-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

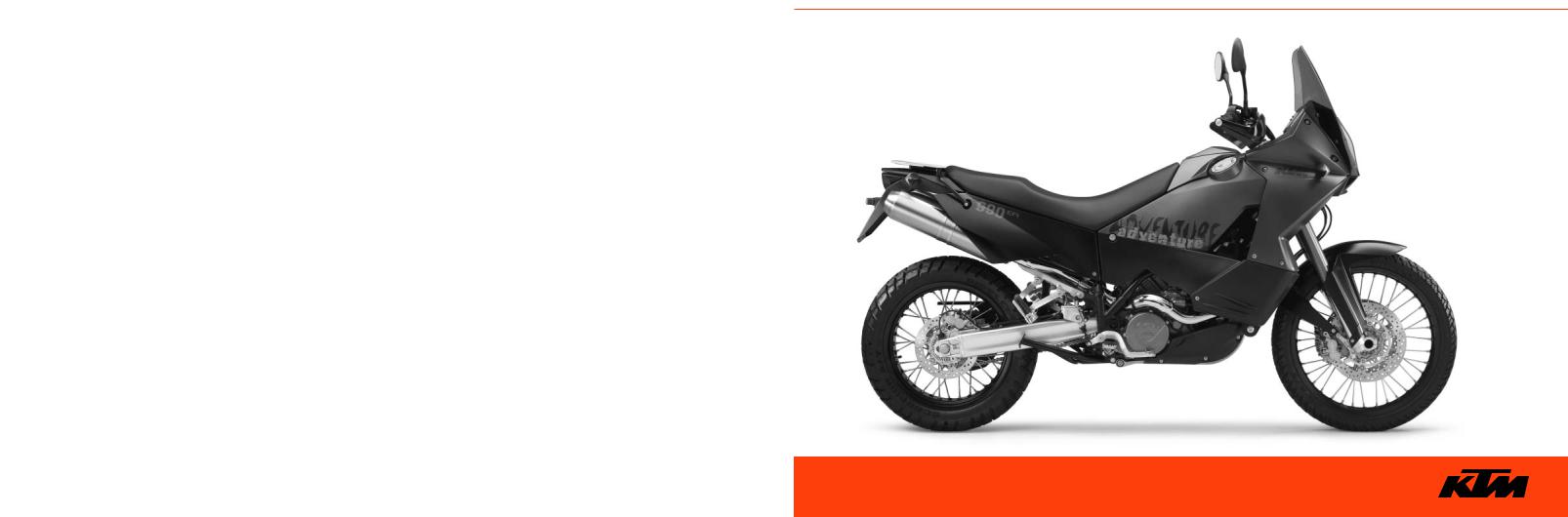

OWNER’S MANUAL

2007

990 ADVENTURE

990 ADVENTURE S

ART. NR. 3.211.149 EN

Related Manuals for KTM 990 ADVENTURE

Summary of Contents for KTM 990 ADVENTURE

-

Page 1

OWNER’S MANUAL 2007 990 ADVENTURE 990 ADVENTURE S ART. NR. 3.211.149 EN… -

Page 2: Introduction

INTRODUCTION We would like to congratulate you on your purchase of a KTM motorcycle. You are now the owner of a state-of-the-art sport motorcycle that guarantees to bring you lots of fun and enjoyment, provided that you clean and maintain it appropriately.

-

Page 3: Important Information

IMPORTANT INFORMATION INTENDED PURPOSE The KTM 990 Adventure is designed to resist the usual wear and tear of normal use on roads and easy terrain (unpaved roads). OWNER’S MANUAL Carefully read the entire Owner’s Manual before you start riding your motorcycle, even if this will take a little time. It contains use- ful tips and information on the best way to handle the motorcycle and how to protect yourself from injuries.

-

Page 4

The service work specified in the „Lubrication and Maintenance Schedule“ must be performed by an authorized KTM workshop. This is the only place that has the qualified technicians and the special tools required for the 990 Adventure. Be sure to have the workshop verify all service work carried out in the service manual to avoid losing your right to claim under the warranty. -

Page 5: Table Of Contents

GENERAL TIPS AND WARNINGS FOR STARTING THE MOTORCYCLE …….24 Instructions for initial operation ….24 Running in the LC8 engine .

-

Page 6

Checking the chain for wear ….. . .49 General informations about KTM disc brakes …50 Adjusting of free travel at the hand brake lever . -

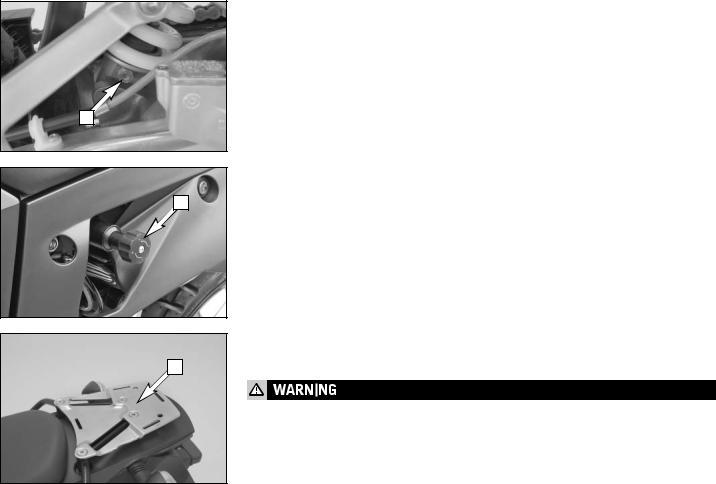

Page 7: Serial Number Locations

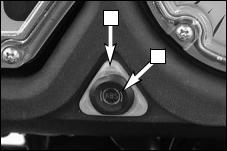

» SERIAL NUMBER LOCATIONS Chassis number The chassis number is located on the right side of the steering head tube and on the type label. Write this number into the relevant area on page 1. Engine number, engine type The engine number and engine type are embossed in the engine case near the shift lever. Write this number into the relevant area on page 1.

-

Page 8: Operation Instruments

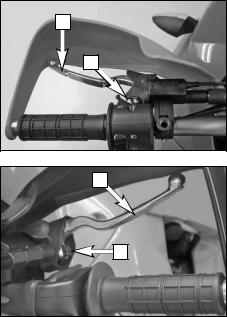

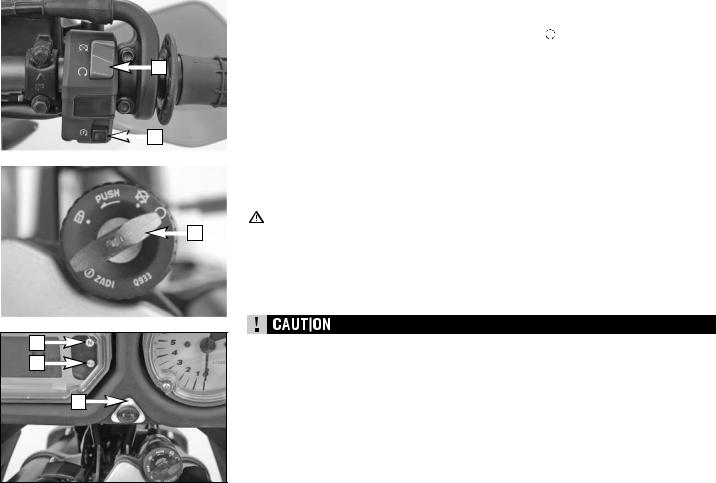

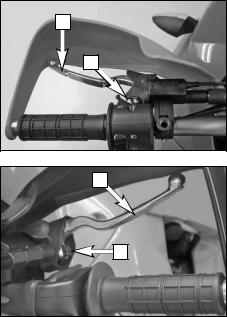

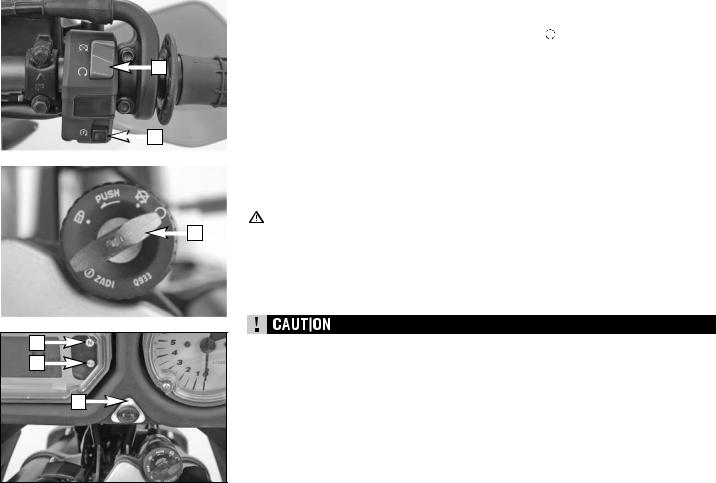

» OPERATION INSTRUMENTS Clutch lever The clutch lever [1] is located on the left side of the handlebar. The adjusting screw [A] is used to change the original position of the clutch lever (see maintenance work on chassis and engine). The clutch is hydraulically actuated and adjusts itself automatically.

-

Page 9: Multi-Functional Digital Speedometer

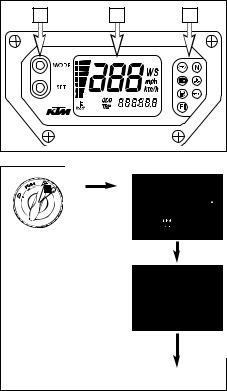

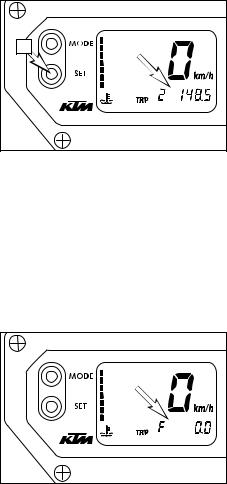

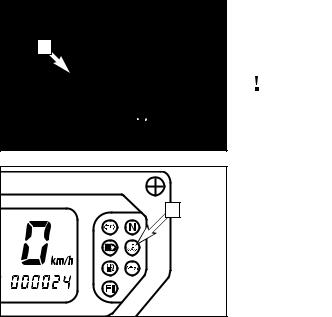

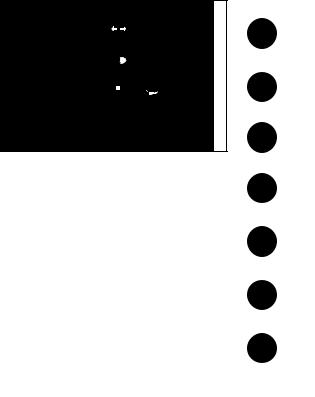

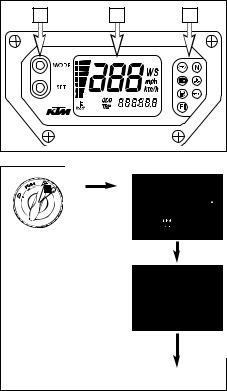

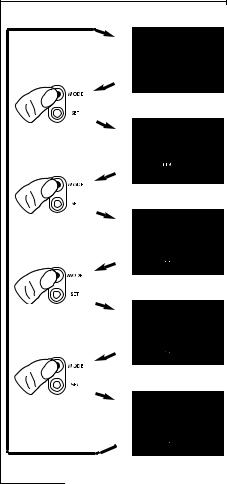

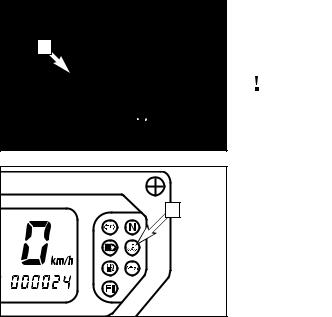

Use the MODE and SET [1] button to change the display and the basic settings in the display. Display [2] shows all of the information that may be of interest to you. 5 display modes can be selected with the MODE button. The indicator lamps [3] provide additional information on the motorcycle’s running condition. Display TEST…

