Руководство по эксплуатации, техническому обслуживанию и ремонту грузовых автомобилей Mercedes-Benz Actros 1996-2007 годов выпуска.

- Автор: —

- Издательство: Диез

- Год издания: —

- Страниц: 704

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту грузовых автомобилей Mercedes-Benz Actros третьего поколения 2008-2011 годов выпуска.

- Автор: —

- Издательство: Диез

- Год издания: —

- Страниц: 496

- Формат: —

- Размер: —

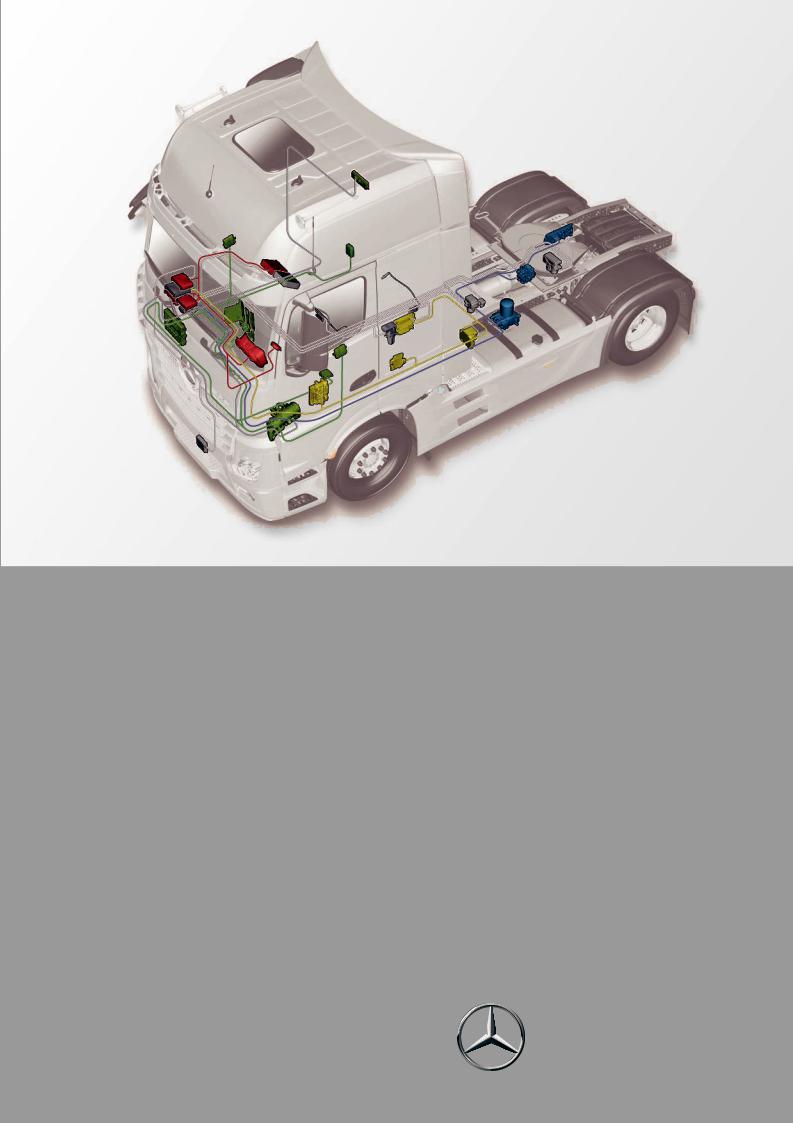

Сборник руководств по диагностике, техническому обслуживанию и ремонту автомобиля Mercedes-Benz Actros первого поколения.

- Автор: —

- Издательство: Mercedes-Benz

- Год издания: —

- Страниц: —

- Формат: ISO

- Размер: 653,9 Mb

Руководство по ремонту автомобиля Mercedes-Benz Actros с 2003 года выпуска.

- Автор: —

- Издательство: Терция

- Год издания: —

- Страниц: 218

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Mercedes-Benz Actros 1996-2003 годов выпуска в кузовах W950/W952/W953/W954.

