Atlas Copco

Oil-injected rotary screw compressors

GA 5, GA 7, GA 11

Instruction book

Atlas Copco

Oil-injected rotary screw compressors

GA 5, GA 7, GA 11

From following serial No. onwards: CAI 700 000

Instruction book

Original instructions

Copyright notice

Any unauthorized use or copying of the contents or any part thereof is prohibited.

This applies in particular to trademarks, model denominations, part numbers and drawings.

This instruction book is valid for CE as well as non-CE labelled machines. It meets the requirements for instructions specified by the applicable European directives as identified in the Declaration of Conformity.

2009 — 12

No. 2920 7090 51

Replaces No. 2920 7090 50

www.atlascopco.com

Instruction book

2

Table of contents

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

1

1.1

1.2

1.3

1.4

1.5

Safety precautions…………………………………………………………………………………………….7

S

AFETY ICONS

…………………………………………………………………………………………………………………..7

S

AFETY PRECAUTIONS

,

GENERAL

……………………………………………………………………………………………..7

S

AFETY PRECAUTIONS DURING INSTALLATION

……………………………………………………………………………….7

S

AFETY PRECAUTIONS DURING OPERATION

………………………………………………………………………………….9

S

AFETY PRECAUTIONS DURING MAINTENANCE OR REPAIR

……………………………………………………………….10

General description…………………………………………………………………………………………12

I

NTRODUCTION

…………………………………………………………………………………………………………………12

A

IR FLOW

………………………………………………………………………………………………………………………16

O

IL SYSTEM

……………………………………………………………………………………………………………………17

C

OOLING SYSTEM

……………………………………………………………………………………………………………..18

C

ONDENSATE SYSTEM

………………………………………………………………………………………………………..19

R

EGULATING SYSTEM

…………………………………………………………………………………………………………20

E

LECTRICAL SYSTEM

………………………………………………………………………………………………………….20

E

LECTRICAL DIAGRAMS

……………………………………………………………………………………………………….21

A

IR DRYER

……………………………………………………………………………………………………………………..24

Elektronikon® controller………………………………………………………………………………….26

E

LEKTRONIKON

®

REGULATOR

……………………………………………………………………………………………….26

C

ONTROL PANEL

………………………………………………………………………………………………………………27

I

CONS USED ON THE DISPLAY

………………………………………………………………………………………………..28

M

AIN SCREEN

………………………………………………………………………………………………………………….30

S

HUT

—

DOWN WARNING

………………………………………………………………………………………………………..30

S

HUT

—

DOWN

……………………………………………………………………………………………………………………32

S

ERVICE WARNING

…………………………………………………………………………………………………………….33

S

CROLLING THROUGH ALL SCREENS

………………………………………………………………………………………..35

C

ALLING UP OUTLET AND DEWPOINT TEMPERATURES

…………………………………………………………………….38

2920 7090 51

Instruction book

4

4.1

4.2

4.3

4.4

3.25

3.26

3.27

3.28

3.29

3.30

3.31

3.32

3.33

3.20

3.21

3.22

3.23

3.24

3.15

3.16

3.17

3.18

3.19

3.10

3.11

3.12

3.13

3.14

C

ALLING UP RUNNING HOURS

………………………………………………………………………………………………..39

C

ALLING UP MOTOR STARTS

…………………………………………………………………………………………………40

C

ALLING UP MODULE HOURS

…………………………………………………………………………………………………41

C

ALLING UP LOADING HOURS

………………………………………………………………………………………………..41

C

ALLING UP LOAD RELAY

…………………………………………………………………………………………………….41

C

ALLING UP

/

RESETTING THE SERVICE TIMER

……………………………………………………………………………..42

S

ELECTION BETWEEN LOCAL

,

REMOTE OR

LAN

CONTROL

………………………………………………………………43

C

ALLING UP

/

MODIFYING

CAN

ADDRESS CONTROL

……………………………………………………………………….43

C

ALLING UP

/

MODIFYING

IP, G

ATEWAY AND

S

UBNETMASK

………………………………………………………………45

C

ALLING UP

/

MODIFYING PRESSURE BAND SETTINGS

………………………………………………………………………47

M

ODIFYING THE PRESSURE BAND SELECTION

……………………………………………………………………………..48

C

ALLING UP

/

MODIFYING SERVICE TIMER SETTINGS

………………………………………………………………………..49

C

ALLING UP

/

MODIFYING THE UNIT OF TEMPERATURE

……………………………………………………………………..49

C

ALLING UP

/

MODIFYING UNIT OF PRESSURE

……………………………………………………………………………….50

A

CTIVATING AUTOMATIC RESTART AFTER VOLTAGE FAILURE

…………………………………………………………….50

S

ELECTION BETWEEN

Y-D

OR

DOL

STARTING

…………………………………………………………………………..50

C

ALLING UP MODIFYING LOAD DELAY TIME

…………………………………………………………………………………51

C

ALLING UP MODIFYING MINIMUM STOP TIME

………………………………………………………………………………51

A

CTIVATING PASSWORD PROTECTION

………………………………………………………………………………………52

A

CTIVATE LOAD

/

UNLOAD REMOTE PRESSURE SENSING

…………………………………………………………………..52

C

ALLING UP

/

MODIFYING PROTECTION SETTINGS

…………………………………………………………………………..53

T

EST SCREENS

………………………………………………………………………………………………………………..55

W

EB SERVER

………………………………………………………………………………………………………………….56

P

ROGRAMMABLE SETTINGS

…………………………………………………………………………………………………..64

Elektronikon® Graphic controller…………………………………………………………………….68

E

LEKTRONIKON

®

G

RAPHIC CONTROLLER

…………………………………………………………………………………..68

C

ONTROL PANEL

………………………………………………………………………………………………………………70

I

CONS USED

……………………………………………………………………………………………………………………71

M

AIN SCREEN

………………………………………………………………………………………………………………….74

2920 7090 51 3

Instruction book

7

7.1

7.2

7.3

6.1

6.2

6.3

6.4

5

5.1

5.2

5.3

6

4.10

4.11

4.12

4.13

4.14

4.15

4.16

4.17

4.18

4.5

4.6

4.7

4.8

4.9

C

ALLING UP MENUS

…………………………………………………………………………………………………………..76

I

NPUTS MENU

…………………………………………………………………………………………………………………..77

O

UTPUTS MENU

……………………………………………………………………………………………………………….78

C

OUNTERS

……………………………………………………………………………………………………………………..80

S

ERVICE MENU

………………………………………………………………………………………………………………..81

S

ETPOINT MENU

……………………………………………………………………………………………………………….85

E

VENT HISTORY MENU

………………………………………………………………………………………………………..87

M

ODIFYING GENERAL SETTINGS

……………………………………………………………………………………………..88

I

NFO MENU

……………………………………………………………………………………………………………………..89

W

EEK TIMER MENU

……………………………………………………………………………………………………………90

T

EST MENU

…………………………………………………………………………………………………………………….99

U

SER PASSWORD MENU

…………………………………………………………………………………………………….100

W

EB SERVER

………………………………………………………………………………………………………………..101

P

ROGRAMMABLE SETTINGS

…………………………………………………………………………………………………109

OSD oil/condensate separator (optional)………………………………………………………..113

OSD

UNIT

……………………………………………………………………………………………………………………113

O

PERATING AND MAINTENANCE INSTRUCTIONS

………………………………………………………………………….114

P

ICTOGRAPHS

……………………………………………………………………………………………………………….115

Installation…………………………………………………………………………………………………….117

D

IMENSION DRAWINGS

………………………………………………………………………………………………………117

I

NSTALLATION PROPOSAL

…………………………………………………………………………………………………..123

E

LECTRICAL CONNECTIONS

…………………………………………………………………………………………………126

P

ICTOGRAPHS

……………………………………………………………………………………………………………….131

Operating instructions…………………………………………………………………………………..133

I

NITIAL START

—

UP

…………………………………………………………………………………………………………….133

B

EFORE STARTING

…………………………………………………………………………………………………………..135

S

TARTING

……………………………………………………………………………………………………………………136

4 2920 7090 51

Instruction book

10

11

9

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

8.1

8.2

8.3

8.4

8.5

7.4

7.5

7.6

7.7

8

D

URING OPERATION

…………………………………………………………………………………………………………137

C

HECKING THE DISPLAY

…………………………………………………………………………………………………….139

S

TOPPING

……………………………………………………………………………………………………………………140

T

AKING OUT OF OPERATION

………………………………………………………………………………………………..141

Maintenance………………………………………………………………………………………………….143

P

REVENTIVE MAINTENANCE SCHEDULE

……………………………………………………………………………………143

O

IL SPECIFICATIONS

…………………………………………………………………………………………………………146

S

TORAGE AFTER INSTALLATION

……………………………………………………………………………………………146

S

ERVICE KITS

………………………………………………………………………………………………………………..147

D

ISPOSAL OF USED MATERIAL

……………………………………………………………………………………………..147

Adjustments and servicing procedures………………………………………………………….148

D

RIVE MOTOR

……………………………………………………………………………………………………………….148

A

IR FILTER

……………………………………………………………………………………………………………………148

O

IL AND OIL FILTER CHANGE

……………………………………………………………………………………………….149

O

IL SEPARATOR CHANGE

…………………………………………………………………………………………………..150

C

OOLERS

…………………………………………………………………………………………………………………….151

B

ELT TENSIONING AND REPLACEMENT