-

Page 10

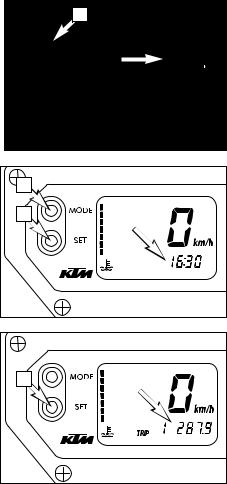

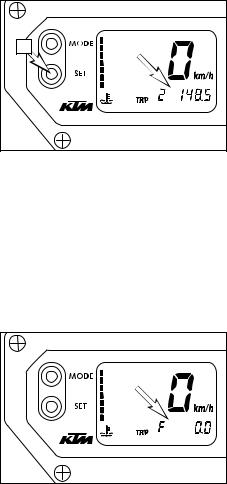

OPERATION INSTRUMENTS CLOCK TRIP 1 TRIP 2 TRIP F » CLOCK You will recognize the CLOCK display by the blinking dots between the hours and minutes. It displays the speed, temperature of the cooling liquid and the clock. To switch to the next display mode, press the MODE button. The speed, temperature of the cooling liquid and the total kilometers or miles traveled are shown in the ODO mode. -

Page 11: Setting Options In The Display

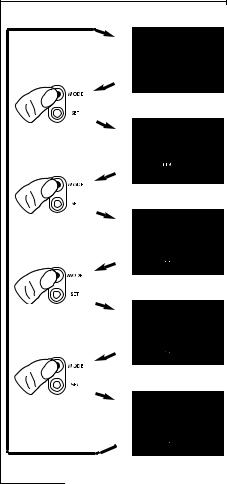

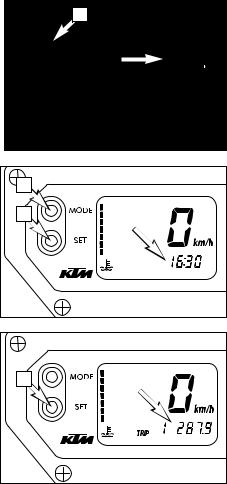

OPERATION INSTRUMENTS 10 sec » Setting options in the display KILOMETERS OR MILES. You can have the speed and distance shown in kilometers or miles in the display. The dis- play can be adapted to the respective country on long-distance trips. To switch from kilometers to miles, switch on the ignition and press the MODE [1] button for approx.

-

Page 12

» OPERATION INSTRUMENTS RESETTING TRIP 2 The trip meter 2 runs continuously and counts up to 999.9. It can be used similarly to TRIP 1 or together with a switch available as an accessory (see below) for trips according to a roadbook. -

Page 13: Cooling Liquid Temperature Display

OPERATION INSTRUMENTS 120°C (248°F) 110°C (230°F) 100°C (212°F) 70°C (158°F) 60°C (140°F) 50°C (122°F) 40°C (104°F) » Cooling liquid temperature display The temperature display [1] is shown in 7 bars. The more bars that light up, the hotter the cooling liquid. When the lowest bar lights up, the cooling liquid has reached a temperature of approx.

-

Page 14: Indicator Lamps

» OPERATION INSTRUMENTS Indicator lamps The green indicator lamp will blink in the blinker rhythm when the blinker is switched on. NOTE: The indicator lamp will blink faster when a blinker is broken. The green indicator lamp will light up when the gearbox is in an idling position.

-

Page 15: Abs Button – Models With Abs (Antilock Brake System)

NOTE: The brake system will still function but ABS control will no longer be active. Continue to drive carefully and have the ABS checked at an authorized KTM workshop. NOTE: The ABS warning lamp can also light up if there is a large deviation between the speed of the front and rear wheel in extreme driving situations, e.g.

-

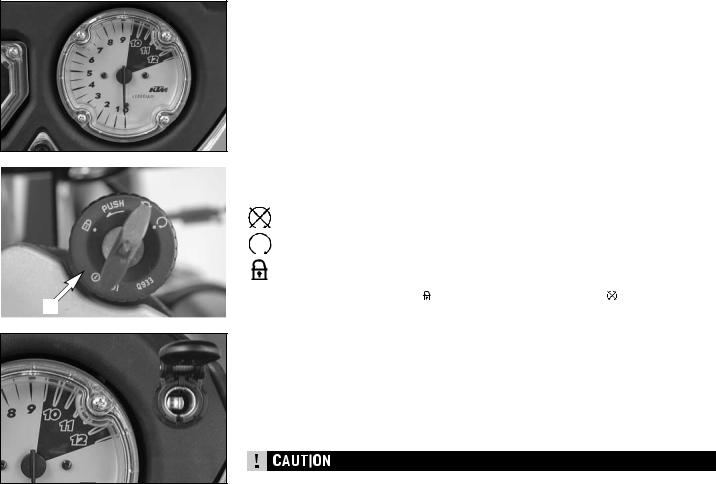

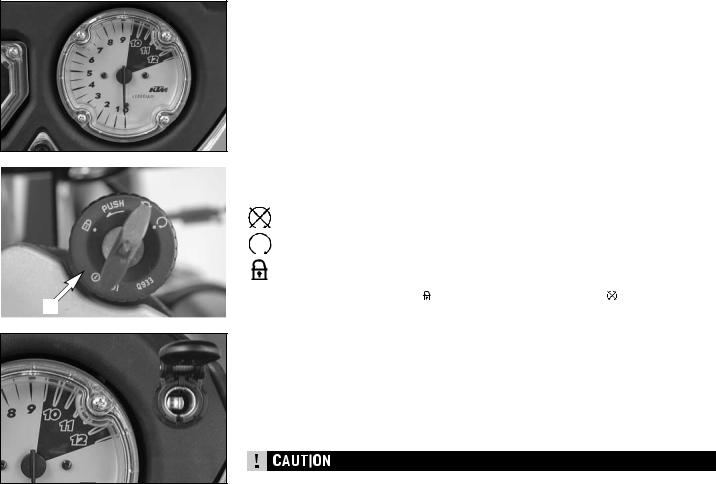

Page 16: Tachometer

OPERATION INSTRUMENTS » Tachometer The tachometer shows the engine speed in revolutions per minute. Do not run the engine beyond the black mark at 9500 rpm. The speed limiter will set in at 9600 rpm, drastically reducing the engine power above this rotational speed.

-

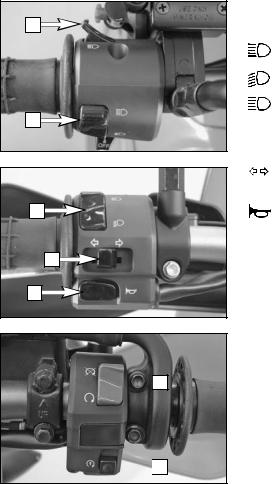

Page 17: Combination Switch

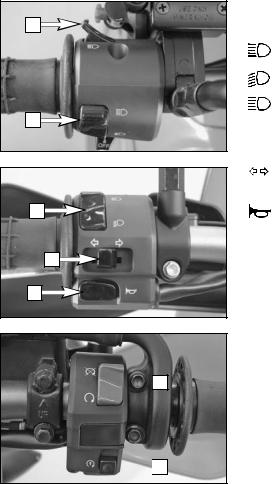

OPERATION INSTRUMENTS » Combination switch The rocker switch LIGHTS [1] actuates the high beam or low beam. = High-beam light = Low-beam light The light signal (high beam) is actuated with button [2]. The indicator switch [3] returns to central position after actuation. Press flasher switch towards switch housing to switch off the flasher.

-

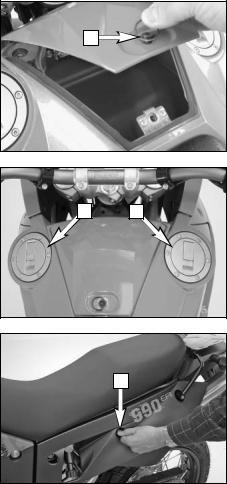

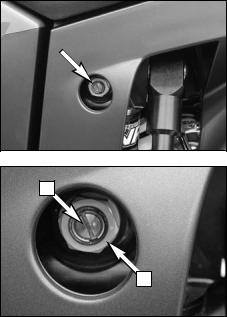

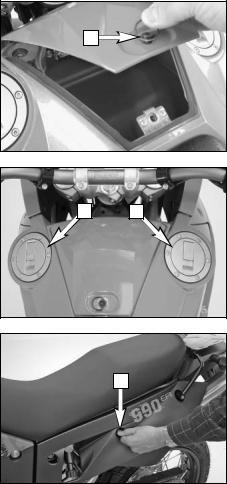

Page 18: Storage Compartment

Filler caps The 990 Adventure has 2 separate fuel tanks. Both filler caps [2] can be locked and are equipped with a tank vent system. To open, insert the ignition key, turn 45° in a clockwise direction and fold up the filler cap.

-

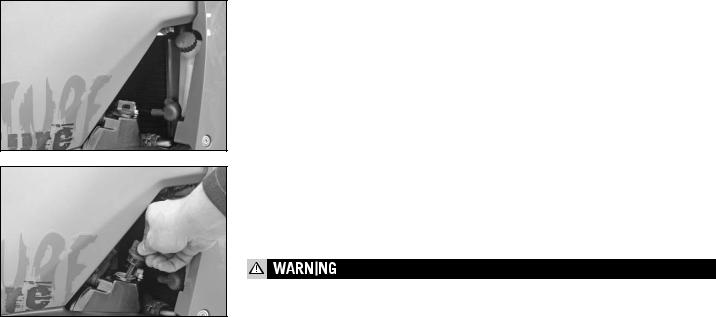

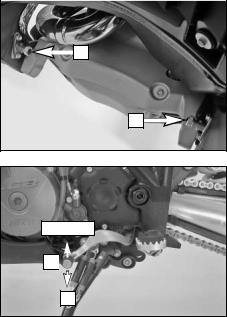

Page 19: Fuel Taps

» OPERATION INSTRUMENTS Fuel taps Both fuel taps [1] must be open when the motorcycle is running. The level in the fuel tanks is equalized by means of a connecting hose. Only close the fuel taps to remove the tanks.

-

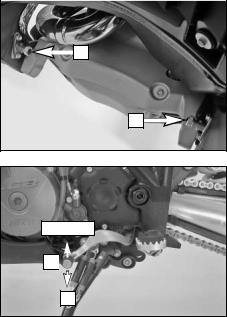

Page 20: Side Stand

» OPERATION INSTRUMENTS Side stand Fold the side stand [1] forward to the stop with your foot and put the weight of the motor- cycle on the stand. Make sure it is standing securely on a firm surface. The side stand is linked to the safety start system;…

-

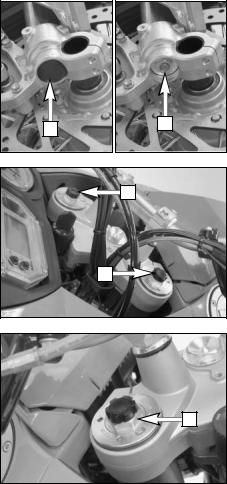

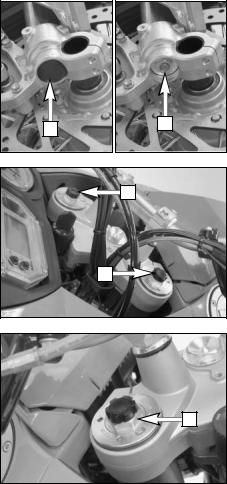

Page 21: Compression Damping Of Fork

» OPERATION INSTRUMENTS Compression damping of fork The fork’s damping action during compression travel (compression damping) can be adjusted. This allows you adjust the damping behavior to match your driving style and the payload. The adjusting screws [2] are located under the cap [1] on the lower end of the fork legs. More information is provided in the chapter «Adjusting the fork and shock absorber.“…

-

Page 22: Damping Action During Compression Of Shock Absorber

The damping rate can be adjusted in the low and high-speed range (Dual Compression Control). The designation low and high-speed refers to the movement of the shock absorber and not to the motorcycle’s driving speed. The adjusting screw [1] for the low-speed range can be adjusted with a screwdriver.

