Комментарии

8

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Я езжу на Toyota Prius (20)

На…я мануал на английском? Хоть написал бы! Только время потратил

Самая Первая картинка, надо помолиться на какой то баллончик, наверное с демексидом. Или лиш бы нечего не пиз…нуло 🤣🤣🤣🤣

ХладагентуHFC134AмаслукомпрессорномуND-OIL11 — ПО-МО-ЛИ-МСЯ!

Что в них ценнейшего? Давно выкладывал никому не нужны

Ценнее дилерских мануалов нет ничего !))

С учетом что большинство россиян не знают английский, то русский перевод. Хотя и его тоже никто не читает. А те кому надо давно имеют такие мануалы.

У нас с детства с журнала мурзилка осталась привычка по картинкам что то делать, а так мы читать не умеем)

kostya-sha

Что в них ценнейшего? Давно выкладывал никому не нужны

Может скинешь мне мануал на русском?)

Toyota Prius (XW20/NHW20, Mark II, MC Platform) с гибридной установкой: бензиновыми двигателями 1NZ-FXE 1.5 л (1496/1497 см³) 76-77 л.с./56-57 кВт и электрическими мотор-генераторами MG1 25 л.с./18 кВт, 3CM MG2 68 л.с./50 кВт; Руководство по эксплуатации, техническому обслуживанию и ремонту, технические характеристики, электросхемы, устройство, диагностика, особенности конструкции. Иллюстрированное практическое пособие гибридный легковой автомобиль компактного «Ц» класса Тойота Приус с цельнометаллическими несущими кузовами пятидверный хэтчбек (лифтбек) переднеприводные модели второго поколения выпуска с августа 2003 по 2009 год

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Видео Toyota Prius XW20 замена подшипника передней ступицы и высоковольтной батареи (Тойота Приус 03-09)

Toyota Prius Mark II общая информация (Тойота Приус 2003-2009)

Высоковольтная батарея

Проверка

Проверка ответной части сервисной перемычки

1. Снимите ответную часть сервисной перемычки и убедитесь в отсутствии проводимости между выводами.

2. Подсоедините к ответной части сервисную перемычку и убедитесь в наличии проводимости между выводами.

Проверка датчика тока высоковольтной батареи

1. Используя диагностический тестер, измерьте сопротивление между выводами «1» и «2».

Номинальное сопротивление:

Щуп «+» тестера к выводу «1» …………. 3,5-4,5 кОм

Щуп тестера к выводу «2» …………. 5,0-7,0 кОм

2. Используя диагностический тестер, измерьте сопротивление между выводами «1» и «3»

Номинальное сопротивление:

Щуп «+» тестера к выводу «1» …………. 3,5-4,5 кОм

Щуп «+» тестера к выводу «3» …………. 5,0-7,0 кОм

3. Измерьте сопротивление между выводами «2» и «3».

Номинальное сопротивление …………. менее 0,2 кОм

Снятие и установка

Примечание: установка производится в порядке, обратном снятию.

Моменты затяжки указаны в тексте.

1. Ознакомьтесь с мерами предосторожности перед проведением работ.

2. Снимите крышку пола №2 багажного отделения.

3. Снимите поддон для хранения инструментов.

4. Снимите боковую крышку пола багажного отделения.

5. Отсоедините провод от отрицательной клеммы аккумуляторной батареи.

Момент затяжки …………. 6,0 Нм

6. Снимите сервисную перемычку.

7. Отсоедините четыре пистона и снимите отделку порога багажного отделения.

8. Снимите шторку багажного отделения.

9. Снимите подушку заднего сиденья.

10. Снимите крышку пола №1 багажного отделения.

11. Снимите боковую отделку заднего сиденья с левой и правой стороны.

12. Снимите боковую крышку пола багажного отделения.

13. Снимите боковой поддон для хранения инструментов.

14. Снимите боковые отделки багажного отделения.

15. Отверните семь болтов и снимите кронштейн высоковольтной батареи.

Момент затяжки …………. 28 Нм

16. Снимите воздуховод №2.

а) Отсоедините фиксатор и реле №1 вентилятора батареи.

б) Отсоедините два держателя.

в) Снимите воздуховод №2.

17. Отверните семь болтов и снимите боковой кронштейн.

Момент затяжки …………. 28 Нм

18. Снимите воздуховод №3.

а) Отсоедините разъем.

б) Снимите фиксатор и отсоедините жгут проводов.

в) Отверните болт, отсоедините пистон и снимите воздуховод №3.

Момент затяжки …………. 4,0 Нм

19. Отверните три болта, две гайки и снимите крышку высоковольтной батареи.

Момент затяжки …………. 7,5 Нм

22. Снимите соединитель.

21. Отсоедините высоковольтные провода от батареи.

Момент затяжки …………. 5,6 Нм

22. Снимите высоковольтную батарею.

Примечание: используйте изоляционные перчатки.

а) Отверните четыре болта и отсоедините провод массы от высоковольтной батареи.

Момент затяжки …………. 19 Нм

б) Отсоедините разъем главного реле.

в) Отсоедините разъем выключателя блокировки.

г) Отсоедините фиксатор и разъем блока управления вентилятором батареи.

д) Отсоедините шланг высоковольтной батареи от панели пола.

е) Снимите высоковольтную батарею.

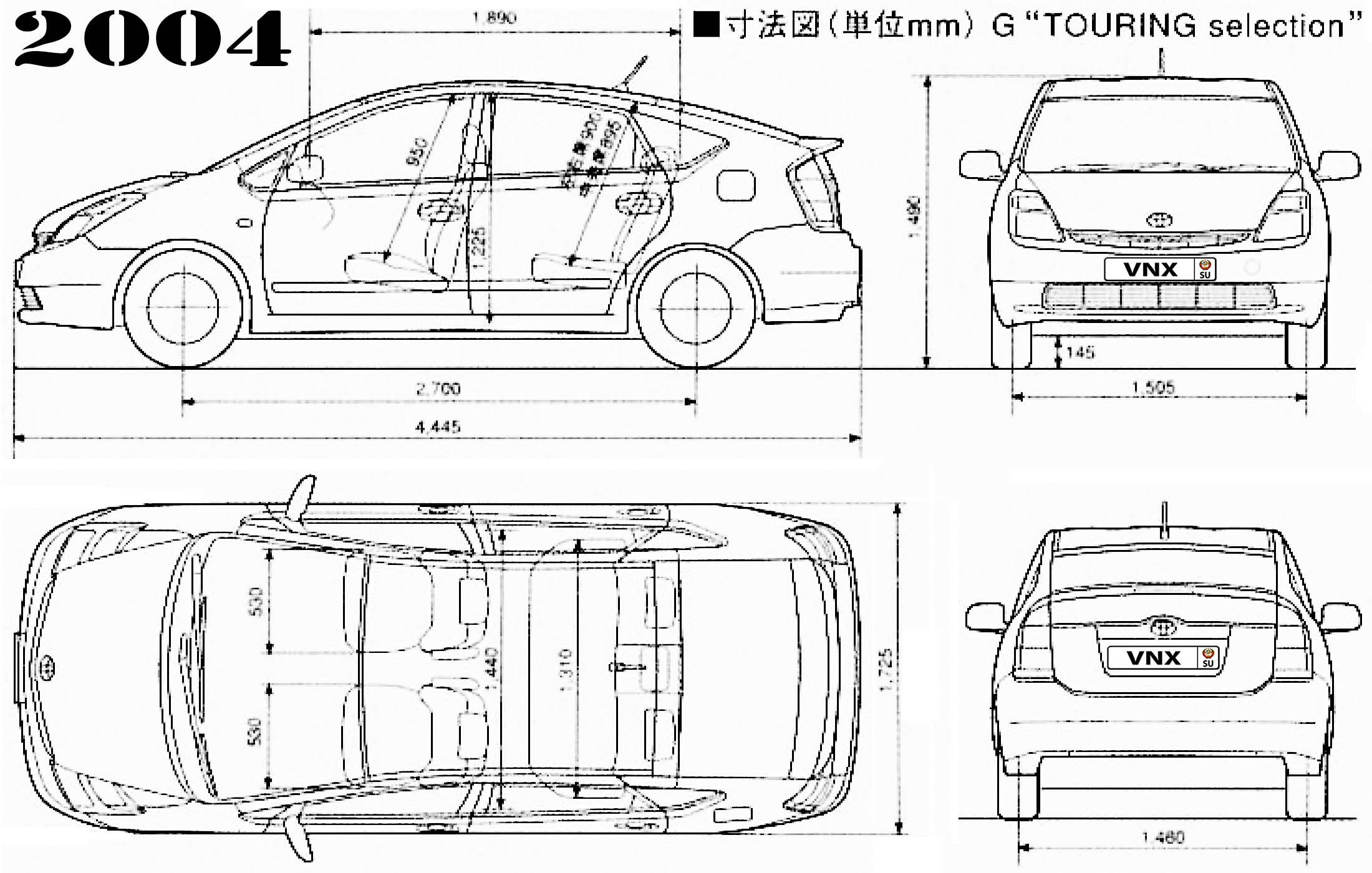

| № | Спецификация / Specs | Данные |

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 4445 |

| 2 | Ширина (без/с зеркалами) / Width | 1725 |

| 3 | Высота (загружен/пустой) / Height | 1490 |

| 4 | Колёсная база / Wheelbase | 2700 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 145 |