…………………………………………………………………………………….151

S

AFETY VALVES

……………………………………………………………………………………………………………..153

D

RYER MAINTENANCE INSTRUCTIONS

……………………………………………………………………………………..154

Problem solving…………………………………………………………………………………………….156

Technical data……………………………………………………………………………………………….159

11.1

11.2

11.3

11.4

11.5

11.6

R

EADINGS ON DISPLAY

……………………………………………………………………………………………………..159

E

LECTRIC CABLE SIZE

………………………………………………………………………………………………………160

S

ETTINGS FOR OVERLOAD RELAY AND FUSES

……………………………………………………………………………162

D

RYER SWITCHES

……………………………………………………………………………………………………………163

R

EFERENCE CONDITIONS AND LIMITATIONS

………………………………………………………………………………163

C

OMPRESSOR DATA

…………………………………………………………………………………………………………164

2920 7090 51 5

Instruction book

11.7

T

ECHNICAL DATA

E

LEKTRONIKON

®

CONTROLLER

……………………………………………………………………….169

14

15

12

13

Instructions for use……………………………………………………………………………………….171

Guidelines for inspection……………………………………………………………………………….172

Pressure equipment directives………………………………………………………………………173

Declaration of conformity………………………………………………………………………………174

6 2920 7090 51

Instruction book

1 Safety precautions

1.1

Safety icons

Explanation

Danger for life

Warning

Important note

1.2

Safety precautions, general

General precautions

1. The operator must employ safe working practices and observe all related work safety requirements and regulations.

2. If any of the following statements does not comply with the applicable legislation, the stricter of the two shall apply.

3. Installation, operation, maintenance and repair work must only be performed by authorized, trained, specialized personnel.

4. The compressor is not considered capable of producing air of breathing quality. For air of breathing quality, the compressed air must be adequately purified according to the applicable legislation and standards.

5. Before any maintenance, repair work, adjustment or any other non-routine checks, stop the compressor, press the emergency stop button, switch off the voltage and depressurize the compressor. In addition, the power isolating switch must be opened and locked.

6. Never play with compressed air. Do not apply the air to your skin or direct an air stream at people. Never use the air to clean dirt from your clothes. When using the air to clean equipment, do so with extreme caution and wear eye protection.

7. The owner is responsible for maintaining the unit in safe operating condition. Parts and accessories shall be replaced if unsuitable for safe operation.

8. It is not allowed to walk or stand on the roof of the compressor canopy.

1.3

Safety precautions during installation

All responsibility for any damage or injury resulting from neglecting these precautions, or non-observance of the normal caution and care required for installation, operation, maintenance and repair, even if not expressly stated, will be disclaimed by the manufacturer.

2920 7090 51 7

Instruction book

Precautions during installation

1. The machine must only be lifted using suitable equipment in accordance with the applicable safety regulations. Loose or pivoting parts must be securely fastened before lifting. It is strictly forbidden to dwell or stay in the risk zone under a lifted load. Lifting acceleration and deceleration must be kept within safe limits. Wear a safety helmet when working in the area of overhead or lifting equipment.

2. Place the machine where the ambient air is as cool and clean as possible. If necessary, install a suction duct. Never obstruct the air inlet. Care must be taken to minimize the entry of moisture at the inlet air.

3. Any blanking flanges, plugs, caps and desiccant bags must be removed before connecting the pipes.

4. Air hoses must be of correct size and suitable for the working pressure. Never use frayed, damaged or worn hoses. Distribution pipes and connections must be of the correct size and suitable for the working pressure.

5. The aspirated air must be free of flammable fumes, vapours and particles, e.g. paint solvents, that can lead to internal fire or explosion.

6. Arrange the air intake so that loose clothing worn by people cannot be sucked in.

7. Ensure that the discharge pipe from the compressor to the aftercooler or air net is free to expand under heat and that it is not in contact with or close to flammable materials.

8. No external force may be exerted on the air outlet valve; the connected pipe must be free of strain.

9. If remote control is installed, the machine must bear a clear sign stating: DANGER: This machine is remotely controlled and may start without warning.

The operator has to make sure that the machine is stopped and that the isolating switch is open and locked before any maintenance or repair. As a further safeguard, persons switching on remotely controlled machines shall take adequate precautions to ensure that there is no one checking or working on the machine. To this end, a suitable notice shall be affixed to the start equipment.

10. Air-cooled machines must be installed in such a way that an adequate flow of cooling air is available and that the exhausted air does not recirculate to the compressor air inlet or cooling air inlet.

11. The electrical connections must correspond to the applicable codes. The machines must be earthed and protected against short circuits by fuses in all phases. A lockable power isolating switch must be installed near the compressor.

12. On machines with automatic start/stop system or if the automatic restart function after voltage failure is activated, a sign stating «This machine may start without warning» must be affixed near the instrument panel.

13. In multiple compressor systems, manual valves must be installed to isolate each compressor. Non-return valves (check valves) must not be relied upon for isolating pressure systems.

14. Never remove or tamper with the safety devices, guards or insulation fitted on the machine. Every pressure vessel or auxiliary installed outside the machine to contain air above atmospheric pressure must be protected by a pressure-relieving device or devices as required.

15. Piping or other parts with a temperature in excess of 80˚C (176˚F) and which may be accidentally touched by personnel in normal operation must be guarded or insulated. Other high-temperature piping must be clearly marked.

16. For water-cooled machines, the cooling water system installed outside the machine has to be protected by a safety device with set pressure according to the maximum cooling water inlet pressure.

17. If the ground is not level or can be subject to variable inclination, consult the manufacturer.

Also consult following safety precautions: Safety precautions during operation

and Safety precautions during maintenance .

These precautions apply to machinery processing or consuming air or inert gas.

Processing of any other gas requires additional safety precautions typical to the application which are not included herein.

Some precautions are general and cover several machine types and equipment; hence some statements may not apply to your machine.

8 2920 7090 51

Instruction book

1.4

Safety precautions during operation

All responsibility for any damage or injury resulting from neglecting these precautions, or non-observance of the normal caution and care required for installation, operation, maintenance and repair, even if not expressly stated, will be disclaimed by the manufacturer.

Precautions during operation

1. Never touch any piping or components of the compressor during operation.

2. Use only the correct type and size of hose end fittings and connections. When blowing through a hose or air line, ensure that the open end is held securely. A free end will whip and may cause injury. Make sure that a hose is fully depressurized before disconnecting it.

3. Persons switching on remotely controlled machines shall take adequate precautions to ensure that there is no one checking or working on the machine. To this end, a suitable notice shall be affixed to the remote start equipment.