-

Page 23: Rebound Damping Of Shock Absorber

OPERATION INSTRUMENTS » Rebound damping of shock absorber The shock absorber’s damping action during rebound travel (rebound damping) can also be adjusted. This allows you adjust the damping behavior to match your driving style and the payload. The adjusting screw [1] is located on the bottom of the shock absorber. More information is provided in the chapter «Adjusting the fork and shock absorber.“…

-

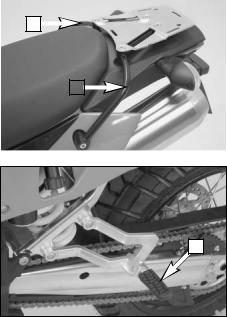

Page 24: Grips

» OPERATION INSTRUMENTS Grips The passenger can hold on to both grab handles [1]. Footrests The passenger footrests [2] fold up. Alarm system An alarm system can be retrofitted. Ask your authorized KTM shop for details.

-

Page 25: General Tips And Warnings For Starting The Motorcycle

GENERAL TIPS AND WARNINGS FOR STARTING THE MOTORCYCLE Instructions for initial operation – Make sure the work for the „pre-delivery inspection“ was performed by your author- ized KTM workshop. The DELIVERY CER- TIFICATE and SERVICE MANUAL will be handed over when you pick up your vehicle.

-

Page 26: Accessories And Payload

– Models with ABS: The ABS is designed to be used with the tires authorized by KTM and works best with these tires. The ABS function cannot be guaranteed if other tires are used. – Models with ABS: an incorrect tire pres-…

-

Page 27: Driving Instructions

Arrange for the braking system to be checked by a KTM specialist, as com- plete failure of the braking system can be avoided.

-

Page 28

Make sure your luggage is correctly fastened before you drive off. Never drive faster than 130 kph (80 mph) if your motorcycle is loaded with cases or other baggage. They will impair the motorcycle’s handling at higher speeds and can easily cause it to go out of control. -

Page 29: Starting The Engine

If the engine is not switched off, engine damage will occur within a short period of time. Check the engine oil level or contact a ktm workshop. – Maximum period for continuous starting: 5 seconds. Wait at least 5 seconds before try- ing again.

-

Page 30: Starting Off

– If this is not the case, refill the tank – if sufficient fuel is in the tank, pro- ceed as described in the „Trouble- shooting“ section or contact a KTM dealer. NOTE: This motorcycle is equipped with a safety start- ing system.

-

Page 31: Braking – Models Without Abs (Antilock Brake System)

Check the engine oil level or con- tact an authorized KTM workshop. – Never have the throttle wide open when changing down to a lower gear. The engine will overspeed, damaging the valves.

-

Page 32: Switching Off The Abs

– If the resistance in the hand brake lever or foot brake pedal feels „spongy“ (too much play), this is an indication that something is wrong with the brake sys- tem. Don’t ride your motorcycle anymore without first having the brake system looked over by a KTM dealer.

-

Page 33: Stopping And Parking

INFORMATION ABOUT THE SIDE STAND Use your foot to push the side stand forward as far as possible, and lean your motorcycle to the side. Make sure that your motorcycle is standing safely on solid ground. Just in case, you can also put in a gear.

-

Page 34

Make sure that the ground is solid and that your motorcycle is standing securely. – The center stand is designed to hold the weight of the motorcycle only. By sitting on the motorcycle, you will put additional weight on the center stand, possibly causing the cen- ter stand or frame to be damaged or the motorcycle to fall down. -

Page 35: Fuel

Please use unleaded fuel only. The 990 Adventure has 2 tanks with 1 filler cap each. Both filler caps can be locked and are equipped with a tank vent system. To open, insert the ignition key, turn 45° in a clock- wise direction and fold up the filler cap.

-

Page 37: Periodic Maintenance Schedule

Clean the oil jet for the clutch lubrication Check rubber boots for cracks or leaks Check fault memory with the KTM diagnosis tool Perform a status check of neutral, clutch, 2nd/3rd gear and side stand switch using the KTM diagnosis tool…

-

Page 38

Check/adjust smooth operation, free travel of handbrake/footbrake levers Check bolts of brake system for tight fit Check the ABS fault memory using the KTM diagnostics tool Check shock absorber and fork for leaks and proper operation Clean fork dust sleeves… -

Page 39: Periodic Maintenance Schedule

If motorcycle is used for competition 7500 km service should be carried out after every race! Service intervalls should never be exceeded by more than 500 km. Maintenance work done by KTM autorized workshops is not a substitute of care and checks done by the rider! 990 ADVENTURE 2007…

-

Page 40

PERIODIC MAINTENANCE SCHEDULE 990 ADVENTURE 2007 VITAL CHECKS AND CARE PROCEDURES TO CONDUCTED BY THE OWNER OR THE MECHANIC Check oil level Check brake fluid level Check brake pads for wear Check lighting system for proper operation Check horn for proper operation… -

Page 41: Maintenance Work On Chassis And Engine

– All screws and nuts must be tightened to the specified torque figures using a torque wrench. If screws or nuts are not adequately tight- ened, they can become loose and cause the motorcycle to go out of control while you drive. Tightening the screws and nuts too tightly can damage the thread and components.

-

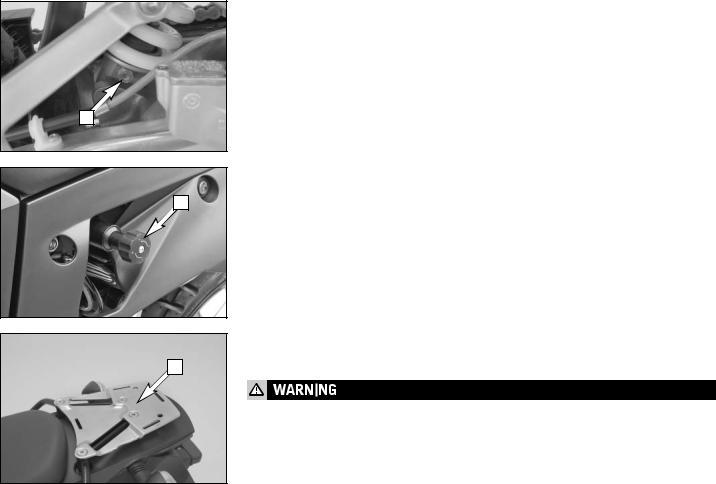

Page 42: Removing And Remounting The Seat

The tool set [4] and an extension piece [5] for some of the wrenches in the tool set are located in the pocket under the seat. The 990 Adventure S model (without ABS) has an additional storage compartment under the cover [6].

-

Page 43: Adjusting The Fork And Shock Absorber

There are a number of ways to adjust the fork and shock absorber to match the chassis to your driving style and the payload. We have provided a table with pragmatical values to help you tune up your motorcycle. These tune-up specifications are reference values only and should serve as a basis for your per- sonal chassis and suspension tuning.

-

Page 44: Adjusting The Spring Preload On The Fork

» MAINTENANCE WORK ON CHASSIS AND ENGINE Adjusting the spring preload on the fork The fork spring preload can be adjusted by turning the adjusting screws [4] (wrench size 24 mm) ± 5 mm (0,2 in). Turning in a clockwise direction will increase the preload, turning in a counterclockwise direc- tion will decrease the preload.

-

Page 45: Compression Damping Of Shock Absorber

– unscrew the respective number of clicks for the specific type of shock absorber in a coun- terclockwise direction. 990 Adventure ..20 clicks 990 Adventure S ..20 clicks »…

-

Page 46: Rebound Damping Of Shock Absorber

– Turn the adjusting screw in a counterclockwise direction the number of turns specified for the respective type of shock absorber. 990 Adventure ..1.5 turns 990 Adventure S ..1.5 turns The damping unit of the shock absorber is filled with high-compression nitrogen.

-

Page 47: Adjusting The Preload Of The Shock Absorber

Breathing the fork legs Breath the fork legs regularly (see Maintenance Schedule). To breath, place the motorcycle on the side stand and briefly remove the bleeder screws [2] to allow any overpressure to escape from the fork. Excessive pressure in the interior of the fork can cause leaks in the fork. If your fork is leak-…

-

Page 48: Cleaning The Dust Sleeves Of The Telescopic Fork

Checking the chain tension Place the motorcycle on the side stand and switch the transmission to idle. Press the chain upwards under the lower chainguard screw [4]. The difference to the sagging chain should be 35 — 40 mm (1.37 ……

-

Page 49: Correct Chain Tension

If you don’t happen to have a torque wrench at hand, make sure you have the tightening torque corrected by a KTM dealer as soon as possible. A loose axle may lead to an unstable driving behavior of your motorcycle.

-

Page 50: Chain Maintenance

– The chain does not have a chain joint for safety reasons. Always have the chain replaced in an authorized KTM workshop where the service technicans have the required riveting tool. – Never mount a normal chain joint.

-

Page 51: General Informations About Ktm Disc Brakes

KTM motorcycle in road traffic. The brake pads design and friction factor and therefore the braking power can deviate significantly from original KTM brake pads. If you use dif- ferent brake pads than those provided with the original equipment, it cannot be war- ranted that they are authorized for use in road traffic.

-

Page 52

DOT 4 brake fluid. Do not, in any event, use DOT 5 brake fluid. It is based on silicone oil and is dyed purple. KTM motorcycle gaskets and brake hoses are not designed for DOT 5 brake fluid. -

Page 53

ABS cannot be warranted. – The ABS is designed to be used with the tires authorized by KTM and works best with these tires. The ABS function cannot be guaranteed if other tires are used. -

Page 54: Adjusting Of Free Travel At The Hand Brake Lever

– If the brake fluid level drops below the minimum either the brake system has a leak or the brake pads are completely worn down. In this case, consult an authorized KTM dealer immediately.

-

Page 55: Checking Rear Brake Fluid Level

– If the brake fluid level drops below the minimum either the brake system has a leak or the brake pads are completely worn down. In this case, consult an authorized KTM dealer immediately.

-

Page 57: Dismounting And Mounting The Front Wheel

MAINTENANCE WORK ON CHASSIS AND ENGINE Dismounting and mounting the front wheel Jack the motorcycle up at the underride protection until the front wheel no longer touches the ground. Loosen the collar screw [1] and the clamp screws [2] at both fork leg axle passages. Unscrew the collar screw approx.

-

Page 58

Now you can tighten the clamp screws on both fork leg axle passages to 15 Nm. – If you do not have a torque wrench to mount the wheel, have the torques corrected by an authorized KTM workshop as soon as possible. A loose axle passage can cause the motorcycle’s handling performance to become instable. -

Page 59: Dismounting And Mounting The Rear Wheel

– If you don’t happen to have a torque wrench at hand, make sure you have the tighten- ing torque corrected by a KTM dealer as soon as possible. A loose wheel spindle may lead to an unstable driving behavior of your motorcycle.

-

Page 60: Tires, Air Pressure

The ABS function can no longer be guaranteed. – Models with ABS: The ABS is designed to be used with the tires authorized by KTM and works best with these tires. The ABS function cannot be guaranteed if other tires are used.

-

Page 61: Checking Spoke Tension

A clear tone must be the result. Dull tones indicate loose spokes. If necessary, have the spokes retightened and the wheel centered by a KTM dealer. – If you continue to drive with loose spokes, the spokes can tear and lead to an instable handling performance.

-

Page 62: Battery

Never operate the motorcycle with a run-down battery or without the battery. This can dam- age the electronic components or safety equipment in either caseand the motorcycle will no longer be roadworthy.

-

Page 63: Demounting And Mounting The Battery

Never disconnect the battery while the engine is running. This will destroy the rectifier- regulator. STORAGE: If the motorcycle is being immobilized for longer periods of time, remove and charge the battery. Storage temperature 0 — 35°C (32 — 95°F), avoid direct sunlight. Charge the battery every 3 months.

-

Page 64: Charging The Battery

5.5 amperes To charge the battery while mounted, always use the KTM battery charger (Item no. 58429074000) to ensure that the electric system is not damaged by excess voltage. Always remove the battery if using other battery chargers! You can also use this charging device to test the off-load voltage and startability of the battery and generator.