| 6 | Снаряжённая масса / Total (curb) weight | 1270 |

| Полная масса / Gross (max.) weight | 1545 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Гибридный, бензиновый, жидкостного охлаждения, четырехтактный, 1NZ-FXE и электрический 3CM MG2 |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 4-цилиндровый, рядный, 16V, DOHC с верхним расположением двух распределительных валов |

| 9 | Диаметр цилиндра / Bore | 75.0 мм |

| 10 | Ход поршня / Stroke | 84.7 мм |

| 11 | Объём / Engine displacement | 1496 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Распределенный впрыск топлива EFI |

| Атмосферный | ||

| 13 | Степень сжатия / Compression ratio | 13.0:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 57 кВт (77 л.с.) при 5000 об/мин, электрический 68 л.с./50 кВт при 1200-1540 об/мин, Синергетический режим: 111.5 л.с./82 кВт |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 115 Нм при 4200 об/мин, электрический 400 Нм при 0-1200 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | Устройство распределения мощности PSD (Power Split Device) |

| 17 | КПП / Transmission type | P112 Планетарная передача (Continuously Variable Transmission CVT — Бесступенчатый Вариатор) |

О Книге

- Название: Toyota Prius Устройство, техническое обслуживание и ремонт

- Бензиновые двигатели: 1NZ-FXE 1.5 л (1496/1497 см³) 76-77 л.с./56-57 кВт и электрическими мотор-генераторами MG1 25 л.с./18 кВт, 3CM MG2 68 л.с./50 кВт

- Выпуск с 2003 года

- Серия: «Ремонт Автомобилей»

- Год издания: 2009

- Автор: Коллектив авторов

- Издательство: «Ассоциация независимых издателей»

- Формат: PDF

- Страниц в книге: 572

- Размер: 423.66 МБ

- Язык: Русский

- Количество электросхем: более 50

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

To assist you in your service activities, this manual explains the main characteristics of the 2006 PRIUS, in

particular providing a technical explanation of the construction and operation of new mechanisms and new

technology used.

This manual is divided into 3 sections.

1. Introduction — Changed features and model line-up are explained.

2. New Features — Technical explanation of the construction and operation of each new system and

component.

3. Appendix — Major technical specifications of the vehicle.

CAUTION, NOTICE, REFERENCE and NOTE are used in the following ways:

CAUTION

NOTICE

REFERENCE

NOTE

For detailed service specifications and repair procedures, refer to the following Repair Manuals:

» 2006 PRIUS Repair Manual

» 2006 PRIUS Electrical Wiring Diagram

All information contained herein is the most up-to-date at the time of publication. We reserve the right to make

changes without prior notice.

2005

TOYOTA MOTOR CORPORATION

All rights reserved. This book may not be repro-

duced or copied., in whole or in part, without the

written permission of Toyota Motor Corporation.

First Printing: Nov. 7, 2005 01-051107-00

FOREWORD

Applicable models: NHW20 series

A potentially hazardous situation which could result in injury if instructions are

ignored.

Damage to the vehicle or components may occur if instructions are ignored.

Explains the theory behind mechanisms and techniques.

Notes or comments not included under the above 3 titles.

Manual Name

Pub. No.

RM01R0U

EM01R0U

Summary of Contents for Toyota 2006 PRIUS

18

Руководство по эксплуатации

ВНИМАНИЕ: при проведении работ в салоне автомобиля, оборудованного системой подушек безопасности и

преднатяжителей ремней (система «SRS»), следует быть особенно внимательными, чтобы не повредить блок

управления системы «SRS». Во избежание случайного срабатывания подушек безопасности или преднатяжи-

телей ремней, перед началом работ установите колеса в положение прямолинейного движения и замок зажи-

гания в положение «LOCK», отсоедините провод от отрицательной клеммы вспомогательной аккумуляторной

батареи и подождите не менее 90 секунд (время разряда резервного питания). Не пытайтесь разбирать узел

подушки безопасности или узел преднатяжителя ремня, т.к. в данных узлах нет деталей, требующих обслужи-

вания. Если подушки безопасности и/или преднатяжители ремней срабатывали (разворачивались), то их

нельзя отремонтировать или использовать повторно.

Общие сведения

и советы по эксплуатации

гибридного автомобиля

Ваш автомобиль является гибридным

и при движении использует энергию,

получаемую как от двигателя внут-

реннего сгорания (ДВС), так и от элек-

тродвигателя, работающего на высо-

ковольтной батарее (ВВБ), обеспечи-

вая оптимальный расход топлива и

экологичность автомобиля.

Зарядка высоковольтной батареи

осуществляется во время движения

автомобиля или при работе двигателя

на холостом ходу.

Внимание: максимальный заряд высо-

ковольтной батареи является по-

стоянным значением. Зарядка ВВБ

свыше этого значения невозможна.

Примечание:

— Поскольку высоковольтная бата-

рея заряжается по мере необходи-

мости во время движения или при

работающем двигателе, ее не

требуется заряжать от внешней

сети.

— Если не запускать двигатель ав-

томобиля более двух недель, это

может привести к разрядке высо-

ковольтной батареи и уменьшению

ее емкости. Поэтому, каждые две

недели рекомендуется хотя бы раз

запускать двигатель и оставлять

его запущенным при выключенных

потребителях электроэнергии

(осветительные приборы, магни-

тола, кондиционер и т.д.) не менее

чем на 30 минут.

Используемая энергия в

зависимости от условий движения

Примечание: в зависимости от усло-

вий движения автомобиля на много-

функциональном дисплее в режиме

«Energy Monitor» отображается схема

распределения энергии от ДВС и

электродвигателя.

1. При запуске двигателя и движении

задним ходом автомобиль работает на

электродвигателе и использует энер-

гию от высоковольтной батареи.

2. При равномерном ускорении или

движении с постоянной скоростью ав-

томобиль работает на ДВС, однако в

зависимости от условий движения к

работе ДВС может подключаться и

электродвигатель, использующий в

данный момент энергию от генератора

автомобиля. Система управления гиб-

ридной установкой обеспечивает оп-

тимальное соотношение используе-

мой энергии от ДВС и электродвига-

теля для снижения расхода топлива и

токсичности автомобиля, не влияя при

этом на динамические характеристики

автомобиля.

3. При движении на максимальных обо-

ротах коленчатого вала автомобиль ра-

ботает одновременно как на ДВС, так и

на электродвигателе, работающем на

высоковольтной батарее, обеспечивая

максимальную динамику автомобиля.

4. При нажатии на педаль тормоза или

замедлении автомобиля, электродви-

гатель работает как генератор и про-

исходит зарядка высоковольтной ба-

тареи (эффект «рекуперативных» тор-

мозов).

«, £

5. При остановке автомобиля ДВС ав-

томатически выключается и автомо-

биль работает на энергии от электро-

двигателя, работающего на высоко-

вольтной батарее.

Советы по повышению

эффективности использования

гибридного автомобиля

1. Плавно нажимайте на педаль аксе-

лератора, а также плавно отпускайте

педаль.

Примечание:

— Избегайте резкого увеличения или

уменьшения скорости автомобиля.

— Помните, что при спокойной ма-

нере движения (при плавном уско-

рении или снижении скорости) ав-

томобиль может работать без

использования ДВС только на

электродвигателе.

Руководство по эксплуатации

19

2. Во время движения убедитесь, что

селектор трансмиссии установлен в

положение «D». При парковке автомо-

биля всегда нажимайте на выключа-

тель режима «Р» трансмиссии.

