ПРОБЛЕМА:

Так как основные работы по ремонту, обслуживанию и улучшению автомобиля я делаю сам,

и владение ИЖ 21261-070 4х4 в свое время меня научило надеяться только на свои силы,

так как аппарат был ещё реже чем AXIOM, и никакой сервис бы мне не помог либо это стоило баснословных средств. Поэтому знакомство всегда начинаю с приобретение Руководства или Справочника по автомобилю.

Так как AXIOM выпускался сравнительно не долго 2001-2004 (как и ИЖ 21261-070 2004-2005), + в стране их не так много — дельного руководства на русском языке нет.

Слава богу есть большой труд на 2100 страниц на английском языке.

Вот ссылка на него

Руководство общее на английском — yadi.sk/i/2YBkSUzOzOs95A

Но в этом ворохе страниц легко запутаться, тем более тем кто не особо силен в техническом английском.

РЕШЕНИЕ:

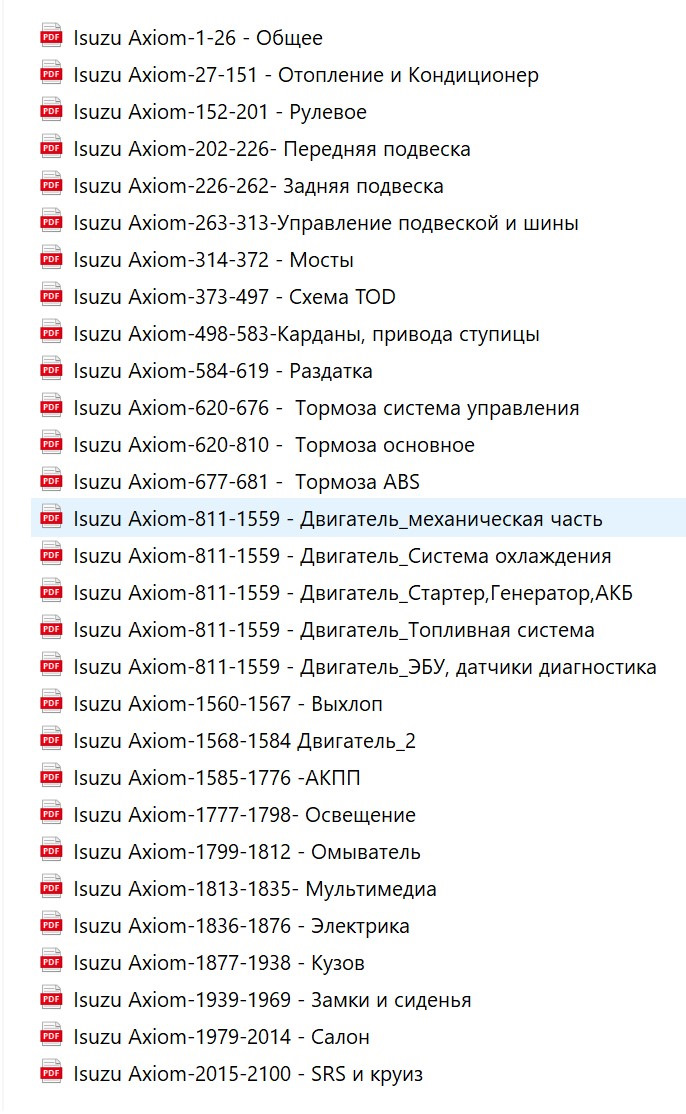

1. Разделить общее руководство на темы

2. Перевести на русский язык

Потратив один выходной сделал себе базу — надеюсь кому-то пригодится

1. Isuzu Axiom-1-26 — Общее yadi.sk/i/QGunXh45ufwXQQ

2. Isuzu Axiom-27-151 — Отопление и Кондиционер yadi.sk/i/RATeDFnN3YfNaw

3. Isuzu Axiom-152-201 — Рулевое yadi.sk/i/DhxVlWQEJyoE8Q

4. Isuzu Axiom-202-226- Передняя подвеска yadi.sk/i/DfK8FCKgaKP8dw

5. Isuzu Axiom-226-262- Задняя подвеска yadi.sk/i/2i8KymQ6TMGTDg

6. Isuzu Axiom-263-313-Управление подвеской и шины yadi.sk/i/dZtc3mHzyvcy9w

7. Isuzu Axiom-314-372 — Мосты yadi.sk/i/eg-9kany—8eYw

8. Isuzu Axiom-373-497 — Схема TOD yadi.sk/i/t9R8h4e_uJMPHA

9. Isuzu Axiom-498-583-Карданы, привода ступицы yadi.sk/i/2XVcEHMGBs9fxw

10. Isuzu Axiom-584-619 — Раздатка yadi.sk/i/rpugLN4OVBFcKg

11. Isuzu Axiom-620-676 — Тормоза система управления yadi.sk/i/EQXLmOXsa1FyFw

12. Isuzu Axiom-620-810 — Тормоза основное yadi.sk/i/xwRl-uM_VEC_ow

13. Isuzu Axiom-677-681 — Тормоза ABS yadi.sk/i/SocauYT5TqgPWA

14. Isuzu Axiom-811-1559 — Двигатель_механическая часть yadi.sk/i/7jNV3PdtdoP2zw

15. Isuzu Axiom-811-1559 — Двигатель_Система охлаждения yadi.sk/i/YrkZfp6uQApA8A

16. Isuzu Axiom-811-1559 — Двигатель_Стартер, Генератор, АКБ yadi.sk/i/3U4Qls1bFNf2YQ

17. Isuzu Axiom-811-1559 — Двигатель_Топливная система yadi.sk/i/ANfcgNmAgN35Dg

18. Isuzu Axiom-811-1559 — Двигатель_ЭБУ, датчики диагностика yadi.sk/i/fHa8-W7j_ZpgBg

19. Isuzu Axiom-1560-1567 — Выхлоп yadi.sk/i/ZYfTcBJWMXkgaw

20. Isuzu Axiom-1568-1584 Двигатель дополнение yadi.sk/i/VTAN8b2grHIelQ

21. Isuzu Axiom-1585-1776 -АКПП yadi.sk/i/Wx3n9WrF_iJxZA

22. Isuzu Axiom-1777-1798- Освещение yadi.sk/i/ZTp4mf4HPaQtGA

23. Isuzu Axiom-1799-1812 — Омыватель yadi.sk/i/e3Y7kreIc81IDA

24. Isuzu Axiom-1813-1835- Мультимедиа yadi.sk/i/kF49cOCNyXDIEg

25. Isuzu Axiom-1836-1876 — Электрика yadi.sk/i/dSLhcvQy_R56dg

26. Isuzu Axiom-1877-1938 — Кузов yadi.sk/i/0tqRSF-_ZylxzQ

27. Isuzu Axiom-1939-1969 — Замки и сиденья yadi.sk/i/-PhKnaUsP9ddWw

28. Isuzu Axiom-1979-2014 — Салон yadi.sk/i/cxQzirf7vJPOTg

29. Isuzu Axiom-2015-2100 — SRS и круиз yadi.sk/i/rjanpEFRTpxMNA

Всем ровных дорог!

Руководство на английском языке по техническому обслуживанию и ремонту Isuzu Amigo/Axiom/Trooper/Rodeo/VehiCross 1999-2002 годов выпуска.

- Автор: —

- Издательство: Isuzu Motors

- Год издания: —

- Страниц: 23403

- Формат: PDF

- Размер: 122,9 Mb

Схемы электрооборудования на английском языке Isuzu Axiom 2002 года выпуска.

- Автор: —

- Издательство: Isuzu Motors

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 2,4 Mb

Схемы электрооборудования на английском языке Isuzu Axiom 2003 года выпуска.

- Автор: —

- Издательство: Isuzu Motors

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 13,3 Mb

Get your hands on the complete Isuzu factory workshop software

Instruments — MID Unit ‘ERROR’ in ‘RESET’ Mode

Instrument Panel Control Module: Technical Service Bulletins Instruments — MID Unit ‘ERROR’ in

‘RESET’ Mode

BULLETIN NUMBER: IB01-04-S005

ISSUE DATE: JUNE 2001

GROUP: ELECTRICAL

AXIOM MID UNIT: SETTING «ERROR» IN «RESET» MODE

AFFECTED VEHICLES All 2002 Axiom models.

SERVICE INFORMATION

All 2002 Axiom models have the MID Unit as standard equipment with six selection buttons:

^ «ILLUM» for the MID indicator brightness only.

^ «SERVICE» for changing the Calendar mode to Service mode and Service mode to Calendar

mode.

^ «RESET» for resetting the Average Fuel Economy and Elapsed Time only.

^ «COMP MODE» for computer mode which will display the Possible running Distance, Average

Fuel Economy, Instantaneous Fuel Economy, and Direction Angle.

^ «CLOCK» will display and change the time and display the elapsed time.

^ «ON/OFF» will turn vehicle information and temperature outside of the vehicle on/off. If the button

is held down for greater than 2 seconds, the indication of units is changed from US to metric and

back.