4. Never operate the machine when there is a possibility of taking in flammable or toxic fumes, vapours or particles.

5. Never operate the machine below or in excess of its limit ratings.

6. Keep all bodywork doors shut during operation. The doors may be opened for short periods only, e.g. to carry out routine checks. Wear ear protectors when opening a door.

7. People staying in environments or rooms where the sound pressure level reaches or exceeds 90 dB(A) shall wear ear protectors.

8. Periodically check that:

• All guards are in place and securely fastened

• All hoses and/or pipes inside the machine are in good condition, secure and not rubbing

• There are no leaks

• All fasteners are tight

• All electrical leads are secure and in good order

• Safety valves and other pressure-relief devices are not obstructed by dirt or paint

• Air outlet valve and air net, i.e. pipes, couplings, manifolds, valves, hoses, etc. are in good repair, free of wear or abuse

9. If warm cooling air from compressors is used in air heating systems, e.g. to warm up a workroom, take precautions against air pollution and possible contamination of the breathing air.

10. Do not remove any of, or tamper with, the sound-damping material.

11. Never remove or tamper with the safety devices, guards or insulations fitted on the machine. Every pressure vessel or auxiliary installed outside the machine to contain air above atmospheric pressure shall be protected by a pressure-relieving device or devices as required.

Also consult following safety precautions: Safety precautions during installation

and Safety precautions during maintenance .

These precautions apply to machinery processing or consuming air or inert gas.

Processing of any other gas requires additional safety precautions typical to the application which are not included herein.

Some precautions are general and cover several machine types and equipment; hence some statements may not apply to your machine.

2920 7090 51 9

Instruction book

1.5

Safety precautions during maintenance or repair

All responsibility for any damage or injury resulting from neglecting these precautions, or non-observance of the normal caution and care required for installation, operation, maintenance and repair, even if not expressly stated, will be disclaimed by the manufacturer.

Precautions during maintenance or repair

1. Always use the correct safety equipment (such as safety glasses, gloves, safety shoes, etc.).

2. Use only the correct tools for maintenance and repair work.

3. Use only genuine spare parts.

4. All maintenance work shall only be undertaken when the machine has cooled down.

5. A warning sign bearing a legend such as «work in progress; do not start» shall be attached to the starting equipment.

6. Persons switching on remotely controlled machines shall take adequate precautions to ensure that there is no one checking or working on the machine. To this end, a suitable notice shall be affixed to the remote start equipment.

7. Close the compressor air outlet valve before connecting or disconnecting a pipe.

8. Before removing any pressurized component, effectively isolate the machine from all sources of pressure and relieve the entire system of pressure.

9. Never use flammable solvents or carbon tetrachloride for cleaning parts. Take safety precautions against toxic vapours of cleaning liquids.

10. Scrupulously observe cleanliness during maintenance and repair. Keep dirt away by covering the parts and exposed openings with a clean cloth, paper or tape.

11. Never weld or perform any operation involving heat near the oil system. Oil tanks must be completely purged, e.g. by steam-cleaning, before carrying out such operations. Never weld on, or in any way modify, pressure vessels.

12. Whenever there is an indication or any suspicion that an internal part of a machine is overheated, the machine shall be stopped but no inspection covers shall be opened before sufficient cooling time has elapsed; this to avoid the risk of spontaneous ignition of the oil vapour when air is admitted.

13. Never use a light source with open flame for inspecting the interior of a machine, pressure vessel, etc.

14. Make sure that no tools, loose parts or rags are left in or on the machine.

15. All regulating and safety devices shall be maintained with due care to ensure that they function properly.

They may not be put out of action.

16. Before clearing the machine for use after maintenance or overhaul, check that operating pressures, temperatures and time settings are correct. Check that all control and shut-down devices are fitted and that they function correctly. If removed, check that the coupling guard of the compressor drive shaft has been reinstalled.

17. Every time the separator element is renewed, examine the discharge pipe and the inside of the oil separator vessel for carbon deposits; if excessive, the deposits should be removed.

18. Protect the motor, air filter, electrical and regulating components, etc. to prevent moisture from entering them, e.g. when steam-cleaning.

19. Make sure that all sound-damping material and vibration dampers, e.g. damping material on the bodywork and in the air inlet and outlet systems of the compressor, is in good condition. If damaged, replace it by genuine material from the manufacturer to prevent the sound pressure level from increasing.

20. Never use caustic solvents which can damage materials of the air net, e.g. polycarbonate bowls.

21.

The following safety precautions are stressed when handling refrigerant:

• Never inhale refrigerant vapours. Check that the working area is adequately ventilated; if required, use breathing protection.

10 2920 7090 51

Instruction book

• Always wear special gloves. In case of refrigerant contact with the skin, rinse the skin with water. If liquid refrigerant contacts the skin through clothing, never tear off or remove the latter; flush abundantly with fresh water over the clothing until all refrigerant is flushed away; then seek medical first aid.

Also consult following safety precautions: Safety precautions during installation

and Safety precautions during operation .

These precautions apply to machinery processing or consuming air or inert gas.

Processing of any other gas requires additional safety precautions typical to the application which are not included herein.

Some precautions are general and cover several machine types and equipment; hence some statements may not apply to your machine.

2920 7090 51 11

Instruction book

2 General description

2.1

Introduction

General

GA 5 up to GA 11 are single-stage, oil-injected screw compressors driven by an electric motor. The compressors are air-cooled. The compressors are enclosed in sound insulating bodywork.

Workplace

compressors have no dryer, while

Workplace Full-Feature (FF)

compressors are provided with an integrated air dryer.

The basic version of GA 5 up to GA 11 is equipped with an Elektronikon controller ( see section Elektronikon controller ). The Elektronikon® Graphic controller is available as option (see section

Elektronikon graphic controller ).

The Elektronikon® controller and the emergency stop button are integrated in the door panel of the electric cubicle. An electric cabinet comprising the motor starter is located behind this panel.

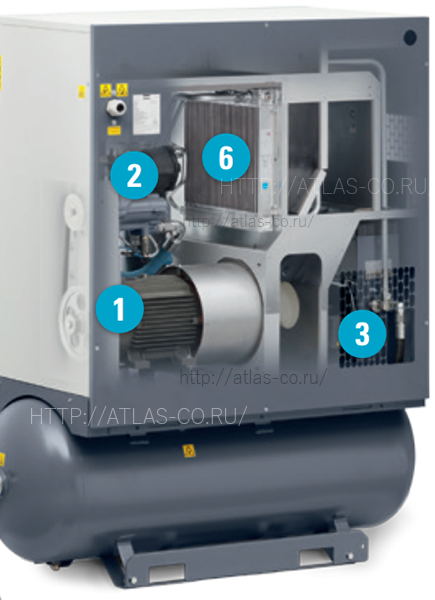

Tank-mounted version

The compressors are mounted on an air receiver.

12 2920 7090 51

Instruction book

Ref.

AR

AV

Da

Dc

Dm1

Dm2

ER1

S3

1

Front view, Workplace tank-mounted with Elektronikon® controller

Name

Air receiver

Air outlet valve

Automatic condensate outlet

OSD drain outlet (option)

Manual condensate drain valve

Manual condensate drain valve

Elektronikon® controller

Emergency stop button

Electric cable entry

2920 7090 51 13

Floor-mounted version

The compressors are installed directly on the floor.

Instruction book

14

ER

S3

Dm1

Da

GA 11 Pack, Floor mounted, Front view

Elektronikon® controller

Emergency stop button

Manual condensate drain valve

Automatic condensate outlet

2920 7090 51

Instruction book

Ref.

AF

AV

C

FN

M1

Floor-mounted Workplace Pack compressor, rear view

Name

Air filter

Air outlet valve

Combicooler

Fan motor

Drive motor

2920 7090 51 15

Instruction book

2.2

Air flow

Flow diagrams

For Workplace units

References

B

C

D

Ref.

A

16

For Workplace Full-Feature units

Description

Intake air

Air/oil mixture

Hot compressed air

Oil

2920 7090 51

Instruction book

F

G

Ref.