Примечание: если селектор транс-

миссии установлен в положение «N»,

зарядка ВВБ не осуществляется.

Более того, продолжительная рабо-

та двигателя при положении «N» се-

лектора трансмиссии может при-

вести к разрядке высоковольтной

батареи.

Режим «EV» движения автомобиля

Внимание: при полном уровне заряда

высоковольтной батареи и обычных

условиях движения, в режиме «EV» ав-

томобиль может проехать около двух

километров. Движение на большее

расстояние при работе автомобиля в

режиме «EV» приведет к критическому

разряду ВВБ, что, в свою очередь,

приведет к безвозвратному уменьше-

нию емкости батареи и невозможно-

сти ее дальнейшей эксплуатации.

Движение автомобиля в режиме «EV»

осуществляется только за счет элек-

троэнергии от высоковольтной бата-

реи, при этом ДВС отключен. Поэтому

данный режим рекомендуется исполь-

зовать при постановке автомобиля в

гараж или движения в недостаточно

вентилируемых помещениях, где не

желательно присутствие выхлопных

газов. Также, в данном режиме значи-

тельно уменьшается шум от автомо-

биля, что актуально при движении по

парковой или дворовой территории.

Внимание: во время движения в дан-

ном режиме ДВС отключен полно-

стью и не участвует ни в движении

автомобиля, ни в подзарядке высоко-

вольтной батареи.

Для включения режима нажмите на

выключатель, расположение которого

показано на рисунке. При этом на

комбинации приборов загорится соот-

ветствующий индикатор.

Выключатель “EV”

I___’)

Примечание:

— В следующих случаях включение

режима «EV» будет невозможно:

— При высокой температуре ком-

понентов гибридной установки.

— При низкой температуре компо-

нентов гибридной установки.

— При температуре охлаждающей

жидкости, близкой к перегреву.

— При уровне заряда высоковольт-

ной батареи, равном трем пунк-

там или меньше.

— При скорости автомобиля более

55 км/ч.

— При сильном нажатии на педаль

акселератора.

— При использовании обогревате-

ля стекла задней двери и т.д.

— Поскольку включение режима «EV»

возможно только на прогретом

автомобиле, включение режима в

холодную погоду осуществляется

либо после того, как перестанет

мигать индикатор «READY”

(свидетельствует о готовности

автомобиля к движению), либо до

запуска двигателя. При этом вы-

ключите все ненужные электро-

приборы и убедитесь, что ВВБ за-

ряжена полностью.

При повторном нажатии на выключа-

тель, режим «EV» отключается и авто-

мобиль продолжает движение, работая

как на ДВС так и на электродвигателе.

Переход автомобиля в режим обычного

движения сопровождается отображе-

нием информационного сообщения на

многофункциональном дисплее и зву-

чанием «зуммера».

Если во время движения автомобиля

в данном режиме звучит звуковой сиг-

нал и индикатор режима «EV» мигает

три раза, а затем гаснет, это свиде-

тельствует о том, что система управ-

ления гибридной установкой автома-

тически отключала режим «EV» для

избежания полной разрядки высоко-

вольтной батареи. Автоматическое

отключение режима происходит в

следующих случаях:

— Если уровень заряда высоковольт-

ной батареи снизился до двух пунк-

тов.

— Если скорость автомобиля более

55 км/ч.

— При сильном нажатии на педаль

акселератора.

Обратите особое внимание

1. Во время движения ДВС включает-

ся и выключается автоматически в за-

висимости от условий движения. В

следующих случаях ДВС может не вы-

ключиться автоматически:

— При перегреве двигателя.

— Во время зарядки высоковольтной

батареи.

— При высокой или низкой темпера-

туре высоковольтной батареи.

2. Поскольку Ваш автомобиль осна-

щен как ДВС, так и электродвигателем

с высоковольтной батареей, некото-

рые узлы автомобиля представляют

собой особую опасность и при недос-

таточном внимании и неправильном

обслуживании могут причинить серь-

езные травмы, ожоги и даже стать

причиной смерти.

Внимание: узлы и агрегаты, а также

соединительные кабели гибридной

установки, приведенные на рисунке

«Компоненты автомобиля, находя-

щиеся под высоким напряжением»,

представляют собой наибольшую

опасность для жизни человека.

— Не прикасайтесь и не пытайтесь

произвести какие-либо подключения

к кабелям высокого напряжения или

клеммам высоковольтной батареи.

Клеммы ВВБ и кабели высокого на-

пряжения (более 200 В), окрашен-

ные в оранжевый цвет, представля-

ют собой наибольшую опасность

для жизни.

— На электродвигателе автомобиля,

электровентиляторе радиатора и на

некоторых других компонентах авто-

мобиля имеются информационные

таблички и этикетки, предупреждаю-

щие о возможной опасности при об-

служивании или проверке данного

компонента, поскольку во время дви-

жения автомобиля они нагреваются

до очень высоких температур.

— Не разбирайте, не демонтируйте,

не усовершенствуйте высоковольт-

ную батарею, кабели высокого на-

пряжения и другие компоненты, на-

ходящиеся под напряжением.

— Не прикасайтесь к аварийному вы-

ключателю ВВБ, расположенному в

левой боковой отделке багажного

отделения. Данный выключатель

предназначен для отключения по-

дачи напряжения от высоковольтной

батареи при ремонте и обслужива-

нии автомобиля.

3. Помните, что когда автомобиль ра-

ботает на электродвигателе, он почти

не производит шума работы двигателя,

тем более характерного для автомоби-

лей с ДВС. Ошибочное суждение лю-

дей, находящихся в непосредственной

близости от Вашего автомобиля, о том,

что автомобиль не работает, может

стать причиной аварии или причинения

вреда окружающим людям.

4. Всегда покидайте автомобиль толь-

ко после того, как убедитесь, что на-

жат выключатель режима «Р» транс-

миссии или селектор установлен в по-

ложение «N».

5. С правой стороны заднего сиденья

установлены воздуховоды, через ко-

торые осуществляется забор воздуха

для охлаждения высоковольтной ба-

тареи. Перед началом движения убе-

дитесь, что дефлекторы воздуховодов

не заслонены багажом или иным гру-

зом, пассажиры заднего сиденья не

ограничивают доступ воздуха к возду-

ховодам, ремни безопасности заднего

сиденья убраны в предназначенные

для них крепления. Ограничение за-

бора воздуха может привести к пере-

греву высоковольтной батареи и стать

причиной серьезных неисправностей.

6. В случае, если Вы попали в аварию,

для уменьшения риска удара током от

компонентов автомобиля, выполните

следующие действия:

а) Нажмите на педаль стояночного

тормоза.

Get your hands on the complete Toyota factory workshop software

IN-26

INTRODUCTION

ABBREVIATIONS USED IN THIS MANUAL

For convenience, the following abbreviations are used in this

manual.

ABS

Antilock Brake System

A/C

Air Conditioner

assy

assembly

ECT

Electronic Controlled Transmission

ECU

Electronic Control Unit

e.g.

Exempli Gratia (for Example)

Ex.

Except

FWD

Front Wheel Drive Vehicles

2WD

Two Wheel Drive Vehicles

4WD

Four Wheel Drive Vehicles

in.

inch

LH

Left-hand

LHD

Left-hand Drive

MIG

Metal Inert Gas

M/Y

Model Year

PPS

Progressive Power Steering

RH

Right-hand

RHD

Right-hand Drive

SRS

Supplemental Restraint System

SSM

Special Service Materials

w/

with

w/o

without

INTRODUCTION

IN-18

FOR ALL OF VEHICLES

PRECAUTION

1.

Service Plug

F13391

WRONG

PRECAUTIONS FOR HIGH-VOLTAGE CIRCUIT INSPECTION

AND SERVICE

(a) Engineer must undergo special training for high-voltage

system inspection and servicing.

(b) All high-voltage wire harness connectors are colored

orange. The HV battery and other high-voltage components have ”High Voltage” caution labels. Do not carelessly

touch these wires and components.

(c) Before inspecting or servicing the high-voltage system, be

sure to follow safety measures, such as wearing insulated

gloves and removing the service plug to prevent electrocution. Carry the removed service plug in your pocket to prevent other technicians from reinstalling it while you are

servicing vehicle.

(d) After removing the service plug, wait 5 minutes before

touching any of the high-voltage connectors and terminals.

HINT:

5 minutes are required to discharge the high-voltage condenser inside the inverter.