-

Page 65: Main Fuse

Two fuses for the ABS are located under the starter relay. Remove the caps and check the fuses [7] and [8]. Replace blown fuses with the same type of fuse. Visit an authorized KTM workshop if the new fuse blows again.

-

Page 66: Fuses For Individual Current Consumers

[1]. Spare 10, 15, 25 and 40-ampere fuses [2] are also located next to the stor- age compartment. Replace a blown fuse only with an equivalent one. Visit an authorized KTM workshop if the new fuse blows again.

-

Page 67: Replacing The Headlight Lamps

MAINTENANCE WORK ON CHASSIS AND ENGINE Replacing the headlight lamps Remove the 5 screws on the left and right and take off both side covers [1]. Use a screw- driver to detach the retaining tabs [2], tilt the windshield and headlight forward and pull the connector off the connector support.

-

Page 68

» MAINTENANCE WORK ON CHASSIS AND ENGINE PARKING LIGHT BULB [C] : Pull the bulb socket [7] out of the reflector and pull the bulb out of the bulb socket. USA design: The parking light [E] is located in the upper part of the headlight in the USA design. Bulb [F] (see Technical specifications –… -

Page 69: Adjusting The Headlight Range

Make a mark on a light wall behind a level surface at a height of 830 mm (32.7 in) (990 Adventure S) or 790 mm (31.1 in) (990 Adventure) respectively. Position your motorcycle loaded ready for the trip (baggage, driver, passenger) 10 meters away from the wall and switch on the low beam.

-

Page 70: Replacing The Flasher Bulbs

Replacing the flasher bulbs Remove the screw on the back of the turn signal, carefully fold the lens [5] towards the motorcycle and remove. Slightly depress the bulb, turn it approx. 30° counterclockwise and pull it out of the socket.

-

Page 71: Cooling System

If the fan is not working, and there appears to be sufficient cool- ing liquid, the only thing you can do is to drive on to your nearest authorized KTM work- shop at the least possible engine load.

-

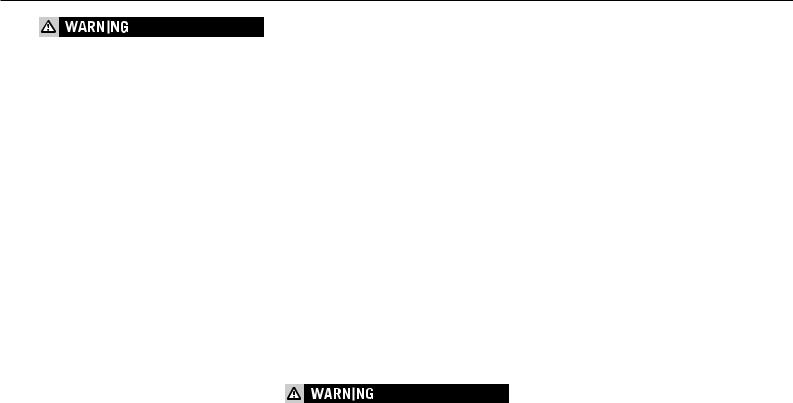

Page 72: Checking The Cooling Liquid Level In The Compensating Tank

If you need to add cooling liquid quite often, the cooling system may leak. If the compen- sating tank is empty, also check the cooling liquid level in the radiator. Have the cooling system checked by an authorized KTM workshop. »…

-

Page 73: Checking The Cooling Liquid Level In The Radiator

If any cooling liquid is missing, the cooling system may leak. Have the cooling system checked by an authorized KTM workshop. If more than 1 liter (0.26 USgal) of cooling liquid needs to be added, the cooling system must be bled.

-

Page 74: Bleeding The Cooling System

Remove the bleeder screw [4] on the left side of the radiator. To be able to completely bleed the cooling system, raise the motorcycle approx. 50 cm in the front. Add cooling liquid until it runs out of the discharge opening without bubbles and immedi- ately mount the screw to prevent more air from getting into the radiator.

-

Page 75: Changing The Original Position Of The Clutch Lever

KTM uses biodegradable, hydraulic mineral oil to actuate the hydraulic clutch. Do not mix this oil with any other hydraulic oil. Always use original KTM hydraulic oil (available from your authorized KTM workshop) to make sure your clutch operates smoothly.

-

Page 76: Checking The Engine Oil Level

Only use fully synthetic engine oils that meet the JASO MA quality requirements (see infor- mation on the can). KTM recommends Motorex Power Synt 4T in the 10W/50 viscosity (for temperatures over 0°C, 32°F) or 5W/40 (for temperatures under 0°C, 32°F).

-

Page 77: Changing The Engine Oil And The Oil Filter Cleaning The Oil Screen

Since many parts must be demounted for an oil change, we recommend having the engine oil changed by an authorized KTM workshop. During the guaranty period, the oil change must be performed by an authorized KTM mechanic. Otherwise, the guarantee will become void.

-

Page 78

» MAINTENANCE WORK ON CHASSIS AND ENGINE Remove the 6 screws and the cover [4]. Remove the 5 screws, take off the left panel [5] and disconnect the turn signal cable. Close both fuel taps [6] on the connecting line. -

Page 79

» MAINTENANCE WORK ON CHASSIS AND ENGINE Remove the 3 screws [1], lift the tank approx. 15 mm and carefully tilt to the side. Disconnect the fuel lines, disconnect the connector for the fuel pump and the pickup cable (fuel level) and set down the tank. -

Page 80

» MAINTENANCE WORK ON CHASSIS AND ENGINE Carefully pull the oil screen [7] out of the oil tank. Thoroughly clean the drain plugs, the cover and both oil screens. Clean all rubber seal rings and check for damage. Replace if necessary. Mount the oil drain plug on the engine with a new seal ring and tighten to 20 Nm. -

Page 81

O-ring. Tighten the screws to 6 Nm. Only use original KTM oil filters. The engine can be damaged if other filters are used. Mount the oil drain plug on the oil tank with a new seal ring and tighten to 20 Nm. -

Page 82

» MAINTENANCE WORK ON CHASSIS AND ENGINE Add 2.5 liters (0.7 USgal) of fully synthetic engine oil meeting the JASO MA standard (e.g. Motorex Power Synt 4T) and mount the oil dipstick. Start the engine, allow to run warm for 4 minutes and switch off the engine. -

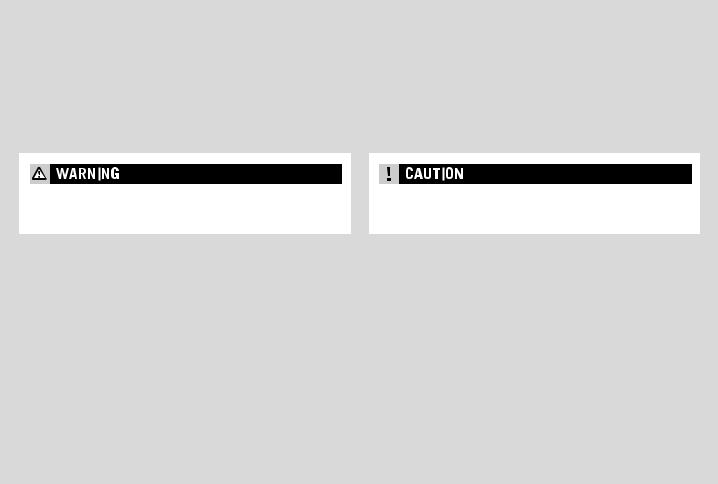

Page 83: Activating The Ignition Curve For Low-Octane Fuel

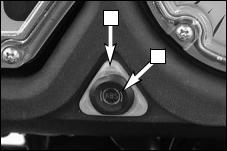

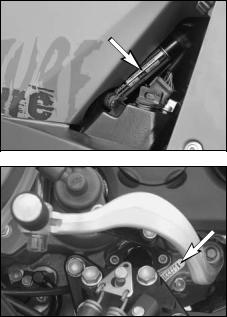

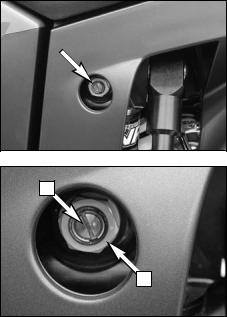

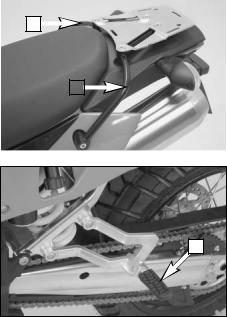

» MAINTENANCE WORK ON CHASSIS AND ENGINE Activating the ignition curve for low-octane fuel If you are traveling to a country where fuel having at least 95 octane (RON) is not available, you can easily activate the corresponding ignition curve. A plug and socket connection [1] on a brown/black cable is located near the upper shock absorber holder .

-

Page 84: Trouble Shooting

If you have your motorcycle serviced as set forth in this manual, no malfunctioning is to be expected. Nevertheless, if an error does arise, we recommend that you look for the error according to the following chart. Please note that you cannot perform all of the work yourself. If you are not sure, contact your KTM dealer. TROUBLE…

-

Page 85

Visit an authorized KTM workshop Switch to neutral gear Have the air filter/fuel filter replaced at an authorized KTM workshop Visit an authorized KTM workshop Activate the ignition curve for 95 octane, if fuel with at least… -

Page 86

Contact an authorized KTM workshop. Bleed the cooling system (see Maintenance work) Have the thermostat checked (opening temperature 75°C, 167°F) or replaced; contact an authorized KTM workshop Visit an authorized KTM workshop Stop, switch off the ignition, start again Replace the ABS fuses (under the right engine cover) -

Page 87

Recharge the battery according to the relevant instructions. Voltage regulator and generator should be checked by an authorized KTM workshop. Replace fuse HORN BRAKELIGHT SPEEDO. Check the pickup cable for damage, visit an authorized KTM workshop Blink code 06: FI blinks 6x short, pause ERROR DESCRIPTION… -

Page 88

» TROUBLE SHOOTING The blink code indicates which component is affected by an error. This allows the error to be identified if no diagnosis tool is available. BLINK CODE SIGNAL / COMPONENT Coolant temperature sensor Air temperature sensor Ambient air pressure sensor Tilt angle sensor Lambda probe for rear cylinder Lambda probe for front cylinder… -

Page 89: Cleaning

(e.g. Motorex 900) and cleaned with a brush. – After the motorcycle has been rinsed with a soft water jet, it should be dried by air pressure and a cloth. Then take a short drive until the engine has reached the working temperature and also use the brakes.

-

Page 90: Storage

– Take a short, careful test ride first. NOTE: Before you put your motorcycle away for the winter, you have to check all parts for their function and wear. Should any service jobs, repairs, or any refitting be necessary, you should have them carried out during the off-season (lower workload at mechanics’ shops). This…

-

Page 91: Technical Specifications – Chassis

USA: high beam + low beam H4 12V 60/55 W (socket P43t) position light front + rear 12V 5W (socket W2.1×9.5d) indicator lamps LED stoplight 12V 21W (socket BA15s) * further tire releases are available on the Internet at www.ktm.com » 4 liters (1 USgal) reserve…

-

Page 92

TECHNICAL SPECIFICATIONS – CHASSIS CHASSIS 990 ADVENTURE / 990 ADVENTURE S Lighting flasher 12V 10W (socket BA15s) licens plate illumination 12V 5W (socket W2.1×9,5d) Battery maintenance-free battery 12V 11.2 Ah Steering head angle 63.4° Wheel base 1570 mm (61.8 in) Seat height, unloaded ADVENTURE: 860 mm (33.8 in), ADVENTURE S: 915 mm (36 in) -

Page 93

TECHNICAL SPECIFICATIONS – CHASSIS TIGHTENING TORQUES – CHASSIS HH clamp bolts on top triple clamp HH clamp bolts for steering stem HH clamp bolts on bottom triple clamp AH bolt for handlebar mount Collar bolts for handlebar clamps HH clamp bolts on fork leg axle passages Collar screw on front wheel spindle Collar nut wheel spindle rear Collar nut for swing arm bolt… -

Page 94

TECHNICAL SPECIFICATIONS – CHASSIS TIGHTENING TORQUES – CHASSIS Exhaust nuts on manifold HH bolts on exhaust suspension Spoke nipple HH nuts on rear sprocket bolts Hexagon nut on engine sprocket Engine carrier bolts HH bolts for side stand bracket — engine HH bolts side stand bracket — side stand console HH bolts side stand mounting HH bolt spring retainer side stand… -

Page 95: Technical Specifications – Engine

TECHNICAL SPECIFICATIONS – ENGINE ENGINE 990 LC8 Design Liquid-cooled, 2-cylinder 4-stroke engine with 75° V arrangement with balancer shaft and electric starter Displacement 999 cc Bore / Stroke 101/62.4 mm Compression ratio 11.5:1 Fuel unleaded fuel with at least RON 95 (USA: Premium PON 91*) / RON 80 — 94 for other ignition curve) Valve timing 4 valves controlled over bucket tappet and 2 camshafts, camshaft drive with gears/chain Valve diameter…

-

Page 96: Engine Oil

Only use fully synthetic engine oils that meet the JASO MA quality requirements (see infor- mation on the can). KTM recommends Motorex Power Synt 4T in the 10W/50 viscosity (for temperatures over 0°C, 32°F) or 5W/40 (for temperatures under 0°C, 32°F).