- Автор: —

- Издательство: Арго-Авто

- Год издания: —

- Страниц: 800

- Формат: —

- Размер: —

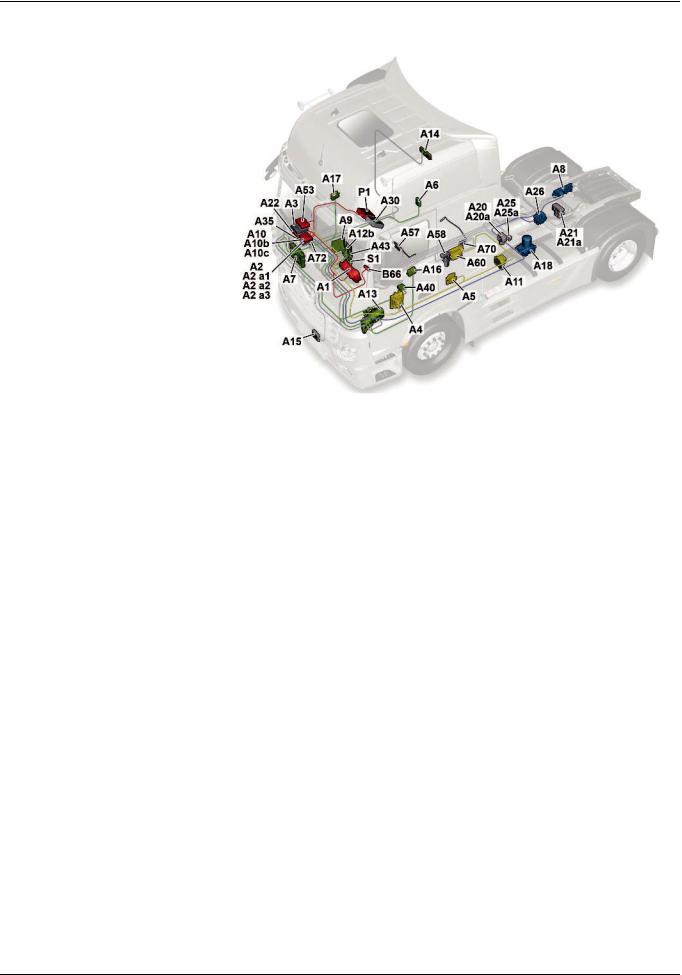

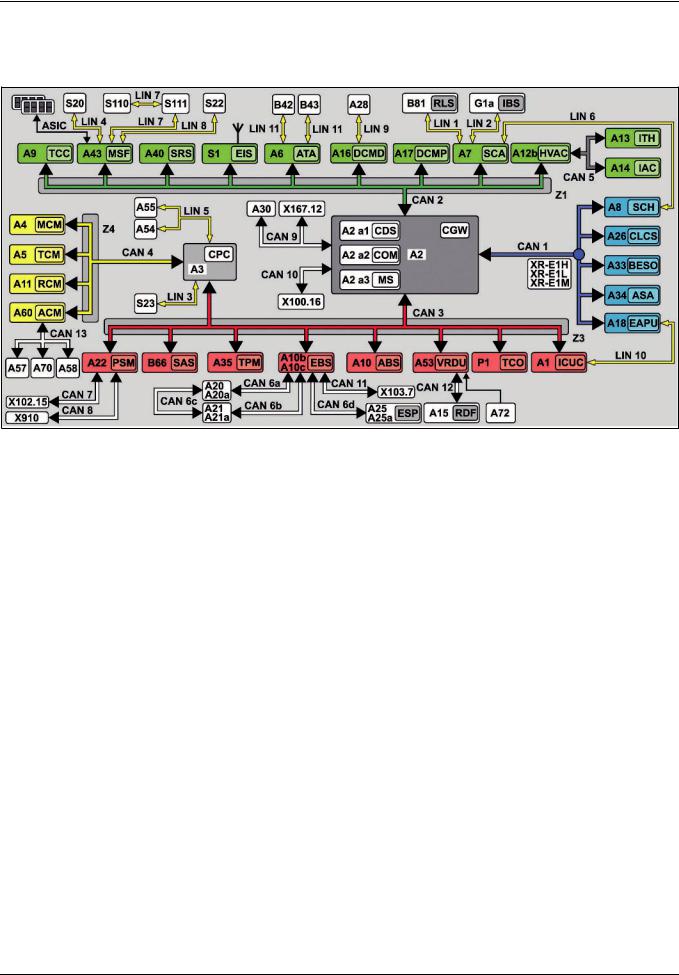

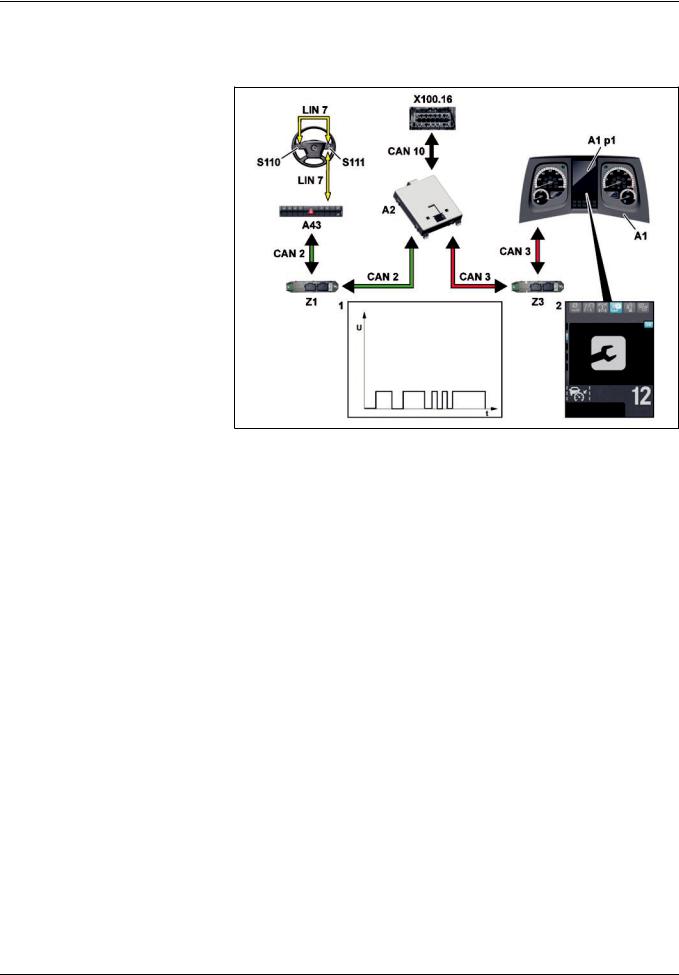

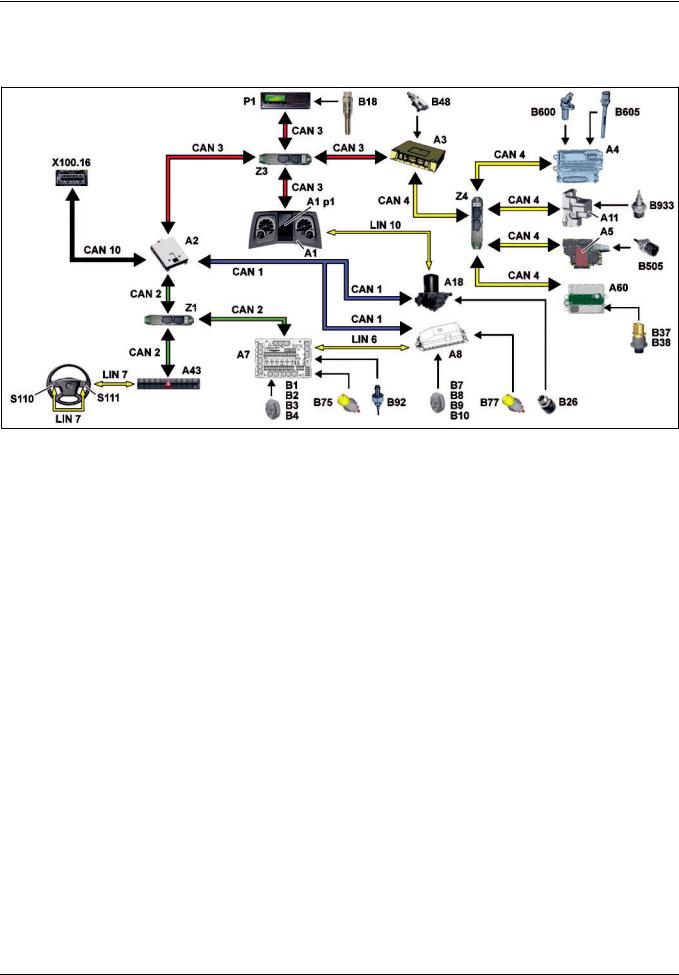

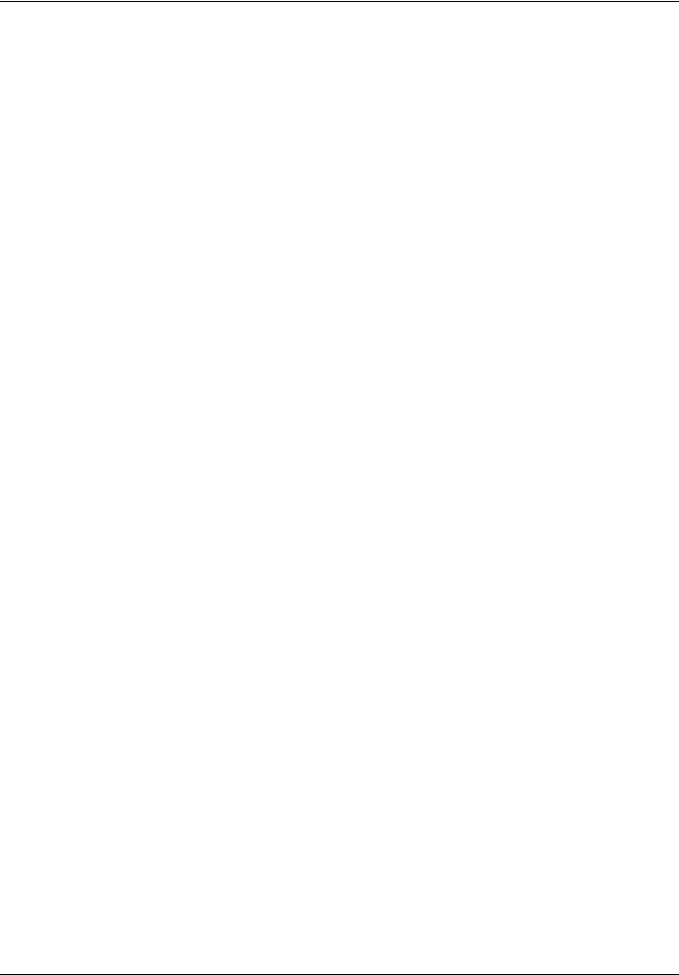

Схемы электрооборудования грузового автомобиля Mercedes-Benz Actros.

- Автор: —

- Издательство: Терция

- Год издания: —

- Страниц: 184

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Mercedes-Benz Actros 2003-2011 годов выпуска в кузовах W930/W932/W933/W934.

- Автор: —

- Издательство: Арго-Авто

- Год издания: —

- Страниц: 808

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту грузовых автомобилей Mercedes-Benz Actros с 2012 года выпуска.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 504

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту грузовых автомобилей Mercedes-Benz Actros с 2012 года выпуска.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 464

- Формат: —

- Размер: —

- Manuals

- Brands

- Mercedes-Benz Manuals

- Trucks

- Actros 2017

- Operating instructions manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Actros, Arocs, Antos

Mercedes-Benz

Related Manuals for Mercedes-Benz Actros 2017

Summary of Contents for Mercedes-Benz Actros 2017

-

Page 1

Actros, Arocs, Antos Operating Instructions Mercedes-Benz… -

Page 2

Symbols WARNING Warning notes make you aware of dangers which could pose a threat to your health or life, or to the health and life of others. Environmental note Environmental notes provide you with infor- mation on environmentally aware actions or disposal. -

Page 3

You can also use the smartphone App, Mercedes-Benz Guide: Please note, the Mercedes-Benz Guide App may not yet be available in your country. The technical documentation team at Daimler AG wishes you safe and pleasant motoring. -

Page 4

Operating safety and vehicle registra- Overview of climate control system tion …………29 functions ……….116 Genuine Mercedes-Benz parts ….33 Switching the cooling with air dehu- Data stored in the vehicle …… 33 midification function on/off ….118 Setting climate control to automatic … 119 Setting the temperature …… -

Page 5

Contents FleetBoard Support ……202 Wind deflector ……..331 Winter operation ……..336 DispoPilot.guide …….. 204 Working mode ……..341 Important safety notes ……204 Note on the Brief Instructions ….. 204 Useful information ……. 341 Declaration of conformity ….204 Power take-offs …….. -

Page 6

Index Refuelling ……..318 1, 2, 3 … Service product ……425 9 gear transmission Storage ………. 425 General notes …….. 252 ® AdBlue tank ……..318 9-speed transmission Additional axle Change shift range ……252 Leading axle ……..300 16-speed transmission Leading/trailing axle (steerable) .. -

Page 7

Index Audio system Setting (heating/air condition- ing) ……….121 ® Bluetooth settings ……. 224 Alarm General notes …….. 214 Operating (on-board computer) ..140 Important safety notes ….214 Ambient lighting Operating system (overview) ..216 Switching on/off ……90 Selecting an audio source …. -

Page 8

Index Berths in the M cab see Berths in an M cab BAS (Brake Assist) ……246 Bi-xenon headlamps Battery Notes on replacing bulbs ….91 Charging ……..206 Bleeding the fuel system Inserting ……..206 Bleeding with the hand pump Replacing …….. -

Page 9

Index Bulbs Hill holder ……..249 Independent trailer brake ….247 Spare bulbs ……..370 Buttons Releasing the spring-loaded park- ing brake ……..400 see On-board computer Brakes, axle 1 Maintenance due immediately Yellow display message ….167 Braking Electrohydraulic cab tilting sys- ABS ………. -

Page 10

Index Turn signal lamp (headlamp) …. 96 Cleaning the camera (Lane Keep- Turn signals (rear lamp cluster) ..97 ing Assist and ATTENTION Changing a wheel ASSIST) ………. 352 Fitting a wheel ……. 385 Cleaning the exterior ….. 349 Important safety notes ….380 Cleaning the interior …… -

Page 11

Index Clutch under heavy strain Fuel ……….313 Continuous brake Grey display message ….153 Yellow display message ….164 Activating/deactivating ….250 Clutch/transmission circuit Important safety notes ….250 Control unit Checking the supply pressure ..241 Coarse filter, heating and climate Level control …….. -

Page 12

Index Diesel particle filter full Deactivating ……..278 Driving ……….. 277 Red display message ….. 176 Driving tips ……..277 Yellow display message ….158 Diesel particle filter: fluid level Functions and conditions for acti- increased vation ……….277 Important safety notes ….276 Yellow display message …. -

Page 13

Index Driving mode Important safety notes ….278 Increasing/reducing speed …. 281 Differential locks ……268 Overview ……..279 Idling speed ……..274 Particular driving situations … 287 Notes on axle and wheel loads ..266 Pulling away and stopping the Stability Control Assist …. -

Page 14

Index Drive functions ……256 Checking the oil level (on-board Electrical fuses computer) ……..148 see Fuses Consumption ……… 313 Electromagnetic compatibility Filler neck ……..356 Declaration of conformity ….30 Miscibility ……..420 Emergency braking finished Multi-grade engine oils ….419 Grey display message …. -

Page 15

Foglamp Generator is not charging battery Replacing bulbs (variant 1) ….96 Yellow display message ….173 Replacing bulbs (variant 2) ….97 Genuine Mercedes-Benz parts … 33 Foglamps Green light Switching on/off ……87 see Nightlight Folding ladder ……..318 Grey display message Folding table …….. -

Page 16

Index Hydrodynamic clutch Electrical system and key ….155 Engine and cooling ……157 General notes …….. 264 Semitrailer ……..156 Hydromove ……..265 Service products and mainte- Manoeuvring mode ……265 nance ……….157 Pulling away ……..264 Hydromove Transmission and clutch …. -