If the «RESET» button is depressed more than once while moving the «COMP MODE» from AVG. to

INST. to COMPASS, the display of «ERROR» on the lower center portion of the MID Unit will occur

(Figure 1). This occurs because the reset has already been performed. This is not a problem and

the MID Unit does not require service.

Disclaimer

Page 363

Abbreviations Chart 2

Page 163

PCM Pinout Table, 80-Way Red Connector _ Row»S61 — 70″ — View/Index — 1

Locations

9. Right Rear of Engine Compartment

Page 209

Suspension Control Module: Service and Repair

Removal

1. Disconnect the battery ground cable. 2. Remove the front console assembly. 3. Disconnect the

connector from the control unit.

View A

4. Remove 4 nuts. 5. Disconnect the control unit with brackets. 6. Remove 4 screws. 7. Disconnect

the control unit from the brackets.

Installation

To install, follow the removal steps in the reverse order, noting the following points. Torque: Nut (1)

8 Nm (69 inch lbs.)

Locations

12. Fuse/Relay Box (Cover Removed)

Page 368

Seat Belt, Lamps-On, And Key-In Ignition Warning System Image 73-1

Description and Operation

Lateral Accelerometer: Description and Operation

G-Sensor

The G-sensor installed inside the EHCU detects the vehicle deceleration speed and sends a signal

to the EHCU. In 4WD operation, all four wheels may be decelerated in almost the same phase,

since all wheels are connected mechanically. This tendency is noticeable particularly on roads with

low friction coefficient, and the ABS control is adversely affected. The G-sensor judges whether the

friction coefficient of road surface is low or high, and changes the EHCU’s operating system to

ensure ABS control.

Page 336

Solar Sensor: Service and Repair

Sun Sensor

Removal

1. Disconnect the battery ground cable. 2. Remove the center cluster upper. 3. Disconnect the sun

sensor connector. 4. Remove the sun sensor.

Installation

To install, follow the removal step in the reverse order.

Page 132

PCM Pinout Table, 80-Way Blue Connector _ Row»F61 — 80″ — View/Index — 2

Page 167

1. Install the PCM to bracket and fix with the clip. 2. Connect the PCM electrical connectors.

3. Install the two screws to PCM electrical connectors.

Page 154

Engine Control Module: Pinout Values and Diagnostic Parameters

PCM Pinout Table, 80-way Blue Connector — Row «F1 — 20»

Page 12

Abbreviations Chart 2

Page 80

Abbreviations Chart 5

Page 351

Dimmer Switch: Service and Repair

Illumination Controller

Removal

1. Disconnect the battery ground cable.

2. Remove the meter cluster panel cover assembly (2).

— Refer to Instrument Panel Assembly in Body Structure section.

3. Remove the illumination controller (1).

— Disconnect the controller connector.

— Remove the controller knob (4).

— Remove the nut (3).

— Remove the controller from the back side of the meter cluster panel assembly.

Installation

To install, follow the removal steps in the reverse order.

Page 120

Illustration Arrows Part 2

Component Tests and General Diagnostics

Engine Control Module: Component Tests and General Diagnostics

To read and clear diagnostic trouble codes, use a Tech 2.

Important: Use of a Tech 2 is recommended to clear diagnostic trouble codes from the PCM

memory.Diagnostic trouble codes can also be cleared by turning the ignition «OFF» and

disconnecting the battery power from the PCM for 30 seconds.Turning off the ignition and

disconnecting the battery power from the PCM will cause all diagnostic information in the PCM

memory to be cleared. Therefore, all the diagnostic tests will have to be re-run.

Since the PCM can have a failure which may affect only one circuit, following the diagnostic

procedures will determine which circuit has a problem and where it is. If a diagnostic chart indicates

that the PCM connections or the PCM is the cause of a problem, and the PCM is replaced, but this

does not correct the problem, one of the following may be the reason:

— There is a problem with the PCM terminal connections.The terminals may have to be removed

from the connector in order to check them properly.

— EEPROM program is not correct for the application. Incorrect components or reprogramming the

PCM with the wrong EEPROM program may cause a malfunction and may or may not set a DTC.

— The problem is intermittent. This means that the problem is not present at the time the system is

being checked. In this case, refer to Symptom Diagnosis and make a careful physical inspection of

all component and wiring associated with the affected system.

— There is a shorted solenoid, relay coil, or harness. Solenoids and relays are turned «ON» and

«OFF» by the PCM using internal electronic switches called drivers. A shorted solenoid, relay coil,

or harness will not damage the PCM but will cause the solenoid or relay to be inoperative.

Locations

16. Right Rear Corner of Engine Compartment

Page 76

Abbreviations Chart 1

Page 26

Keyless Entry Module: Service and Repair Anti-Theft & Keyless Entry Controller

Removal

1. Disconnect the battery ground cable.

2. Remove the glove box from the instrument panel assembly (1).

— Refer to Instrument Panel Assembly in Body Structure section.

3. Remove the anti-theft & keyless entry controller (2).

— Disconnect the connector.

— Remove two fixing screws.

Installation

To install, follow the removal steps in the reverse order.

Diagram Information and Instructions

A/T Shift Indicator Module: Diagram Information and Instructions

Illustration Arrows Part 1

Page 16

General Module: Electrical Diagrams

Alarm And Relay Control Unit

Page 383

10. Disconnect the wiring harness connectors located under the steering column then remove

combination switch and SRS coil assembly.

Installation

1. Install combination switch and SRS coil assembly. After installation of combination switch

assembly, connect the combination switch wiring

harness connector and the SRS 2-way connector located under the steering column. Then turn the

SRS coil counter clockwise to full, return about 3 turns and align the neutral mark.

Caution: Turn the SRS coil counter clockwise until some resistance is felt, or damage may occur to

the SRS coil.

Page 365

Abbreviations Chart 4

Page 147

Engine Control Module: Description and Operation PCM Function

The PCM supplies either 5 or 12 volts to power various sensors or switches.The power is supplied

through resistances in the PCM which are so high in value that a test light will not light when

connected to the circuit.In some cases, even an ordinary shop voltmeter will not give an accurate

reading because its resistance is too low. Therefore, a digital voltmeter with at least 10 megohms

input impedance is required to ensure accurate voltage readings. Tool J 39200 meets this

requirement.The PCM controls output circuits such as the injectors, fan relays, etc., by controlling

the ground or the power feed circuit through transistors or through either of the following two

devices:

— Output Driver Module (ODM)

— Quad Driver Module (QDM)

Page 176

Fuel Pump Relay: Description and Operation

In order to control the FPS operation, the FPS relay is provided. When the starter switch is turned

to «ON» position, the FPS relay operates the FPS for 2 seconds.

When the key turned to «START» position, the Engine Control Module receives the reference pulse

from the Ignition Control Module and it operates the relay, again causing the FPS to feed fuel.

Page 18

Alarm And Relay Controls Image 70-1

Locations

93. Bottom of Tailgate Door (Panel Removed)

Page 17

Alarm And Relay Controls Image 70

Locations

82. Left Front Door (Right Similar)

Locations

Brake Light Switch: Locations

51. Below Left Side of I/P

Page 117

26. Left Side of Engine Compartment

Page 367

Key Reminder Switch: Electrical Diagrams

Seat Belt, Lamps-On, And Key-In Ignition Warning System Image 73

Page 345

Abbreviations Chart 1

Page 126

Abbreviations Chart 4

Page 133

PCM Pinout Table, 80-Way Red Connector _ Row»S1 — 20″ — View/Index — 1

Locations

13. Fuse/Relay Box (Cover Removed)

Page 366

Abbreviations Chart 5

Page 280

Front Wheel Speed Sensor and Associated Parts

Page 359

Illustration Arrows Part 2

Page 308

Ambient Temperature Sensor / Switch HVAC: Testing and Inspection

Ambient Sensor

1. Disconnect the connector (C-19) on the ambient sensor.

2. Measure resistance between the ambient sensor side terminals.

Locations

44. Dash Fuse Box

Diagrams

Page 21

General Module: Service and Repair

Alarm and Relay Control Unit

Removal

1. Disconnect the battery ground cable. 2. Remove the grove box (1). 3. Remove the alarm and

relay control unit (2).

4. Disconnect the connector.

Installation

To install, follow the removal steps in the reverse order.

Page 150

— Quad Driver Module (QDM)

PCM Voltage Description

The PCM supplies a buffered voltage to various switches and sensors. It can do this because

resistance in the PCM is so high in value that a test light may not illuminate when connected to the

circuit.An ordinary shop voltmeter may not give an accurate reading because the voltmeter input

impedance is too low. Use a 10-megohm input impedance digital voltmeter (such as J 39200) to

assure accurate voltage readings.

The input/output devices in the PCM include analog-to-digital converters, signal buffers, counters,

and special drivers. The PCM controls most components with electronic switches which complete a

ground circuit when turned «ON.»These switches are arranged in groups of 4 and 7, called either a

surface-mounted quad driver module (QDM), which can independently control up to 4 output

terminals, or QDMs which can independently control up to 7 outputs. Not all outputs are always

used.