-

Page 97: Head Word Index

» HEAD WORD INDEX ABS button – models with ABS (antilock brake system) ..14 ABS fuses – models with ABS (antilock brake system) ..64 ABS warning lamp – models with ABS (antilock brake system) . .14 Accessories and payload .

-

Page 98

Fuses for individual current consumers ….65 General informations about KTM disc brakes … . .50 General tips and warnings for starting the motorcycle . -

Page 99: Consumer Information For Usa Only

» CONSUMER INFORMATION FOR USA ONLY Sticker positions: 4 5 6…

-

Page 100

CONSUMER INFORMATION FOR USA ONLY [1] EAVP [4] Fuel level [7] Noise emission » [2] Type label USA [5] Before you go for the first ride [8] Technical information [2] Type label CAN [6] Vehicle emission [9] Exhaust system… -

Page 101: Consumer Information For Usa Only

NOISE EMISSION WARRANTY KTM Sportmotorcycle AG warrants that this exhaust system, at the time of sale, meets all applicable U.S. EPA Federal noise standards. This warranty extends to the first per- son who buys this exhaust system for purposes other than resale, and to all subsequent buyers.

-

Page 102

10/2006 FOTO: MITTERBAUER KTM Group Partner KTM Sportmotorcycle AG A–5230 Mattighofen www.ktm.at…

- Manuals

- Brands

- KTM Manuals

- Motorcycle

- 990 ADVENTURE

- Repair manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

REPAIRMANUAL2003-2008

950/990 ADVENTURE

990 SUPER DUKE/R

950/990 SUPERMOTO/R

950 SUPER ENDURO

REPARATURANLEITUNG

MANUALE DI RIPARAZIONE

MANUEL DE RÉPARATION

MANUAL DE REPARACIÓN

Related Manuals for KTM 990 Adventure

Summary of Contents for KTM 990 Adventure

-

Page 1

REPAIRMANUAL2003-2008 950/990 ADVENTURE 990 SUPER DUKE/R 950/990 SUPERMOTO/R 950 SUPER ENDURO REPARATURANLEITUNG MANUALE DI RIPARAZIONE MANUEL DE RÉPARATION MANUAL DE REPARACIÓN… -

Page 3

KTM Group Partner… -

Page 5

1 SERVICE-INFORMATIONS 2 GENERAL INFORMATION 3 REMOVING AND REFITTING ENGINE 4 DISASSEMBLING ENGINE 5 SERVICING INDIVIDUAL COMPONENTS 6 ASSEMBLING ENGINE 7 ELECTRICAL / INJECTION 8 FUEL SYSTEM 9 TROUBLE SHOOTING 10 CHASSIS 11 TECHNICAL SPECIFICATIONS 12 PERIODIC MAINTENANCE SCHEDULE 13 WIRING DIAGRAMS… -

Page 7

12-10 to 12-28 13-2 to 13-141 13-2 to 13-159 KTM REPAIR MANUAL IN LOOSE-LEAF FORM STORING THE REPAIR MANUAL IN THE BINDER – Put the index into the binder. – Put the front page of the repair manual (210×297 mm) into the transparent pocket provided for this purpose on the outside of the binder. -

Page 9

X P L A N A T I O N P D A T I N G 3.206.009-E Repair Manual Basicversion Modelyear 2003 4/2003 3.206.016-E Updating of Rep.Manual 3.206.009-E Modelyear 2004 (Engine number with first digit “4“) 11/2003 3.206.025-E Updating of Rep.Manual 3.206.009-E Modelyear 2005 (Engine number with first digit “5“) 01/2005… -

Page 11

„NOTE” POINTS OUT USEFUL TIPS. Use only ORIGINAL KTM SPARE PARTS when replacing parts. The KTM high performance engine is only able to meet user expectations if the maintenance work is performed regularly and professionally. In accordance with the international quality management ISO 9001 standard, KTM uses quality assurance processes that lead to the highest possible product quality. -

Page 13

REPLY FAX FOR REPAIR MANUALS We have made every effort to make our repair manuals as accurate as possible but it is always possible for a mistake or two to creep in. To keep improving the quality of our repair manuals, we request mechanics and shop foremen to assist us as follows: If you find any errors or inaccuracies in one of our repair manual –… -

Page 15

GENERAL INFORMATION INDEX OIL SYSTEM ……….2-2 AIR INTAKE SYSTEM . -

Page 17: Oil System

Oil system Pressure pump draws engine oil from oil tank through oil filter and the oil return valve and pumps it past the pressure relief valve through the oil filter into the annular groove The main bearing , the conrod bearings and the spraying nozzle (front timing chain) are supplied with oil through holes in the…

-

Page 18

Intake system Fresh air is drawn into the filter box through the intake snorkel , past the carburetors and through the air filter The cleaned air is conducted to the combustion chamber through the carburetors and intake ports. The diagram for the injection engine is similar; the air flows to the intake ports through the throttle body instead of through the carburetor. -

Page 19

Secondary air system The secondary air system supplies fresh air to the emissions in the exhaust port, resulting in the afterburning (oxidation) of the emissions. A line leads from the filter box to the control valve which opens as soon as the throttle valves are opened. -

Page 20: Cooling System

Cooling system Closed thermostat The thermostat is closed if the temperature of the cooling liquid drops below 75° C. The water pump pumps the cooling liquid through the cylinder and cylinder heads and the thermostat Open thermostat The thermostat opens at 75° C. The water pump pumps the cooling liquid through the cylinder and cylinder heads , the aluminum cooler…

-

Page 21

ABS is switched off. To switch the ABS on again, stop and switch off the ignition. The ABS will be active again when you switch on the ignition. See the KTM ABS training documents for a detailed description of the ABS system. -

Page 22

SPECIAL TOOLS – ENGINE PART NO DESCRIPTION 309098 Seal Three-Bond 0113 080802 Crankshaft locking bolt 151.12.017.000 Gear puller 451.29.075.000 Tachometer 503.29.050.000 Bleeding syringe for hydraulic clutch 560.12.001.000 Universal-engine work stand 584.29.059.000 Loctite 648 green 20 ml 585.29.005.000 Protection sleeve for shaft seal ring of water pump 590.29.019.000 Valve spring mounter 590.29.021.044… -

Page 23

br bs bt cs ct dk dl dm dn ds dt ek el… -

Page 24

SPECIALTOOLS – CHASSIS PART NO DESCRIPTION 151.12.017.000 Gear puller 584.29.086.000 Pressing tool for swing arm bearing 584.29.089.000 Chassis tool holder 584.29.091.000 Press-in tool for bearing seat / rear wheel bearing 584.29.092.000 Knock-out tool for bearing seat 600.03.022.000 Center stand 600.10.013.000 Sleeve for pressing tool for swim arm bearing 600.29.018.000 Internal gear puller 28 mm… -

Page 25

2-10 Checking the oil level of the hydraulic clutch — 950/990 Adventure, 950 Supermoto/R To check the oil level in the master cylinder of the clutch remove the cover. For this purpose, remove bolts and cover together with the rubber boot . -

Page 26

The engine may have a poor idle behavior if the control unit is not reset. – Connect the KTM diagnostics tool, turn the ignition switch on and start the program. – Select «Extend»… -

Page 27

KTM diagnostics tool. If this step is omitted, the throttle cable clearance cannot be correctly adjusted. – Connect the KTM diagnostics tool, turn the ignition switch on and start the program. – Select «Extend» – Select «Device operation»… -

Page 28

The software can be downloaded from KTM’s dealer.net site; the software is transferred to the control unit via the KTM diagnostics tool (FAN). – Some exhaust systems require new «mapping». If these exhaust systems are replaced by the production system again, the «mapping»… -

Page 29

DMT program. NOTE: – If the DMT is not installed yet, install with the KTM diagnostics tool – If the program is already installed but the DMT icon does not appear on your screen, start the program under «Start» (in the task bar at the bottom of the screen) by clicking «Programs». -

Page 30

2-15 – The mapping file will be transferred to the ECU. CAUTION O NOT SWITCH OFF THE IGNITION OR DISCONNECT THE DIAGNOSTICS CABLE WHILE (» «). T ECU. THE FILE IS BEING TRANSFERRED FLASHING HIS CAN DAMAGE THE NOTE: – All of the indicator lamps in the digital speedometer will light up while the file is being transferred. -

Page 31: Table Of Contents

REFITTING THE ENGINE ……… .3-7 990 ADVENTURE REMOVING THE ENGINE .

-

Page 33: Removing The Engine

Removing the engine — 950 Adventure – Screw the center stand 600.03.022.000 onto the frame and jack up the motorcycle on a firm, even surface. – Remove the left bump rubber and lock the center stand with the lock 600.29.055.000 NOTE: if available, use the center stand already on the bike.

-

Page 34

– Unscrew the bolts and remove the intake snorkel together with the frame from the air filter box. – Disconnect the vent hose and the EPC hose and remove the upper half of the air filter box. – Turn the intake trumpet in a clockwise direction and remove. -

Page 35

– Disconnect the electric connections from the fan motor and the temperature switch – Drain the cooling liquid from the radiator and engine: see Chapter 12. – Detach the water hoses from the radiator (special pliers 600.29.057.100) and unscrew the radiator NOTE: fan and radiator shield do not need to be dismounted from the radiator. -

Page 36

– Unscrew the nut on the wheel spindle, pull out the rear wheel spindle, take the chain off of the rear sprocket and place over the side of the bracket . Remove the chain from the engine sprocket. – Detach the connector –… -

Page 37

– Use the trolley jack to position the attachment 600.29.055.100 on the engine, insert the bolt through the front of the engine bracket and fasten with the nut. Screw one of the bolts on the rear of the side stand fixture and slightly lift the engine. –… -

Page 38: Refitting The Engine

Refitting the engine — 950 Adventure – Before mounting the engine, attach the water, SLS and vacuum hoses (Öttiger clamps — special pliers 600.29.057.000 or spring- loaded band-type clamps — special pliers 600.29.057.100) – Position the swing arm and fix with the swing arm pivot on the right and a suitable pipe on the left.