(e) Be sure install the service plug before starting the hybrid

system. Starting the hybrid system with the service plug removed may damage the vehicle.

(f) Before wearing insulated gloves, make sure that they are

not cracked, ruptured, torn, or damaged in any way. Do not

wear wet insulated gloves.

(g) When servicing the vehicle, do not carry metal objects like

mechanical pencils or scales that can be dropped accidentally and cause a short circuit.

(h) Before touching a bare high-voltage terminal, wear insulated gloves and use an electrical tester to ensure that the

terminal is not charged with electricity (approximately 0 V).

F13392

(i)

(j)

(k)

(l)

F13393

After disconnecting or exposing a high-voltage connector

or terminal, insulate it immediately using insulation tape.

The screw of a high-voltage terminal should be tightened

firmly to the specified torque. Both insufficient and excessive torque can cause failure.

Use the ”CAUTION: HIGH VOLTAGE. DO NOT TOUCH

DURING OPERATION” sign to notify other engineers that a

high-voltage system is being inspected and/or repaired.

Do not place the battery upside down while removing and

installing it.

INTRODUCTION

IN-19

(m) After servicing the high-voltage system and before reinstalling the service plug, check again that you have not left a

part or tool inside, that the high-voltage terminal screws are

firmly tightened, and that the connectors are correctly connected.

IN-20

INTRODUCTION

CAUTION:

HIGH VOLTAGE. DO

NOT TOUCH DURING

OPERATION.

Person in charge:

Copy this page and put it after folding on the roof of the vehicle in service.

F13394

INTRODUCTION

2.

IN-21

ACTIONS TO BE TAKEN FOR VEHICLE DAMAGED BY

IMPACT

(a) Items to be prepared or operation at the site of the accident

Protective clothing (insulated gloves, rubber gloves,

goggles, and safety shoes)

Saturated boric acid solution 20 L (obtain 800 g of boric acid powder, put it into a container, and dissolve it in

water)

Red litmus paper

ABC fire extinguisher (effective against both oil flames

and electrical flames)

Shop rags (for wiping off the electrolyte)

Vinyl tape (for insulating cable)

Electrical tester

(b) Actions to be taken at the place of accident

(1) Wear insulated or rubber gloves, goggles and safety

shoes.

(2) Do not touch a bare cable that could be a high voltage

cable. If the cable must be touched or if accidentalcaontact is unavoidable, follow these instructions: 1)

wear insulated or rubber gloves and goggles, 2) measure the voltage between the cable and the body

ground using an electrical tester, and 3) insulate the

cable using vinyl tape.

(3) If the vehicle catches fire, use an ABC fire extinguisher

to extinguish the fire. Trying to extinguish a fire using

only a small amount of water can be more dangerous

than effective. Use a substantial amount of water or

wait for firefighters.

(4) Check the HV battery and immediate area for any

electrolyte leakage. Do not touch any leaked liquid because it could be highly alkaline electrolyte. Wear rubber gloves and goggles, and then apply red litmus paper to the leak. If the paper turns blue, the liquid must

be neutralized before wiping. Neutralize the liquid using the following procedures:

1) apply saturated boric acid solution to the liquid, and

2) reapply red litmus paper and make sure it does not

turn blue. Repeat steps 1 and 2 above until the paper

does not turn blue. Then wipe the neutralized liquid

with a shop rag.

(5) If a damage to any of the high-voltage components

and cables is suspended, cut the high-voltage circuit

using the procedure on the following pages.

INTRODUCTION

IN-22

High–voltage part and Wiring

HV Battery

Inverter and Converter

Power Cable

A/C Compressor

Hybrid Transaxle

B76085

Service Plug

F13396

Push the shift switch to the P position and engage the parking brake.

Remove the key from the key slot. Then disconnect the power cable from the negative (–) terminal of the auxiliary battery.

Remove the service plug while wearing insulated

gloves. If the service plug cannot be removed

due to damage to the rear portion of the vehicle,

remove the HV fuse instead.

Do not turn the power switch on whicle removing

the service plug.

INTRODUCTION

IN-23

If the service plug cannot be removed due to damage to the rear

portion of the vehicle, remove the HV fuse instead.

(c) Moving the damaged vehicle

HINT:

If any of the following applies, tow the vehicle away using a

tow truck.

One or more of the high-voltage components and

cables are damaged.

The driving, traction, or fuel system is damaged.

Engine Room J/B

Power Integration

HV Fuse

F13397

F13398

The READY lamp is not illuminated when you turn.

NOTICE:

Before towing the vehicle away using a tow truck,

disconnect the cable from the negative (–) terminal of the auxiliary battery and remove the service

plug.

Only if none of the above applies and there are no

problems that might affect driving, drive the vehicle away from the place of accident to a safe,

nearby place.

Perform the procedure below if the READY lamp

turns off, or there are abnormal noises, unusual

smells, or strong vibrations while driving:

(1) Park the vehicle in a safe place.

(2) Push the selector lever to the P position and engage the parking brake.

(3) Disconnect the power cable from the negative (–)

terminal of the auxiliary battery.

(4) Remove the service plug while wearing insulated

gloves.

(d) Actions required after moving the damaged vehicle

If you see any liquid on the road surface, it could be highly

alkaline electrolyte leakage.

Wear rubber gloves and goggles, and apply red litmus paper to the leak. If the paper turns blue, the liquid must be

neutralized befor wiping. Neutralize the liquid using the following procedures: 1) apply saturated boric acid solution to

the liquid, and 2) reapply red litmus paper and make sure it

does not turn blue. Repeat steps 1 and 2 above until the paper does not turn blue. Then wipe the neutralized liquid with

a shop rag.

IN-24

INTRODUCTION

(e) Items to be prepared (when repairing damaged vehicles)

Protective clothing (Insulated gloves, rubber gloves,

goggles, and safety shoes)

Saturated boric acid solution 20 L (obtain 800 g of boric acid powder, put it into a container, and dissolve it in

water)

Red litmus paper

Shop rags (for wiping off the electrolyte)

Vinyl tape (for insulating cable)

Electrical tester

(f) Precautions to be observed when servicing the damaged

vehicle:

(1) Wear insulated or rubber gloves, goggles, and safety

shoes.

(2) Do not touch a bare cable that could be a high voltage

cable. If the cable must be touched or if accidental

contact is unavailable, follow these instructions: 1)

wear insulated or rubber gloves and goggles, 2) measure the voltage between the cable and the body

ground using an electrical tester, and 3) insulate the

cable using vinyl tape.

(3) Check the HV battery and immediate area for any

electrolyte leakage. Do not touch any leaked liquid because it could be highly alkaline electrolyte. Wear rubber gloves and goggles, and then apply red litmus paper to the leak. If the paper turns blue, the liquid must

be neutralized before wiping. Neutralize the liquid using the following procedures:

1) apply saturated boric acid solution to the liquid, and

2) reapply red litmus paper and make sure it does not

turn blue. Repeat steps 1 and 2 above until the paper

does not turn blue, Then wipe the neutralized liquid

with a shop rag.

(4) If the electrolyte adheres to your skin, wash the skin

immediately using saturated boric acid solution or a

large amount of water. If the electrolyte adheres to an

article of clothing, take it off immediately.

(5) If the electrolyte comes in contact with your eyes, call

out loudly for help. Do not rub your eyes. Wash them

with the large amount of water and seek medical care.

(6) If damage to any of the high-voltage components and

cables is suspected, cut the high-voltage circuit using

the procedure below.

Push the selector lever to the P position and engage the parking brake.

Remove the key from the key slot. Then disconnect the power cable from the negative (–) terminal of the auxiliary battery.

INTRODUCTION

IN-25

Wear insulated gloves, and then remove the service plug.

If you connot remove the service plug due to

damage to the rear portion of the vehicle, remove

the HV fuse or IGCT relay instead.

(g) Precautions to be taken when disposing of the vehicle

When scrapping the vehicle, remove the HV battery from

the vehicle and return it to the location specified by the

manufacturer. The same applies to any damaged HV battery.

(h) After removing the battery, keep it away from water. Water

may heat the battery, which results in fire.

(i) Precautions to be observed when towing

Tow the damaged vehicle with its front wheels or its front

and rear wheels lifted off the ground.

NOTICE:

Towing the damaged vehicle with its front wheels on the

ground may cause the motor to generate electricity. This

electricity could, depending on the nature of the damage,

leak and cause a fire.