PCM Inputs/Outputs

Inputs — Operating Conditions Read

— Air Conditioning «ON» or «OFF»

— Engine Coolant Temperature

— Crankshaft Position

— Exhaust Oxygen Content

— Electronic Ignition

— Manifold Absolute Pressure

— Battery Voltage

— Throttle Position

— Vehicle Speed

— Fuel Pump Voltage

— Power Steering Pressure

— Intake Air Temperature

— Mass Air Flow

— Engine Knock

— Acceleration Position

Outputs — Systems Controlled

— EVAP Canister Purge

— Exhaust Gas Recirculation (EGR)

— Ignition Control

— Fuel Control

— ION Sensing Module

— Electric Fuel Pump

— Air Conditioning

— Diagnostics Malfunction Indicator Lamp

— Data Link Connector (DLC)

— Data Output

— Transmission Control Module

Locations

76. Front of Roof (Headliner Removed)

Page 128

Engine Control Module: Connector Views

PCM Pinout Table, 80-way Blue Connector — Row «F1 — 20″

Page 196

diagnostic trouble code should be referenced. The SDM should not be replaced for a history

diagnostic trouble code.

2. This test checks for a malfunction introduced into the SRS during the diagnostic process. It is

extremely unlikely that a malfunctioning SDM

would cause a new malfunction to occur during the diagnostic process.

3. When all circuitry outside the SDM has been found to operate properly, as indicated by the

appropriate diagnostic chart, then and only then should

the SDM be replaced.

Page 155

PCM Pinout Table, 80-Way Blue Connector _ Row»F20 — 40″ — View/Index

Diagram Information and Instructions

Dimmer Switch: Diagram Information and Instructions

Illustration Arrows Part 1

Page 110

Relay / Fuse Box (Engine Room) Part 2

Page 156

PCM Pinout Table, 80-Way Blue Connector _ Row»F41 — 60″ — View/Index

Page 313

1. Dismount the in car sensor from the automatic heater/air conditioner control unit. Connect (+)

end and (-) end of the battery to the aspirator motor

side terminals No. I17-1 and No. I17-2, respectively, then check if the motor runs normally.

Locations

32. Left Front of Engine

Page 350

Illumination Light

Page 360

Illustration Arrows Part 3

Page 370

Key Reminder Switch: Service and Repair

Key Remind Switch (Starter Switch)

Removal and Installation

Refer to Lock Cylinder in Steering System.

Page 198

2. Connect the SDM harness connector (2) and after that, put CPA into connector (1). 3. Install air

conditioning duct for rear seat to normal position. 4. Return carpet normal position. 5. Install right

side stay between instrument panel and floor, tighten to the specified torque.

Torque: 10 N.m ± 3 N.m (87 lb in ± 26 lb in)

6. Install PCM with bracket and tighten to the specified torque.

Torque: 10 N.m ± 3 N.m (87 lb in ± 26 lb in)

7. Reconnect three connector to PCM. 8. Install the center console. 9. Install the transfer shift lever

knob.

10. Install the dressing panel around the radio and reconnect cigar lighter harness.

11. Enable the SRS. Refer to Enabling the SRS in this section.

Page 36

Sunroof / Moonroof Module: Service and Repair

Sunroof Control Unit

Removal

1. Disconnect the battery ground cable.

2. Remove the headlining.

— Refer to Headlining in Exterior/Interior Trim section.

3. Remove the sunroof control unit (1).

— Disconnect two connectors.

— Remove two screws.

Installation

To install, follow the removal steps in the reverse order.

Service and Repair

Sunroof / Moonroof Switch: Service and Repair

Removal

1. Disconnect the battery ground cable.

2. Remove the sunroof switch (1).

— Remove the switch by pushing the spring with the tip of a screwdriver.

— Disconnect the switch connector.

Installation

To install, follow the removal steps in the reverse order.

Locations

69. Under Front of Center Console

Page 240

4. Remove the inside handle.

— Open the screw corer (1) and remove the screw.

— Disconnect the cable.

5. Remove the door mirror cover.

6. Pull the door trim panel at the 8 clip positions (1).

— Disconnect the courtesy light and tweeter harness connectors.

7. Remove the pull box bracket.

8. Remove the inside lock bracket.

— Disconnect the cable.

9. Remove the waterproof sheet.

— Taking notice of the door harness, peel the waterproof sheet off the door panel carefully.

10. Raise the glass up to the uppermost position.

Page 20

General Module: Description and Operation

Circuit Operation

The alarm and relay control unit controls the UPSHIFT INDICATOR lamp (2.2L), Key-in ignition

warning, seat belt warning, horns, windshield wiper/washer system, and the rear wiper/washer

system.

Locations

11. Fuel Relay Box (Cover Removed)

Page 83

A/T Shift Indicator Module: Description and Operation

Circuit Operation

With the starter switch in ON OR START battery voltage is applied to the automatic transmission

mode switch through the C-14 BACKUP TURN fuse. The automatic transmission mode switch

sends a signal to the powertrain control module (PCM) and the multi-plexed indicator control unit

corresponding to the gear selected. The multi-plexed indicator control unit applies voltage to the

appropriate A/T shift indicator lamp in the meter assembly, causing it to come on.

Page 327

Pressure Switch And Associated Parts

Page 290

Engine Temperature Sensor: Description and Operation

The engine coolant temperature (ECT) sensor is a thermistor (a resistor which changes value

based on temperature) mounted in the engine coolant stream. Low coolant temperature produces a

high resistance of 100,000 ohms at -40 °C (-40 °F). High temperature causes a low resistance of

70 ohms at 130 °C (266 °F).The PCM supplies a 5-volt signal to the ECT sensor through resistors

in the PCM and measures the voltage.The signal voltage will be high when the engine is cold and

low when the engine is hot.By measuring the voltage, the PCM calculates the engine coolant

temperature. Engine coolant temperature affects most of the systems that the PCM controls.

The Tech 2 displays engine coolant temperature in degrees. After engine start-up, the temperature

should rise steadily to about 85 °C (185 °F).It then stabilizes when the thermostat opens.If the

engine has not been run for several hours (overnight), the engine coolant temperature and intake

air temperature displays should be close to each other.A hard fault in the engine coolant sensor

circuit will set DTC P0177 or DTC P0118. An intermittent fault will set a DTC P1114 or P1115.

Page 160

PCM Pinout Table, 80-Way Red Connector _ Row»S1 — 20″ — View/Index — 2

Page 158

PCM Pinout Table, 80-Way Blue Connector _ Row»F61 — 80» — View/Index — 2

Page 279

110. Right Rear of Transfer Case

113. Under Rear of Vehicle, on Differential

Page 384

2. When installing the steering column cover, be sure to route each wire harness as illustrated so

that the harnesses do not catch on any moving parts. 3. Align the setting marks made when

removing then install steering wheel.

Caution: Never apply force to the steering wheel shaft a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft is designed as an energy absorbing unit.

4. Tighten the steering wheel fixing nut to the specified torque.

Torque: 34 Nm (25 ft. lbs.)

5. Support the inflator module and carefully connect the SRS connector and horn lead.

Note: Pass the lead wire through the tabs on the plastic cover (wire protector) of inflator to prevent

lead wire from being pinched.

6. Tighten bolts to specified torque.

Torque: 9 (78 inch lbs.)

7. Install driver knee bolster (reinforcement). 8. Install instrument panel lower cover then Install the

engine hood opening lever. 9. Connect the SRS connector.

10. Connect the battery «-» terminal cable. 11. Turn the ignition switch to the «ON» position and

observe the warning lamp. The lamp should flash 7 times. If the lamp does not operate correctly,

refer to Restraint Systems.

Page 231

Hood Sensor/Switch (For Alarm): Service and Repair

Engine Hood Switch

Removal

1. Disconnect the battery ground cable. 2. Disconnect the connector.

3. Remove the engine hood switch (1).

Installation

To install, follow the removal steps in the reverse order.

Page 178

2. Press down until the catch engages.

— An audible «click» will be heard.

3. Install the fuse and relay box cover.

Page 56

Blower Motor Relay: Testing and Inspection Heater (X-1) and Compressor (X-2) Relay

Heater (X-1) And Compressor (X-2) Relay

1. Disconnect relays and check for continuity and resistance between relay terminals.

— For handling of these relays, refer to Heater Relay in this section.

Page 349

Abbreviations Chart 5

Page 239

Door Lock Cylinder Switch: Service and Repair

Door Lock Key Switch

Removal

1. Disconnect the battery ground cable.

2. Remove the pull box.

— Remove the one fixing screw.

3. Remove the power window switch (1).

— Pry the power window switch and remove the connector.

Page 281

Wheel Speed Sensor: Description and Operation

Wheel Speed Sensor

It consists of a sensor and a rotor. The sensor is attached to the knuckle on the front wheels and to

the rear axle case on the rear differential. The front sensor rotor is attached to the each brake rotor

by bolts. The rear rotor is press-fit in the differential case. The magnetic flux generated from

electrodes magnetized by a magnet in the sensor varies due to rotation of the rotor, and the

electromagnetic induction generates alternating voltage in the coil. This voltage draws a «sine

curve» with the frequency proportional to rotor speed and it allows detection of wheel speed.