-

Page 39

– Mount the front oil line inserting new O-rings. Tighten the bolts. NOTE: up to engine number 2-600-1186 a washer must be used to preload the O-rings on the oil terminal. – Align the side supports and battery case against the engine, insert the bolt and mount the nut. -

Page 40

– Place the chain over the pinion and rear sprocket, lift the rear wheel and slide the wheel spindle through. – Press the rear wheel towards the front to apply the chain tensioner and tighten the nut on the wheel spindle to 90 Nm. –… -

Page 41

3-10 – Screw on the radiator together with the fan and the radiator shield , tighten the bolts to 10 Nm. – Connect water hoses radiator (special pliers 600.29.057.100) – Attach the electric connections for the fan motor and the temperature switch –… -

Page 42

3-11 – Fit the upper battery cover and place a battery with battery cover into the battery compartment. – Fit the front battery compartment lid and connect both battery cables together to the connections on the front lid (start with the positive cable). -

Page 43

3-12 Removing the engine — 990 Adventure – Screw the center stand 600.03.022.000 onto the frame and jack up the motorcycle on a firm, even surface. – Remove the left bump rubber and lock the center stand with the lock 600.29.055.000 NOTE: if available, use the center stand already on the bike. -

Page 44

3-13 – Unscrew the bolts and remove the intake snorkel together with the frame from the air filter box. – Disconnect the vent hose and the EPC hose and remove the upper half of the air filter box. – Turn the intake trumpet in a clockwise direction and remove. -

Page 45

3-14 – Expose the electric lines of the lambda probes at the front and rear and disconnect plug-in connections – Unscrew both nuts on the front exhaust manifold flange on the cylinder head, loosen the exhaust clamp on the front exhaust manifold, pull the front exhaust manifold out of the rear exhaust pipe and remove. -

Page 46

3-15 – Disconnect the side stand switch and take the cable out of the cable clips. – Loosen the two bolts and the nut and remove the side stand. – Unscrew the clutch slave cylinder and the chainguard – Remove the adapter for the clutch slave cylinder and the chain securing guide –… -

Page 47

3-16 – Take off the positive starter cable cover . Unscrew the positive starter engine cable and draw out the wiring harness. – Detach connector on the starter relay. – Unscrew the ground connection – Pull off the cover from the positive terminal, unscrew the nut beneath it and remove the lines from the stud. -

Page 48

3-17 – Unscrew the ground wire connection – Detach the connector from the pulse generator – Detach the connector from the oil pressure switch , the temperature sensor and from the front and rear ignition coil. Remove any cable clips necessary. –… -

Page 49

3-18 Refitting the engine — 990 Adventure – Before mounting the engine, attach the water, SLS and vacuum hoses (Öttiger clamps — special pliers 600.29.057.000 or spring- loaded band-type clamps — special pliers 600.29.057.100) – Position the swing arm and fix with the swing arm pivot on the right and a suitable pipe on the left. -

Page 50

3-19 – Align the side supports and battery case against the engine, insert the bolt and mount the nut. – Mount the bolts (M10x23), lifting the engine slightly if necessary. Tighten the nut and bolts to 45 Nm. – Tighten the nut on the swing arm pivot to 130 Nm. –… -

Page 51

3-20 – Insert the locking pin in the pushrod. – Mount the adapter for the hydraulic clutch – Mount the chain securing guide and the adapter for the clutch slave cylinder – Screw on the clutch slave cylinder and the chainguard –… -

Page 52

3-21 – Screw on the radiator together with the fan and the radiator shield , tighten the bolts to 10 Nm. – Connect water hoses radiator (special pliers 600.29.057.100) – Attach the electric connections for the fan motor and the temperature switch –… -

Page 53

3-22 – Place the lower section of the air filter box onto the intake flange. CAUTION EMOVE THE CLOTH USED TO COVER THE INTAKE PORTS – Place the throttle body into the lower section of the air filter box. NOTE: The lower section of the air filter box must be raised slightly to make room for the plug-in connection of the throttle body –… -

Page 54

3-23 – Fill cooling liquid into the radiator, compensating tank and engine: see Chapter 12. – Fill engine oil: see Chapter 12. – Attach both tanks and fix them with the screws (M8x40). – Connect the tank line. – Mount the lower tank compartment and screw on the fuse box Mount the fuse box cover. -

Page 55

3-24 Dismounting the engine — 990 Super Duke NOTE: the procedure for dismounting the engine is the same as the procedure used for the 950 Adventure; the only deviations are in the preparatory work: – Remove the spoiler and tank side covers. –… -

Page 56

3-25 Mounting the engine — 990 Super Duke – Connect the water, SLS and vacuum hoses to the engine before mounting (Öttiger clamps — special pliers 600.29.057.000 or spring-loaded band-type clamps — special pliers 600.29.057.100). – Position the exhaust system under the motorcycle according to the installation position. -

Page 57

3-26 – Mount the exhaust pipe clamp between the manifold and the main silencer and slightly tighten. – Slightly tighten the exhaust pipe clamp on the rear manifold. NOTE: – Do not tighten the screw connections until the exhaust system is completely installed and mounted stress-free. -

Page 58

3-27 – Place the battery in the battery case and attach the battery case cover. – Connect the positive starter relay cable to the positive pole on the battery. – Connect the two ground connections to the negative pole on the battery (2 green cables from the controller and 1 black cable from the starter engine). -

Page 59

3-28 – Fasten the wiring harnesses and connector on the pulse generator with cable clips. – Run the chain over the pinion and rear sprocket, raise the rear wheel and push the wheel spindle through. – Push the rear wheel forward until the chain tensioner rests against the stop screw and tighten the wheel spindle nut to 90 Nm. -

Page 60

3-29 – Screw on the radiator, the fan and the radiator shield , tighten the screws to 10 Nm. – Mount water hoses radiator (special pliers 600.29.057.100) – Connect the electric connectors for the temperature switch fan motor – Connect the hose on the front vacuum sensor and the connector on the front lambda probe ;… -

Page 61

3-30 – Mount the throttle cable duct – Screw on the left side cover of the lower air filter box together with the bracket for the vacuum hose to the rear vacuum sensor. – Connect the hose on the rear vacuum sensor. CAUTION –… -

Page 62

3-31 – Run the tank vent hose down parallel to the overflow hose on the compensating tank, tilt the tank forward and screw on. Connect the tank vent hose and fuel connector. – Mount both tank side covers and the spoiler and tighten the screws. –… -

Page 63

3-32 Dismounting the engine — 990 Super Duke R NOTE: the procedure for dismounting and mounting the engine is the same as the procedure used for the 950 Adventure; the only deviations are in the preparatory work: – Remove the spoiler and tank side covers. –… -

Page 64

3-33 – Expose the lines of the ignition coil connectors for the cylinder at the front and rear, take the plug-in connections off of the holder and disconnect the plug-in connections for the cylinder at the front and rear. – Unscrew the holder of the front exhaust manifold from the engine. -

Page 65

3-34 Dis-/Mounting the engine — 950 Supermoto/R NOTE: the procedure for dismounting the engine is the same as the procedure used for the 950 Adventure; the only difference is in the preparatory work: Jack up the motorcycle with the assembly stand 625.29.055.000: –… -

Page 66

3-35 Removing the engine — 990 Supermoto – Jack up the motorcycle on the link fork using assembly stand 625.29.055.000. – Open the seat lock with the ignition key and take off the seat. – Unscrew the screws on the left and right of the side cover and take off the side cover. -

Page 67

3-36 – Loosen the nuts of the front exhaust manifold and take off the front exhaust manifold. – Loosen the nuts of the rear exhaust manifold and take off the rear exhaust manifold. – Remove the retaining pin by remove the lock on the retaining pin. –… -

Page 68

3-37 – Unscrew the screws and take the intake snorkel with the frame off of the air filter box. – Pull off the vent and EPC hoses and remove the top section of the air filter box. – Turn the intake trumpet clockwise and take it off;… -

Page 69

3-38 – Detach the oil line between the oil tank and the valve cover from the front of the oil tank (special pliers 600.29.57.100). – Unscrew the oil lines from the oil terminal and pull them out; remove the O-rings. –… -

Page 70

3-39 – Loosen the chain adjuster. – Loosen the nut of the wheel spindle. – Push the wheel into the frontmost position. – Remove the chain from the rear sprocket and place it over the link fork. – Take the chain off of the engine sprocket. NOTE: To avoid damaging the link fork, place a cloth between the link fork and the chain –… -

Page 71

3-40 Refitting the engine — 990 Supermoto – Before mounting the engine, attach the water, SLS and vacuum hoses (Öttiger clamps — special pliers 600.29.057.000 or spring- loaded band-type clamps — special pliers 600.29.057.100) – Position the swing arm and fix with the swing arm pivot on the right and a suitable pipe on the left.. -

Page 72

3-41 – Insert the locking pin in the pushrod. – Mount the adapter for the hydraulic clutch – Mount the chain securing guide and the adapter for the clutch slave cylinder – Screw on the clutch slave cylinder and the chainguard –… -

Page 73

3-42 – Screw on the radiator together with the fan and the radiator shield , tighten the bolts to 10 Nm. – Connect water hoses radiator (special pliers 600.29.057.100) – Create the electrical plug-in connection of the horn, fan motor and temperature switch –… -

Page 74

3-43 – Take down the motorcycle with the help of a second person and take the assembly stand out of the footrest holder. – Jack up the motorcycle on the link fork. – Mount the footrests on both sides. – Position the foot brake pedal and tighten the screw with 25 Nm (+ Loctite 243). -

Page 75

3-44 – Position the side stand. – Tighten the screw and the nut with 45 Nm (+ Loctite 243). – Create the plug-in connection of the side stand switch and secure the cable with cable binders. – Mount both side covers –… -

Page 77

DISASSEMBLING THE ENGINE INDEX VALVE COVERS ……….4-2 SPARK PLUG SHAFT INSERTS . -

Page 79

Clean the engine thoroughly on the outside prior to disassembling. – Clamp the engine in the work stand using the special tool 600.29.002.000. Valve covers – 990 Super Duke R only: remove screw – Pull out the spark plug connectors.. –… -

Page 80

Setting cylinder rear to TDC – Unscrew the plug from the generator cover to be able to turn the crankshaft. – Turn the crankshaft in a counterclockwise direction until the rear cylinder is in the TDC position. The marks (points as of model year 2007) must coincide with the flat outer surface of the cylinder head at the camshaft gears. -

Page 81

Chain tensioner cylinder rear – Remove the bolt from the chain tensioner NOTE: measure the preload on the chain tensioner element before dismounting: – Apply the chain tensioner bolt to the chain tensioner element without compressing the spring. – Measure the distance between the sealing washer and the cylinder head. -

Page 82

Double timing gear – Lift the double timing gear out of the cylinder head, letting the chain fall into the slot. Cylinder head rear with cylinder – Remove the outer nut – Loosen cylinder-head nuts crosswise. Special 600.29.083.000 is required for the inside nuts –… -

Page 83

Camshafts cylinder front – Check and note down the valve clearance before you dismount the camshafts. Valve clearance (at 20ºC): intake 0.10 — 0.15 mm exhaust 0.25 — 0.30 mm – Loosen the bolts on the camshaft bearing bridge from the front cylinder and carefully remove the camshaft bearing bridge. -

Page 84

Timing chain cylinder front NOTE: Valid up to and including model year 2006 – Loosen the bearing bolt on the double timing gear and pull out of the cylinder head together with the needle bearing. The double timing gear will slide down slightly, relieving the timing chain. NOTE: Valid as of model year 2007 –… -

Page 85

Water pump – Remove the water pump cover , discard the O-ring gasket. NOTE: also remove the 2 dowel pins used to keep the water pump cover in a central position. – Hold the water pump wheel with special tool 600.29.082.000, remove the bolt and pull the water pump wheel off of the… -

Page 86

Clutch – Remove the bolts on the clutch springs crosswise and lift off the pressure cap. – Pull out the clutch push rod. – Insert a wire hook in the recess in the clutch disks and pull all of the clutch disks out of the clutch hub. NOTE: leave the spring washer and supporting ring in the clutch. -

Page 87

4-10 Primary pinion and clutch If you are completely dismounting the engine, the primary pinion must be detached before you remove the clutch. – Mount the special tool 0113 080802 (engine locking bolt) and hold the crankshaft in the rear or front cylinder’s TDC position. –… -

Page 88

4-11 – Insert the pressure tool 600.29.031.000 in the crankshaft bore, turn the balance weight up and pull the primary pinion off the crankshaft with the puller 600.29.033.000. – Remove the balance weight from the balancer shaft; carefully pry the woodruff key out of the shaft groove with a screwdriver. –… -

Page 89

4-12 Freewheel – Remove the freewheel lock and lift the freewheel of the crankshaft. – Pull the lower starter idler gear from the balancer shaft. Balancer shaft – Gently tap the balancer shaft off on the clutch side with a rubber hammer. -