E

Description

Dry air

Condensate

Dry air (compressors with integrated dryer)

Description

Air drawn through filter (AF) and open inlet valve (IV) into compressor element (E) is compressed.

Compressed air and oil flow into the air receiver/oil separator (OT). The air flows through minimum pressure valve (Vp) to air cooler (Ca).

Minimum pressure valve (Vp) prevents the receiver pressure from dropping below a minimum pressure and includes a check valve which prevents blow-back of compressed air from the net.

On Full-Feature compressors the air flows through air dryer (DR).

Air is discharged through outlet valve (AV).

2.3

Oil system

Flow diagram

Oil system

2920 7090 51 17

Instruction book

B

C

References

A

D

Description

Intake air

Air/oil mixture

Compressed air

Oil

Description

The air/oil mixture coming from the compressor element flows into the oil separator/tank, where most of the oil is separated by centrifugal action. The oil collects in the lower part of air receiver/oil separator (OT) which serves as oil tank. The remaining oil is removed by oil separator (OS). A small pipe returns the separated oil towards the compressor element.

Air pressure forces the oil from oil separator/tank (OT) through oil cooler (Co) and filter (OF) towards compressor element (E).

The system comprises a thermostatic bypass valve (BV). Only when the oil is warm, the valve allows the oil to pass through the oil cooler.

2.4

Cooling system

Flow diagram

Cooling system

18 2920 7090 51

Instruction book

B

C

References

A

D

Description

Intake air

Compressed air/oil

Compressed air

Oil

Description

The cooling system comprises of air cooler (Ca) and oil cooler (Co). The cooling air is generated by a fan

(FN). The fan is set on the shaft of the motor.

2.5

Condensate system

Condensate drains

Condensate drains on a floor-mounted version

Condensate drains on a tank-mounted Full-Feature version

Pack versions are equipped with a condensate trap in the air outlet system. The trap is equipped with a valve for automatic draining during operation and is connected to the automatic drain outlet (Da) and to a manually operated valve (Dm1) for draining after stopping the compressor.

Tank-mounted compressors are also provided with a manual condensate drain valve (Dm2) for draining the condensate trapped in the receiver.

Full-Feature versions are equipped with an electronic water drain for automatic draining of the condensate during operation. The electronic drain is connected to automatic drain outlet (Da) and to a manually operated valve (Dm1) for draining after stopping the compressor.

2920 7090 51 19

Instruction book

2.6

Regulating system

Flow diagram

Unloading

If the air consumption is less than the air output of the compressor, the net pressure increases. When the net pressure reaches the unloading pressure, solenoid valve (Y1) is de-energised.

• The control pressure present in the chambers of loading plunger (LP) and unloading valve (UV) is vented to atmosphere via solenoid valve (Y1).

• Loading plunger (LP) moves upwards and causes inlet valve (IV) to close the air inlet opening.

• Unloading valve (UV) is opened by the pressure in the oil separator vessel. The pressure from the oil separator vessel is released into atmosphere through the unloader (UA).

• The pressure in the oil separator vessel stabilises at low value. A reduced amount of air is compressed to guarantee a minimal pressure, required for lubrication during unloaded operation.

Air output is stopped (0%), the compressor runs unloaded.

Loading

When the net pressure decreases to the loading pressure, solenoid valve (Y1) is energised.

• Control pressure is fed from the oil separator vessel via solenoid valve (Y1) to loading plunger (LP) and unloading valve (UV).

• Unloading valve (UV) closes the air blow-off opening. Loading plunger (LP) moves downwards and causes inlet valve (IV) to open fully.

Air delivery is resumed (100%), the compressor runs loaded.

2.7

Electrical system

General

Also consult sections Electrical diagrams

and Electrical connections

.

The electrical system comprises following components:

20 2920 7090 51

Instruction book

KD

KY

KL

T1

PE

Reference

F1

F2-F3

FM

Electric cabinet

Description

Fuses

Fuses

Overload relay, compressor motor

Delta contactor

Star contactor

Line contactor

Transformer

Earth terminal

2.8

Electrical diagrams

The service diagram and the explanatory designations below are given as typical example only. Some of the texts may not be applicable to a specific case.

The applicable service diagram is situated in the electric cubicle of the compressor.

2920 7090 51 21

Instruction book

22

Designations

Service diagram

2920 7090 51

Instruction book

Reference

PT20

TT11

TT90

TT91

Y1

Reference

M1

M2

T1

KA

S1′

S2′

S3

S3′

Reference

E1

F1-F11

FM1

KMD

KL

KY

KD

I

Reference

0

K01

K02

K03

K04

K05

K06

Reference

A1

B1/B2

KPH

K34/K35

Sensors / solenoid valves / electronic water drain

Pressure sensor, air outlet

Temperature sensor, element outlet

Temperature sensor, dew-point (Full Feature)

Temperature sensor, ambient (Full Feature)

Loading solenoid valve

Motors

Compressor motor

Fan motor, cooler

Electric cabinet

Compressor control module

Fuses

Overload relay, compressor motor

Contactor for dryer (Full-Feature)

Line contactor

Star contactor

Delta contactor

Transformer

Auxiliary relay for heaters and auxiliary fan

Remote Start/programmed stop

Remote Load/unload

Emergency stop

Remote emergency stop

Control module

Start button

Stop button

Blocking relay

Auxiliary relay, star contactor

Auxiliary relay, delta contactor

Auxiliary relay, loading/unloading

Auxiliary relay, general shutdown

Auxiliary relay, dryer

Optional equipment

Dryer (Full-Feature)

Electronic Water Drain (EWD)

Phase sequence relay

Thermistor relay

2920 7090 51 23

Reference

R1/K34

R96

KE

S10

Y2

Optional equipment

Drive motor thermistor protection, shut-down

Anti-condensation heaters

Auxiliary relay, load/unload signal for ES100

Main power isolating switch

Solenoid valve for modulating control

2.9

Air dryer

Flow diagram

Instruction book

24

4

5

2

3

Reference

AI

AO

1

Air dryer

Name

Air inlet

Air outlet

Air/air heat exchanger

Air/refrigerant heat exchanger/evaporator

Condensate separator

Automatic drain / condensate outlet

Refrigerant compressor

2920 7090 51

Instruction book

7

8

Reference

6

9

10

11

Name

Refrigerant condenser

Liquid refrigerant dryer/filter

Capillary

Hot gas by-pass valve

Condenser cooling fan

Pressure switch, fan control

Compressed air circuit

Compressed air enters heat exchanger (1) and is cooled by the outgoing, cold, dried air. Water in the incoming air starts to condense. The air then flows through heat exchanger/evaporator (2), where the refrigerant evaporates, causing the air to be cooled further to close to the evaporating temperature of the refrigerant. More water in the air condenses. The cold air then flows through separator (3) where all the condensate is separated from the air. The condensate is automatically drained through outlet (4).

The cold, dried air flows through heat exchanger (1) where it is warmed up by the incoming air.

Refrigerant circuit

Compressor (5) delivers hot, high-pressure refrigerant gas which flows through condenser (6) where most of the refrigerant condenses.

The refrigerant enters evaporator (2) where it withdraws heat from the compressed air by further evaporation at constant pressure. The heated refrigerant leaves the evaporator and is sucked in by the compressor (5).

By-pass valve (9) regulates the refrigerant flow. Fan (10) is switched on or off by switch (11) depending on the loading degree of the refrigerant circuit.

The refrigerant compressor motor has a built-in thermic protection. If the motor stops after tripping of the thermic protection, it may take up to 2 hours for the motor windings to cool down and before the motor can restart.

2920 7090 51 25

Instruction book

3 Elektronikon® controller

3.1

Elektronikon

®

regulator

Control panel

Introduction

In general, the Elektronikon

®

regulator has following functions:

• Controlling the compressor

• Protecting the compressor

• Monitoring components subject to service

• Automatic restart after voltage failure (made inactive)

Automatic control of the compressor

The regulator maintains the net pressure between programmable limits by automatically loading and unloading the compressor. A number of programmable settings, e.g. the unloading and loading pressures, the minimum stop time and the maximum number of motor starts are taken into account.

