3) Air compressor pumping oil. Fault phenomenon: There is engine oil overflows in air filter and air compressor exhaust port, and engine oil comes out with water when discharging the gasholder (wet). -

Page 116

Service Manual for WP6 Diesel Engine π Piston displacement n Piston quantity, Note: Theoretical air displacement Q where n is compressor rated speed. 2) Ensure the exhaust pipe inner diameter meets the minimum requirements. Table 2 Minimum inner diameter requirements for exhaust pipe… -

Page 117

Service Manual for WP6 Diesel Engine bearing shell is worn or damaged that result in crash noise. 2) The belt is too loose, driving and driven pulley groove type is not uniform, which lead to slipping squeal. 3) No engine oil is supplied to air compressor, dry friction of metal leading to squeal. -

Page 118

Service Manual for WP6 Diesel Engine Troubleshooting: 1) Check engine oil quality and impurity content, compare it with application standard, replace the oil immediately if out of limits; 2) Check engine oil pressure (air compressor oil inlet port), check whether engine oil pipe is damaged or blocked, adjust, clean or replace the invalid pipe if the oil pressure is insufficient;… -

Page 119

Service Manual for WP6 Diesel Engine 5) Check compressor housing for casting or manufacturing deficiency (whether the oil return hole is unblocked), repair or replaced the flawed housing. (7) Air compressor overheating Fault phenomenon: Air compressor exhaust temperature is too high; the running parts are hot.

Operators must carefully read Diesel Engine Instruction Manual, all technical operations and

maintenance regulations specified in the manual must be strictly complied with, and also pay

attention to warning instructions and labels;

Each diesel engine has passed strict and specified pre-delivery test, accelerator throttle has been

lead sealed, do not casually remove the lead seal to increase throttle;

Turbocharger rotor is high-speed rotating component, it is strictly prohibited to approach the

intake port of turbocharger with any removable object (such as hand, tools, gauze, etc.) when

the engine is running, in order to avoid human body damage or machine damage; For rotor

module, it can only be disassembled by qualified maintenance personnel in professional

maintenance site authorized by Weichai Power;

Various bolts like diesel engine main bearing bolts and connecting rod bolts have strict torque

requirements and limiting use times, users are not allowed to loosen or remove the bolts

casually; connecting rod bolts are disposable bolts, do not reuse them;

The added engine oil or diesel oil, whose brand must complied with requirements specified in

operation and maintenance manual, moreover, all oil must be filtered with specialized clean

filter, fuel must be subsided for more than 72 hours; Before operating the machine each time,

check and make sure coolant level and engine oil level meet the requirements;

Test run a new machine for 50 hours (run-in period) before putting it into operation, replace

engine oil and engine oil filter element after run-in period;

Increase the engine rotating speed slowly after cold starting, neither increase the speed abruptly

or long-term idling is proper; After heavy load running, do not stop the engine immediately

(peculiar circumstance exception), you should run it at low speed for 5~10 minutes before

shutting down;

After parking, if the ambient temperature is likely to be lower than 0

coolant in the machine, please be sure to drain the coolant in water tank and diesel engine out;

It is forbidden to run the diesel engine without an air filter to prevent unfiltered air entering into

cylinders. Air filter should be enlarged or replaced more frequently when operating in severe

conditions, in order to prevent engine failure, such as premature wear;

Overhaul of electrical components must be carried out by electrical professionals.

Service Manual for WP6 Diesel Engine

Special Tips

o

C and there is unused

Модераторы: Aston, AB-Engine, Администраторы

-

jgflhgj

- Пилот

- Сообщения: 28

- Зарегистрирован: 09 ноя 2018, 00:20

-

wal

- Технический директор

- Сообщения: 2483

- Зарегистрирован: 20 авг 2008, 21:45

- Откуда: moscow city

Re: Любые вопросы о дизелях Deutz всех серий

Сообщение

wal » 31 июл 2019, 13:08

Приветствую всех. Возник такой вопрос, нужны размеры шеек колнвала двигателя Deuz 226B.Эко китайская копия немецкого мотора. Такие моторы оч на фронтальных погрузчиках встречаются. На китайских.

-

yuri_sh

- Технический директор

- Сообщения: 3985

- Зарегистрирован: 06 апр 2013, 12:47

- Откуда: РБ Минск

Re: Любые вопросы о дизелях Deutz всех серий

Сообщение

yuri_sh » 31 июл 2019, 20:04

wal писал(а):Приветствую всех. Возник такой вопрос, нужны размеры шеек колнвала двигателя Deuz 226B.Эко китайская копия немецкого мотора. Такие моторы оч на фронтальных погрузчиках встречаются. На китайских.

больше ничего не интересует?

-

yuri_sh

- Технический директор

- Сообщения: 3985

- Зарегистрирован: 06 апр 2013, 12:47

- Откуда: РБ Минск

Re: Любые вопросы о дизелях Deutz всех серий

Сообщение

yuri_sh » 31 июл 2019, 21:19

здесь вся информация.

а по ремонтным размерам, в первую очередь я бы искал вкладыши ремонтные.

кто его знает, есть ли они вообще нормальные, по качеству?

я их делал пару раз, но вот с валами там все в норме было.