Page 90

4-13 Engine case half – Remove the gear shift sensor with the pin and spring. Unscrew the oil filter cover , discarding the gasket on the oil filter cover and the oil filter. – Unscrew all HH bolts accessible from the generator side. –… -

Page 91

4-14 Transmission – Remove the oil rail for the transmission lubrication. It is secured at the bottom to keep it from twisting. NOTE: the oil rail is sealed with 2 O-rings from the 2005 model which should be replaced. – Pull out the shift rails together with the upper shift rail springs. -

Page 92

4-15 Oil pumps – Remove the lock ring from the oil pump shaft; remove the spacing washer and oil pump gear – Pull the needle roller out of the pump gear and remove the washer underneath. – Loosen the bolts on the outer oil pump (pressure pump) and remove the oil pump housing. -

Page 93

SERVICING INDIVIDUAL COMPONENTS INDEX ROLLER BEARING ……….5-2 MAIN BEARINGS — GENERAL INFORMATION . -

Page 95

– the output-end antifriction bearing on the countershaft mounted by KTM does not have a sealing from the 2005 model. An antifriction bearing with a one-sided sealing is provided for repair; to keep it from blocking the lubrication, the open side must point towards the inside (towards the center of the housing). -

Page 96

Replacing the main bearings-general information NOTE: – The bearing shells for the friction bearings are pressed in and out in a cold state. – Mark the position of the bearing end gap on the engine case with a felt-tip pin to facilitate reassembly. NOTE: the main bearing shells have retaining brackets to hold them in position from the 2005 model;… -

Page 97

Replacing bearing shells, output end – Center the new bearing shells (both smooth) with the assembling sleeve 600.29.044.050 . The assembling sleeve is beveled on one side so the bearing shells can be pushed in easily. The bearing shells should protrude 1-2 mm on the other side of the assembling sleeve to make it easier to position them in the engine case. -

Page 98

Replacing the conrod bearings – Clamp each conrod in a vise using protective jaws. – Loosen the bolts on the conrod bearing covers with the special wrench socket 600.29.075.000 and remove the bearing covers. NOTE: mark the conrod caps to ensure that each cap is mounted to the same conrod when it is measured and assembled. -

Page 99

Replacing the supporting bearings in the clutch cover – Pull the bearing shells out of the clutch cover using the puller 151.12.017.000 and the internal extractor 600.29.018.000 – Measure the diameter of the bearing pin at 3 points that are 120° apart using a micrometer gauge. -

Page 100

Overhauling the water pump – Remove the washer from the water pump shaft and pry the shaft sealing ring out of the case. NOTE: if the water pump wheel cannot be removed because it is being held by residual thread adhesive, the water pump shaft and the water pump wheel can be pressed out from the inside after the lock ring removed. -

Page 101

Checking the suction pump for wear – Insert both suction pump rotors in the housing. – Use a feeler gauge to check the clearance between the inner and outer rotor: Setpoint value: 0.1 mm Wear limit: 0.2 mm – Use a feeler gauge to check the clearance between the outer rotor and the housing: Setpoint value: 0.2 mm… -

Page 102

Disassembling the cylinder head and checking parts for wear NOTE: the illustration shows the font cylinder. The procedure for the rear cylinder is identical. – Pull all of the bucket tappets out of the cylinder head. NOTE: – Note down the mounting position to ensure that the same bucket tappet is inserted in the same bore during installation. -

Page 103

5-10 Checking the pistons – Mark the position of the piston arrow in the cylinder to facilitate reassembly and to ensure that the same piston is mounted in the same cylinder again. – Press the piston up out of the cylinder. –… -

Page 104

5-11 Piston and cylinder identification The cylinder size is impressed in the bottom of the cylinder near the chain tunnel; 1 is size I, 2 is size II. The piston size is impressed in the top of the piston; 1 is size I, 2 is size II. -

Page 105

5-12 – Place the lubricated piston on the cylinder and clamp the piston rings together with the piston ring clamping band 600.29.015.000 – Use a plastic hammer to tap lightly on the top of the piston ring clamping band until it is flush with the cylinder. –… -

Page 106

5-13 Generator cover – Loosen the three bolts on the stator. – Tilt the cable retaining bracket away from the cable with long nose pliers (see small arrow) and pull out of the housing. Take the cable duct out of the generator cover and remove the stator. –… -

Page 107

5-14 Preassembling the spreader drive NOTE: – The tension spring bolts must be attached as illustrated. – The other holes are used to block the spreader drive. – Attach the tension spring bolts in the drive wheel and press the tension spring into the recess of the drive wheel. –… -

Page 108

5-15 Clutch – checking parts for wear Check the thrust bearing for wear. Check the front end of the pushrod for wear and blow compressed air through the holes. NOTE: the pushrod is made of nitride steel from the 2005 model. If you are repairing an engine older than the 2004 model, replace the old pushrod with the newer version. -

Page 109

5-16 Shift mechanism – checking parts for wear Shift forks Check the leaf for wear. Check the driving bolt for the shift drum for wear. Shift rolls Check the shift rolls for hair cracks and pressure marks. It should be easy to turn the shift rolls on the driving bolts of the shift forks. -

Page 110

5-17 General information on servicing the transmission – Clamp the main shaft in the vise (use protective jaws) and remove the gears. – Clean and check all parts. Use new lock rings whenever you repair the transmission. Check the tooth profile on the transmission shafts and sliding gears for wear. -

Page 111

5-18 General information on servicing the transmission – Clamp the main shaft or countershaft in the vise (use protective jaws) and remove the gears. Pull off the bearing ring. – Clean and check all parts. Use new lock rings whenever you repair the transmission. Check the tooth profile on the transmission shafts and sliding gears for wear. -

Page 112

5-19 Checking the freewheel – Insert the freewheel gear in the freewheel. – You should be able to turn the freewheel gear in a counterclockwise direction. – The freewheel gear should block without backlash in a clockwise direction. – Check the reduction gear and the needle bearings for wear, replace if necessary. -

Page 113

ASSEMBLING THE ENGINE INDEX OIL PUMPS ………..6-2 AXIAL CLEARANCE OF THE MAIN SHAFT . -

Page 115

Clean all parts thoroughly before reassembling. – Clamp the output-end engine case on the engine work stand and move into a vertical position (installation position). Oil pumps NOTE: lubricate the oil pump rotors and the oil pump shaft prior to installation. -

Page 116

– Apply Loctite 243 to the three remaining oil pump bolts (M6x40) and screw in. Tighten bolts to 10 Nm. – Slide on the disk, insert the needle roller and mount the oil pump gear with the collar facing the rear. –… -

Page 117

Transmission – Simultaneously push both transmission shafts into the bearing seats. NOTE: pay attention to the spacing washer on the countershaft. – Slide the washer on the counter shaft and mount the lock ring – Move the engine into a horizontal position. –… -

Page 118

– Insert the crankshaft in the friction bearing. NOTE: – The crankshaft end with the thread for the primary pinion bolt connection must point down. – The conrod for the rear cylinder must face up. Both conrods should be in the position shown in the illustration. –… -

Page 119

Shift mechanism – Mount the locking lever with the spring. Apply Loctite 243 to the M5x20 bolt and tighten to 6 Nm. – Press the locking lever down and mount the shift locating drum NOTE: the flat parts of the shift locating drum are off center. –… -

Page 120

– Screw on the generator-end timing chain tensioning rail . Apply Loctite 243 to the bolt and tighten to 20 Nm. CAUTION AKE SURE NO LOCTITE THREAD ADHESIVE IS ON THE PIVOT AREA OF THE BOLT THIS COULD CAUSE THE TIMING CHAIN TENSIONING RAIL TO BLOCK AND BREAK Balancer shaft –… -

Page 121

Generator cover – Mount dowel pins on the engine case and put a new gasket in place. M6x30 Position the generator cover and tighten the generator cover bolts to M6x30 (A) 10 Nm (see illustration for bolt lengths). NOTE: the bolts marked with an A must be mounted with new copper M6x30 (A) sealing washers (6x10x1);… -

Page 122

Primary pinion – Mount the woodruff key for the primary pinion in the shaft groove (if dismounted). – Mount the primary pinion with the longer collar towards the rear. The bore for the pickup ring must face towards the outside. –… -

Page 123

6-10 – Slide the 25 x 48 x 6.5 mm disk and inner clutch hub together with the clutch pressure booster onto the main shaft teeth. NOTE: the two clutch pressure booster parts are marked with coinciding circles. – Attach the holder for the inner clutch hub 600.29.003.000. -

Page 124: Clutch Cover

6-11 Clutch cover – A vibration damper is mounted in the outer clutch cover from the 2005 model, screw may not be loosened. CAUTION F THE SCREW ON THE VIBRATION DAMPER IS LOOSENED A NEW OUTER CLUTCH OVER WITH A VIBRATION DAMPER OR THE OLD CLUTCH OVER WITHOUT THE VIBRATION DAMPER MUST BE USED SINCE THE SELF CUTTING SCREW CANNOT BE…

-

Page 125

6-12 Oil screen – Insert the oil screen in the opening in the case. NOTE: the oil screen has a TOP marking which must point up. – Mount the oil screen cover; tighten the two M6x35/M6x40 bolts to 10 Nm. Water pump –… -

Page 126

6-13 Cylinder head rear with timing chain – Remove the M10x161 stud bolts, strength class 10.9, and replace with stud bolts in class 12.9. NOTE: you can tell the two strength classes apart by their thread length. Stud bolts in class 12.9 have a thread length of 26 mm; stud bolts in any other length must be replaced. -

Page 127

6-14 – Push the double timing gear down into the chain tunnel draw the timing chain along the side on the inside. – Use the wire hook to lift the side of the chain on the inside over the gear teeth onto the chain teeth of the double timing gear. -

Page 128

6-15 Chain tensioner cylinder rear – Insert the chain tensioner element in the cylinder head bore. NOTE: the housing and tensioning piston of the chain tensioner are compression molded. If the two parts cannot be separated, the chain tensioner must be replaced. –… -

Page 129

6-16 Camshafts cylinder rear – Insert the two camshafts marked «in re» (rear intake camshaft) and «ex re» (rear exhaust camshaft) into the bearings without tilting. The marks on the camshaft gears must coincide with the flat outer surface of the cylinder head (see illustrations). NOTE: –… -

Page 130

6-17 Setting cylinder front to TDC – Loosen crankshaft locking bolt turn engine counterclockwise 1 rotation and then 75° towards the front cylinder’s TDC position, keeping the timing chain on the cylinder rear slightly tensioned and holding the conrod in the center of the opening in the case. -

Page 131

6-18 – Push the cylinder head and cylinder down. Oil the cylinder head nuts and mount with the washer — see Technical Information. The cylinder head nuts are tightened in 2 stages. 1st stage: – Tighten the cylinder head nuts crosswise. Use the special nut 600.29.083.000 for the internal nuts and the special wrench 600.29.081.000 for the outer nut… -

Page 132

6-19 Chain tensioner cylinder front – Insert the chain tensioning element in the cylinder head bore. NOTE: the housing and tensioning piston of the chain tensioner are compression molded. If the two parts cannot be separated, the chain tensioner must be replaced. –… -

Page 133

6-20 Camshafts cylinder front – Insert the two camshafts marked «in fr» (front intake camshaft) and «ex fr» (front exhaust camshaft) into the bearings without tilting. The marks on the camshaft gears must coincide with the cylinder head surface (see illustrations). NOTE: –… -

Page 134

6-21 NOTE: – Check the position of the camshafts on cylinder front in the TDC position of cylinder rear. The cams on the exhaust camshaft point towards the inside and push open the exhaust valves, the cams on the intake camshaft also point towards the inside, the bucket tappets are not actuated. -

Page 135

6-22 Spark plug shaft inserts – Mount new O-rings on the spark plug shafts and grease. Push the spark plug shaft inserts all the way in. – Mount the valve cover gaskets and spark plug shaft gaskets Valve cover – Mount the valve cover. Insert bolts with the sealing washers and tighten to 10 Nm. -

Page 137

ELECTRIC STARTER SYSTEM 950 SUPERMOTO/950 SUPER ENDURO ..7-6 ELECTRIC STARTER SYSTEM 990 ADVENTURE -2007 ….7-7 ELECTRIC STARTER SYSTEM 990 ADVENTURE 2007- . -

Page 139: Abs-System

WIRING DIAGRAM 990 SUPER DUKE R ……7-31 WIRING DIAGRAM 990 ADVENTURE -2007 ……7-32 WIRING DIAGRAM 990 ADVENTURE 2007- .