The regulator stops the compressor whenever possible to reduce the power consumption and restarts it automatically when the net pressure decreases. If the expected unloading period is to short, the compressor is kept running to prevent too short stand-still periods.

Protecting the compressor

Shut-down

If the compressor element outlet temperature exceeds the programmed shut-down level, the compressor will be stopped. This will be indicated on the display of the regulator. The compressor will also be stopped in case of overload of the drive motor.

Air-cooled compressors will also be stopped in the event of overload of the fan motor.

Before remedying, consult the

Safety precautions.

Shut-down warning

A shut-down warning level is a programmable level below the shut-down level.

26 2920 7090 51

Instruction book

If one of the measurements exceeds the programmed shut-down warning level, this will also be indicated to warn the operator before the shut-down level is reached.

Service warning

If the service timer exceeds a programmed value, this will be indicated on the display to warn the operator to carry out some service actions.

Automatic restart after voltage failure

The regulator has a built-in function to automatically restart the compressor when the voltage is restored after voltage failure. This function is deactivated in compressors leaving the factory. If desired, the function can be activated. Consult the Atlas Copco Customer Centre.

If activated, and if the regulator was in the automatic operation mode, the compressor will automatically restart when the supply voltage to the module is restored!

3.2

Control panel

Detailed description

Control panel of the Elektronikon with standard display

6

7

4

5

8

Reference

1

2

3

Designation

Display

Automatic operation symbol

LED, Automatic operation

Warning symbol

LED, Warning

Voltage symbol

LED, Voltage on

Service symbol

Function

Shows icons and operating conditions.

Indicates that the regulator is automatically controlling the compressor: the compressor is loaded, unloaded, stopped and restarted depending on the air consumption and the limitations programmed in the regulator.

Is lit if a warning condition exists.

Indicates that the voltage is switched on.

2920 7090 51 27

Instruction book

12

13

14

Reference

9

10

11

Designation

LED, Service

Start button

Stop button

Scroll buttons

Enter button

Escape button

Function

Is lit when service is needed.

This button starts the compressor. Automatic operation

LED (3) lights up. The Elektronikon is operative.

This button is used to stop the compressor. Automatic operation LED (3) goes out.

Use these buttons to scroll trough the menu .

Use this button to confirm the last action

Use this button to go to previous screen or to end the current action.

3.3

Icons used on the display

Function

Compressor status

Icon Description

When the compressor is stopped, the icon stands still.

When the compressor is running, the icon is rotating.

Motor stopped

Running unloaded

Running loaded

Machine control mode Remote start / stop

LAN control

Automatic restart after voltage failure is active Automatic restart after voltage failure

Timer

Active protection functions

Service

Emergency stop

Service required

28 2920 7090 51

2920 7090 51

Instruction book

Function

Units

Icon Description

Pressure unit (Mega Pascal)

Pressure unit (pounds per square inch)

Pressure unit (bar)

Temperature unit

Temperature unit

Hours (always shown together with seconds)

Percent

The value shown must be multiplied by 10 to get the actual value

The value shown must be multiplied by 100 to get the actual value

The value shown must be multiplied by 1000 to get the actual value

Motor (overload)

Element outlet temperature.

Filter

Drain

Energy saving (dryer)

Ambient temperature

29

Instruction book

Function Icon Description

Dewpoint temperature

3.4

Main screen

When the voltage is switched on, the first screen is a test screen. The next screen is the Main screen, shown automatically.

The Main screen shows:

• The compressor status by means of pictographs

• The air outlet pressure

Always consult Atlas Copco if the pressure on the display is preceded by a «t».

3.5

Shut-down warning

Description

A shut-down warning will appear in the event of:

• Too high a temperature at the outlet of the compressor element

• Too high a dewpoint temperature (Full-Feature compressors)

Compressor element outlet temperature

• If the outlet temperature of the compressor element exceeds the shut-down warning level (factory set at

110 ˚C / 230 ˚F), warning LED (5) starts blinking.

30 2920 7090 51

Instruction book

• Press Scroll down button (12). The screen shows the temperature at the compressor element outlet:

The screen shows that the temperature at the element outlet is 122 °C

It remains possible to scroll through other screens, using the Scroll buttons up and down (12) to check the actual status of other parameters. Press button (11) to stop the compressor and wait until the compressor has stopped. Switch off the voltage, inspect the compressor and remedy. The warning message will disappear as soon if the warning condition disappears.

Dewpoint temperature

On compressors with integrated dryer, alarm LED (5) will light up and the related pictograph will appear flashing if the dewpoint temperature exceeds the warning level (programmable).

The related pictograph

Main screen with the dewpoint temperature warning

will appear flashing

Press the Scroll button (12) until the actual dewpoint temperature appears.

2920 7090 51 31

Instruction book

Warning screen, dewpoint temperature

The screen shows that the dewpoint temperature is 9˚C.

• It remains possible to scroll through other screens (using Scroll buttons 12) to check the actual status of other parameters.

• Press button (11) to stop the compressor and wait until the compressor has stopped.

• Switch off the voltage, inspect the compressor and remedy.

• The warning message will disappear as soon as the warning condition disappears.

3.6

Shut-down

Description

The compressor will be shut down:

• In case the temperature at the outlet of the compressor element exceeds the shut-down level

• In case of error of the outlet pressure sensor

• In case of overload of the drive motor

• In case of overload of the fan motor on air-cooled compressors

Compressor element outlet temperature

• If the outlet temperature of the compressor element exceeds the shut-down level (factory setting 120 ˚C /

248 ˚F, programmable) the compressor will be shut-down, alarm LED (5) will flash, automatic operation

LED (3) will go out and the following screen will appear:

32

Main screen with shut-down indication, element outlet temperature

The related pictograph will appear flashing.

2920 7090 51

Instruction book

• Press Scroll buttons (12) until the actual compressor element temperature appears.

Shut-down screen, element outlet temperature

The screen shows that the temperature at the outlet of the compressor element is 122 ˚C.

• Switch off the voltage and remedy the trouble.

• After remedying and when the shut-down condition has disappeared, switch on the voltage and restart the compressor.

Motor overload

• In the event of motor overload, the compressor will be shut-down, alarm LED (5) will flash, automatic operation LED (3) will go out and the following screen will appear:

Main screen with shut-down indication, motor overload

• Switch off the voltage and remedy the trouble.

• After remedying and when the shut-down condition has disappeared, switch on the voltage and restart the compressor.

3.7

Service warning

Description

A service warning will appear when the service timer has reached the programmed time interval.

2920 7090 51 33

Instruction book

• If the service timer exceeds the programmed time interval, alarm LED (5) will light up.

• Press Scroll buttons (12) to scroll to <d.6> and the service symbol is shown. Press button (13): the actual reading of the service timer appears and is shown in <hrs> or <x1000 hrs> (if the service timer value is higher than 9999).

Example of service timer screen

The screen shows that the reading of the service timer is 4002.

• Press Scroll button (12) to scroll to <d.1> and the running hours symbol is shown. Press button (13): the actual reading of the service timer appears and is shown in <hrs> or <x1000 hrs> (if the service timer value is higher than 9999).

34

Example of running hours screen

• Stop the compressor, switch off the voltage and carry out the required service actions. See section

Preventive Maintenance.

• The longer interval service actions must also include the shorter interval actions.

In the example above, carry out all service operations belonging to the 8000 running hours interval as well as those belonging to the 4000 running hours interval.

• If using mineral oil instead of Atlas Copco Roto-Inject Fluid, the service timer has to be decreased. See section Preventive maintenance schedule.

2920 7090 51

Instruction book

• After servicing, reset the service timer. See section Calling up/resetting the service timer

3.8

Scrolling through all screens

Control panel

Control panel

Scroll buttons (12) can be used to scroll through all screens. The screens are divided into register screens, measured data screens, digital input screens (numbered as <d.in>, <d.1>, …), parameter screens (numbered as <P.01>, <P.02>, …), protections screens (numbered as <Pr.01>,…) and test screens (numbered as <t.01>,…).