Page 186

Ignition Control Module: Service and Repair

Removal Procedure

1. Disconnect the negative battery cable. 2. Disconnect the ION sensing module connector.

3. Remove the bolts and the ION sensing module from the common chamber.

Installation Procedure

1. Install the ION sensing module on the common chamber with the bolts.

Tighten Tighten the ION sensing module to 4 N-m (35 lb in.).

2. Connect the ION sensing module connectors as shown in the illustration. 3. Connect the

negative battery cable.

Page 81

A/T Shift Indicator Module: Electrical Diagrams

A/T Shift Indicator Image 89

Page 364

Abbreviations Chart 3

Page 348

Abbreviations Chart 4

Page 125

Abbreviations Chart 3

Page 191

Sensing And Diagnostic Module: Description and Operation

The SRS consists of the Sensing and Diagnostic Module (SDM), the driver air bag assembly, the

SRS coil assembly, the passenger air bag assembly, and the «AIR BAG» warning lamp in the

instrument cluster. The SDM, SRS coil assembly (driver side only), driver air bag assembly,

passenger air bag assembly and connector wire make up the deployment loops. The function of

the deployment loops is to supply current through air bag assembly, which will cause deployment

of the air bags in the event of a frontal crash of sufficient force, up to 30 degrees off the centerline

of the vehicle. The air bag assemblies are only supplied enough current to deploy when the SDM

detects vehicle velocity changes severe enough to warrant deployment.

The SDM contains a sensing device which converts vehicle velocity change to an electrical signal.

The electrical signal generated is processed by the SDM and then compared to a value stored in

memory. When the generated signal exceeds the stored value, the SDM will cause current to flow

through the air bag assembly deploying the air bags.

Page 44

Electronic Brake Control Module: Description and Operation

Electronic Hydraulic Control Unit (EHCU)

The EHCU consists of ABS control circuits, fault detector, and a fail-safe. The signal received from

each sensor activates the hydraulic unit accordingly and cancels the ABS to return to normal

braking if a malfunction occurs in the ABS system. The EHCU has a self-diagnosing function which

can indicate faulty circuits during diagnosis. The EHCU is mounted on the engine compartment

rear right side. It consists of a Motor, Plunger Pump, Solenoid Valves.

Solenoid Valves: Reduces or holds the caliper fluid pressure for each front disc brake or both rear

disc brakes according to the signal sent from the EHCU. Reservoir: Temporarily holds the brake

fluid that returns from the front and rear disc brake caliper so that pressure of front disc brake

caliper can be reduced smoothly. Plunger Pump: Feeds the brake fluid held in the reservoir to the

master cylinder. Motor: Drives the pump according to the signal from EHCU. Check Valve: Controls

the brake fluid flow.

Locations

57. Behind Glove Box

Locations

10. Right Rear of Engine Compartment

Locations

18. Top Rear of Engine

Locations

Headlamp Relay: Locations

11. Fuel Relay Box (Cover Removed)

12. Fuse/Relay Box (Cover Removed)

Page 322

Discharge Air Temperature Sensor / Switch: Service and Repair Duct Sensor

Duct Sensor

Duct Sensor

Removal

1. Disconnect the battery ground cable. 2. Remove the evaporator assembly.

— Refer to Evaporator Assembly in this section.

3. Remove the duct sensor assembly.

Installation

To install, follow the removal step in the reverse order.

Page 347

Abbreviations Chart 3

Page 321

9. Remove evaporator core.

10. Remove expansion valve.

— Tear off the insulator carefully.

— Remove the sensor fixing clip.

— Use a back-up wrench when disconnecting all refrigerant pipes.

Installation

To install, follow the removal steps in the reverse order, noting the following points:

1. The sensor is installed on the core with the clip. 2. The sensor must not interfere with the

evaporator core.

3. When installing the new evaporator core, install the duct sensor (2) to the evaporator core (1)

specified position with the clip in the illustration. 4. O-rings cannot be reused. Always replace with

new ones. 5. Be sure to apply new compressor oil to the O-rings when connecting lines. 6. Be sure

to install the sensor and the insulator on the place where they were before. 7. To install a new

evaporator core, add 50 cc (1.7 fl. oz.) of new compressor oil to the new core. 8. Tighten the

refrigerant lines to the specified torque. Refer to Main Data and Specifications for Torque

Specifications in this section. 9. Apply an adhesive to the parting face of the lining when

assembling the evaporator assembly.

Page 138

PCM Pinout Table, 80-Way Red Connector _ Row»S71 — 80″ — View/Index — 2

Page 108

Relay / Fuse Box (instrument Panel) Part 2

Engine Control Module

Engine Control Module: Service and Repair Engine Control Module

Removal Procedure

1. Disconnect the negative battery cable. 2. Block the wheels. 3. Remove the two screws from the

PCM electrical connectors.

4. Disconnect the PCM electrical connectors.

5. After removing the clip which fixes the PCM to the bracket, remove PCM.

Installation Procedure

Page 382

Warning: THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED WITH THE TRIM COVER

AWAY FROM YOUR BODY AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY BECAUSE FREE SPACE IS PROVIDED TO

ALLOW THE AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF ACCIDENTAL

DEPLOYMENT. OTHERWISE, PERSONAL INJURY MAY RESULT.

8. Apply a setting mark (1) across the steering wheel and shaft so parts can be reassembled in

their original position. Move the front wheels to the

straight ahead position, then use steering wheel remover J-29752 to remove the steering wheel.

Caution: Never apply force to the steering wheel shaft a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft is designed as an energy absorbing unit.

9. Remove steering column cover.

Page 362

Abbreviations Chart 1

Page 137

PCM Pinout Table, 80-Way Red Connector _ Row»S61 — 70″ — View/Index — 1

Page 146

Engine Control Module: Description and Operation EEPROM

General Description

The Electronically Erasable Programmable Read Only Memory (EEPROM) is a permanent memory

that is physically soldered within the PCM. The EEPROM contains program and calibration

information that the PCM needs to control powertrain operation.

EEPROM Programming

1. Set-up — Ensure that the following conditions have been met:

— The battery is fully charged.

— The ignition is «ON.»

— The Vehicle Interface Module cable connection at the DLC is secure.

2. Program the PCM using the latest software matching the vehicle. Refer to up-to-date Techline

equipment user»s instructions. 3. If the PCM fails to program, proceed as follows:

— Ensure that all PCM connections are OK.

— Check the Techline equipment for the latest software version.

— Attempt to program the PCM. If the PCM still cannot be programmed properly, replace the PCM.

The replacement PCM must be programmed.

Functional Check

1. Perform the On-Board Diagnostic System Check. 2. Start the engine and run for one minute. 3.

Scan for DTCs using the Tech 2.

Service and Repair

Fuel Gauge Sender: Service and Repair

Removal Procedure

Refer to Fuel Gauge Unit in Engine Fuel section.

Page 276

NOTE:

Pay careful attention not to damage the sensor rotor and hubmating surface. Do not allow debris to

enter inside the hub housing.

4. Apply silicone gasket sealer Isuzu P/N 2-90067-801-0 around the flange surface (see figure 3).

NOTE:

Do not allow excess silicone and/or debris to enter the sensor housing.

5. Position the speed sensor on the hub as shown (see figure 4).

Locations

43. Dash Fuse Box

Page 32

Keyless Entry Module: Service and Repair Anti-Theft & Keyless Entry Controller

Removal

1. Disconnect the battery ground cable.

2. Remove the glove box from the instrument panel assembly (1).

— Refer to Instrument Panel Assembly in Body Structure section.

3. Remove the anti-theft & keyless entry controller (2).

— Disconnect the connector.

— Remove two fixing screws.

Installation

To install, follow the removal steps in the reverse order.

Page 208

Suspension Control Module: Service Precautions

Computer System Service Precautions

The Intelligent Suspension Control interfaces directly with the Control Unit which is a control

computer that is similar in some regards to the Powertrain Control Module. These modules are

designed to withstand normal current draws associated with vehicle operation. However care must

be taken to avoid overloading any of the Control Unit circuits. In testing for opens or shorts, do not

ground or apply voltage to any of the circuits unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be tested with a high impedance multimeter

(J-39200) or special tools. Power should never be removed or applied to any control module with

the ignition in the «ON» position. Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the «OFF» position.

Technician Safety Information

Engine Control Module: Technician Safety Information

NOTE: To prevent possible electrostatic discharge damage to the PCM, do not touch the connector

pins or soldered components on the circuit board.

Page 381

Combination Switch: Service and Repair

Removal

1. Turn the steering wheel so that the vehicle’s wheels are pointing straight ahead. 2. Turn the

ignition switch to «LOCK». 3. Disconnect the battery ground cable, and wait at least 5 minutes. 4.

Disconnect the yellow 2-way SRS connector located under the steering column.

Caution: The wheels of the vehicle must be straight ahead and the steering column in the «LOCK»

position before disconnecting the steering wheel. Failure to do so will cause the coil assembly to

become uncentered which will cause damage to the coil assembly.

5. Remove the engine hood opening lever, then remove instrument panel lower cover. 6. Remove

the driver knee bolster (reinforcement).