Page 17

Index Language Automatic control system (on- board computer) ……149 Setting (on-board computer) ..150 Dimming ………. 89 Laptop holder ……..114 Nightlight (button) ……90 Leading axle ……..300 Nightlight (on-board computer) ..149 Leading/trailing axle (steerable) ..301 Notes on replacing bulbs …. -

Page 18

Stopping ……..259 headlamp cleaning system Transmission mode selection ..256 washer fluid ……..356 Mercedes star Maintenance system (WS) Switching the illumination on/off ..91 Due date (on-board computer) ..355 Mercedes-Benz Service Centre Introduction ……..354 see Qualified specialist workshop… -

Page 19

Index Minimum tyre tread depth ….402 Switching on ……..225 Navigation lights Mirrors Replacing bulbs ……. 94 see Exterior mirrors Nightlight Mobile device Switching on/off (button) ….90 Truck-App ……..112 Mobile devices Switching on/off (on-board com- puter) ……….149 Authorising (registering) …. -

Page 20

Index Adjusting the headlamp range ..149 Operation and maintenance Alarm ……….140 menu ……….143 Areas in the display ……. 134 Overview of warning and indicator Audio and communications menu .. 140 lamps ……….187 Blocking diesel particle filter Setting delayed switch-off, exte- regeneration …….. -

Page 21

Index Declaration of conformity ….30 Preselecting working speed … 342 Notes on operating the vehicle ..29 Transmission-driven ……. 341 Qualified specialist workshops ..31 Transmission-independent ….. 341 Power windows Registering your vehicle ….31 Operating system see Side windows Power-steering assistance over- see On-board computer Operating temperature (coolant… -

Page 22

Index Radio Rear lamp cluster Adjusting the volume ….. 142 Changing a bulb ……. 97 Rear lamps Anti-theft protection …… 215 Changing the audio source or Replacing bulbs ……. 97 Rechargeable battery title/station ……..142 Function overview ……223 Replacing (multifunction key) ..65 Red display message General notes …….. -

Page 23

Index Interior lighting …….. 98 Roller sunblind ……..71 Licence plate lamp ……97 Roof position marker lamps Main-beam headlamps ….. 95 Switching on/off ……91 Navigation lights ……94 Rotating beacon ……..91 Perimeter/side marker lamps ..97 Route Rear foglamps …….. -

Page 24

Index Cleaning the cover ……349 Service brake ……..244 Correct driver’s seat position … 73 Service products Function seat ……..76 ® AdBlue ……… 425 Important safety notes ….73 Coolant ………. 420 Luxury suspension seat ….74 Diesel fuel ……..422 Selecting a menu item Engine oil …….. -

Page 25

Index Smoke detector Starting Function test ……… 106 see Starting (engine) General information ……. 106 Starting (engine) …….. 240 Starting-off aid Replacing the battery ….. 107 Temporarily deactivating ….106 Operation ……..300 Snow chains Starting-off aid active Checking the tyre clearance ..337 Yellow display message …. -

Page 26

Index Driver’s workstation ……43 Wheel nuts ……..428 Tilting system Multifunction lever ……48 Multifunction steering wheel …. 47 Electrohydraulic cab tilting sys- Switch units above the wind- tem ……….374 screen ……….45 Mechanical-hydraulic cab tilting Swivel angle ……..321 system ……….. -

Page 27

Index Transmission/clutch reserve pres- Information on tractor/trailer syn- sure too low chronisation ……..321 Swivel angle ……..321 Yellow display message ….162 Trailer tow hitch Trip computer see Separate operating instructions Calling up/resetting (on-board Trailer/semitrailer computer) ……..137 Notes about trailer/semitrailer Trip data (on-board computer) .. -

Page 28

Index Tyre pressure monitor faulty Loading/unloading when the igni- Yellow display message ….175 tion is switched off (level control) .. 298 Tyre pressure monitor in spare Locking/unlocking the doors … 60 wheel faulty Operating safety ……29 Grey display message ….156 Parking up …….. -

Page 29

Index Wheel brake overloaded Yellow display message ….166 Yellow display message Wheel chock ……..372 ® BlueTec 5 exhaust gas aftertreat- Wheel loads ……..266 ment ……….158 Wheel nuts ® BlueTec 6 exhaust gas aftertreat- For light-alloy disc wheels ….385 ment ………. -

Page 30

Do not attempt to modify the wiring as well as your vehicle’s original purchase agreement. electronic components or their software. Contact a Mercedes-Benz Service Centre if you Always have work on electrical and electronic have any questions about equipment or opera- components carried out at a qualified special- tion. -

Page 31

Introduction WARNING Operating conditions Gases and liquids from substances that con- avoid short trips as these increase fuel con- stitute a health hazard or react aggressively sumption. can escape, even from securely closed con- make sure that the tyre pressures are tainers. -

Page 32

Introduction Jack such as leaves, grass or twigs can gather between the underbody and the underbody pan- Transcript and translation of the original decla- elling. If these materials come in contact with ration of conformity: hot parts of the exhaust system for an extended EC Declaration of conformity 2006/42/EC period, they can catch fire. -

Page 33

Vehicle registration Any tampering with the engine management system in order to increase the engine power Mercedes-Benz may ask its Service Centres to output will lead to the loss of warranty entitle- carry out technical inspections on certain vehi- ments. -

Page 34

Other emissions- Mercedes-Benz in the event of deviations relevant malfunctions, e.g. dosage malfunctions from approved body/equipment mounting or sensor errors, are also detected and logged. -

Page 35

Mercedes-Benz. Electronic control units contain data memories This could lead to malfunctions in safety-rele- that can temporarily or permanently store tech- vant systems, e.g. -

Page 36

Introduction the vehicle’s technical states, is used to help in There is no additional interaction between the finding faults and improving quality and is sent smartphone and the vehicle, particularly active to the manufacturer where necessary. In addi- access to vehicle data. The type of additional tion, the manufacturer is subject to product lia- data processing is determined by the provider of bility. -

Page 37

Introduction For this reason, please ask the service provider for information about the type, extent and pur- pose of the collection and use of personal data when services are provided by third parties. -

Page 38

Cockpit Cockpit Overview, left-hand-drive vehicle Function Page Function Page Switch units Folding table Air vents 24 V socket Light switch Parking brake Instrument cluster Main fuse carrier covering Multifunction steering wheel Trays Multifunction lever Ashtray Climate control panel Cup holder Radio and/or navigation Ignition lock on the dash- device… -

Page 39

Cockpit Overview, right-hand-drive vehicle Function Page Function Page Switch units Instrument cluster Air vents Light switch Folding table Multifunction lever Stowage spaces Horn (air horn) Climbing aids Ignition lock on the dash- board (example) Lane Keeping/ATTENTION ASSIST camera and rain/ Adjusts the multifunction light sensor steering wheel… -

Page 40

Overhead control panel Overhead control panel Overview, left-hand-drive vehicle Function Page Function Page Two-way radio, see the sepa- Stowage compartments rate operating instructions Smoke detector Digital tachograph, see the separate operating instruc- Stowage spaces tions Switch units ® FleetBoard DIN slot for:… -

Page 41

Overhead control panel Overview, right-hand-drive vehicle Function Page Function Page Digital tachograph, see the Smoke detector separate operating instruc- tions Stowage compartments ® FleetBoard DIN slot for: Radio, see the separate oper- Switch units ating instructions Stowage spaces Two-way radio, see the sepa- rate operating instructions… -

Page 42

Instrument cluster Instrument cluster Displays Example: instrument cluster Function Page Function Page Speedometer Total distance and trip dis- tance On-board computer Clock and outside tempera- Rev counter ture display ® AdBlue level (Vehicles with Fuel level ® BlueTec exhaust gas after treatment) Reservoir pressure of brake circuits (vehicles without… -

Page 43

Instrument cluster Indicator lamps Example: instrument cluster Function Page Function Page Warning and indicator À ASR (acceleration skid con- lamps in the speedometer trol system) ; Engine diagnostics ! ABS (Anti-lock Braking Sys- tem) º Cab tilt lock J Brake malfunction ¸… -

Page 44

Instrument cluster Function Page Function Page U Side lamps X Hydrodynamic clutch puter can be found under «On-board com- An overview of the warning and indicator puter and displays» ( page 187). lamps in the status area of the on-board com-… -

Page 45

Switch units Switch units Cockpit Driver’s workstation Function Page Function Page Switch panel n Coolbox Ó FleetBoard with driver card: þ Battery isolator switch Service Call q Anti-lock braking system ã Active Brake Assist â Rotation chains (see the sep- m Lane Keeping Assist arate Operating Instructions) Ø… -

Page 46

Switch units Function Page Function Page i Differential locks D Loading tailgate (see the sep- arate Operating Instructions) â Leading/trailing axle i Working-area lamp (switches å Starting-off aid off automatically after pulling away) Õ Steerable additional axle ¥ Level control: raises the * Reverse warning device chassis frame À… -

Page 47

Switch units Above the windscreen Driver’s door Function Page Function Page Switch panels Switch panel ¤ Opens the left-hand roller | Exterior mirror, left sunblind ~ Exterior mirror, right ¥ Closes the left-hand roller Í Adjusts the exterior mirrors sunblind z Exterior mirror heating ¦… -

Page 48

Switch units Co-driver’s door Berth Function Page Switch panel p Co-driver’s reading lamp c Interior lamps Function Page W Opens/closes co-driver’s side window Reading lamp: bed/berth Ë Locks the doors Switch panel: bed/berth Ì Unlocks the doors ÷ Auxiliary heating Æ… -

Page 49

Multifunction steering wheel Multifunction steering wheel Right-hand button group on the multifunction steering wheel Left group of buttons on the multifunction steering Function Page wheel Operating the driving sys- Function Page tems: Operating the on-board computer: é Selects cruise control Selecting the distance con- u To select the next main trol assistant… -

Page 50

Combination switch and multifunction lever Combination switch and multifunction lever Function Page Function Page Combination switch Automatic gearshift – trans- mission mode selection Main-beam headlamps off (when dipped-beam head- Automatic drive program lamps are switched on) with the economy, power, fleet, offroad, heavy, Main-beam headlamps on municip… -

Page 51

Mercedes-Benz recommends that you use a Mercedes-Benz Service Centre. The components of the restraint system work in conjunction with each other. They can only offer protection if all vehicle occupants always:… -