(j) Towing with 4 wheels on the ground

NOTICE:

If the damaged vehicle needs to be towed using a rope,

do not exceed 30 km/h and tow only for very short distances. For example, towing from the accident site to a

nearby tow truck is permissible.

Set the power switch on and selector lever to the N

position.

If any abnormalityis present in the damaged vehicle

during the towing, stop towing immediately.

(k) Towing eyelet

(1) Install the hook.

(2) Hook a rope on to the illustrated area for towing.

F13399

BP-26

BODY PANEL REPLACEMENT

COWL TOP INNER SIDE PANEL (ASSY)

REPLACEMENT

F16146-A

REMOVAL

F16146

POINT

1

Remove the [A] the same time.

PART NAME

[A] Front Apron To Cowl Sidemember Plate

BODY PANEL REPLACEMENT

BP-27

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F16147

POINT

1

Inspect the fitting of the front fender and hood, etc., before welding, since this affects the appearance of the finish.

PART NAME

[A] Front Apron To Cowl Sidemember Plate

15mm (0.59in.)

[B]

Hood Damper Mounting Bracket

BP-24

BODY PANEL REPLACEMENT

COWL TOP SIDE PANEL (ASSY)

REPLACEMENT

F16144-A

REMOVAL

F16144

BODY PANEL REPLACEMENT

BP-25

F16145

15mm (0.59in.)

30mm (1.18in.)

FOREWORD

This repair manual has been prepared to provide essential information on body panel repair methods (including cutting and

welding operations, but excluding painting) for the TOYOTA

PRIUS.

Applicable models: NHW 20 series

This manual consists of body repair methods, exploded diagrams and illustrations of the body components and other information relating to body panel replacement such as handling

precautions, etc. However, it should be noted that the front fenders of the TOYOTA model is bolted on and require no welding.

When repairing, don’t cut and join areas that are not shown in

this manual. Only work on the specified contents to maintain

body strength.

Body construction will sometimes differ depending on specifications and country of destination. Therefore, please keep in mind

that the information contained herein is based on vehicles for

general destinations.

For the repair procedures and specifications other than collisiondamaged body components of the TOYOTA PRIUS refer to the

repair manuals.

If you require the above manuals, please contact your TOYOTA

Dealer.

All information contained in this manual is the most up-to-date at

the time of publication. However, specifications and procedures

are subject to change without prior notice.

NOTE: The Vehicle Lift and Support Locations sections

and For Vehicles Equipped With SRS Airbag and Seat

Belt Pretensioner sections refer to the TOYOTA PRIUS

Repair Manual.

BODY PANEL REPLACEMENT

BP-17

FRONT FENDER APPON (ASSY)

REPLACEMENT

With the radiator upper support and cowl top side panel removed.

F16137-A

REMOVAL

F16137

BP-18

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F16138

POINT

1

Make sure each measurement is correct, as this parts affects the front wheel alignment.

2

Inspect the fitting of the front fender and hood, etc., before welding, since this affects the appearance of the

finish.

13mm (0.51in.)

15mm (0.59in.)

BP-14

BODY PANEL REPLACEMENT

FRONT FENDER APRON FRONT WITH

SUPPORT (ASSY)

REPLACEMENT

With the radiator upper support removed.

F16134-A

REMOVAL

F16134

BODY PANEL REPLACEMENT

BP-15

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F16135

POINT

1

Inspect the fitting of the front fender and hood, etc., before welding, since this affects the appearance of the

finish.

BP-16

BODY PANEL REPLACEMENT

F16136

POINT

1

These values are reference values.

145mm (5.71in.)

157mm (6.18in.)

330mm (12.99in.)

372mm (14.65in.)

BODY DIMENSIONS

Three-dimensional

distance

Center-to-center

straight-line

distance

DI-1

GENERAL INFORMATION

1.

BASIC DIMENSIONS

(a) There are two types of dimensions in the diagram.

(1) (Three-dimensional distance)

Straight-line distance between the centers of two

measuring points.

Two-dimensional

distance

Vertical distance

in center

Center-to-center

Horizontal distance

in forward / rearward

Vertical distance

in lower surface

Imaginary Standard Line

Under Surface of

The Rocker Panel

(2) (Two-dimensional distance)

Horizontal distance in forward/rearward between the

centers of two measuring points.

The height from an imaginary standard line.

(b) In cases in which only one dimension is given, left and right

are symmetrical.

(c) The dimensions in the following drawing indicate actual distance. Therefore, please use the dimensions as a reference.

(d) The line that connects the places listed below is the imaginary standard line when measuring the height. (The dimensions are printed in the text.)

SYMBOL

Name

1

The place that was lowered A mm from the under surface of

the rocker panel centered on the front jack up point.

2

The place that was lowered B mm from the under surface of

the rocker panel centered between 1 and 3.

3

The place that was lowered C mm from the under surface of

the rocker panel centered on the rear jack up point.

Imaginary Standard Line

BODY DIMENSIONS

DI-2

Plate Looseness

Body Looseness

Pointer Looseness

2.

MEASURING

(a) Basically, all measurements are to be done with a tracking

gauge. For portions where it is not possible to use a tracking gauge, a tape measure should be used.

(b) Use only a tracking gauge that has no looseness in the

body, measuring plate, or pointers.

Pointer

Master Gauge

Wrong

Correct

Pointer

HINT:

1) The height of the left and right pointers must be equal.

2) Always calibrate the tracking gauge before measuring

or after adjusting the pointer height.

3) Take care not to drop the tracking gauge or otherwise

shock it.

4) Confirm that the pointers are securely in the holes.

(c) When using a tape measure, avoid twists and bends in the

tape.

INTRODUCTION

IN-1

GENERAL REPAIR INSTRUCTIONS

1.

WORK PRECAUTIONS

(a) VEHICLE PROTECTION

(1) When welding, protect the painted surfaces, windows,

seats and carpet with heat resistant, fire-proof covers.

Glass Cover

Seat Cover

F10001A

(b) SAFETY

(1) Never stand in direct line with the chain when using a

puller on the body or frame, and be sure to attach a

safety cable.

WRONG

F10002A

(2) Before performing repair work, check for fuel leaks.

If a leak is found, be sure to close the opening totally.

(3) If it is necessary to use a flame in the area of the fuel

tank, first remove the tank and plug the fuel line.

WRONG

F10003A

(c)

F10004

SAFETY WORK CLOTHES

(1) In addition to the usual mechanic’s wear, cap and

safety shoes, the appropriate gloves, head protector,

glasses, ear plugs, face protector, dust-prevention

mask, etc. should be worn as the situation demands.

Code

Name

A

Dust-Prevention Mask

B

Face Protector

C

Eye Protector

D

Safety Shoes

E

Welder’s Glasses

F

Ear Plugs

G

Head Protector

H

Welder’s Gloves

INTRODUCTION

IN-2

2.

HANDLING PRECAUTIONS OF PLASTIC BODY PARTS

(1) The repair procedure for plastic body parts must conform with the type of plastic material.

(2) Plastic body parts are identified by the codes in the following table.

(3) When repairing metal body parts adjoining plastic body parts (by brazing, frame cutting, welding, painting etc.), consideration must be given to the property of the plastic.

Code

Material

name

Heat*

resistant

temperature

limit C (F)

Resistance to

alcohol or gasoline

Notes

AAS

Acrylonitrile

Acrylic Styrene

80

(176)

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Avoid gasoline and organic

or aromatic solvents.

ABS

Acrylonitrile

Butadiene Styrene

80

(176)

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Avoid gasoline and organic

or aromatic solvents.

AES

Acrylonitrile

Ethylene Styrene

80

(176)

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Avoid gasoline and organic

or aromatic solvents.

ASA

Acrylonitrile

Styrene

Acrylate

80

(176)

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Avoid gasoline and organic

or aromatic solvents.

CAB

Cellulose

Acetate

80

(176)

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Avoid gasoline and organic

or aromatic solvents.

EPDM

Ethylene

Propylene

100

(212)

Alcohol is harmless.

Gasoline is harmless if applied only for

short time in small amounts.

Most solvents are harmless

but avoid dipping in gasoline,

solvents, etc.

FRP

Fiber

Reinforced

Plastics

180

(356)

Alcohol and gasoline are harmless.

Avoid alkali.

EVA

Ethylene

Acetate

70

(158)

Alcohol is harmless if applid only for short

time in small amounts (e.g., quick wiping

to remove grease).