7. Loosen the inflator module fixing bolt from behind the steering wheel assembly using a TORX

driver or equivalent until the inflator module can

be released from steering assembly. Disconnect the yellow 2-way SRS connector and horn lead

located behind the inflator module, then remove inflator module.

Page 14

Abbreviations Chart 4

Page 164

PCM Pinout Table, 80-Way Red Connector _ Row»S71 — 80″ — View/Index — 2

Locations

34. Bottom Center Front of Engine

Anti-Theft & Keyless Entry Control Unit Replacement

Keyless Entry Module: Service and Repair Anti-Theft & Keyless Entry Control Unit Replacement

Anti-theft & Keyless Entry Control Unit Replacement

1. Remove and install the control unit.

— Refer to Anti-Theft & Keyless Entry Controller in this section.

2. Register ID code.

— Refer to ID Code Registration in this section.

3. Check that the keyless entry system works normally.

Page 135

PCM Pinout Table, 80-Way Red Connector _ Row»S21 — 40″ — View/Index

Page 343

Illustration Arrows Part 3

Page 346

Abbreviations Chart 2

Page 157

PCM Pinout Table, 80-Way Blue Connector _ Row»F61 — 80″ — View/Index — 1

Diagram Information and Instructions

Key Reminder Switch: Diagram Information and Instructions

Illustration Arrows Part 1

Page 375

Brake Light Switch: Adjustments

Brake Switch

Adjustment

1. Check that the brake pedal (3) is fully returned by pedal return spring. 2. Disconnect the switch

connector. 3. Loosen the lock nut (2). 4. Rotate the brake switch (1) by hand until push rod

disappears from brake switch tip (4). 5. Return the brake switch by a half turn. 6. Tighten the lock

nut.

7. Connect the switch connector.

Page 344

Illustration Arrows Part 4

Page 277

6. Place the hub assembly and speed sensor face down on J-39825 Bearing Remover. Using a

hydraulic press, press until the hub and speed sensor are fully mated, applying 1.5 TONS (see

figure 5).

NOTE:

To avoid speed sensor breakage DO NOT use excessive force when pressing the sensor into

place.

7. To reinstall the front hub assembly to the knuckle refer to the Front Hub and Disc section of the

Service Manual (refer to figure 1).

Disclaimer

Locations

82. Left Front Door (Right Similar)

Page 129

PCM Pinout Table, 80-Way Blue Connector _ Row»F20 — 40″ — View/Index

Locations

8. Right Side of Engine Compartment

Page 161

PCM Pinout Table, 80-Way Red Connector _ Row»S21 — 40″ — View/Index

Page 77

Abbreviations Chart 2

Locations

68. Below Center of I/P (Console Removed)

Page 130

PCM Pinout Table, 80-Way Blue Connector _ Row»F41 — 60″ — View/Index

Page 43

Page 57

Blower Motor Relay: Testing and Inspection Thermostat (X-8) Relay

Thermostat (X-8) Relay

1. Disconnect relays and check for continuity and resistance between relay terminals.

— For handling of these relays, refer to Heater (X-1) And Compressor (X-2) Relay in this section.

Locations

117. Left Side of Driver’s Seat (Right Front Similar)

Page 143

Engine Control Module: Vehicle Damage Warnings

PCM Service Precautions

The PCM is designed to withstand normal current draws associated with vehicle operation.Avoid

overloading any circuit.When testing for opens and shorts, do not ground or apply voltage to any of

the PCM»s circuits unless instructed to do so.These circuits should only be tested using digital

voltmeter J 39200.The PCM should remain connected to the PCM or to a recommended breakout

box.

Electrostatic Discharge Damage

Electronic components used in the PCM are often designed to carry very low voltage.Electronic

components are susceptible to damage caused by electrostatic discharge.Less than 100 volts of

static electricity can cause damage to some electronic components.By comparison, it takes as

much as 4000 volts for a person to feel even the zap of a static discharge.

There are several ways for a person to become statically charged. The most common methods of

charging are by friction and induction.

— An example of charging by friction is a person sliding across a vehicle seat.

— Charge by induction occurs when a person with well insulated shoes stands near a highly

charged object and momentary touches ground. Charges of the same polarity are drained off

leaving the person highly charged with the opposite polarity. Static charges can cause damage,

therefore it is important to use care when handling and testing electronic components.

NOTE: To prevent possible electrostatic discharge damage, follow these guidelines: —

Do not touch the PCM connector pins or soldered components on the PCM circuit board.

— Do not open the replacement part package until the part is ready to be installed.

— Before removing the part from the package, ground the package to a known good ground on the

vehicle.

— If the part has been handled while sliding across the seat, while sitting down from a standing

position, or while walking a distance, touch a known good ground before installing the part.

Reprogramming the PCM

Reprogramming of the PCM is done without removing it from the vehicle . This provides a flexible

and cost-effective method of making changes in software calibrations.

Refer to the latest Techline information on reprogramming or flashing procedures.

Page 140

PCM-2

Page 134

PCM Pinout Table, 80-Way Red Connector _ Row»S1 — 20″ — View/Index — 2

Page 284

Wheel Speed Sensor: Service and Repair Rear Wheel Speed Sensor

Removal

1. Disconnect harness connector (1). 2. Remove sensor fixing bolt (2). 3. Remove speed sensor

(3).

Inspection and Repair

1. Check speed sensor pole piece for presence of foreign materials; remove any dirt, etc. 2. Check

the pole piece for damage, and replace speed sensor if necessary. 3. Check speed sensor cable

for short or open, and replace with a new one if necessary. To check for cable short or open, bend

or stretch the cable

while checking for continuity.

4. Check the sensor ring for damage including tooth chipping, and if damaged, replace the axle

shaft assembly.

Installation

1. Install speed sensor (3). 2. Tighten the sensor fixing bolt (2) to the specified torque.

Torque: 24 Nm (17 ft. lbs.)

3. Connect harness connector (1).

Service and Repair

Cruise Control Switch: Service and Repair

Cruise Control Main Switch

Removal

1. Disconnect the battery ground cable. 2. Remove the meter cluster assembly (1).

— Refer to Instrument Panel Assembly in Body Structure section.

3. Remove the cruise control main switch (2).

— Disconnect the switch connector.

— Push the lock from the back side of the instrument panel cluster assembly.

Installation

To install, follow the removal steps in the reverse order.

Locations

30. Left Side of Engine Compartment

Page 331

Refrigerant Pressure Sensor / Switch: Service and Repair

Pressure Switch

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

— Refer to Refrigerant Recovery in this section.

3. Remove the front bumper assembly.

— Refer to Front Bumper in Body Structure section.

4. Remove the front side turn signal light (LH). 5. Remove the head light (LH). 6. Disconnect

pressure switch connector.

7. Disconnect pressure switch.

— When removing the switch connected part, the connecting part should immediately be plugged or

capped to prevent foreign matter from being mixed into the line.

Installation

To install, follow the removal steps in the reverse order, noting the following point:

1. O-ring cannot be reused. Always replace with a new one. 2. Be sure to apply new compressor oil

to the O-ring when connecting pressure switch.

3. Tighten the pressure switch to the specified torque.

Torque: 13 N.m (113 lb in)

Page 122

Illustration Arrows Part 4

Page 75

Illustration Arrows Part 4

Page 197

Sensing And Diagnostic Module: Service and Repair

WARNING:

— DURING SERVICE PROCEDURES, BE VERY CAREFUL WHEN HANDLING SDM. NEVER

STRIKE OR JAR SDM. UNDER SOME CIRCUMSTANCES, IT COULD CAUSE DEPLOYMENT

AND RESULT IN PERSONAL INJURY OR IMPROPER OPERATION OF THE SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). SDM MOUNTING BRACKET BOLTS MUST BE CAREFULLY

TORQUED TO ASSURE PROPER OPERATION. NEVER POWER UP THE SRS WHEN SDM IS

NOT RIGIDLY ATTACHED TO THE VEHICLE. THE SDM COULD BE ACTIVATED WHEN

POWERED WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY.

— PROPER OPERATION OF THE SENSING AND DIAGNOSTIC MODULE (SDM) REQUIRES

THE SDM TO BE RIGIDLY ATTACHED TO THE VEHICLE STRUCTURE AND THAT THE

ARROW ON THE SENSOR BE POINTING TOWARD THE FRONT OF THE VEHICLE.

SDM is specifically calibrated and is keyed to the SDM location SRS wiring harness. Caution

should be used to ensure proper location of the SDM. The keying of the SDM to its location and

wiring harness connectors should never be modified in the field.

Removal

1. Disable the SRS. Refer to Disabling the SRS in this section. 2. Remove dressing panel around

the radio and disconnect cigar lighter harness. 3. Remove the transfer sift lever knob. 4. Remove

the center console. 5. Remove three connector from PCM. 6. Remove PCM with bracket.(Fixed

four bolts) 7. Remove right side stay between instrument panel and floor. 8. Remove driver and

passenger seat. 9. Turn over carpet to rear side.

10. Remove air conditioning duct for rear seat. (Transform the duct during removing it) 11. Pull

CPA (1) (Connector Position Assurance-red color) out and push connector lock down to disconnect

the SDM harness connector (2).