Page 52

There is an increased Always secure the child in a child restraint system suitable for this Mercedes-Benz vehi- risk of injury, possibly even fatal. cle. The child restraint system must be appro-… -

Page 53

Mercedes-Benz recommends that you use seat Also ensure that no objects are placed belts that have been specifically approved for between a person and the seat. e.g. a cush- the relevant vehicle type by Mercedes-Benz. -

Page 54

Occupant safety The 7 seat belt warning lamp goes out and the warning tone ceases as soon as the driver has fastened the seat belt. Airbag Introduction The driver’s airbag installation location is iden- tified by the label AIRBAG. An airbag supplements a correctly fastened seat belt. -

Page 55

Mercedes-Benz recommends that you have the no accessories are attached to the vehicle vehicle towed to a qualified specialist workshop within the deployment area of an airbag, e.g. -

Page 56

Particular attention must be paid to always secure the child in a child restraint children. system suitable for Mercedes-Benz vehicles. The child restraint system must be appropri- Observe the safety notes on the seat belt ate to the age, weight and size of the child. -

Page 57

Children in the vehicle Child restraint system Immediately replace child restraint systems that have been damaged or subjected to a WARNING load in an accident. Have the child restraint If the child restraint system is incorrectly fit- securing systems checked in a qualified spe- ted on the seat position suitable for this pur- cialist workshop before fitting a child restraint pose, it cannot perform its intended protec-… -

Page 58

Pets in the vehicle You can obtain child restraint systems and infor- mation about the correct child restraint system from any Mercedes-Benz Service Centre. Pets in the vehicle WARNING If you leave animals unsupervised or unse- cured in the vehicle, they may push a button or a switch, for example. -

Page 59

If a vehicle key is lost, obtaining a replace- Useful information ment is a time-consuming process. This can only be done through a Mercedes-Benz Ser- These Operating Instructions describe all the vice Centre. models and standard and optional equipment of… -

Page 60

Locking system Multifunction key You can use the % and & buttons to oper- ate the central locking and the convenience opening and closing functions ( page 62). Operating the multifunction key The remote control works regardless of the direction in which it is pointed. You can lock/ unlock the vehicle from a distance of up to approximately 30 m. -

Page 61

Locking system The display fades out if you do not press any ß Vehicle check buttons on the multifunction key before the set standby time has elapsed. The multifunc- The display shows Ä. The lamp check tion key then deactivates itself if no buttons assists you in making your departure checks are pressed before the set switch-off time has and helps you identify defective bulbs. -

Page 62

Locking system â Operation ä Multifunction key settings The display shows i. The working area The display shows Ç. The brightness of the lamp can be switched on/off. key display can be adjusted. The display shows õ. If the ignition lock is The display shows È. -

Page 63

Locking system External door lock and hold both remote control buttons simul- taneously for approximately 30 seconds. If you have selected the function that only Unlocking and locking using the key unlocks the driver’s door, you can unlock the co-driver’s door by pressing the % button again. -

Page 64

Locking system Convenience closing: insert the integrated Enhanced central locking system key into driver’s door in lock position 2, then turn it to position 3 and hold it there. WARNING When the convenience closing feature is oper- Vehicles without ATA: press and hold the ating, parts of the body could become trapped &… -

Page 65

Locking system ATA monitors: Close the exterior flaps. Detach/remove any loose objects in the cab, on the tractor vehicle: e.g. mascots or coat hangers. the doors the exterior flaps Priming and deactivating ATA the power supply the cab tilt lock Priming ATA with interior motion sensor the vehicle interior (can be deactivated) WARNING… -

Page 66

Locking system Triggering and deactivating the panic alarm Press & on the key with remote control or the multifunction key. WARNING All turn signals flash three times and the indi- cator lamp in the , button flashes. The Limbs could get trapped if they are in the vehicle is locked. -

Page 67

Locking system Replacing the battery Battery and rechargeable battery of the key Important safety notes WARNING Batteries contain toxic and corrosive substan- ces. If batteries are swallowed, it can result in severe health problems. There is a risk of fatal injury. -

Page 68

Remove battery tray :. matically via the ignition lock. A new recharge- Lift battery = at the back and remove it from able battery can be ordered at a Mercedes-Benz battery tray :. Service Centre. Insert new battery = first at the front and Remove integrated key ;… -

Page 69

Side windows WARNING If you close a side window again immediately after it has been blocked or reset, the side window closes with increased or maximum force. The reversing function is then not active. Parts of the body could be trapped in the closing area in the process. -

Page 70

Roof Convenience closing (vehicles with the enhanced central locking system): pull button : or ; past the point of resistance. The corresponding side window closes com- pletely. If the side window is obstructed while closing, the automatic re-opening function halts its movement. If the side window is obstructed and you pull and hold corresponding button : or ;, the window closes without the automatic re-… -

Page 71

Roof Closing the sliding sunroof manually Reset the sliding sunroof after a malfunction or voltage supply interruption ( page 70). Vehicles with ClassicSpace/Compact- Sun screen/insect screen Space cab Vehicles with ClassicSpace cab Example, sliding sunroof: roller blinds The pop-up roof and the sliding sunroof are equipped with an insect screen :. -

Page 72

Roof Pass Allen key = through the opening and If necessary, press the blinds against the roof insert it into the actuator. frame and fit Allen key A through opening ? on the actuator motor. Turn Allen key = clockwise until the sliding sunroof is completely closed. -

Page 73

Roller sunblind Vehicles with BigSpace/StreamSpace/ Roof hatch GigaSpace cab You can open the roof hatch at one end (at the Vehicles with BigSpace/StreamSpace/GigaSpace front or rear) or at both ends (at the front and rear). Remove flat-blade screwdriver (blade width Push the roof hatch up or pull it down by han- 4 mm) from the vehicle tool kit. -

Page 74

Roller sunblind To retract: briefly push the ¤ or ¦ button upwards. The roller sunblinds are retracted to the extreme position. Push the ¤ or ¦ button upwards until the corresponding roller sunblind has reached the desired position. If an error has occurred and you press the button, the roller sunblind carries out a refer- ence run. -

Page 75

Seats Useful information Adjust the seat properly before beginning your journey. Always ensure that the backrest These Operating Instructions describe all the is in an almost vertical position and that the models and standard and optional equipment of shoulder section of your seatbelt is routed your vehicle that were available at the time of across the centre of your shoulder. -

Page 76

Seats Also observe the safety notes on the airbag sys- To prevent damage to the seats and the seat tem ( page 52) and on children in the vehicle heating, observe the following notes: page 54). Do not pour any fluid on the seats. If fluid is If your vehicle is equipped with a suspension poured on the seats, dry it as quickly as seat, always use the EASY-ENTRY/EXIT feature… -

Page 77

Seats Release lever ?. To set the upper portion of the backrest: pull lever K on the rear of the backrest upward and hold it. Tilt the upper portion of the seat backrest to the desired position. Release lever K. To adjust the seat height: pull lever A up or push it down one level. -

Page 78

Seats To use the EASY-ENTRY/EXIT feature: Press button M. press button D. The side contour increases. The seat is lowered completely. Press button O. Press the D button again. The side contour decreases. The seat returns to the previously set height. To set to the rest position: pull lever E Function seat upwards and hold it. -

Page 79

Beds in an L cab Beds in an L cab Only use the bed when the vehicle is station- ary. Overview Make sure that the bed does not hit the The following beds may be fitted in the L cab: seats when you fold it up or down. -

Page 80

Beds in an L cab under the berth and re-clip it at the other end Lower bed of the bed. The air bubble in the spirit level must always be between the lines. Lower bed Release release button ;. Folding the bed up/down Retaining straps : engage automatically and the bed is held in position at that angle. -

Page 81

Beds in an L cab Setting up the safety net backrest can hit the seat and damage both components. WARNING When resetting the seat position, make sure A vehicle occupant cannot be restrained if the that the adjustable backrest of the lower bed vehicle occupant is on the bed while the vehi- is lowered completely. -

Page 82

Beds in an L cab Lower berth WARNING If the seat cushion is not locked in the seat position, it could move. The seat belt cannot perform its intended protective function. There is an increased risk of serious or even fatal injuries. -

Page 83

Beds in an L cab Upper berth Clip belt tongues B into seat belt buckles A on the right and left. Folding the seat backrest up to the fully Folding the seat backrest down to the reclined position upright position Lift up backrest ;… -

Page 84

Beds in an L cab Only use the bed when the vehicle is station- ary. Make sure that the bed does not hit the seats when you fold it up or down. Swing or fold the backrests of the driver’s and co-driv- er’s seats forward or adjust the seats further forward. -

Page 85

Berths in an M cab Standard berth, lower/padded stow- age space WARNING A vehicle occupant on the berth while the vehicle is in motion cannot be restrained. There is a risk of injury, possibly even fatal. Only use the berth when the vehicle is sta- tionary. -

Page 86

Adjusting the multifunction steering wheel Turn hook : 90° and hook it into wall Lower standard berth, split bracket ;. WARNING Push front berth section ? against rear berth section = until locking catch A engages. A vehicle occupant on the berth while the vehicle is in motion cannot be restrained. -

Page 87

Adjusting the exterior mirrors To adjust: step on and hold down yellow but- Adjusting the exterior mirrors ton :. The steering column is unlocked. Adjust the multifunction steering wheel height and angle. Remove your foot from button :. The steering column is locked. Adjusting the exterior mirrors Important safety notes WARNING… -

Page 88

Lighting system swing the exterior mirror into the previously Make sure that the vehicle is safeguarded at set manoeuvring position. the rear in accordance with national legal To swing the exterior mirrors into the requirements, e.g. with a warning triangle. driving position: press the Ï… -

Page 89

Lighting system where vehicles drive on the opposite side of When it is dark or foggy, turn the light switch the road to the country where the vehicle is from c to L in good time. The headlamps registered, there is a danger of oncoming traf- may otherwise be switched off temporarily. -

Page 90

Lighting system Push the combination switch in the direction Cornering lights of arrow ; and engage. Vehicles with foglamps and LED daytime run- The K indicator lamp in the instrument ning lamps: cluster lights up. When the dipped-beam headlamps are switched To use the headlamp flasher: briefly pull the on, the cornering lights improve the illumination combination switch in the direction of… -