Avoid gasoline and organic

or aromatic solvents.

Polyamide

(Nylon)

80

(176)

Alcohol and gasoline are harmless.

Avoid battery acid.

PBT

Polybutylene

Terephthalate

160

(320)

Alcohol and gasoline are harmless.

Most solvents are harmless.

PC

Polycarbonate

120

(248)

Alcohol is harmless.

Avoid gasoline brake fluid,

wax, wax removers and

organic solvents. Avoid alkali.

PA

*Temperatures higher than those listed here may result in material deformation during repair.

INTRODUCTION

Code

Material

name

Heat*

resistant

temperature

limit C (F)

Resistance to

alcohol or gasoline

IN-3

Notes

PE

Polyethylene

80

(176)

Alcohol and gasoline are harmless.

Most solvents are harmless.

PET

Polyethylene

Terephthalate

75

(167)

Alcohol and gasoline are harmless.

Avoid dipping in water.

PMMA

Polymethyl

Methacrylate

80

(176)

Alcohol is harmless if applied only for

short time in small amounts.

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

Polyoxymethylene

(Polyacetal)

100

(212)

Alcohol and gasoline are harmless.

Most solvents are harmless.

PP

Polypropylene

80

(176)

Alcohol and gasoline are harmless.

Most solvents are harmless.

PPO

Modified

Polyphenylene

Oxide

100

(212)

Alcohol is harmless.

Gasoline is harmless if

applied only for quick wiping

to remove grease.

Polystyrene

60

(140)

Alcohol and gasoline are harmless if

applied only for short time in small

amounts.

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

PUR

Polyurethane

80

(176)

Alcohol is harmless if applied only for very

short time in small amounts (e.g., quick

wiping to remove grease).

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

PVC

Polyvinylchloride

(Vinyl)

80

(176)

Alcohol and gasoline are harmless if

applied only for short time in small

amounts (e.g., quick wiping to remove

grease).

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

SAN

Styrene

Acrylonitrile

80

(176)

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Avoid dipping or immersing

in alcohol, gasoline, solvents

etc.

TPO

Thermoplastic

Olefine

80

(176)

Alcohol is harmless.

Gasoline is harmless if applied only for

short time in small amounts.

Most solvents are harmless

but avoid dipping in gasoline,

solvents, etc.

TPU

Thermoplastic

Polyurethane

80

(176)

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

TOYOTA

Super

Olefine Polymer

80

(176)

Alcohol and gasoline are harmless.

Most solvents are harmless.

Unsaturated

Polyester

110

(233)

Alcohol and gasoline are harmless.

Avoid alkali.

POM

PS

TSOP

UP

*Temperatures higher than those listed here may result in material deformation during repair.

INTRODUCTION

IN-4

3.

LOCATION OF PLASTIC BODY PARTS

Parts Name

Code

Radiator Grille

TSOP

Front Bumper Cover

TSOP

Headlight

PP/PC

Front Foglight

PC

Side Turn Signal Light

ABS/PMMA

Outer Rear View Mirror

ABS

Door Outside Handle

PC/PBT

Window Frame Moulding

ASA

Rear Door Rear Guide Seal

AES

Side Mudguard

TSOP

Rear Spoiler

ABS

High Mount Stop Light

ABS/PMMA

Back Door Outside Garnish

ABS

Rear Combination Light

ASA/PMMA

Rear Bumper Cover

TSOP

Rear No.1 Spoiler

PP/EPDM

Rear Side Spoiler

PP/EPDM

License Plate Light

PC

Resin material differs with model.

/ Made up of 2 or more kinds of materials.

INTRODUCTION

IN-15

HANDLING PRECAUTIONS ON RELATED COMPONENTS

1.

BRAKE SYSTEM

The brake system is one of the most important safety components. Always follow the directions and

notes given in brake (32) of the repair manual for the relevant model when handling brake system parts.

NOTICE: When repairing the brake master cylinder or TRAC system, bleed the air out of the TRAC system.

2.

DRIVE TRAIN AND CHASSIS

The drive train and chassis are components that can have great effects on the running performance and

vibration resistance of the vehicle. After installing components in the sections listed in the table below,

perform alignments to ensure correct mounting angles and dimensions. Particularly accurate repair of

the body must also be done to ensure correct alignment.

HINT: Correct procedures and special tools are required for alignment. Always follow the directions given in the repair manual for the relevant model during alignment and section DI of this section.

3.

Component to be aligned

Section of repair manual

for relevant model

Front Wheels

Front Suspension (26) section

Rear Wheels

Rear Suspension (27) section

COMPONENTS ADJACENT TO THE BODY PANELS

Various types of component parts are mounted directly on or adjacently to the body panels. Strictly observe the following precautions to prevent damaging these components and the body panels during handling.

Before repairing the body panels, remove their components or apply protective covers over the components.

Before prying components off using a screwdriver or a scraper, etc., attach protective tape to the tool

tip or blade to prevent damaging the components and the body paint.

Before removing components from the outer surface of the body, attach protective tape to the body to

ensure no damage to painted areas.

HINT: Apply touch-up paint to any damaged paint surfaces.

Before drilling or cutting sections, make sure that there are no wires, etc. on the reverse side.

4.

ECU (ELECTRONIC CONTROL UNIT)

Many ECUs are mounted in this vehicle.

Take the following precautions during body repair to prevent damage to the ECUs.

Before starting electric welding operations, disconnect the negative (–) terminal cable from the battery.

When the negative (–) terminal cable is disconnected from the battery, memory of the clock and audio

systems will be cancelled. So before starting work, make a record of the contents memorized by each

memory system. Then when work is finished, reset the clock and audio systems as before.

When the vehicle has tilt and telescopic steering, power seat and outside rear view mirror, which are

all equipped with memory function, it is not possible to make a record of the memory contents.

So when the operation is finished, it will be necessary to explain this fact to the customer, and request

the customer to adjust the features and reset the memory.

Do not expose the ECUs to ambient temperatures above 80C (176F).

NOTICE: If it is possible the ambient temperature may reach 80C (176F) or more, remove the ECUs

from the vehicle before starting work.

Be careful not to drop the ECUs and not to apply physical shocks to them.

IN-16

INTRODUCTION

PRECAUTIONS FOR REPAIRING BODY

STRUCTURE PANELS

1.

HEAT REPAIR FOR BODY STRUCTURE

PANELS

Toyota prohibits the use of the heat repair method on body

structure panels when repairing a vehicle damaged in a collision.

Panels that have high strength and rigidity, as well as a long

life span for the automobile body are being sought after.

At Toyota, in order to fulfill these requirement, we use high

tensile strength steel sheets and rust preventive steel

sheets on the body.

High tensile steel sheets are made with alloy additives and

a special heat treatment in order to improve the strength.

To prevent the occurrence of rust for a long period of time,

the surface of the steel is coated with a zinc alloy.

If a body structure parts are heat repaired with an acetylene

torch or other heating source, the crystalline organization of

the steel sheet will change and the strength of the steel

sheet will be reduced.

The ability of the body to resist rust is significantly lowered

as well since the rust resistant zinc coating is destroyed by

heat and the steel sheet surface is oxidized.

2.

STRUCTURE PANEL KINKS

A sharp deformation angle on the panel that cannot be returned to its original shape by pulling or hammering is

called a kink.

Since structure parts were designed to exhibit a 100% performance when they were in their original shape, if they are

deformed in an accident, or if the deformed parts are repaired and reused, they become unable to exhibit the same

performance as intended in the design.

It is necessary to replace the part where the kink has occurred.

INTRODUCTION

3.

IN-17

IMPACT BEAM REPAIR

The impact beam and bracket are necessary and important

parts in maintaining a survival space for passengers in a

side collision.

For impact beam, we use special high tensile strength

steel.

The high tensile strength steel maintains its special crystalline organization by heat treatment or alloy additives.

Since these parts were designed to exhibit a 100% performance when they were in their original shape, if they are

deformed in an accident, or if the deformed parts are repaired and reused, they become unable to exhibit the same

performance as intended in the design.

It is necessary to replace the door assembly when impact

beam or bracket is damaged.

INTRODUCTION

IN-10

PROPER AND EFFICIENT WORK

PROCEDURES

1.

REMOVAL

(a) PRE-REMOVAL MEASURING

(1) Before removal or cutting operations, take measurements in accordance with the dimension diagram. Always use a puller to straighten a damaged body or

frame.