12. Remove the three SDM fixing bolts (4) and remove SDM (3).

Installation

1. Install the SDM (3) on bracket and fixing bolts (4) and tighten the fixing bolts to the specified

torque.

Torque: 10 N.m ± 3 N.m (87 lb in ± 26 lb in)

Triple Pressure Switch (V 6, A/T)

Refrigerant Pressure Sensor / Switch: Testing and Inspection Triple Pressure Switch (V 6, A/T)

1. Disconnect the connector and check for continuity between pressure switch side connector

terminals (1) and (2).

2. Reconnect the connector to activate the A/C switch, and check to see if there is continuity

between the chassis side connector terminals (3) and (4)

and the fan operates.

Diagram Information and Instructions

General Module: Diagram Information and Instructions

Illustration Arrows Part 1

Page 124

Abbreviations Chart 2

Page 8

Illustration Arrows Part 2

Page 177

Fuel Pump Relay: Service and Repair

Removal Procedure

1. Remove the fuse and relay box cover from under the hood. 2. Consult the diagram on the cover

to determine which is the correct relay.

3. Insert a small screwdriver into the catch slot on the forward side of the fuel pump relay.

— The screwdriver blade will release the catch inside.

4. Pull the relay straight up and out of the fuse and relay box.

Installation Procedure

1. Insert the relay into the correct place in the fuse and relay box with the catch slot facing forward.

Component Locations

Relay Box: Component Locations

Relay / Fuse Box Location

Page 82

A/T Shift Indicator Image 89-1

Page 67

3. Install the fuse and relay box cover.

Service and Repair

Power Mirror Switch: Service and Repair

Power Door Mirror System

Door Mirror Switch

Removal

1. Disconnect the battery ground cable. 2. Remove the instrument panel lower cover (2). 3.

Remove the door mirror switch (1).

Locations

70. Under Center Console

Page 11

Abbreviations Chart 1

Diagrams

Disassembled View

Page 326

3. Left Front of Vehicle Behind Grill

Page 168

Engine Control Module: Service and Repair PCM Connectors and Terminals

Removal Procedure

1. Remove the connector terminal retainer. 2. Push the wire connected to the affected terminal

through the connector face so that the terminal is exposed. 3. Service the terminal as necessary.

Installation Procedure

1. Bend the tab on the connector to allow the terminal to be pulled into position within the

connector. 2. Pull carefully on the wire to install the connector terminal retainer.

Testing and Inspection

Cabin Temperature Sensor / Switch: Testing and Inspection

Individual Inspection

In Car Sensor

1. Disconnect the in car sensor connector (I-17).

2. Measure resistance between the in car sensor side terminal No. I17-3 and No. I17-4.

In Car Sensor

1. Turn on the ignition switch (the engine is started). Start the air conditioner in «Auto». 2. Make

sure that the in car sensor suctions cigarette smokes and such.

In Car Sensor

Page 292

3. Connect the electrical connector. 4. Fill the radiator with coolant. Refer to Draining and Refilling

Cooling System in Engine Cooling section. 5. Connect the negative battery cable.

Duct Sensor, Evaporator Core and/or Expansion Valve

Discharge Air Temperature Sensor / Switch: Service and Repair Duct Sensor, Evaporator Core

and/or Expansion Valve

Disassembled View

Duct Sensor, Evaporator Core and/or Expansion Valve

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

— Refer to Refrigerant Recovery in this section.

3. Remove evaporator assembly.

— Refer to Evaporator Assembly in this section.

4. Remove the duct sensor fixing clip.

Pull the sensor from the evaporator assembly.

5. Remove clip. 6. Remove attaching screw.

Page 162

PCM Pinout Table, 80-Way Red Connector _ Row»S41 — 60″ — View/Index

Page 330

Refrigerant Pressure Sensor / Switch: Testing and Inspection Triple Pressure Switch

Triple Pressure Switch

1. Disconnect the connector and check for continuity between pressure switch side connector

terminals (1) and (2).

2. Reconnect the connector to activate the A/C switch, and check to see if there is continuity

between the chassis side connector terminal (3) and (4)

and the fan operates.

Front Wheel Speed Sensor

Wheel Speed Sensor: Service and Repair Front Wheel Speed Sensor

Removal

1. Remove speed sensor connector. 2. Remove sensor cable fixing bolt (Upper side). 3. Remove

sensor cable fixing bolt (Lower side). 4. Remove the speed sensor cable fixing bolt. 5. Remove

speed sensor.

Inspection and Repair

1. Check the speed sensor pole piece for presence of foreign materials; remove any dirt, etc. 2.

Check the pole piece for damage; replace speed sensor if necessary. 3. Check the speed sensor

cable for short or open circuit, and replace with a new one if necessary. To check for cable short or

open, bend or stretch

the cable while checking for continuity.

4. Check the sensor ring for damage including tooth chipping, and if damaged, replace the sensor

ring assembly.

Installation

1. Install speed sensor and take care not to hit the speed sensor pole piece during installation. 2.

Install speed sensor fixing bolt and tighten the fixing bolt to the specified torque.

Torque: 11 Nm (95 inch lbs.)

3. Install speed sensor cable fixing bolt (Lower side) and tighten the fixing bolt to the specified

torque.

Torque: 24 Nm (17 ft. lbs.)

4. Install speed sensor cable fixing bolt (Upper side) and tighten the fixing bolt to the specified

torque.

Torque: 6 Nm (52 inch lbs.)

NOTE: Confirm that a white line marked on the cable is not twisted when connecting the speed

sensor cable.

5. Install speed sensor connector.

Anti-Theft & Keyless Entry Control Unit Replacement

Keyless Entry Module: Service and Repair Anti-Theft & Keyless Entry Control Unit Replacement

Anti-theft & Keyless Entry Control Unit Replacement

1. Remove and install the control unit.

— Refer to Anti-Theft & Keyless Entry Controller in this section.

2. Register ID code.

— Refer to ID Code Registration in this section.

3. Check that the keyless entry system works normally.

Page 278

Wheel Speed Sensor: Locations

1. Behind Left Front Wheel (Right Wheel Similar)

108. Right Rear of Transfer Case

Page 149

Engine Control Module: Description and Operation

Powertrain Control Module (PCM)

The powertrain control module (PCM) is located in the engine compartment.

The PCM controls the following:

— Fuel metering system.

— Transmission shifting (automatic transmission only).

— Ignition timing.

— On-board diagnostics for powertrain functions.

The PCM constantly observes the information from various sensors. The PCM controls the

systems that affect vehicle performance. The PCM performs the diagnostic function of the system.

It can recognize operational problems, alert the driver through the MIL (Check Engine lamp), and

store diagnostic trouble codes (DTCs). DTCs identify the problem areas to aid the technician in

making repairs.

EEPROM

General Description

The Electronically Erasable Programmable Read Only Memory (EEPROM) is a permanent memory

that is physically soldered within the PCM. The EEPROM contains program and calibration

information that the PCM needs to control powertrain operation.

EEPROM Programming

1. Set-up — Ensure that the following conditions have been met:

— The battery is fully charged.

— The ignition is «ON.»

— The Vehicle Interface Module cable connection at the DLC is secure.

2. Program the PCM using the latest software matching the vehicle. Refer to up-to-date Techline

equipment user»s instructions. 3. If the PCM fails to program, proceed as follows:

— Ensure that all PCM connections are OK.

— Check the Techline equipment for the latest software version.

— Attempt to program the PCM. If the PCM still cannot be programmed properly, replace the PCM.

The replacement PCM must be programmed.

Functional Check

1. Perform the On-Board Diagnostic System Check. 2. Start the engine and run for one minute. 3.

Scan for DTCs using the Tech 2.

PCM Function

The PCM supplies either 5 or 12 volts to power various sensors or switches.The power is supplied

through resistances in the PCM which are so high in value that a test light will not light when

connected to the circuit.In some cases, even an ordinary shop voltmeter will not give an accurate

reading because its resistance is too low. Therefore, a digital voltmeter with at least 10 megohms

input impedance is required to ensure accurate voltage readings. Tool J 39200 meets this

requirement.The PCM controls output circuits such as the injectors, fan relays, etc., by controlling

the ground or the power feed circuit through transistors or through either of the following two

devices:

— Output Driver Module (ODM)

Page 9

Illustration Arrows Part 3

Locations

13. Fuse/Relay Box (Cover Removed)

Page 45

Electronic Brake Control Module: Service and Repair

Removal

1. Remove brake pipes.

^ After disconnecting brake pipe, cap or tape the openings of the brake pipe to prevent the entry of

foreign matter.

2. Remove three bracket fixing bolts.

3. Disconnect red clip from harness connector. 4. Remove harness connector. 5. Remove

Electronic Hydraulic Control Unit (EHCU) ASM. 6. Remove EHCU.

Disassembly

1. Remove fixing bolts from EHCU. 2. Remove coil integrated module from hydraulic unit.

Reassembly

To reassembly, follow the disassembly steps in the reverse order, noting the following points:

Torque: Fixing Bolts: 4.4 Nm (39 inch lbs.)