-

Page 141

Checking for loss of current Check for loss of current before you check the rectifier regulator. – Switch off the ignition and disconnect the ground wire from the battery. – Connect an ammeter between the ground wire and the negative pole on the battery. -

Page 142

start/stop switch start-relay orange 1 fuse C_BB/9 10 A C_AB/9 C_AE/4 black-orange 0.5 start auxillary relay yellow 0.5 battery C_AI/2 C_AI1/2 red 4 red 0.5 diode diode C_AL starter motor C_AR/2 C_AT2/2 C_AM3/3 page 7/9 page 4/9 clutch switch sidestand switch Electric starter system 950 Adventure NOTE: the starter system is equipped with a safety feature. -

Page 143

s / t a r o r — r i f i t t i n a l l l e r t u l Electric starter system 990 Super Duke/R NOTE: The starting system is equipped with security features. The motorcycle can only be started under the following conditions: –… -

Page 144

s / t o i t i f i t a l l k n i 5 . 0 a p — 8 / 3 l l e 5 . 0 e r g — n e a l b 5 . -

Page 145

— 9 / 3 Electric starter system 990 Adventure -2007 NOTE: The electric starter system is equipped with a safety feature. You will only be able to start under the following conditions: – If the ignition switch is in the ON position –… -

Page 146

C-page 5/9 F-page7/9 D-page 5/9 E-page3/9 Starting system 990 Adventure 2007- NOTE: The starting system is equipped with security features. The motorcycle can only be started under the following conditions: – Ignition lock in the ON position – Emergency-off switch in the ON position –… -

Page 147

antenna immobilizer ignition switch start/stop switch diode Immobilizer C_DN/8 starter start relay battery splice C_DO/8 motor C_AI/2 C_BC/6 C_EL/2 C_BK/4 C_AC/6 C_DV/2 C_BR/4 -X12 splice regulator-rectifier C_AF/4 re-wh re-wh 175,143 -X12-P1 /3.B2 -A1-X5 /2.C1 generator splice /3.B2 5,13,20,38,76,197,159 GND-X14 /2.C1 fuel-A2 /2.E5 lig-X19… -

Page 148

NOTE: the 12 V battery must be connected to the two terminals to which the orange and yellow cable colors (950 Adventure/950 Supermoto) or red/black and yellow/white (990 Adventure/Super Duke) are connected when the plug is connected. – Use an ohmmeter to measure the continuity between terminals Ω… -

Page 149

990 Super Duke/R) – Pull the auxiliary start relay out of the holder. – Connect the voltmeter to the red/blue (990 Adventure) or red/white (990 Super Duke/R) cable of the auxiliary start relay and measure the voltage to chassis. – Perform the tests in the specified order. The auxiliary start relay… -

Page 150

– the diode has no continuity. – the diode has continuity in both directions. Various malfunctions can occur, depending on the type of defect. Each diode (950/990 Adventure), (990 Super Duke/R) and (950 Supermoto/R, 990 Supermoto) is plugged into a bipolar connector (connector AI) Functional check: –… -

Page 151

(nonrecurring «click»). NOTE: the 12 V battery must be connected to the terminals to which the connectors with following cable colors 950 Adventure: white/red and brown 990 Adventure: red/blue and brown 990 Super Duke: white red and brown 950 Supermoto: red/blue and brown –… -

Page 152

– Disconnect the clutch switch connector from the cable tree. – Connect an ohmmeter to the bipolar connector AT2 (950 Adventure) or AT1 (990 Adventure) or AT1 (990 Super Duke/R) or AT3 (950 Supermoto/R, 990 Supermoto) of the clutch switch and slowly pull the clutch lever. -

Page 153

7-15 Checking the tip switch and emergency OFF switch – Disconnect the four-terminal connector BB (950/990 Adventure), (990 Super Duke/R) or (950 Supermoto/R, 990 Supermoto) on the tip switch / emergency OFF switch from the cable tree. – Check both switches with an ohmmeter. -

Page 154

7-16 orange 1 start/stop switch pick up throttle position sensor orange 1 fuse fuse 10 A C_BB/9 C_AB/9 C_AR1/2 C_AT/2 C_AL1/2 orange 0.5 C_AM/3 black-orange 0.5 orange 0.5 fuel pump relay yellow-blue 0.5 page 2/9 yellow-white 0.5 blue 0.5 yellow 0.5 black 0.5 blue-grey 0.5 page 7/9… -

Page 155

7-17 s / t a p — 8 / 2 c t i a p — 8 / 2 e l t o i t d e r 5 . 0 l l e n a r 5 . 0 l l e e u l 5 . -

Page 156

7-18 a p — 8 / 2 a p — 8 / 5 n a r — e g a l b 5 . 0 a p — 8 / 2 t i s c t i d e r 5 . -

Page 157

7-19 ECU 950 Adventure/Supermoto/Super Enduro Check the cables and socket connectors on the ECU (950 Adventure) and (950 Supermoto/Super Enduro). A functional check of the ECU can only be performed on an ignition test stand. – Check the ignition coil control: remove the ignition coil connector and apply the measuring tips of the peak voltage adapter to the pins of the connector AS (see checking the ignition coils). -

Page 158

7-20 Checking the fuel pump relay 950 Adventure/950 Supermoto – Dismount the fuel pump relay (950 Adventure) and (950 Supermoto). NOTE: black/blue, blue/gray, yellow/black and brown cable colors – Connect the fuel pump relay to a 12 V battery as shown, making sure you hear the relay switch (nonrecurring «click»). -

Page 159

7-21 Troubleshooting in the ignition system 950 Adventure/950 Supermoto Before checking the ignition, make sure: – the ignition lock is in the ON position – the emergency OFF switch is in the ON position (does not apply to the 950 Super Enduro) –… -

Page 160

7-22 orange 1 start/stop switch pick up throttle position sensor orange 1 fuse fuse 10 A C_BB/9 C_AB/9 C_AR1/2 C_AT/2 orange 0.5 C_AL1/2 C_AM/3 black-orange 0.5 orange 0.5 fuel pump relay yellow-blue 0.5 page 2/9 yellow-white 0.5 blue 0.5 yellow 0.5 black 0.5 blue-grey 0.5 page 7/9… -

Page 161

7-23 s / t a p — 8 / 2 c t i a p — 8 / 2 e l t o i t d e r 5 . 0 l l e n a r 5 . 0 l l e e u l 5 . -

Page 162

7-24 a p — 8 / 2 a p — 8 / 5 n a r — e g a l b 5 . 0 a p — 8 / 2 t i s c t i d e r 5 . -

Page 163

7-25 Checking the solenoid valve for the EPC 950 Adventure, 950 Supermoto/R, 950 Super Enduro – To check, disconnect connector AW from the solenoid valve. – Connect a 12-V battery with the two terminals on the solenoid valve. – You should hear a click in the solenoid valve (the diaphragm opening) when the circuit is closed. -

Page 164

7-26 g i l c t i — e r — e r r g — l b — a l l — e r e r — r o — l e r — u b — c t i — l b l b — l b -… -

Page 165

7-27 INJECTION/IGNITION SYSTEM Establishing the injection period (injection volume) Generally, the injection volume, i.e. the quantity of injected fuel, is dependent on the fuel pressure and the time the injection valve is open. Since the fuel pressure regulator keeps the fuel pressure constant, the quantity of fuel injected is controlled by the time the injection valve is open. -

Page 166

7-28 SYSTEM DIAGRAM CLUTCH: Clutch switch MR: Main relay CRK: Pulse generator NLSW: Neutral switch ECU: Control unit PA: Ambient air pressure sensor EXAI: Secondary air valve PM: Manifold air pressure sensors FLPR: Fuel pump relay PRESSURE REGULATOR: Pressure FUEL PUMP: Fuel pump regulator GP2: 2nd gear switch PVC: Carbon canister purge valve (USA) -

Page 167

The error lamp will stay on during operation if an error is detected; if the vehicle is standing (gear in neutral) the error lamp will start to blink according to the respective error code. The registered error codes can be read out through the diagnostics connector using the KTM diagnostics tool and deleted after the error has been eliminated. -

Page 168

7-30 WIRING DIAGRAM 990 SUPER DUKE… -

Page 169

7-31 SCHALTPLAN 990 SUPER DUKE R… -

Page 170

7-32 WIRING DIAGRAM 990 SUPERMOTO… -

Page 171

7-33 WIRING DIAGRAM 990 ADVENTURE -2007… -

Page 172

7-34 WIRING DIAGRAM 990 ADVENTURE 2007-… -

Page 173

7-35 BLOCK DIAGRAM Ignition Switch Kill Switch Battery Power Relay Start button Starter Regulator / Relay1 Generator. RECTA Starter Relay2 Sidestand Switch SSTAND(A/D) Fuel Injector INJ#1 #1(REAR) Starter MAP Sensor PM#2 Motor #2(FRONT) Fuel Injector HEGO Sensor #1(REAR) INJ#2 #2(FRONT) HG#1 HGHT#1 HEGO Sensor #2(FRONT) -

Page 174

7-36 DESCRIPTION OF THE ELECTRIC SYSTEM Fuel pump relay: A positive charge travels to the start/stop switch via the ignition switch and a fuse (10 amperes), then via the diode to the relay coil (positive side). The ground for the relay coil is switched for several seconds by the control unit with the ignition on during the starting process. -

Page 175

7-37 DESCRIPTION OF THE COMPONENTS Fuel pump The vane-type pump mounted in the fuel tank is driven by an electric motor whose rotor is rinsed and simultaneously cooled and lubricated with fuel. A back-pressure valve is installed in the outlet opening which closes when the ignition is switched off, stopping the pump in order to maintain the residual fuel pressure;… -

Page 176

Reducing jets with a 1 mm air hole are connected to the intake port. NOTE: If the vacuum hoses are damaged, they must be replaced with new, original KTM hoses. CAUTION – A LWAYS REPLACE THE VACUUM HOSES ON THE INTAKE MANIFOLD IF THEY WERE PULLED OFF –… -

Page 177

7-39 Pulse generator (crankshaft) The pulse generator is located under the clutch cover on the right side of the engine. It is an inductive sensor, i.e. the control unit calculates the speed and the crankshaft position based on the output signal. -

Page 178

7-40 Catalytic converter The catalytic converter is installed in the main silencer and transforms most of the main toxic constituents into non-toxic compounds. It is designed as a three-way catalytic converter and consists of a coiled metal support whose surface is coated with precious metals such as platinum and rhodium;… -

Page 179

Fresh air is drawn into the exhaust resulting in afterburning. Octane selector connections (990 Adventure only) If fuel having at least 95 octane (ROZ) is not available, you can easily activate the corresponding ignition curve by reducing the ignition timing. -

Page 180

Installation: behind the headlight mask. Diagnostics connector The diagnostics connector is located under the seat. The diagnostics connector connects the KTM diagnostics tool and the control unit to read error codes or perform function tests. Side stand switch The side stand switch… -

Page 181

7-43 SAFETY AGAINST FAILURE/EMERGENCY OPERATION Defective component Defect/Effect Backup value/ Possible to Possible to Spare sensor start engine? run vehicle? Fuel pump Total failure: will not start Lack of pressure: power loss limited Pressure regulator same as fuel pump see above see above Injection valve Electric error… -

Page 182

Checking the fuel presure Switch on the ignition, the pump will run for 2 seconds or switch on the pump with the KTM diagnostics tool. If not, perform the following tests: – Scan the fault memory with the KTM diagnostics tool. -

Page 183