F10007

(b) CUTTING AREA

(1) Always cut in a straight line and avoid reinforced area.

Cutting Okay

Reinforcement

Corners

F10008A

(c)

WRONG

PRECAUTIONS FOR DRILLING OR CUTTING

(1) Check behind any area to be drilled or cut to insure

that there are no hoses, wires, etc., that may be damaged.

HINT: See “Handling Precautions on Related Components” on page IN-15.

F10009A

(d) REMOVAL OF ADJACENT COMPONENTS

(1) When removing adjacent components, apply protective tape to the surrounding body and your tools to prevent damage.

HINT: See “Handling Precautions on Related Components” on page IN-15.

F10010

INTRODUCTION

2.

IN-11

PREPARATION FOR INSTALLATION

(a) SPOT WELD POINTS

(1) When welding panels with a combined thickness of

over 3mm (0.12in.), use a MIG (Metal Inert Gas) welder for plug welding.

HINT: Spot welding will not provide sufficient durability

for panels over 3mm (0.12in.) thick.

Less than

3mm

F10011A

(b) APPLICATION OF WELD-THROUGH PRIMER

(SPOT SEALER)

(1) Remove the paint from the portion of the new parts

and body to be welded, and apply weld-through primer.

F10012

(c)

MAKING HOLES FOR PLUG WELDING

(1) For areas where a spot welder cannot be used, use a

puncher or drill to make holes for plug welding.

REFERENCE:

mm (in.)

Thickness of welded portion

Puncher

Size of plug hole

1.0 (0.04) under

5 (0.20) ø over

1.0 (0.04) – 1.5 (0.06)

6.4 (0.26) ø over

1.5 (0.06) over

8 (0.31) ø over

F10013A

(d) SAFETY PRECAUTIONS FOR ELECTRICAL COMPONENTS

(1) When welding, there is a danger that electrical components will be damaged by the electrical current flowing

through the body.

(2) Before starting work, disconnect the negative terminal

of the battery and ground the welder near the welding

location of the body.

F10014

20 30mm

Air Saw

Overlap

F10015A

(e) ROUGH CUTTING OF JOINTS

(1) For joint areas, rough cut the new parts, leaving 20 –

30mm (0.79 – 1.18in.) overlap.

INTRODUCTION

IN-12

3.

INSTALLATION

(a) PRE-WELDING MEASUREMENTS

(1) Always take measurements before installing underbody or engine components to insure correct assembly. After installation, confirm proper fit.

Body

Measurement

Diagrams

F10016A

(b) WELDING PRECAUTIONS

(1) The number of welding spots should be as follows.

Spot weld: 1.3 X No. of manufacturer’s spots.

Plug weld: More than No. of manufacturer’s plugs.

(2) Plug welding should be done with a MIG (Metal Inert

Gas) welder. Do not gas weld or braze panels at areas

other than specified.

WRONG

F10017A

(c)

CORRECT

POST-WELDING REFINISHING

(1) Always check the welded spots to insure they are secure.

(2) When smoothing out the weld spots with a disc grinder, be careful not to grind off too much as this would

weaken the weld.

WRONG

F10018A

(d) SPOT WELD LOCATIONS

(1) Try to avoid welding over previous spots.

Tip Cutter

F10019A

Old

Spot

Locations

New Spot

Locations

F10020A

(e) SPOT WELDING PRECAUTIONS

(1) The shape of the welding tip point has an effect on the

strength of the weld.

(2) Always insure that the seams and welding tip are free

of paint.

INTRODUCTION

4.

Sealer Gun

IN-13

ANTI-RUST TREATMENT

(a) BODY SEALER APPLICATION

(1) For water-proofing and anti-corrosion measures, always apply the body sealer to the body panel seams

and hems of the doors, hoods, etc.

F10021A

(b) UNDERCOAT APPLICATION

(1) To prevent corrosion and protect the body from damage by flying stones, always apply sufficient undercoat to the bottom surface of the under body and inside of the wheel housings.

F10022

5.

ANTI-RUST TREATMENT AFTER PAINTING

PROCESS

(a) ANTI-RUST AGENT (WAX) APPLICATION

(1) To preserve impossible to paint areas from corrosion,

always apply sufficient anti-rust agent (wax) to the inside of the hemming areas of the doors and hoods,

and around the hinges, or the welded surfaces inside

the boxed cross-section structure of the side member,

body pillar, etc.

F10023

INTRODUCTION

IN-14

6.

ANTI-RUST TREATMENT BY PAINTING

REFERENCE:

Painting prevents corrosion and protect the sheet

metal from damage. In this section, anti-chipping paint

only for anti-corrosion purpose is described.

(a) ANTI-CHIPPING PAINT

(1) To prevent corrosion and protect the body from damage by flying stones, etc., apply anti-chipping paint to

the rocker panel, wheel arch areas, balance panel,

etc.

HINT:

Depending on the model or the application area, there

are cases where the application of anti-chipping paint

is necessary before the second coat or after the top

coat.

Apply the anti-chipping paint after

the top coat.

Apply the anti-chipping paint before

the second coat.

Anti-Chipping Paint

Top Coat

Second Coat

Top Coat

Second Coat

Anti-Chipping Paint

Under Coat (ED Primer)

Under Coat (ED Primer)

Steel Metal

Steel Metal

F10024A

VIEWS OF THIS TEXT

Scope of the repair work explanation

This text explains the welding panel replacement instructions from the vehicle’s white body condition. We have abbreviated the explanations of the removal and reinstallation of the equipment parts

up to the white body condition and of the installation, inspection, adjustment and final inspection of

equipment parts after replacing the weld panel.

Section categories

Each section has been divided as shown below.

Section Title

Contents

Examples

INTRODUCTION

Explanation of general body repair.

Views of weld panel replacement instructions.

Cautionary items.

Views of weld panel replacement instructions.

BODY PANEL REPLACEMENT

Instructions for replacing the weld panels

from the white body condition, from which

bolted parts have been removed, with

individual supply parts.

Front side member replacement.

Quarter panel replacement.

BODY DIMENSIONS

Body aligning measurements.

Dimension diagrams.

PAINT COATING

Scope and type of anti-rust treatment, etc.

together with weld panel replacement.

Under coat.

Body sealer.

Abbreviation of contents in this text.

The following essential procedures have been abbreviated. When actually working, conduct this

work properly.

(1) Jack and lift operations.

(2) Clean and wash removed parts, if necessary.

(3) Visual inspection.

NOTE: The Vehicle Lift and Support Locations sections

and For Vehicles Equipped With SRS Airbag and Seat

Belt Pretensioner sections refer to the TOYOTA PRIUS

Repair Manual.

BP-4

BODY PANEL REPLACEMENT

RADIATOR SIDE SUPPORT (ASSY)

REPLACEMENT

With the radiator upper support removed.

F16121-A

REMOVAL

F16123

BODY PANEL REPLACEMENT

BP-5

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F16124

BODY PANEL REPLACEMENT

BP-77

FIT STANDARDS

4.3mm

3.7mm

3.3mm

1.4mm

0.8mm

0.3mm

7.0mm

4.9mm

4.9 mm

0.8mm

4.9mm

0.3mm

5.8mm

F16115

0.3mm (0.01in.)

0.8mm (0.03in.)

1.4mm (0.06in.)

3.3mm (0.13in.)

3.7mm (0.15in.)

4.3mm (0.17in.)

4.9mm (0.19in.)

5.8mm (0.23in.)

7.0mm (0.28in.)

BP-78

BODY PANEL REPLACEMENT

5.1mm

5.2mm

6.2mm

3.7mm

4.0mm

5.7mm

4.0mm

4.0mm

5.7mm

F16116

3.7mm (0.15in.)

4.0mm (0.16in.)

5.2mm (0.20in.)

5.7mm (0.22in.)

5.1mm (0.20in.)

—

INTRODUCTION

IN-5

HOW TO USE THIS MANUAL

1.

BODY PANEL REPLACEMENT THIS MANUAL

BP-34

BODY PANEL REPLACEMENT

QUARTER PANEL (CUT)

REPLACEMENT

REMOVAL

POINT

1

Remove the [A] at the same time.

PART NAME

[A] Fuel Filler Opening Lid

A : REPLACEMENT PART AND METHOD

QUARTER PANEL (CUT)

Replacement method

(ASSY) … Assembly replacement

(CUT) … Major cutting (less than 1 / 2 of part used)

(CUT-H) … Half cutting (about 1 / 2 of part used)

(CUT-P) … Partial cutting (most of part used)

Replacement part

B : REMOVAL CONDTIONS

C : PART LOCATION

D : REMOVAL DIAGRAM

Describes in detail removal of the damaged part involving repair by cutting.