Installation

To install, follow the removal steps in the reverse order, noting the following points Torque:

Hydraulic unit fixing nuts: 22 Nm (16 ft. lbs.) Ground cable: 14 Nm (10 ft. lbs.) Brake pipe (joint

bolts): 16 Nm (12 ft. lbs.) ^

After installing the hydraulic unit, bleed brakes completely. Refer to Brake Bleeding.

Page 159

PCM Pinout Table, 80-Way Red Connector _ Row»S1 — 20″ — View/Index — 1

Specifications

Refrigerant Pressure Sensor / Switch: Specifications

PRESSURE SWITCH

Type……………………………………………………………………………………………………………………………………

………………………………………….Triple pressure switch

Low pressure control

— ON: 206.0+ / — 30.0 kPa (29.8 + / -4.3 psi)

— OFF: 176.5+ / -19.6 kPa (25.6+ / -2.8 psi)

Medium pressure control

— ON: 1471.0+ / -98.1 kPa (213.3+ / -14.2 psi)

— OFF: 1078.7+ / -117.7 kPa (156.4+ / -17.7 psi)

High pressure control

— ON: 2353.6+ / -196.1 kPa (341.3+ / -28.4 psi)

Page 320

7. Remove upper case.

8. Remove lower case.

— Slit the case parting face with a knife since the lining is separated when removing the evaporator.

— Lift to remove the upper case.

Page 74

Illustration Arrows Part 3

Page 121

Illustration Arrows Part 3

ABS — Front Wheel Speed Sensor Replacement

Wheel Speed Sensor: Technical Service Bulletins ABS — Front Wheel Speed Sensor Replacement

TSB SBO3-09-S002

2WD Front Wheel Speed Sensor Replacement (Service Manual Replacement)

ISSUE DATE: MARCH 2003

Affected Vehicles

^ 2002.7-2003 Axiom (UP), 2WD models.

^ 2002-2003 Rodeo (UE) and Rodeo Sport (UA), 2WD models.

Service Information

Front wheel speed sensor is now available for individual installation.

NOTE:

If diagnosis leads to replacement of the sensor with related DTC, do not replace the complete hub

assembly.

Service Procedure

1. Diagnose speed sensor according to the Brake Control System section in the Service Manual.

2. Remove the front hub assembly from the knuckle. Refer to the Front Hub and Disc section of the

Service Manual (see figure 1).

3. Insert J-37228 Seal Cutter between the hub mating surface and remove the speed sensor from

the hub (see figure 2).

Page 241

11. Remove the door lock assembly.

— Disconnect the locking links and harness connector.

— Remove the 3 fixing TORX screws and bolt.

Installation

To install, follow the removal steps in the reverse order, noting the following points:

1. Apply chassis grease to the lock assembly and striker moving surface. 2. Tighten the door lock

assembly fixing screws to the specified torque.

Torque: 7 N.m (61 lb.in)

3. Check that the door lock operates smoothly.

Page 151

58X Reference PCM Input

The powertrain control module (PCM) uses this signal from the crankshaft position (CKP) sensor to

calculate engine RPM and crankshaft position at all engine speeds.The PCM also uses the pulses

on this circuit to initiate injector pulses.If the PCM receives no pulses on this circuit, DTC P0337 will

set. The engine will not start and run without using the 58X reference signal.

PCM Service Precautions

The PCM is designed to withstand normal current draws associated with vehicle operation.Avoid

overloading any circuit.When testing for opens and shorts, do not ground or apply voltage to any of

the PCM»s circuits unless instructed to do so.These circuits should only be tested using digital

voltmeter J 39200.The PCM should remain connected to the PCM or to a recommended breakout

box.

Reprogramming the PCM

Reprogramming of the PCM is done without removing it from the vehicle . This provides a flexible

and cost-effective method of making changes in software calibrations.

Refer to the latest Techline information on reprogramming or flashing procedures.

Engine Controls — ECM Reprogramming

Recommendations

Engine Control Module: Technical Service Bulletins Engine Controls — ECM Reprogramming

Recommendations

Information IB03-14-S002

Reprogramming of Powertrain Control Modules (PCM)

ISSUE DATE: FEBRUARY 2003

Affected Vehicles All Isuzu Vehicles.

Service Information

American Isuzu Motors Inc. continually strives to provide the most technically advanced vehicles

possible to meet the ever-increasing demands of the SUV market place. One such area of constant

change is the calibrations used within the vehicles Powertrain Control Module (PCM). These

changes are made as a part of on going product improvements and may take place at anytime

including during mid-year production.

WHEN SHOULD A PCM CALIBRATION BE UPDATED?

Emission Related — Anytime Isuzu determines that a vehicle’s calibration may cause emissions

non-conformity, Isuzu will release a campaign bulletin. Vehicle owners and dealership personnel

will be notified of the campaign. If re-programming is required, all vehicles listed as affected in the

campaign bulletin should have the PCM programmed with the updated calibration.

Symptom Related — Some vehicles operated under certain conditions may exhibit symptoms that

lead to a customer concern. Information relating to symptoms that may be affected by an updated

calibration can be found in the comment section of the calibration selection tables. Vehicles should

be diagnosed using the symptom description diagnostic tables first, repaired and verified. If (after

repairs are completed and verified) the customer’s symptom closely match a symptom listed in the

comment section of a calibration table for the vehicle, the PCM should be programmed with the

updated calibration. All diagnostics, symptoms, Diagnostic Trouble Codes, and broadcast codes

must be documented on the dealership repair order.

(Reference Section 14 Service Policy and Procedure manual)

Diagnostic Trouble Code (DTC) Related — Some vehicles operated under certain conditions may

illuminate the Malfunction Indicator Light (MIL). Information relating to DTC’s that may be affected

by an updated calibration can be found in the comment section of the calibration selection tables.

Vehicles should be diagnosed using the DTC diagnostic tables first, repaired and verified. If (after

repairs are completed and verified) the customers DTC match a DTC listed in the comment section

of a calibration table for the vehicle, the PCM should be programmed with the updated calibration.

All diagnostics, symptoms, Diagnostic Trouble Codes and broadcast codes must be documented

on the dealership repair order. (Reference Section 14 Service Policy and Procedure manual)

Technical Service Bulletin (TSB) — Anytime when performing the operations listed in a TSB and you

are directed to program with an updated calibration.

WHEN SHOULD A PCM CALIBRATION NOT BE UPDATED?

No Problem Found (NPF) — Unless specifically directed by an Isuzu Service Bulletin, a PCM should

not be programmed with an updated calibration before repairs have been diagnosed, repaired and

verified.

Vehicle is found not to have the latest calibration available — Do not reprogram a PCM with an

updated calibration under warranty solely because a later version is available. Do not assume all

vehicle operators will benefit from changes made in later calibration releases. Beginning with the

2000 model year lsuzu PCM’s have an adaptive learning function. During the «learning» cycle,

engine performance and transmission shift characteristics will be altered that could lead to

customer complaints. Programming a PCM with an updated calibration is warrantable only as a

result of a failure as listed above. Isuzu does not warrant that vehicles will be provided product

improvements made after manufacture.

Disclaimer

Locations

12. Fuse/Relay Box (Cover Removed)

Page 107

Relay Box: Connector Locations

Relay / Fuse Box (Instrument Panel) Part 1

Page 127

Abbreviations Chart 5

Page 139

Engine Control Module: Electrical Diagrams

PCM-1

Service and Repair

Control Module: Service and Repair

TOD Control Unit

Removal

1. Disconnect the battery ground cable. 2. Disconnect the harness connector from the TOD control

unit. 3. Remove the bracket retaining nuts (3 pieces) and the bracket with TOD control unit. 4.

Remove the TOD control unit from the bracket.

Installation

1. Install the TOD control unit to the bracket. 2. Install the bracket with TOD control unit to the

chassis. 3. Connect the harness connector to the TOD control unit. 4. Connect the battery ground

cable.

Locations

43. Dash Fuse Box

Page 19

Alarm And Relay Controls Image 70-2

Page 136

PCM Pinout Table, 80-Way Red Connector _ Row»S41 — 60″ — View/Index

Service and Repair

Control Module HVAC: Service and Repair

Removal Procedure

1. Remove the fuse and relay box cover from under the hood. 2. Consult the diagram on the cover

to determine which is the correct relay.

3. Insert a small screwdriver into the catch slot on the forward side of the fuel pump relay.

— The screwdriver blade will release the catch inside.

4. Pull the relay straight up and out of the fuse and relay box.

Installation Procedure

1. Insert the relay into the correct place in the fuse and relay box with the catch slot facing forward.

2. Press down until the catch engages.

— An audible «click» will be heard.

Diagram Information and Instructions

Engine Control Module: Diagram Information and Instructions

Illustration Arrows Part 1

Locations

64. Top Center of I/P

Page 123

Abbreviations Chart 1

Page 10

Illustration Arrows Part 4

Page 377

3. Install lock nut (3).

Locations

74. Front of Roof (Headliner Removed)

Page 15

Abbreviations Chart 5

Service and Repair

Air Door Position Sensor / Switch: Service and Repair

Tailgate Lock Switch

Removal

1. Disconnect the battery ground cable.

2. Remove the tailgate outside handle.

— Refer to Tailgate Lock Outside Handle in Security and Locks section.