Page 91

Lighting system Interior lighting Interior lighting switch Switch panel, bed/berth with reading lamp (exam- ple: lower berth) To switch on/off or to dim the driver’s read- ing lamp Switch panel above the windscreen (variant 1) To switch on/off or to dim the interior light To switch on/off or to dim the ambient light (blue) To switch the automatic control of the inte-… -

Page 92

Lighting system Automatic control of the interior light- Switching the bed/berth reading lamp on/off Depending on the equipment, switch the auto- matic control system of the interior lighting on/ off: Lighting using the menu window in the ä menu settings ( page 149) using button ? as described in the following To switch on/off using the button: press… -

Page 93

Lighting system Observe the legal requirements for the country Illuminated Mercedes star you are currently in when operating the vehicle with the rotating beacon. If the required field of vision is obscured by trailers, special bodies or other attachments, make the vehicle safe by using additional lights. -

Page 94

You must therefore ensure that all bulbs are functioning at all times. Main-beam head- H1 24 V Mercedes-Benz recommends that if a dipped- lamps beam headlamp or main-beam headlamp bulb Daytime driving lights H 21 W 24 V fails, the corresponding bulb in the other head- lamp should be replaced at the same time. -

Page 95

Mercedes-Benz recommends that you have headlamp bulbs replaced at a qualified spe- cialist workshop. Unscrew screws with grey washers =. Do not turn headlamp adjustment screws ?. -

Page 96

Lighting system Do not turn headlamp adjustment screws A. Do not rest on the headlamp when it has The headlamp must otherwise be readjusted. been swung out. Swing the headlamp out in the direction of the Swinging out the headlamps: variant 2 arrow. -

Page 97

Lighting system Main-beam headlamps Daytime driving lights Headlamp, variant 1 Headlamp, variant 1 Headlamp, variant 2 Headlamp, variant 2 Observe the notes on replacing bulbs Observe the notes on replacing bulbs page 91). page 91). Swing out the headlamps – variant 1 Swing out the headlamps –… -

Page 98

Lighting system Turn signal lamps Observe the notes on replacing bulbs page 91). Pull lamp : back d and unclip at the front by turning e. Turn the bulb holder anti-clockwise, applying light pressure, and remove it. Turn the bulb anti-clockwise, applying light pressure, and remove it. -

Page 99

Lighting system Unscrew the bulb from the reflector anti- Roof position marker lamps clockwise. Insert the new bulb and turn it clockwise into the reflector. Foglamp: variant 2 Roof position marker lamps Remove screws :. Remove lamp lens ;. Turn the bulb anti-clockwise, applying light pressure, and remove it. -

Page 100

Lighting system Replacing bulbs Turn the bulb anti-clockwise, applying light pressure, and remove it. Insert the new bulb and turn clockwise, apply- ing light pressure. Interior lighting Interior lighting/reading lamp Six-chamber lamp cluster, rear left (example: plat- form truck) Observe the notes on replacing bulbs page 91). -

Page 101

Lighting system Additional bulbs Side marker lamps Turn bulb ; with cable connector = upwards and remove it. Press the retainers on cable connector = together and hold in this position. Side marker lamps (example: platform truck) Disconnect cable connector =. Observe the notes on replacing bulbs Replace bulb ;. -

Page 102

Halogen headlamps must be masked in accord- ance with the following Mercedes-Benz specifi- cations as close to the border as possible before crossing into one of these countries. Use a com- mercially available opaque adhesive tape. -

Page 103

Good visibility Good visibility Windscreen wipers Vehicles with rain/light sensor: In dry weather conditions, switch the wind- screen wipers off. Otherwise, dirt or optical effects may cause undesired windscreen wiper sweeps. This could then damage the windscreen wiper blades or scratch the wind- screen. -

Page 104

Voltage supply sensitive than in the Ä position, causing the Windscreen heating windscreen wipers to wipe more frequently. If the rain and light sensor fails, the wiper auto- matically switches to the wiping interval corre- sponding to the position of the switch. Windscreen washer system The windscreen heating is operational when the engine is running and deactivates automatically… -

Page 105

Voltage supply event window in the on-board computer. Move may therefore be restricted or unavailable, the ignition lock to position 0 and remove the e.g. power steering, lighting system and ABS. key from the ignition lock. On vehicles with a The compressed-air supply fails. -

Page 106

Voltage supply Sockets Overview Example: 24 V socket Example: power sockets on the dashboard Example: power socket by the bed/berth Cigarette lighter 5 A (max. 120 W) or 24 V socket 15 A (max. 360 W) 24 V socket 15 A (max. 360 W), circuit 1 Example: power socket in the stowage compart- 24 V socket 15 A (max. -

Page 107

600 W (25 A). To use The voltage transformer is supplied perma- 24 V power socket B Mercedes-Benz recom- nently on vehicles without the J button. mends that you have adapter plug C fitted at a qualified specialist workshop. -

Page 108

Practical tips Cigarette lighter Smoke detector General notes WARNING You can burn yourself if you touch the hot heating element or the socket of the cigarette lighter. In addition, flammable materials can ignite if: the hot cigarette lighter falls a child holds the hot cigarette lighter to objects, for example There is a risk of fire and injury. -

Page 109

Practical tips Press and hold button :. WARNING If the smoke detector is working correctly, the If the maximum permissible load of the stow- alarm sounds. The smoke detector is deacti- age compartment is exceeded, the cover can- vated for approximately 20 minutes after the not restrain the objects. -

Page 110

Practical tips Drawer/coolbox under the berth To open: pull handle : and swing the lid upwards. The stowage compartment lighting comes on Drawer automatically. To close: swing the lid downwards and engage it in the lock. The stowage compartment lighting switches off automatically. -

Page 111

Practical tips Installation position of the waste container To switch on: press the upper section of the n switch. Place the waste container in position d or e The indicator lamp in the switch comes on. only. Otherwise, the waste container is not secure and could fall over during the journey. -

Page 112

Practical tips Always comply with the maximum permissible load of the folding table. Do not place more than 15 kg on the folding table. Stowage compartment exterior flap Release lever for the stowage compartment exterior flap Release lever for the tool kit compartment exterior flap Tool kit compartment exterior flap Folding out the folding table… -

Page 113

Practical tips Folding table on the co-driver’s side Folding in the folding table Fold folding table half ? forward. Fold upper cover : upwards and hold it in place. Swing folded folding table = forward as far as it will go into the stowage compartment. Fold upper cover : down. -

Page 114

Communications Truck-App Always hold the compressed-air pistol away from your body. Never aim the compressed- The Truck-App can be purchased in the Google air pistol towards other people. Play Store and in the Apple App Store and allows you to access the vehicle’s network (Wi-Fi). You Do not clean the air filter with the can operate various vehicle functions and call compressed-air pistol. -

Page 115

H button. Operating the audio system (radio) General notes Telephone If you have fitted Mercedes-Benz audio equip- Important safety notes ment, you can operate your audio equipment: WARNING using the buttons on the multifunction steer-… -

Page 116

To charge the Bluetooth Front mobile phone in the vehicle, you need a suitable charger bracket. These are available from retail- ers of Mercedes-Benz accessories. You can operate the mobile phone using the 6 and ~ buttons on the multifunction steering wheel ( page 141). -

Page 117

Communications Using upper clip A, hook the laptop holder onto a grab handle on the upper part of the doors. Using upper clip A and lower clip C, hook the laptop into the sidewall stowage compart- ment of the lower bed or lower berth. -

Page 118

Overview of climate control system functions Useful information Overview of climate control system functions These Operating Instructions describe all the Heating models and standard and optional equipment of your vehicle that were available at the time of going to print. Country-specific differences are possible. -

Page 119

Overview of climate control system functions Air-conditioning system Heating/air-conditioning system with auxiliary heating K Sets the airflow ( page 121) ¿/Á Switches the cooling or cooling K Sets the airflow ( page 121) with air dehumidification function on/off Display page 118), Á switches residual ù… -

Page 120

Switching the cooling with air dehumidification function on/off Only use demisting mode until the misted can also control an auxiliary heating system windscreen is clear again. and/or an auxiliary air-conditioning system. Only use air-recirculation mode briefly, e.g. if Recommendations for optimal climate control: there are unpleasant odours or in dusty con- Switch on automatic mode. -

Page 121

Setting climate control to automatic Dual-stage function Condensation may appear on the underside of the vehicle in cooling mode. To activate: press the Á button . The indicator lamp in the button lights up green and the display appears briefly. The Air-conditioning system «cooling»… -

Page 122

Adjusting the air vents To deactivate: press both of the à but- centre air vent in the driver’s workstation all the way to the top. tons . Set the airflow ( page 121) and the air dis- Centre air vents tribution ( page 121). -

Page 123

Demisting the windscreen and windows Side air vents Heating/air-conditioning system with auxiliary heating Set air-distribution control for heating/air conditioning ? to the corresponding symbol page 116). Automatic climate control Set air-distribution control B to the corre- sponding symbol ( page 116). Press one of the Ã… -

Page 124

Switching the auxiliary ventilation on/off cially at low outside temperatures. Only switch Heating/air-conditioning system air-recirculation mode on for a short time. Only use the following settings until the wind- Switch the flow of fresh air off temporarily and screen and windows are clear again. switch on air-recirculation mode if there are unpleasant odours or in dusty conditions. -

Page 125

Electrical auxiliary air conditioning in the cab before and while using the auxiliary Note that the battery may discharge if the air conditioning. auxiliary ventilation is left running. If you close the curtains and move the backrests forwards, less heat will enter the cab and the Electrical auxiliary air conditioning auxiliary air conditioning will be more effective. -

Page 126

Electrical auxiliary air conditioning Press the ù button . Immediate cooling mode Display shows the selected climate control systems, the Æ auxiliary air conditioning, the y auxiliary heating and the ü engine preheating. Press the s or r button to select the Æ… -

Page 127

Auxiliary heating using fatty acid methyl ester (FAME) fuel Auxiliary heating using conventional diesel fuel with the addi- Important safety notes tion of more than 10 % fatty acid methyl ester (FAME) fuel DANGER The auxiliary heating system operates inde- If the exhaust pipe is blocked or sufficient pendently of the engine and complements the ventilation is not possible, toxic exhaust… -