E : REMOVAL GUIDE

Provides additional information to more efficiently help you perform the removal.

F13890A

INTRODUCTION

IN-6

BODY PANEL REPLACEMENT

BP-35

INSTALLATION

Temporaily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fiting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F

I

J

G

I

5mm

POINT

1

Before temporarily installing the new parts, apply body sealer to the wheel arch.

HINT:

1) Apply body sealer about 5mm (0.20in.) front the flange, avoiding any oozing.

2) Apply sealer evenly, about 3 – 4mm (0.12 – 0.16in.) in diameter.

3) For other sealing points, refer to section PC.

H

PART NAME

[A] Fuel Filler Opening Lid

[B] Waterproof Rivet

F : INSTALLATION CONDITIONS

G : INSTALLATION DIAGRAM

Describes in detail installation to the new part involving repair by welding and / or

cutting, but excluding painting.

H : INSTALLATIOLN GUIDE

Provides additional information to more efficiently help you perform the installation.

I : SYMBOLS

(See page IN-7)

J : ILLUSTRATION OF WELD POINTS

Weld method and panel position symbols (See page IN-9)

K : PART NAME

F13891A

INTRODUCTION

2.

IN-7

SYMBOLS

The following symbols are used in the welding diagrams in section BP of this manual to indicate cutting areas

and the types of weld required.

SYMBOLS

MEANING

ILLUSTRATION

CUT AND JOIN LOCATION

(SAW CUT)

CUT AND JOIN LOCATION

(Cut Location for

Supply Parts)

CUT LOCATION

CUT WITH DISC

SANDER, ETC.

BRAZE

(Removal)

BRAZE

(Installation)

—

WELD POINTS

—

SPOT WELD OR

MIG PLUG WELD

(See Page IN-9)

CONTINUOUS

MIG WELD

(BUTT WELD)

CONTINUOUS

MIG WELD

(TACK WELD)

BODY SEALER

F13893A

INTRODUCTION

IN-8

SYMBOLS

MEANING

ILLUSTRATION

Assembly Mark

—

—

BODY SEALER

(Flat Finishing)

—

BODY SEALER

(No flat Finishing)

F13894A

INTRODUCTION

IN-9

3. ILLUSTRATION OF WELD POINT SYMBOLS

EXAMPLE:

REMOVAL

INSTALLATION

Weld points

Weld points

Remove weld point and panel position

SYMBOLS

MEANING

ILLUSTRATION

Remove

Weld

Points

Weld method and panel position

SYMBOLS

MEANING

ILLUSTRATION

Spot Weld

(Outside)

MIG Plug

Weld

(Middle)

(Inside)

Spot MIG

Weld

HINT: Panel position symbols are as seen from

the working posture.

F13892A

BP-40

BODY PANEL REPLACEMENT

ROCKER OUTER PANEL (CUT-H)

REPLACEMENT

F16156A

REMOVAL

F16156

30mm (1.18in.)

BODY PANEL REPLACEMENT

BP-41

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F16157

POINT

1

Inspect the fitting of the front door, etc., before welding, since this affects the appearance of the finish.

BODY PANEL REPLACEMENT

BP-1

RADIATOR UPPER SUPPORT (ASSY)

REPLACEMENT

F16119-A

REMOVAL

F16119

BP-2

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F16120

BODY PANEL REPLACEMENT

BP-3

F16133

POINT

1

Measure the dimensions before installing headlights.

2

These values are reference values.

190mm (7.48in.)

582mm (22.91in.)

710mm (27.95in.)

817mm (32.17in.)

BODY PANEL REPLACEMENT

BP-21

FRONT SIDE MEMBER (ASSY)

REPLACEMENT

With the radiator side support, front crossmember and front fender apron

removed.

F16141-A

REMOVAL

F16141

BP-22

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F16142

20mm (0.79in.)

30mm (1.18in.)

BODY PANEL REPLACEMENT

BP-23

F16143

POINT

1

Make sure each measurement is correct, as this parts affects the front wheel alignment.

PART NAME

[A] Front Sidemember Extension

90mm (3.54in.)

PAINT COATING

PC-1

BODY PANEL SEALING AREAS

HINT:

1) Prior to applying body sealer, clean the area with a rag soaked in grease,wax and silicone remover.

2) If weld-through primer was used, first wipe off any excess and coat with anti-corrosion primer before applying

body sealer.

3) Wipe off excess body sealer with a rag soaked in a grease, wax and silicone remover.

4) If body sealer is damaged by peeling, cracks, etc., be sure to repair as necessary.

Flat Finishing

1.

No Flat Finishing

ENGINE COMPARTMENT

F16101

PAINT COATING

PC-2

2.

INSIDE

F16102

PAINT COATING

3.

PC-3

REAR LUGGAGE COMPARTMENT

F16103

PAINT COATING

PC-4

4.

DOOR PARTS

F16104

PAINT COATING

PC-5

F16105

BP-36

BODY PANEL REPLACEMENT

FRONT DOOR OUTER PANEL (ASSY)

REPLACEMENT

F16162A

REMOVAL

Positioning Tape

Installation

Position

Hemming Location

Disk Sander

F16162

POINT

1

Before removing the outer panel, make the installation position with a tape.

2

After grinding off the hemming location, remove the outer panel.

BODY PANEL REPLACEMENT

BP-37

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

Positioning Tape

Do not close the

drain hole,

Cloth Tape

Hemming Tool

F16163

POINT

1

Before temporarily installing the new parts, apply body sealer to the reinforcement, side impact protection

beam and back side of the new parts.

HINT:

1) Apply sealer evenly about 10mm (0.39in.) from the flange and 3mm (0.12in.) in diameter to the outer

panel and apply just enough sealer for the reinforcement and side impact protection beam to make contact.

2

Bend the flange hem about 30 with a hammer and dolly, then fasten tightly with a hemming tool.

HINT:

1) Perform hemming in three steps, being careful not to warp the panel.

2) If a hemming tool cannot be used, hem with a hammer and dolly.

BODY PANEL REPLACEMENT

BP-19

FRONT SIDE MEMBER (CUT-P)

REPLACEMENT

With the radiator side support and front crossmember removed.

F16139-A

REMOVAL

F16139

POINT

1

Rmove the [A] at the same time.

PART NAME

[A] Front Sidememeber Extension

20mm (0.79in.)

BP-20

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F16140

PART NAME

[A] Front Sidememeber Extension

BODY DIMENSIONS

DI-6

BODY OPENING AREAS (Rear View)

(Three-Dimensional Distance)

1,095

(43.11)

1,110

(43.70)

1,216

(47.87)

1,255

(49.41)

488

(19.21)

1,117

(43.98)

1,201

(47.28)

1,418

(55.83)

1,252

(49.29)

1,095

(43.11)

1,062

(41.81)

1,067

(42.01)

Vehicle Dimensions

E-G

e-g

F-G

F-g

775

(30.51)

776

(30.55)

873

(34.37)

929

(36.57)

f-G

f-g

G-g

G-h

or

g-H

926

(36.46)

882

(34.72)

898

(35.35)

1,626

(64.02)

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (Seen from rear).

Symbol

Name

mm (in.)

Hole dia.

Symbol

Name

Hole dia.

A, a

Back door hinge installation hole-outer

15 (0.59)

F, f

Body lower back panel reinforcement working hole

8 (0.31)

B, b

Back door damper stay installation nut

6 (0.24) nut

G, g

Back door lock striker installation nut

C, c

Back door cushion installation nut

6 (0.24) nut

H, h

Rear absorber mounting bracket standard hole

D, d

Quarter panel standard hole

13 (0.51)

I, i

E, e

Deck trim side board installation hole

8.5 (0.335)

—

Center body pillar assembly mark

—

6 (0.24) nut

13 (0.51)

—

—

BODY DIMENSIONS

DI-5

BODY OPENING AREAS (Side View: Rear)

(Three-Dimensional Distance)

1,052

(41.42)

809

(31.85)

910 1,031

(35.83) (40.59)

1,026

(40.39)

710

(27.95)

Vehicle Dimensions Left Right

N-n

O-o

P-p

Q-q

R-r

S-s

1,337

(52.64)

1,426

(56.14)

1,434

(56.46)