3. Remove the tail gate lock switch (1).

— Disconnect the switch connector (2) and lock actuator connectors (3).

Installation

To install, follow the removal steps in the reverse order.

Page 335

Solar Sensor: Testing and Inspection

Sun Sensor

1. Disconnect the sun sensor connector (I-15).

2. Measure the current value on the sun sensor when placed it approximately 15 cm away from 60

W incandescent lamp.

Page 342

Illustration Arrows Part 2

Max Hi Relay

Blower Motor Relay: Testing and Inspection Max Hi Relay

MAX HI Relay

1. Remove the MAX — HI relay connector (C-35) from the blower assembly.

2. Check the conduction between the MAX — HI relay side terminals.

Page 13

Abbreviations Chart 3

Page 109

Relay / Fuse Box (Engine Room) Part 1

Page 369

Key Reminder Switch: Description and Operation

Circuit Operation

Key-In Ignition Warning

The alarm and relay control unit sounds when the key remind switch is closed, with the starter

switch in the OFF position, and the key left in.

Seat Belt Warning

With the starter switch in ON or START voltage is applied to the seat belt reminder lamp. If the

driver does not fasten his or her seat belt, the switch remains closed, which grounds the circuit,

illuminating the seat belt reminder lamp.

Lamps-on Warning

With the lamp switch in HEAD or PARK, the alarm and relay control unit sounds when the starter

switch is in the OFF position.

Initial Inspection and Diagnostic Overview

Sensing And Diagnostic Module: Initial Inspection and Diagnostic Overview

CAUTION: Certain SRS components must be replaced after a frontal crash involving air bag

deployment.

In all types of accidents regardless of «Air Bag» deployment, visually inspect all of the following

components and replace as required:

— Driver air bag assembly

— Passenger air bag assembly

— Steering wheel

— SRS coil assembly

— Steering column

— Knee bolster and instrument panel mounting attachments

— Driver seat and belt

— Passenger seat and belt

— SDM

SDM always should be checked according to «SDM Replacement Guidelines».

CAUTION: Refer to Sensing and Diagnostic Module (SDM) below for important information on

SDM replacement in both deployment and non-deployment crashes.

Inspect SRS coil assembly wiring and steering wheel for any signs of scorching, meting, or damage

due to excessive heat. If coil assembly wire or steering wheel is damaged, replace them. The

steering column and wheel must be dimensionally checked to determine if they are damaged.

Never use SRS parts from another vehicle. This does not include remanufactured parts purchased

from an authorized Retailer; they may be used for SRS repairs.

Do not attempt to repair the SDM, the SRS harness, the SRS coil assembly, the air bag assembly,

the steering wheel, or the steering column. Service of these items is replacement only. Verify

replacement part numbers.

CAUTION: Proper operation of the SDM and Supplemental Restraint System (SRS) requires that

any repairs to the vehicle structure return it to its original production configuration.

Page 73

Illustration Arrows Part 2

Locations

93. Bottom of Tailgate Door (Panel Removed)

Page 79

Abbreviations Chart 4

Page 291

Engine Temperature Sensor: Service and Repair

Removal Procedure

NOTE: Care must be taken when handling the engine coolant temperature (ECT) sensor.Damage

to the ECT sensor will affect proper operation of the fuel injection system.

1. Disconnect the negative battery cable. 2. Drain the radiator coolant.Refer to Draining and

Refilling Cooling System in Engine Cooling section.

3. Disconnect the electrical connector.

4. Remove the ECT sensor from the coolant crossover.

Installation Procedure

1. Apply sealer or the equivalent to the threads of the ECT sensor.

2. Install the ECT sensor in the coolant crossover.

Tighten Tighten the ECT sensor to 30 N-m (22 lb ft.).

Powertrain Control Module (PCM)

Engine Control Module: Description and Operation Powertrain Control Module (PCM)

The powertrain control module (PCM) is located in the engine compartment.

The PCM controls the following:

— Fuel metering system.

— Transmission shifting (automatic transmission only).

— Ignition timing.

— On-board diagnostics for powertrain functions.

The PCM constantly observes the information from various sensors. The PCM controls the

systems that affect vehicle performance. The PCM performs the diagnostic function of the system.

It can recognize operational problems, alert the driver through the MIL (Check Engine lamp), and

store diagnostic trouble codes (DTCs). DTCs identify the problem areas to aid the technician in

making repairs.

Page 78

Abbreviations Chart 3

Page 195

Step 1 — 4

Chart Test Description

Number(s) below refer to step number(s) on the diagnostic chart

1. This test Confirm s a current malfunction. If no current malfunction is occurring (history DTC set)

the «Diagnostic Aids» for the appropriate

Page 131

PCM Pinout Table, 80-Way Blue Connector _ Row»F61 — 80″ — View/Index — 1

Page 361

Illustration Arrows Part 4

Page 194

Sensing And Diagnostic Module: Component Tests and General Diagnostics

Circuit Description

When the SDM recognizes ignition 1″ voltage, applied to terminals 12″, is greater than 9 volts, the

«AIR BAG» warning lamp is flashed 7 times to verify operation. At this time the SDM performs

«Turn-ON» tests followed by «Continuous Monitoring» tests. When a malfunction is detected, the

SDM sets a current diagnostic trouble code and illuminates the «AIR BAG» warning lamp. The SDM

will clear current diagnostic trouble codes and move them to a history file when the malfunction is

no longer detected and/or the ignition switch is cycled, except for DTCs 51, 53 and 71. DTC 71 can

only be cleared using a scan tool «Clear Codes» command in case that the malfunction on DTC 71

has been solved and no DTCs 51 and 53 were remained. DTCs 51, 53 and 71 can not be cleared

after a «Clear Codes» command is issued.

Page 376

Brake Light Switch: Service and Repair

Removal

1. Disconnect connector (1). 2. Remove lock nut (3). 3. Remove switch (2).

Installation

1. Adjust the stop light switch to the specified clearance (between switch housing and brake pedal)

by rotating the switch housing.

Clearance: 0 — 0.2 mm (0 — 0.08 inch)

Note: Do not attempt to force the push rod into position during the stop light switch installation and

adjustment procedure.

2. Connect connector (1).

Locations

9. Right Rear of Engine Compartment

Page 106

8. Right Side of Engine Compartment

14. Fuse/Relay Box (Cover Removed)

Electronic Hydraulic Control Unit and Associated Parts

Page 314

Cabin Temperature Sensor / Switch: Service and Repair

In Car Sensor

Removal

1. Disconnect the battery ground cable. 2. Remove the meter cluster.

— Refer to Instrument Panel Assembly in Body Structure section.

3. Remove the in car sensor.

Installation

To install, follow the removal step in the reverse order.

Page 246

Hood Sensor/Switch (For Alarm): Service and Repair

Engine Hood Switch

Removal

1. Disconnect the battery ground cable. 2. Disconnect the connector.

3. Remove the engine hood switch (1).

Installation

To install, follow the removal steps in the reverse order.

Locations

3. Left Front of Vehicle Behind Grill

Page 148

Engine Control Module: Description and Operation PCM Voltage Description

The PCM supplies a buffered voltage to various switches and sensors. It can do this because

resistance in the PCM is so high in value that a test light may not illuminate when connected to the

circuit.An ordinary shop voltmeter may not give an accurate reading because the voltmeter input

impedance is too low. Use a 10-megohm input impedance digital voltmeter (such as J 39200) to

assure accurate voltage readings.

The input/output devices in the PCM include analog-to-digital converters, signal buffers, counters,

and special drivers. The PCM controls most components with electronic switches which complete a

ground circuit when turned «ON.»These switches are arranged in groups of 4 and 7, called either a

surface-mounted quad driver module (QDM), which can independently control up to 4 output

terminals, or QDMs which can independently control up to 7 outputs. Not all outputs are always

used.

Locations

43. Dash Fuse Box

Locations

13. Fuse/Relay Box (Cover Removed)

Page 309

Ambient Temperature Sensor / Switch HVAC: Service and Repair

Ambient Sensor

Ambient Sensor

Removal

1. Disconnect the battery ground cable. 2. Remove the horn (LH). 3. Disconnect the ambient

sensor connector. 4. Remove the ambient sensor.

Installation

To install, follow the removal step in the reverse order.

- 5929

Техническое обслуживание и смазка, отопления, вентиляции и кондиционирования воздуха, передняя подвеска, задняя подвеска, колеса и шины система, интеллектуальная система подвески, трансмиссия Control System, System Drive Shaft, раздаточная коробка (TOD), Brake Control System, Anti -Lock Brake System, Power-Assisted тормозная система, стояночный тормоз системы (4’4 модели), система стояночного тормоза (4’2 модель)

Двигатель Механическая, охлаждения двигателя, моторного топлива, Электрическая система двигателя, системы зажигания, запуска и зарядки системы, управляемость и выбросов, выхлопных газов двигателя, смазки двигателя, числа оборотов двигателя системы управления, индукционные

передача

Автоматическая коробка передач, системы управления передачей Кузов и аксессуары