During scrolling, the numbers of the screens appear consecutively. For most screens, the unit of measurement and the related pictograph are shown together with the screen number.

Example

The screen shows the screen number <d.1>, the unit used <hrs> and the related symbol for running hours.

Press Enter key (13) to call up the actual running hours.

Overview of the screens

Digital input screens

<d.in>

<d.1>

<d.2>

<d.3>

Designation

Digital input status

Running hours (hrs or x 1000 hrs)

Motor starts (x 1 or x 1000)

Module hours (hrs or x 1000 hrs)

Related topic

See section

Calling-up running hours

See section

Calling up motor starts

See section

Calling up module hours

2920 7090 51 35

36

Instruction book

<P.10>

<P.11>

<P.12>

<P.13>

<P.14>

Digital input screens

<d.4>

<d.5>

<d.6>

<d.7>

Parameter screens

<P.01>

<P.02>

<P.03>

<P.04>

<P.05>

<P.06>

<P.07>

<P.08>

<P.09>

Protections screens

<Pr.01>

<Pr.02>

<Pr.03>

Designation

Loading hours (hrs or x1000 hrs)

Load relay (x1 or x 1000)

Service timer reading (hrs or x 1000 hrs)

Actual program version

Related topic

See section

Calling up loading hours

See section Calling up Calling up load relay

See section

Calling up/resetting the service timer

Designation Related topic

Selection between local, remote or LAN control

Setting a node ID for LAN control and the channels for Mk 4 and Mk 5

See section

Selection between Local

Remote and LAN control

See section

Calling up/modifying CAN address control

Settings for IP, gateway and Subnet mask See section

Calling up/modifying IP,

Gateway and Subnetmask

Pressure band settings See section

Calling up/modifying pressure band settings

Setting a pressure band selection See section

Modifying pressure band selection

Modifying a service timer

Setting of unit for temperature

Setting of unit for pressure

See section

Calling up/modifying service timer settings

See section

Calling up/modifying unit of temperature

See section

Calling up/modifying unit of pressure

See section

Activating automatic restart

Selection for function: Automatic restart after voltage failure (active or not, only for Atlas

Copco)

Selection between Y-D or DOL starting

Setting of load delay time

Setting of minimum stop time

See section

Selection between Y-D or DOL starting

See section Calling up/modifying load delay time

See section

Calling up/Modifying minimum stop time

Setting a password

Remote pressure sensing

See section

Activating password protection

See section

Activate Load/Unload remote sensing

Designation

Protections screens

Related topic

See section

Calling up/modifying protection settings

2920 7090 51

Instruction book

Test screens

<t.01>

<t.02>

<t.03>

Designation

Display test

Safety valve test

Production test

Menu flow

Related topic

See sections Test screens

See sections Test screens

See sections Test screens

2920 7090 51

Simplified menu flow

37

(5)

(6)

(7)

(8)

(9)

(10)

(11)

Ref.

(1)

(2)

(3)

(4)

(12)

(13)

(14)

(15)

Description

Compressor outlet pressure

Compressor outlet temperature

Dewpoint temperature

Digital input status

Running hours

Motor starts

Module hours

Loading hours

Load relay

Service timer reading

Actual program version

LAN selection

Settings node ID

IP settings

Pressure band selection

(20)

(21)

(22)

(23)

(24)

(25)

(26)

Ref.

(16)

(17)

(18)

(19)

(27)

(28)

(29)

Description

Pressure band setting

Service timer settings

Temperature unit

Unit pressure

Auto restart

Selection Y-D/DOL

Load delay time

Minimum stop time

Password settings

Remote pressure sensing

Protections

Display test

Safety valve test

Production test

3.9

Calling up outlet and dewpoint temperatures

Control panel

Instruction book

Starting from the Main screen:

38

• Press Scroll button (12). The outlet temperature will be shown:

2920 7090 51

Instruction book

The screen shows that the outlet temperature is 82 ˚C.

• For Full-Feature compressors:

Press Scroll button (12). The dewpoint temperature will be shown:

The screen shows that the dewpoint temperature is 3 ˚C.

• Press Scroll button (12) to scroll downwards or upwards through the screens.

3.10 Calling up running hours

Control panel

Starting from the Main screen:

• Press Scroll button (12) until <d.1> is shown and then press Enter button (13):

2920 7090 51 39

Instruction book

The screen shows the unit used (x1000 hrs) and the value (11.25): the running hours of the compressor are

11250 hours.

3.11 Calling up motor starts

Control panel

40

Starting from the Main screen:

• Press Scroll button (12) until <d.2> is shown and then press Enter button (13):

This screen shows the number of motor starts (x 1 or — if <x1000> lights up — x 1000). In the above example, the number of motor starts is 10100.

2920 7090 51

Instruction book

3.12 Calling up module hours

Control panel

Starting from the Main screen:

• Press Scroll button (12) until <d.3> is shown and then press Enter button (13):

In the example shown, the screen shows the unit used (hrs) and the value (5000): the regulator module has been in service during 5000 hours.

3.13 Calling up loading hours

Starting from the Main screen:

• Press Scroll button (12) until <d.4> is shown and then press Enter button (13):

The screen shows the unit used <hrs> (or <x1000 hrs>) and the value <1755>: the compressor has been running loaded during 1755 hours.

3.14 Calling up load relay

Starting from the Main screen:

2920 7090 51 41

Instruction book

• Press Scroll button (12) until <d.5> is shown and then press Enter button (13):

This screen shows the number of unload to load actions (x 1 or — if <x1000> lights up — x 1000). In the above example, the number of unload to load actions is 10100.

3.15 Calling up/resetting the service timer

Calling up the service timer

Starting from the Main screen:

42

• Press Scroll button (12) until <d.6> is shown and then press Enter button (13):

2920 7090 51

Instruction book

This screen shows the unit used <hrs> (or <x1000 hrs>) and the value <1191>. In the example shown, the compressor has run 1191 hours since the previous service.

Resetting the service timer

After servicing, see section

Service warning , the timer has to be reset:

• Scroll to register screen <d.6> and press Enter button (13).

• The reading (e.g. 4000) will appear.

• Press Enter button (13) and — if a password is set — enter the password.

The icon will flash (indicating that resetting is possible).

• Press Enter button (13) to reset the timer to <0.000> or press the Escape button (14) to cancel the operation.

3.16 Selection between local, remote or LAN control

Starting from the Main screen:

• Press Scroll button (12) until <P.01> is shown and then press Enter button (13). The actually used control mode is shown: <LOC> for local control, <rE> for remote control or <LAn> for LAN control.

• Press Enter button (13) and if necessary enter the password. The actually used control mode is blinking.

Use Scroll button (12) to change the control mode.

• Press Enter button (13) to program the new starting mode or press Escape button (14) to cancel.

3.17 Calling up/modifying CAN address control

Calling up

Starting from the main screen,

Press the Scroll button (12) until <P.02> is shown and then press Enter button (13).

2920 7090 51 43

Instruction book

If necessary enter the password. The next screen shows that the function is “ON or OFF” Press the Enter button (13) to change this mode Use the Scroll buttons (12) to select ON or OFF.

When this function is ON, use the Scroll buttons up or down (12) to see the node ID.

If desired the user can change this ID. Press the Enter button (13): the node ID value starts blinking. Use the

Scroll buttons (12) to change the node ID. Press the Enter button (13) to program the new node ID or press the Escape button (14) to leave this screen or to cancel this operation.

Modifying the Node ID

The Node ID can be changed; use a value between 1 and 31. When the function is ON, the parameters cannot be modified. Change the function to OFF to change the node ID.

44

It is also possible to change the channels. The controller has 4 channels. When changing the channels, the controller can act as a Mk IV controller. To set the channels, go to the screen where the node ID is visible.

Press the Scroll button down (12). The following screen appears:

2920 7090 51

Instruction book

Press the Enter button (13) to modify the setting. The utmost left value will blink. Change this value by using the Scroll buttons (12). Press the Enter button (13) to confirm. Change the other values in the same way, as required.