Page 128

Auxiliary heating Immediate heating mode Setting the switch-on time DANGER If you have preselected a switch-on time, the auxiliary heating system switches on auto- matically. Toxic exhaust fumes may accumulate if there is insufficient ventilation, carbon monoxide in particular. This is the case in enclosed spaces, for example. -

Page 129

Auxiliary heating the operating time does not overlap with the The engine preheating and auxiliary heating sys- operating time of the auxiliary air condition- tems switch off automatically after approx- ing. imately 2 hours. The auxiliary heating runs on for approximately 2 minutes after shutdown. -

Page 130

Instrument cluster stop immediately, paying attention to the road Useful information and traffic conditions. These Operating Instructions describe all the models and standard and optional equipment of Rev counter your vehicle that were available at the time of going to print. Country-specific differences are If you exceed the maximum permissible possible. -

Page 131

Instrument cluster In engine braking mode, use yellow engine ® ® BlueTec 4 vehicles and BlueTec 5 vehicles: speed range ;. The highest engine braking if you do not observe the yellow event window effect will be achieved just before red over- ®… -

Page 132

Instrument cluster Menu menu window within the ä settings menu Clock and outside temperature page 149). Odometer Instrument cluster (example: display in speedom- eter) You should pay special attention to road condi- tions when temperatures are around freezing Instrument cluster (example: display in rev coun- point. -

Page 133

Instrument cluster ® ® BlueTec 4 vehicles and BlueTec 5 vehicles Problem Possible causes/consequences and M Solutions The ; indicator lamp If there are no malfunctions, the indicator lamp lights up briefly during lights up, then goes off the instrument cluster’s display check and then goes out after the again after starting the engine starts. -

Page 134

Instrument cluster Problem Possible causes/consequences and M Solutions The ; indicator lamp An emissions-related malfunction has been detected. lights up. Follow the instructions in the event window. The on-board computer ® Have the BlueTec exhaust gas aftertreatment checked immedi- shows an event window ately at a qualified specialist workshop. -

Page 135

On-board computer ® BlueTec exhaust gas aftertreatment ditions. You could then lose control of the status indicator vehicle. There is a risk of an accident. Only operate these devices if road traffic con- ® Only on BlueTec 6 vehicles, the status of the ditions permit. -

Page 136

On-board computer Whilst you are driving, the on-board computer To save a favourite menu window: call up provides information about: the desired menu window and press the Ú button for approximately 2 seconds. fuel consumption A tone sounds and the menu window is saved. trip time To display the favourite menu window: operating conditions… -

Page 137

On-board computer For the following driving systems, status area = page 137) Trip data ß displays the following corresponding informa- tion: Since reset Displays/resets trip data — all since Reset — all Cruise control: the é symbol and the set 85 km/h speed, e.g. -

Page 138

On-board computer Audio and com- page 140) Monitoring info page 148) munications á ã Reserve pres‐ Displays the reservoir Audio Controls the volume sure pressure in brake circuits Displays the audio and ^ source Changes the audio Coolant Displays the coolant tem- source, title, station or perature frequency… -

Page 139

On-board computer To reset the trip meter: press 9. page 149) Settings ä The input window displays the message Reset trip meter? No/Yes. Service prod‐ Displays/sets service ucts product values Use the r button to select the menu bar and press the u or 9 button to con- Systems Starts or blocks regen- firm. -

Page 140

On-board computer To display performance and level data: Driving mode menu press the 9 button. Consumption menu window shows Speed menu window the average total fuel consumption Use the u or t button to scroll to à the average fuel consumption while driving driving mode. -

Page 141

On-board computer If you often reduce the vehicle speed by If you exceed the air filter maintenance rolling, you receive a positive evaluation. due date, you receive a negative evalua- tion. Stop The on-board computer evaluates the braking phases that lead to the vehicle Press the r or s button to select the category. -

Page 142

The input window shows: Alarm clock menu window for reverse gear for neutral If your vehicle is equipped with Mercedes-Benz for the slow gear, 2nd gear audio equipment, you can set the radio as an for the fast gear, 6th gear alarm in alarm mode. -

Page 143

The input window shows: ® Bluetooth can be obtained: Alarm clock 1/Alarm the alarm clock at your Mercedes-Benz Service Centre clock 2 on the Internet at http://www.mercedes- Audio/Buzzer/Off the alarm mode benz.com/connectivity the hour of the alarm time, e.g. -

Page 144

Audio menu window Audio source, title/station/frequency, MP3 browser Audio menu window is available on vehicles with Mercedes-Benz audio equipment. Switch on the audio equipment ( page 216). Use the u or t button to scroll to á audio and communications. -

Page 145

On-board computer menu. To do this, the Truck-App must be instal- To remove all authorised devices, use the led on the mobile device. All devices r or s button to select and confirm with the 9 button. Further information on the «Remote Online» The input window shows the confirmation function and on the Truck-App can be found Are you sure you want to… -

Page 146

On-board computer Tyres Setting the axle load indicator menu window is available on vehicles with the tyre pressure monitor system. You can adjust the axle load indicator if there is The tyre pressure monitor is a convenience sys- a notable difference between the axle load indi- tem that: cator and the weighbridge results. -

Page 147

On-board computer Trailer tored and displayed in the menu the tyre pressures and temperatures for the tyres on this axle window ( page 147). depending on the equipment If radio transmitting equipment (e.g. cordless the specified pressure for the tyres on headphones, two-way radios) is operated inside the vehicle or in the vicinity of the vehicle, this this axle (at 20 †) -

Page 148

On-board computer vehicle heights for the country you are currently Set the driving level before pulling away. It is necessary to raise/lower the chassis to pick up/set down demountable bodies or semitrail- ers. If you continue a journey after having changed the chassis height, it is necessary to lower/raise the chassis to driving level. -

Page 149

Use the u or t button to scroll to â If the maintenance work is carried out at a operation and maintenance. Mercedes-Benz Service Centre, the fact that the Using the r or s button, scroll to the work has been carried out professionally will be Trailer menu window. -

Page 150

On-board computer Rear axle If you call up the oil level too early or while Not available the engine is running, Transmission appears in the menu window. Brakes, axle 1/2/3/4/5 Use the u or t button to scroll to ã Air filter monitoring info. -

Page 151

You can obtain further information from any set the delayed switch-off of the exterior light- Mercedes-Benz Service Centre. ing (dipped-beam headlamps and foglamp) Use the u or t button to scroll to ã for the surround lighting monitoring info. -

Page 152

On-board computer Change the setting with the u or t Information on installing more languages can be button. obtained from any Mercedes-Benz Service s, the If you set the delayed switch-off to Centre. surround lighting is switched off. Use the u or t button to scroll to ä… -

Page 153

312) Set the oil grade of the engine oil used according Starting manual regeneration ( page 312) to the Sheet Numbers of the Mercedes-Benz You will find information about the drive func- Specifications for Service Products under Engine Oil grade. -

Page 154

On-board computer event window Observe the instructions in the event window. On-board computer event window Immediately stop the vehicle while paying attention to the traffic conditions and contact Notes on events a qualified specialist workshop. If the quali- Messages include operating information, error fied specialist workshop determines it is pos- messages or warnings that the on-board com- sible to continue driving, adapt your driving… -

Page 155

On-board computer event window ® BlueTec exhaust gas aftertreatment Display messages Possible causes/consequences and M Solutions The «HC burn-off» feature reduces deposits of hydrocarbons in the  catalytic converter. This is done by increasing the engine speed. The Engine speed process cannot be cancelled once the message has appeared. -

Page 156

On-board computer event window Driving systems Display messages Possible causes/consequences and M Solutions ABS may be switched off. There may be a fault in Active Brake Assist È or a fault with the vehicle’s brake system. Active Brake Assist WARNING cannot be activated If Active Brake Assist cannot be activated, you will not receive any collision warnings. -

Page 157

On-board computer event window Electrical system and key Display messages Possible causes/consequences and M Solutions The engine is switched off and the battery charge level is low. The following electrical consumers are automatically deactivated: Consumer shutoff audio equipment active 24 V power sockets 12 V socket cigarette lighter seat heating… -

Page 158

On-board computer event window Tyres Display messages Possible causes/consequences and M Solutions ÛCheck and correct tyre pressure Additional text In addition to the event window, the h indicator lamp lights up in Tyre pressure in grey in the status area of the on-board computer. The tyre pressure of spare wheel too low the spare wheel is too low. -

Page 159

On-board computer event window Service products and maintenance Display messages Possible causes/consequences and M Solutions The washer fluid level in the washer fluid reservoir for the windscreen ¥ washer/headlamp cleaning system has fallen to approximately 1 litre. Refill the washer fluid reservoir ( page 357). -

Page 160

On-board computer event window Yellow event window Notes Important safety notes If you ignore warning and indicator lamps and the event window, you will not be able to recognise failures and malfunctions in components or systems. Driving/braking characteristics may be affec- ted and the operating and road safety of your vehicle may be limited. -

Page 161

On-board computer event window ® BlueTec Display messages Possible causes/consequences and M Solutions Please top up AdBlue. Supplementary text Û: Ø ® The AdBlue level has dropped to approximately 10%. AdBlue reserve ® Top up the AdBlue tank immediately ( page 318). -

Page 162

On-board computer event window Display messages Possible causes/consequences and M Solutions Please top up with AdBlue Risk of Supplementary text Û: · limit speed Engine power reduced Additionally, the on-board computer displays the · indicator lamp ® in the status area. The AdBlue level has dropped to approximately 2.5%. -

Page 163

On-board computer event window Diesel particle filter Display messages Possible causes/consequences and M Solutions Please start regeneration Please Supplementary text Û:  observe Operating Instructions Diesel part. fil‐ The  indicator lamp also lights up yellow in the instrument cluster. ter: fluid level The diesel particle filter is in need of regeneration. -

Page 164

On-board computer event window Compressed-air system, engine and cooling system Display messages Possible causes/consequences and M Solutions The compressed-air dryer is malfunctioning. Have the compressed-air dryer checked at a qualified specialist Condensation in workshop. compressed-air res‐ ervoir The reservoir pressure in the transmission/clutch is too low. WARNING Transmission/ clutch reserve pres‐… -