-

yuri_sh

- Технический директор

- Сообщения: 3985

- Зарегистрирован: 06 апр 2013, 12:47

- Откуда: РБ Минск

Re: Любые вопросы о дизелях Deutz всех серий

Сообщение

yuri_sh » 31 июл 2019, 21:26

wal писал(а):Ну и такой вопрос ремонтные размеры есть у коленвал?

есть зато встречный вопрос.

CAT C13. ориентировка поршней и шатунов?

а то как всегда, привезли, кота, в мешке.

а в сисе толком ничего и не описано.

-

wal

- Технический директор

- Сообщения: 2483

- Зарегистрирован: 20 авг 2008, 21:45

- Откуда: moscow city

Re: Любые вопросы о дизелях Deutz всех серий

Сообщение

wal » 31 июл 2019, 23:08

Шатуны замками вправо.Замки со стороны выхлопа.А поршни не помню….там они стальные полностью.Если нет надписей на них и стрелок,то без разницы как ставить.

-

yuri_sh

- Технический директор

- Сообщения: 3985

- Зарегистрирован: 06 апр 2013, 12:47

- Откуда: РБ Минск

-

Malkin

- Технический директор

- Сообщения: 448

- Зарегистрирован: 06 сен 2017, 21:30

- Откуда: Ульяновская область.

Re: Любые вопросы о дизелях Deutz всех серий

Сообщение

Malkin » 01 авг 2019, 13:02

Здравствуйте, как установить ТНВД(13053063) после ремонта на двигатель DEUTZ WP6G125e22? Демонтировал не сам. И регулировка зазоров клапанов. Куда капать? Что читать? В общем и целом что делать? Подскажите пожалуйста.

-

yuri_sh

- Технический директор

- Сообщения: 3985

- Зарегистрирован: 06 апр 2013, 12:47

- Откуда: РБ Минск

Re: Любые вопросы о дизелях Deutz всех серий

Сообщение

yuri_sh » 01 авг 2019, 19:56

Malkin писал(а):Здравствуйте, как установить ТНВД(13053063) после ремонта на двигатель DEUTZ WP6G125e22? Демонтировал не сам. И регулировка зазоров клапанов. Куда капать? Что читать? В общем и целом что делать? Подскажите пожалуйста.

буквально вчера выложил инструкцию по этому мотору.

там и ищите.

-

jgflhgj

- Пилот

- Сообщения: 28

- Зарегистрирован: 09 ноя 2018, 00:20

Re: Любые вопросы о дизелях Deutz всех серий

Сообщение

jgflhgj » 05 авг 2019, 18:35

Всем привет! Подскажите Дойц 1012 долгий пуск. Установлены новые секции Тнвд,распылители. Ход рейки 17мм. Без салиноида глушения запускается нормально пробывал ставить другой с рабочего ДВС без изменений.

-

yuri_sh

- Технический директор

- Сообщения: 3985

- Зарегистрирован: 06 апр 2013, 12:47

- Откуда: РБ Минск

- Главная

- Автокаталог

- Двигатели, КПП, ТНВД

- Weichai

- WP6G125E22

- Crankcase ventilation assembly

1

Номер детали на чертеже:

1

Oil Connecting Rubber Pipe

Заводской номер: 13022800

Количество на модель: 1

13022800

1

2

Номер детали на чертеже:

2

Хомут рукава

Заводской номер: 12151665

Количество на модель: 1

12151665

1

3

Номер детали на чертеже:

3

Hexagon bolt

Заводской номер: 01127051

Количество на модель: 1

01127051

1

4

Номер детали на чертеже:

4

Пластинчатая шайба

Заводской номер: 01152752

Количество на модель: 1

01152752

1

5

Номер детали на чертеже:

5

Pipe Clamp Assembly

Заводской номер: 612600011361

Количество на модель: 1

612600011361

1

6

Номер детали на чертеже:

6

Oil-gas separator assembly

Заводской номер: 13037977

Количество на модель: 1

13037977

1

7

Номер детали на чертеже:

7

Пластинчатая шайба

Заводской номер: 01132562

Количество на модель: 1

01132562

1

8

Номер детали на чертеже:

8

Шестигранная гайка

Заводской номер: 01112829

Количество на модель: 1

01112829

1

9

Номер детали на чертеже:

9

Clamp

Заводской номер: 13039655

Количество на модель: 2

13039655

2

10

Номер детали на чертеже:

10

Пружина

Заводской номер: 12270389

Количество на модель: 1

12270389

1

11

Номер детали на чертеже:

11

Hose

Заводской номер: 13031742

Количество на модель: 1

13031742

1

12

Номер детали на чертеже:

12

Шестиугольный головочный болт

Заводской номер: 01112339

Количество на модель: 1

01112339

1

13

Номер детали на чертеже:

13

Пружинная шайба

Заводской номер: 01177981

Количество на модель: 1

01177981

1

14

Номер детали на чертеже:

14

Inner hexagon screw

Заводской номер: 13026585

Количество на модель: 1

13026585

1

15

Номер детали на чертеже:

15

Пружинная шайба

Заводской номер: 01178366

Количество на модель: 1

01178366

1

16

Номер детали на чертеже:

16

Пластичная шайба

Заводской номер: 01151002

Количество на модель: 1

01151002

1

17

Номер детали на чертеже:

17

Bracket

Заводской номер: 13037005

Количество на модель: 1

13037005

1