After modifying the settings, the screen may look as follows:

3.18 Calling up/modifying IP, Gateway and Subnetmask

Calling up

Starting from the Main screen:

Press the Scroll button (12) until <P.03> is shown and then press Enter button (13).

The next screen shows either OFF or ON. If ON, press the Enter button (13) to modify it to OFF. Use the

Scroll buttons Up or Down (12) to scroll between the items in this list (<IP> for IP address, <SUB> for

Subnetmask or <GATE> for Gateway):

2920 7090 51 45

Instruction book

Modification

Press the Enter button (13) and if necessary enter the password. The first digits are blinking. Use the Scroll buttons Up or Down (12) to modify the settings and press Enter (13) to confirm. Modify the next digits the same way. The standard IP address is set as 192.168.100.100.

46 2920 7090 51

Instruction book

3.19 Calling up/modifying pressure band settings

Calling up the settings

Starting from the Main screen:

• Press Scroll button (12) until <P.04> is shown and then press Enter button (13). Pressure band 1 (<Pb.1>) is shown on the display. Button (12) can be used to scroll to pressure band 2 (<Pb.2>).

• Press Enter button (13) on the desired pressure band. The load level of the selected pressure band appears.

Button (12) can be used to scroll to the unload level.

2920 7090 51 47

Instruction book

Loading pressure

Unloading pressure

• Press Enter button (13) to modify the load level (value starts blinking). A password may be required. Use

Scroll buttons (12) to change the loading pressure.

• Press Enter button (13) to program the new values or press the Escape button (14) to cancel.

3.20 Modifying the pressure band selection

Control panel

48 2920 7090 51

Instruction book

Starting from the Main screen:

• Press Scroll button (12) until <P.05> is shown and then press Enter button (13). The active pressure band

1 (<Pb.1>) is shown on the display.

• Press Enter button (13) to modify the pressure band selection (a password may be required). The active pressure band <Pb.1> starts blinking.

• Press button (12) to modify the active pressure band. Press Enter button (13) to confirm or the Escape button (14) to cancel.

3.21 Calling up/modifying service timer settings

Control panel

Starting from the Main screen:

• Press Scroll button (12) until <P.06> is shown and then press Enter button (13): the setting of the service timer is shown in <hrs> (hours) or <x1000 hrs> (hours x 1000). Example: <4000 hrs> means the timer is set at 4000 running hours.

• Press Enter button (13) to modify this value (a password may be required): the value blinks. Use the Scroll buttons (12) to modify the setting.

• Press Enter button (13) to program the new value.

3.22 Calling up/modifying the unit of temperature

Control panel

Starting from the Main screen:

• Press Scroll button (12) until <P.07> is shown and then press Enter button (13). The actually used unit is shown. Possible settings are <˚C> and <˚F>.

• Press Enter button (13) (unit blinks) and use the Scroll buttons (12) to select another unit of temperature.

• Press Enter button (13) to program the new unit or press Escape button (14) to return to the parameter screen without changes.

2920 7090 51 49

3.23 Calling up/modifying unit of pressure

Control panel

Instruction book

Starting from the Main screen:

• Press Scroll button (12) until <P.08> and the possible settings are shown (<Mpa>, <psi>, and <bar>).

Press Enter button (13) and the actually used unit is shown.

• Press Enter button (13) (unit starts blinking) and use the Scroll buttons (12) to select another unit of pressure.

• Press Enter button (13) to program the new unit of pressure. Press the escape button (14) to return to the parameter screens.

3.24 Activating automatic restart after voltage failure

Description

This parameter, accessible in screen <P.09>, can only be modified after entering a code. Consult Atlas Copco if this function is to be activated.

3.25 Selection between Y-D or DOL starting

Control panel

Starting from the Main screen:

• Press Scroll button (12) until <P.10> and the motor pictograph is shown and then press Enter button (13).

The actually used starting mode is shown: <Y-D> (star-delta) or <doL> (Direct-On Line).

50 2920 7090 51

Instruction book

• This parameter can only be modified after entering a code. Consult Atlas Copco if the parameter is to be changed.

3.26 Calling up modifying load delay time

Control panel

Starting from the Main screen:

• Press Scroll button (12) until <P.11> and the compressor load pictograph is shown and press the Enter button (13):

• This screen shows the load delay time 10 and the unit <s> seconds. To modify this value press the Enter button (13) (a password may be required).

• The value starts blinking and Scroll buttons (12) can be used to modify the value.

• Press the Enter button (13) to program the new value.

The minimum and maximum value depends on the parameters.

3.27 Calling up modifying minimum stop time

Starting from the Main screen:

2920 7090 51 51

Instruction book

• Press the Scroll button (12) until <P.12> and the motor pictograph is shown and press the Enter button

(13):

• This screen shows the minimum stop time (20) and the unit <s> (seconds).

• To modify this value press the Enter button (13). The value starts blinking and Scroll buttons (12) can be used to modify this value.

• Press Enter button (13) to program the new value.

The minimum and maximum values depend on the parameters.

3.28 Activating password protection

Important settings such as the setting of the service timer, pressure band setting, control mode settings,… can be protected by a password.

Starting from the Main screen:

• Press Scroll buttons (12) until <P.13> is shown and press Enter button (13):

• Password (<PASS>) appears on the screen. Press the Enter button (13).

• The screen shows the password status (ON (<On>) or OFF (<OFF>). Press Enter button (13) to modify.

• Change the value with Scroll buttons (12).

• Select <On> and press Enter button (13).

• Enter the new password and press Enter button (13) to confirm.

• Enter the password again and press Enter button (13) to confirm.

• <On> appears on the display. Press reset key to return to the parameter screen.

Lost passwords can not be recovered. Save the password carefully.

3.29 Activate load/unload remote pressure sensing

Starting from the Main screen:

• Press the Scroll button (12) until <P.14> appears

.

52 2920 7090 51

Instruction book

• Press the Enter button (13).

• The function of this screen is to activate the remote load/unload relay. To be able to activate this remote

Load/Unload functionality, a physical digital input with function Load/Unload is required.

Once this parameter is activated, the physical digital input can be used to switch the compressor between

Load and Unload.

3.30 Calling up/modifying protection settings

Available protections

A number of protection settings are provided. The protection screens are labelled <Pr.>. The pictograph shown with the protection screen indicates the purpose of the protection.

Possible combinations are <Pr.> followed by a number and one of the next pictographs:

Pictograph Designation

<Pr.> shown with the pressure pictograph shows the pressure protections.

<Pr.> shown with the element outlet temperature pictograph shows the element outlet temperature protections.

<Pr.> shown with the dewpoint temperature pictograph shows the dewpoint temperature protections.

<Pr.> shown with the ambient temperature pictograph shows the ambient temperature protections.

Following protection settings are available:

2920 7090 51 53

• A low warning level, shown on the display as <AL-L>.

• A high warning level, shown on the display as <AL-H>.

• A low shut-down level, shown on the display as <Sd-L>.

• A high shut-down level, shown on the display as <Sd-H>.

• Service level shown on the display as <SE-L>.

• Service level shown on the display as <SE-H>.

Example of protection screens

Instruction book

Changing the settings

Starting from the Main screen (the example given describes the protection of the element outlet temperatures):

Press Scroll buttons (12) until <Pr.> followed by a number and the element outlet temperature pictograph is shown and press Enter button (13):

• The warning level for the high temperature warning level <AL-H> and the high temperature shut-down level <Sd-H> become visible. Use Scroll keys (12) to move between the warning level (<AL>) and the shut-down level (<Sd>), press the Enter button (13) to modify the value.

• An optional password may be required, the value starts blinking and Scroll buttons (12) can be used to modify the value.

• Press the Enter button (13) to program the new value.

Programmable settings can only be modified within allowed limits.

54 2920 7090 51

Instruction book

3.31 Test screens

Display test

Starting from the Main screen:

• Press Scroll buttons (12) until <t.01> is shown and then press Enter button (13).

Safety valve test

In the test screen <t.02> a safety valve test is provided. The safety valves can only be tested after entering a code. Consult Atlas Copco if the safety valves are to be tested.