Page 165

On-board computer event window Display messages Possible causes/consequences and M Solutions The coolant temperature is too high. Engine power output is auto- matically reduced. Engine protection: Reduce the speed. engine power reduced Shift to a lower gear. Stop the vehicle, paying attention to road and traffic conditions. Switch off the engine. -

Page 166

On-board computer event window Transmission and clutch Display messages Possible causes/consequences and M Solutions Visit workshop. Supplementary text Û: Ú WARNING Transmission faulty The transmission gearshift system is malfunctioning. The journey can be continued, but with restrictions. Have the transmission checked at a qualified specialist workshop. Visit workshop. -

Page 167

On-board computer event window Display messages Possible causes/consequences and M Solutions Visit workshop Supplementary text Û: Ø WARNING Clutch faulty The clutch is malfunctioning. The journey can be continued, but with restrictions. Have the clutch checked at a qualified specialist workshop. The permissible operating temperature of the clutch has been Ô… -

Page 168

On-board computer event window Trailers/semitrailers Display messages Possible causes/consequences and M Solutions Adapt your driving style Supplementary text Û: The temperature of one of the drum brakes/disc brakes on the tractor Wheel brake overload vehicle is too high. The drum brake/disc brake may overheat. WARNING The vehicle’s driving and braking characteristics may change. -

Page 169

On-board computer event window Display messages Possible causes/consequences and M Solutions The ï indicator lamp lights up yellow in the instrument cluster as ñ well as in the event window. The level control of the trailer/semitrailer Note trailer height is not at driving level. WARNING The vehicle’s driving and braking characteristics may change when driving. -

Page 170

On-board computer event window Display messages Possible causes/consequences and M Solutions Adapt your driving style Supplementary text Û: The temperature of one of the disc brakes on the tractor vehicle is too Braking effect limi‐ high. WARNING The disc brake may overheat. Driving/braking characteristics may change. -

Page 171

On-board computer event window Display messages Possible causes/consequences and M Solutions Please have rectified at Example: supplementary text Û: È next maintenance Active Brake Assist Active Brake Assist is not available. not available WARNING If Active Brake Assist is not available, you will not receive any collision warnings. -

Page 172

On-board computer event window Display messages Possible causes/consequences and M Solutions Visit workshop Lane Keeping Assist Supplementary text Û: Ô and ATTENTION ASSIST not available Lane Keeping Assist Lane Keeping Assist and ATTENTION ASSIST are malfunctioning. faulty WARNING If Lane Keeping Assist and ATTENTION ASSIST are unavailable, you will not receive any warnings from Lane Keeping Assist or ATTENTION ASSIST. -

Page 173

On-board computer event window Display messages Possible causes/consequences and M Solutions Do not steer when the vehicle is Supplementary text Û: at a standstill. Steer carefully when the vehicle is Steering character‐ moving at walking pace Please have rectified at next istics changed maintenance The power-steering function has detected a malfunction. -

Page 174

On-board computer event window Display messages Possible causes/consequences and M Solutions The # indicator lamp lights up yellow supplemented by s in the ¯ status area of the on-board computer. Brakes, axle 1 The service work due has not been performed. Maintenance due The wear limit of the brake pads/linings and/or brake discs has been immediately… -

Page 175

On-board computer event window Lighting system, electrical system and key Display messages Possible causes/consequences and M Solutions Please have rectified at next Supplementary text Û: maintenance Battery charge sta‐ The measured values for the battery charge level are unavailable. You tus not available will not be warned when the battery charge level is critical. -

Page 176

On-board computer event window Display messages Possible causes/consequences and M Solutions The entire exterior lighting of the vehicle is electronically monitored. When the event window is shown, a bulb has failed. The event window contains information about fault location and fault assistance, e.g. Replace light bulb. -

Page 177

On-board computer event window Tyres Display messages Possible causes/consequences and M Solutions The h indicator lamp lights up yellow in the status area of the on- board computer as well as in the event window. The tyre pressure Tyre pressure moni‐ monitor is faulty. -

Page 178

On-board computer event window Display messages Possible causes/consequences and M Solutions ÛCheck and correct tyre pressure Supplementary text The h indicator lamp lights up yellow in the status area of the on- Tyre pressure too board computer as well as in the event window. The tyre pressure in one or more of the tyres is too low. -

Page 179

On-board computer event window Compressed-air system Display messages Possible causes/consequences and M Solutions In addition, the J warning lamp lights up red in the instrument cluster. Brake sup‐ Example: The reservoir pressure in brake circuit 1 or 2 ^ is too low. ply pressure in cir‐… -

Page 180

On-board computer event window Engine and cooling Display messages Possible causes/consequences and M Solutions Stop vehicle. Switch off engine. Supplementary text Û: The 5 indicator lamp lights up red in the status area of the on- Engine oil pressure board computer as well as in the event window. The engine oil pres- too low sure is too low. -

Page 181

On-board computer event window Transmission and clutch Display messages Possible causes/consequences and M Solutions Stop vehicle. Contact service Supplementary text Û: Ø centre. Clutch faulty WARNING The transmission no longer changes gear. The reservoir pressure in the transmission/clutch may be too low. Stop the vehicle at once, paying attention to road traffic conditions. -

Page 182

On-board computer event window Semitrailers Display messages Possible causes/consequences and M Solutions The £ indicator lamp lights up red in the status area of the on- £ board computer as well as in the event window. Open semitrailer If the on-board computer displays a warning and a warning tone coupling sounds: the semitrailer coupling pin was detected during coupling/decou-… -

Page 183

On-board computer event window Display messages Possible causes/consequences and M Solutions The ¤ indicator lamp lights up red in the status area of the on- ¤ board computer as well as in the event window. Check semitrailer If the on-board computer displays a warning and a warning tone coupling sounds, the sensor-monitored semitrailer coupling is engaged and the semitrailer was not correctly detected. -

Page 184

On-board computer event window Braking and driving systems Display messages Possible causes/consequences and M Solutions · WARNING Active Brake Assist warns you of a risk of colliding with the vehicle in front. There is a risk of an accident. When an automatic collision warning is being given, you must brake the vehicle using the service brake if: the on-board computer displays the ·… -

Page 185

On-board computer event window Display messages Possible causes/consequences and M Solutions Vehicles with a programmable special module: the parking brake is not applied. Engage parking brake The parking brake has not been applied before engaging power take- off. WARNING The parked vehicle could roll away. You could endanger yourself and others. -

Page 186

On-board computer event window Display messages Possible causes/consequences and M Solutions Stop vehicle Check hydraulic Supplementary text Û: steering during shunting Consult service centre Power steering: In addition, the D warning lamp lights up red in the instrument function not assured cluster. -

Page 187

On-board computer event window Display messages Possible causes/consequences and M Solutions Stop vehicle. Switch off engine. Supplementary text Û: In addition, the D warning lamp lights up red in the instrument Power-steering cluster. assistance overhea‐ The steering gear has overheated. Stop the vehicle immediately, paying attention to road and traffic conditions. -

Page 188

On-board computer event window Tyres Display messages Possible causes/consequences and M Solutions Change tyre Supplementary text Û: The h indicator lamp lights up red in the status area of the on- Flat tyre board computer as well as in the event window. The tyre pressure has suddenly dropped in one or more tyres. -

Page 189

Indicator lamps in the status area of the display Display messages Possible causes/consequences and M Solutions Stop the vehicle. Pay attention to the traffic conditions. Check wheel position and release blockage if necessary. Indicator lamps in the status area of Warning and indicator lamps the display Driver’s airbag (… -

Page 190

Indicator lamps in the status area of the display Warning and indicator lamps Warning and indicator lamps Sensor-monitored semitrailer cou- ABS equipment ! shown with î pling malfunction ( page 180) s, r or u for tractor vehi- cle and/or trailer/semitrailer Semitrailer coupling, refill grease page 245) reservoir (see separate Operating… -

Page 191

Indicator lamps in the status area of the display Red warning/indicator lamp Problem Possible causes/consequences and M Solutions The Û indicator lamp Risk of accident in the status area of the The trailer’s/semitrailer’s brake system is malfunctioning or the on-board computer trailer/semitrailer is automatically braked. -

Page 192

Board can be operated, e.g. a service contract. For more information, please contact Fleet- Board Support, see contact details in the publi- cation details. You can obtain information on FleetBoard from any Mercedes-Benz Service Centre. FleetBoard vehicle management enables unlimi- ted access to consumption figures and informa-… -

Page 193

LED indicator lamp flashes three times when the message has been successfully sent. The roadside assis- tance data is now available to Mercedes-Benz Service. Switch the ignition lock to position 0. Contact Mercedes-Benz Service (Customer Avoid touching the contact surface points of Assistance Centre or national organisation). -

Page 194

FleetBoard vehicle computer with integrated card reader If a longer warning tone sounds over the loud- The FleetBoard DriverCard is used to identify the speaker and the red LED indicator lamp flashes driver for driver-related evaluation. three times, the message has not been sent: Avoid touching the contact surface points of memory chip with your fingers. -

Page 195

FleetBoard vehicle computer with integrated card reader Driver card read-out error Problem Possible causes/consequences and M Solutions The LED indicator lamp The FleetBoard vehicle computer has not detected a valid driver card. lights up green and you There could be several reasons for this: hear a continuous warn- an invalid driver card has been inserted. -

Page 196

You can obtain information on imately 4 seconds. The roadside assistance FleetBoard from any Mercedes-Benz Service data is now available to Mercedes-Benz Ser- Centre. vice. FleetBoard vehicle management enables unlimi- Switch the ignition lock to position 0. -

Page 197

FleetBoard vehicle computer with driver card transmitted from the FleetBoard vehicle com- Reading out the driver card and send- puter to the FleetBoard Service Centre. Once ing the data the data has been transmitted, the central fleet office can download the data from the Fleet- Board Service Centre via the Internet. -

Page 198

FleetBoard Truck Data Center 6 (DTCO) Safety notes on electromagnetic fields Free and open source software The FleetBoard vehicle computer receives and Information on licences for the free and open transmits radio waves when in operation. The source software used in your device can be FleetBoard vehicle computer was constructed found on this website: and manufactured so that it does not exceed the… -