Production test

Test screen <t.03> is only intended for production test. If the Main screen shows following screen, the controller is in production test mode:

How to solve?

Use the Scroll buttons (12) and scroll to menu <t.03>.

The screen shows:

Press the Enter button (13): the text starts blinking. Press enter again and the menu disappears.

2920 7090 51 55

Instruction book

3.32 Web server

All Elektronikon controllers have a built-in web server that allows direct connection to a PC via a local area network (LAN). This allows to consult certain data and settings via the PC instead of via the display of the controller.

Getting started

Make sure you are logged in as administrator.

• Use the internal network card from your computer or an USB to LAN adapter (see picture below).

USB to LAN adapter

• Use an UTP cable (CAT 5e) to connect to the controller (see picture below).

Configuration of the network card

• Go to My Network places (1).

56 2920 7090 51

Instruction book

• Click on View Network connections (1).

• Select the Local Area connection (1), which is connected to the controller.

• Click with the right button and select properties (1).

2920 7090 51 57

Instruction book

• Use the checkbox Internet Protocol (TCP/IP) (1) (see picture). To avoid conflicts, de-select other properties if they are selected. After selecting TCP/IP, click on the Properties button (2) to change the settings.

• Use the following settings:

• IP Address 192.168.100.200

• Subnetmask 255.255.255.0

Click OK and close network connections.

Configuration of the web server

Configure the web interface

The internal web server is designed and tested for Microsoft® Internet Explorer 6, 7 and

8. Other web browsers like Opera and Firefox do not support this internal web server.

When using Opera or Firefox, a redirect page opens. Click on the hyperlink to connect to the download server from Microsoft® to download the latest version of Internet Explorer, and install this software.

• When using Internet Explorer:

Open Internet Explorer and click on Tools — Internet options (2).

58 2920 7090 51

Instruction book

• Click on the Connections tab (1) and then click on the LAN settings button (2).

• In the Proxy server Group box, click on the Advanced button (1).

2920 7090 51 59

Instruction book

• In the Exceptions Group box, enter the IP address of your controller. Multiple IP addresses can be given but they must be separated with semicolons (;).

Example: Suppose that you already added two IP addresses (192.168.100.1 and 192.168.100.2). Now you add 192.168.100.100 and separate the 3 IP addresses by putting semicolons between them (1) (see picture).

Click OK (2) to close the window.

60

Viewing the controller data

• Open your browser and type the IP address of the controller you want to view in your browser (in this example http://192.168.100.100). The interface opens:

2920 7090 51

Instruction book

Navigation and options

• The banner shows the compressor type and the language selector. In this example, three languages are installed on the controller.

• On the left site of the interface you can find the navigation menu (see picture below).

If a license for ESi is foreseen, the menu contains 3 buttons.

• Compressor: shows all compressor settings.

• Es: shows the ESi status (if a license is provided).

• Preferences: allows to change temperature and pressure unit.

2920 7090 51 61

Instruction book

Compressor settings

All compressor settings can be hidden or shown. Put a mark for each setting. Only the machine status is fixed and can not be removed from the main screen.

Analog inputs

(The units of measure can be changed in the preference button from the navigation menu).

Counters

Counters give an overview of all actual counters from controller and compressor.

Info status

Machine status is always shown on the web interface.

Digital inputs

Gives an overview of all Digital inputs and status.

62 2920 7090 51

Instruction book

Digital outputs

Shows a list of all digital outputs and their status.

Special protections

Give an overview of all special protections of the compressor.

Service plan

Shows all levels of the service plan and status. This screen only shows the running hours. It is also possible to show the actual status of the service interval.

ES screen controller

If a ESi license is provided, the button ES is shown in the navigation menu. At the left all compressors in the

ES and at the right the ES status is shown.

2920 7090 51 63

Instruction book

A possible ESi screen

3.33 Programmable settings

Parameters: unloading/loading pressures for compressors without built-in refrigeration dryer

Minimum setting

Factory setting

Maximum setting

Unloading pressures

Unloading pressure (7.5 bar compressors)

Unloading pressure (7.5 bar compressors)

Unloading pressure (8.5 bar compressors)

Unloading pressure (8.5 bar compressors)

Unloading pressure (10 bar compressors)

Unloading pressure (10 bar compressors)

Unloading pressure (13 bar compressors)

Unloading pressure (13 bar compressors)

Unloading pressure (100 psi compressors)

Unloading pressure (100 psi compressors)

Unloading pressure (125 psi compressors)

Unloading pressure (125 psi compressors)

Unloading pressure (150 psi compressors)

Unloading pressure (150 psi compressors)

Unloading pressure (175 psi compressors)

Unloading pressure (175 psi compressors)

Loading pressures

Loading pressure (7.5 bar compressors)

Loading pressure (7.5 bar compressors)

Loading pressure (8.5 bar compressors)

Loading pressure (8.5 bar compressors)

Loading pressure (10 bar compressors)

Loading pressure (10 bar compressors)

Loading pressure (13 bar compressors) bar(e) psig bar(e) psig bar(e) psig bar(e)

5.5

80

5.5

80

5.5

80

5.5

80

5.5

80

5.5

80

5.5

80

5.5

80 bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig

5.4

78

5.4

78

5.4

78

5.4

6.9

100

8.6

125

10.3

150

12

175

7

101.5

8

116

9.5

137.8

12.5

181.3

6.4

92.8

7.4

107.3

8.9

129.1

11.9

7.4

107.3

8.4

121.8

9.9

143.6

12.9

7.4

107.3

9.1

132

10.8

156.6

12.5

181.2

7.5

108.8

8.5

123.5

10

145.0

13

188.6

64 2920 7090 51

Instruction book

Loading pressure (13 bar compressors)

Loading pressure (100 psi compressors)

Loading pressure (100 psi compressors)

Loading pressure (125 psi compressors)

Loading pressure (125 psi compressors)

Loading pressure (150 psi compressors)

Loading pressure (150 psi compressors)

Loading pressure (175 psi compressors)

Loading pressure (175 psi compressors) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig

78

5.4

78

5.4

78

Minimum setting

78

5.4

78

5.4

Factory setting

172.6

6.3

91.4

8

116

9.7

140.7

11.4

165.3

Parameters: unloading/loading pressures for compressors with built-in refrigeration dryer

Minimum setting

Factory setting

Maximum setting

Unloading pressures

Unloading pressure (7.5 bar compressors)

Unloading pressure (7.5 bar compressors)

Unloading pressure (8.5 bar compressors)

Unloading pressure (8.5 bar compressors)

Unloading pressure (10 bar compressors)

Unloading pressure (10 bar compressors)

Unloading pressure (13 bar compressors)

Unloading pressure (13 bar compressors)

Unloading pressure (100 psi compressors)

Unloading pressure (100 psi compressors)

Unloading pressure (125 psi compressors)

Unloading pressure (125 psi compressors)

Unloading pressure (150 psi compressors)

Unloading pressure (150 psi compressors)

Unloading pressure (175 psi compressors)

Unloading pressure (175 psi compressors)

Loading pressures

Loading pressure (7.5 bar compressors)

Loading pressure (7.5 bar compressors)

Loading pressure (8.5 bar compressors)

Loading pressure (8.5 bar compressors)

Loading pressure (10 bar compressors)

Loading pressure (10 bar compressors)

Loading pressure (13 bar compressors)

Loading pressure (13 bar compressors)

Loading pressure (100 psi compressors) bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) psig bar(e) bar(e) psig

5.4

78

5.4

78

5.4

78

5.4

78

5.4

80

5.5

80

5.5

80

5.5

80

5.5

80

5.5

80

5.5

80

5.5

5.5

80

6.4

92.8

7.4

107

8.9

129.1

11.9

172.6

6.3

181.3

6.9

100

8.6

125

10.3

150

7

101.5

8

116

9.5

137.8

12.5

12

175

7.1

103

8.2

119

9.6

139.2

12.6

182.8

7

184.2

7.1

103

8.8

127.6

10.5

152.3

7.2

104.4

8.3

120