Page 199

It allows ded in the scope of delivery.) for remote readout of the vehicle fault memory throughout Europe by Mercedes-Benz Service Trailer services links data on the truck and 24h. trailer to one another. -

Page 200

LED indicator lamp lights up green for approx- LED indicator lamp Meaning imately 4 seconds. The roadside assistance data is now available to Mercedes-Benz Ser- Flashes green The FleetBoard vehi- vice. cle computer starts Turn ignition lock to position u. -

Page 201

Protection (ICNIRP) for exposure to radio waves. what is shown in some of the descriptions and Notes on radio malfunctions and interferen- illustrations. Contact a Mercedes-Benz Service Centre if you have any questions about equip- Radio malfunctions can be caused by any device ment or operation. -

Page 202

FleetBoard Truck Data Center 6 (FB Card) Transmitter frequencies Mobile communications 3G UMTS/HSDPA/HSUPA 2G GSM/GPRS/EDGE 5-band support: 4-band support: Band I 2100 MHz GSM 850 MHz Band II 1900 MHz E-GSM 900 MHz Band V 850 MHz DCS 1800 MHz Band VI 800 MHz PCS 1900 MHz Band VII 900 MHz… -

Page 203

FleetBoard Truck Data Center 6 (FB Card) Time recording provides an overview of the current driving and rest periods of drivers. Messaging facilitates communication between the driver and logistics via DispoPi- lot.guide (DispoPilot.guide is not included in the scope of delivery). Trailer services links data on the truck and trailer to one another. -

Page 204

The roadside assis- tance data is now available to Mercedes-Benz Switch the ignition lock to the drive position. Service. When the green LED on the FleetBoard vehi- Turn the ignition to position g. -

Page 205

FleetBoard Support Telephone Germany/ +49 711 17 91 999 International Austria +43 1 36 02 77 30 24 Belgium +32 2 62 00 453 Czech Republic +420 22 53 76 440 Denmark +45 35 15 80 32 (in English) Finland +358 98 17 10 433 (in English) France… -

Page 206

Internet at diverted from the traffic conditions. You could www.mercedes-benz.de/betriebsanleitung-lkw then lose control of the vehicle. There is a risk or in the Operating Instructions on the DispoPi- lot. -

Page 207

Transmitter frequencies mum distance of 15 cm to avoid cardiac pace- makers experiencing any malfunctions. Transmitter frequencies Serial number Mobile communications WCDMA/HSDPA/HSUPA/ Class 3 (23.5 dBm) @ Class 3 (+24 dBm +1/-3 dB) HSPA+ Power Class: 900/2100 MHz for UMTS 2100, WCDMA FDD Class 3 (+24 dBm +1/-3 dB) for UMTS 1900, WCDMA FDD BdII… -

Page 208

First steps Serial number IEEE hrs 802.11n (HT40) 16 dBm ® Bluetooth 2.4 GHz ® 3 dBm 3 dBm Bluetooth Classic 3 dBm 3 dBm ® Bluetooth Low Energy NFC 13.56 MHz -3 dBµA/m @ 3 m 12 dBµA/m @ 3 m Operation restriction Inserting and removing DispoPi- lot.guide… -

Page 209

Overview Overview Operating system To switch DispoPilot.guide on/off Slot for Kensington lock DispoPilot.guide serial number Micro USB port (only for charging the rechargeable battery) Card slot for microSD card Homepage Connection status overview FleetBoard portal homepage Vehicle computer and FleetBoard Server connected Status indicator (GPS status, connection status, time, GSM status, charge status) -

Page 210

Basic functions This allows you to navigate through lists or The connection status in the display shows menus or move the map. whether DispoPilot.guide is connected to the vehicle computer and FleetBoard Server. If there is no connection to the FleetBoard Rapid view change Server, no messages or orders can be trans- mitted. -

Page 211

Navigation Opening the menu Zooming out of the map Place two fingers a larger distance apart on Press and hold the touch-sensitive surface the touch-sensitive surface. with one finger until the menu opens. Slide your fingers together. The map will zoom out. Rapidly zooming in on the map Navigation Important safety notes… -

Page 212

Navigation Calling up the submenu For example, if the routing or the direction of a one-way street has been changed. For this reason, you must always observe road and traffic rules and regulations during your journey. Traffic regulations always take prece- dence over the navigation system’s recommen- dations. -

Page 213

Navigation along the route. To specify a stopover: enter the desired stopover. near the destination. The destination appears on the map. Add to «Current route». Select Example of selecting a destination with Stopovers are added to the route in the order the address: they are entered. -

Page 214

Navigation Display during route guidance (route destinations and traffic messages on the route. Only the next 50 km will be displayed view) for roads longer than 50 km. To display the entire route, the progress bar can be moved. Lane recommendations To switch between 2D and 3D view Next change of direction and distance to change of direction… -

Page 215

+31 20 72 19 232 Dispose of rechargeable batteries in an envi- ronmentally responsible manner at a special- Address Daimler FleetBoard GmbH, ist workshop, a Mercedes-Benz Service HPC: Z400, 70546 Stuttgart, Ger- Centre or a collection point. many Internet http://www.fleetboard.com DispoPilot.guide is only available with a pre-… -

Page 216

General notes Important safety notes WARNING If you handle or operate mobile audio/video WARNING sources while driving, your attention may be diverted from the traffic conditions. You could The CD/DVD drive is a class 1 laser product. then lose control of the vehicle. There is a risk If you open the housing of the CD/DVD drive, of an accident. -

Page 217

Anti-theft protection Please switch on ignition. Disabled, www.mercedes-benz.de/betriebsanleitung-lkw or in the Digital Operating Instructions (radio/ please switch on ignition BLOCKED navigation system only). appears in the audio system display. Switch on the ignition. You can now use the audio system. -

Page 218

Operating system Operating system Radio/navigation system overview Function Page Function Page Display Turn 3 the controller: To select a station Number pad To select a list item To set a station via the sta- To adjust the map scale tion presets To change the adjustment To store stations manually value… -

Page 219

Operating system Function Page Function Page :9 Vertical arrow F Press briefly: buttons: To select stations using the To select a function from the station search function submenu To select the next track To move the map vertically F Press and hold: (in full-screen display) Fast forward To select a DVD menu item… -

Page 220

Operating system Main function navigation ¡ Radio/navigation system display ¢ Basic display with map overview £ Destination entry ¤ Trip entry ¥ Traffic announcements m Navigation settings Main function telephone w x Basic display with keypad Phone book Unanswered calls Accepted calls Dialled numbers Main function video t… -

Page 221

Operating system CD radio overview Function Page Function Page Press V the controller: Display To confirm your selection Number keypad: To display stored stations To set a station via the sta- To display playback options tion presets =; Horizontal arrow To store stations manually buttons: To enter a passkey… -

Page 222

Operating system Function Page Function Page 8/8 Press the mute/ Mini USB socket and AUX eject button briefly: jack To mute Disc slot: To switch off traffic To insert CDs announcements To remove CDs 8/8 Press and hold: o Turn: To eject a CD To adjust the volume F Press briefly:… -

Page 223

Operating system Main function settings ä CD radio menu overview Language Main function radio ´ Display brightness Switching FM stations/traffic announcement ® Bluetooth settings priority on/off System settings Switching automatically stored FM stations/ traffic announcement priority on/off Switching between AM stations/wavebands Radio/navigation system and CD Switching between automatically stored AM radio controller… -

Page 224

Operating system Radio overview Function Page Function Page SRC source button: To select a menu To select an audio source In CD/USB mode: to switch Press and hold: A‑STORE to the track time display To mute the current traffic announcement To select the sound menu 8 Mute button: To end the current traffic… -

Page 225

Audio mode Function Page Function Page üû Arrow buttons q Press the control knob: In radio mode: To switch audio equipment on/off Press briefly: to start station search q Turn: Press and hold: manual sta- To adjust the volume tion search In CD/USB mode: Press briefly: to skip to the next/previous track… -

Page 226

-capable mobile follows (visible by the symbol): phones with the audio system can be obtained: no symbol devices within range from your Mercedes-Benz Service Centre or which have not yet on the Internet at http://www.mercedes- been authorised benz.com/connect Ï greyed out / devices out of range Ï… -

Page 227

Navigation ® If the desired Bluetooth device is not in the list, Navigation you must update the list. Important safety notes Turn 3 the controller to select Update. Press V the controller. WARNING ® The audio system searches for Bluetooth Operating the integrated information systems devices within range. -

Page 228

Navigation Turn 3 the controller to select the desired Showing/hiding the menu country. To hide the menu: press V the controller. To confirm your selection: press V the The map appears in the full-screen display. controller. To show the menu: press the % back The character entry menu for entering the button when the map is shown in full-screen. -

Page 229

Digital Operating Instructions Starting route guidance Change of direction In the address input menu, turn 3 the con- Introduction Start route guidance. troller to select Changes of direction have three phases: To confirm your selection: press V the preparation phase controller. -

Page 230

Digital Operating Instructions Opening the Digital Operating Instruc- tions Press the = or ; button until n (Digital Operating Instructions) is selected in the main function bar. The entry screen appears. Turn V the controller to select More. To confirm your selection: press V the controller. -

Page 231

Digital Operating Instructions Press the 9 or : button to select s Operating the Digital Operating (quick access) in the menu of the Digital Oper- Instructions ating Instructions. The display shows a list of keywords for quick To change the submenu: press the 9 access to the corresponding contents of the or : button. -

Page 232

Important safety notes Important safety notes Only handle a disc when the vehicle is sta- tionary. WARNING Bear in mind that, at a speed of only 50 km/h If you operate information and communica- your vehicle is covering a distance of nearly tion equipment integrated in the vehicle when 14 m per second. -

Page 233

These brief instructions only describe the basic operation of your multimedia system. All further information on the individual func- tions can be found on the Internet at www.mercedes-benz.de/betriebsanleitung- lkw. Press the touch-sensitive surface with one finger until the point of resistance is reached. -

Page 234

Screen operation Overview To switch on and off To select a waveband To call up the radio menu Time To call up the telephone display ® To select/connect Bluetooth equipment To call up the homepage To switch on the voice control system To call up settings To select an App To call up MirrorLink™… -

Page 235