- Manuals

- Brands

- Allen-Bradley Manuals

- Controller

- MicroLogix 1400

- User manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

User Manual

MicroLogix 1400 Programmable Controllers

Bulletin 1766 Controllers and 1762 Expansion I/O

Related Manuals for Allen-Bradley MicroLogix 1400

Summary of Contents for Allen-Bradley MicroLogix 1400

-

Page 1

User Manual MicroLogix 1400 Programmable Controllers Bulletin 1766 Controllers and 1762 Expansion I/O… -

Page 2

Identifies information that is critical for successful application and understanding of the product. Allen-Bradley, Rockwell Automation, MicroLogix, RSLinx, RSLogix 500 and TechConnect are trademarks of Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automation are property of their respective companies. -

Page 3: Summary Of Changes

Summary of Changes To help you find new and updated information in this release of the manual, we have included change bars as shown to the right of this paragraph. The table below lists the sections that document new features and additional or updated information about existing features.

-

Page 4

Chapter Summary of Changes Summary of Changes Notes: Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 5: Table Of Contents

Component Descriptions ……… . . 2 MicroLogix 1400 Memory Module and Built-in Real-Time Clock . . 2 1762 Expansion I/O .

-

Page 6

Table of Contents DIN Rail Mounting……… . . 21 Panel Mounting . -

Page 7

Table of Contents Connecting the Communication Cable to the DH-485 Connector. . Grounding and Terminating the DH-485 Network … . . 75 Connecting the AIC+ ……….76 Cable Selection Guide . -

Page 8

Online Editing Directions and Cautions for MicroLogix 1400 Online Editing User ……….. . 151 A Download is Required Before Starting Online Editing . -

Page 9

Replacement Parts MicroLogix 1400 Replacement Kits ……175 Lithium Battery (1747-BA) ……..175 Installation . -

Page 10

Internal Indications ……… . 256 DNP3 Objects and MicroLogix 1400 Data Files ….256 DNP3 Data Files . -

Page 11

MicroLogix 1400 Controllers and Ethernet Communication ..351 MicroLogix 1400 Performance Considerations ….352 Ethernet Interface MicroLogix 1400 and PC Connections to the Ethernet Network. -

Page 12

Table of Contents Index Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 13: Preface

If you do not, obtain the proper training before using this product. Purpose of this Manual This manual is a reference guide for MicroLogix 1400 controllers and expansion I/O. It describes the procedures you use to install, wire, and troubleshoot your controller.

-

Page 14: Related Documentation

Information on the MicroLogix 1400 Controllers instruction set. Reference Manual 1766-RM001 MicroLogix 1400 Programmable Controllers Installation Information on mounting and wiring the MicroLogix 1400 Controllers, including a Instructions 1766 -IN001 mounting template for easy installation. Advanced Interface Converter (AIC+) User Manual A description on how to install and connect an AIC+.

-

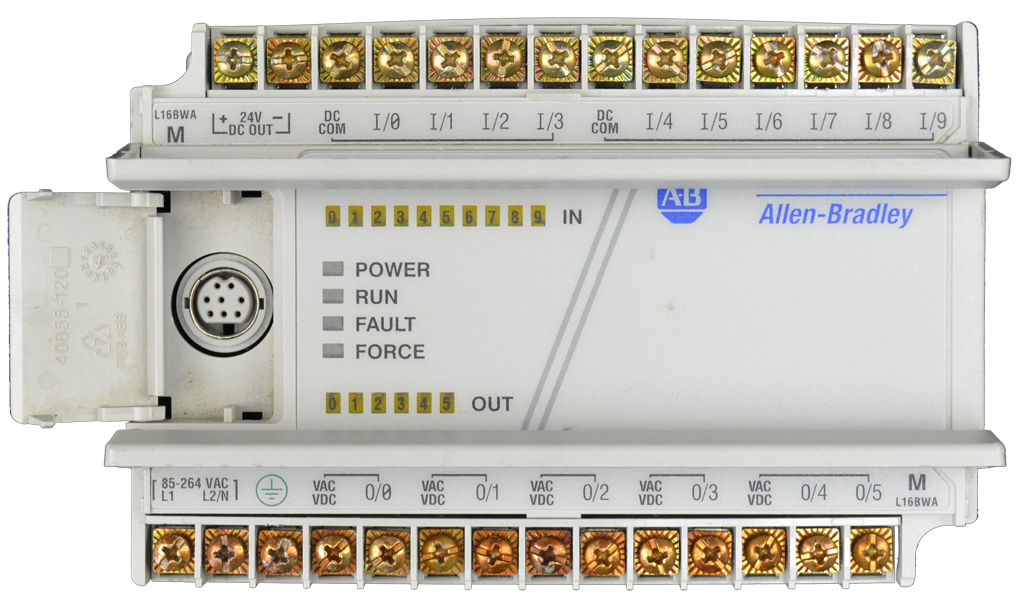

Page 15: Hardware Overview

Chapter Hardware Overview Hardware Features The Bulletin 1766, MicroLogix 1400 programmable controller contains a power supply, input and output circuits, a processor, an isolated combination RS-232/485 communication port, an Ethernet port, and a non-isolated RS-232 communication port. Each controller supports 32 discrete I/O points(20 digital inputs, 12 discrete outputs) and 6 analog I/O points(4 analog inputs and 2 analog outputs : 1766-L32BWAA, 1766-AWAA and 1766-BXBA only).

-

Page 16: Component Descriptions

The program and data in your MicroLogix 1400 is non-volatile and is stored when the power is lost to the controller. The memory module provides additional backup that can be stored separately.

-

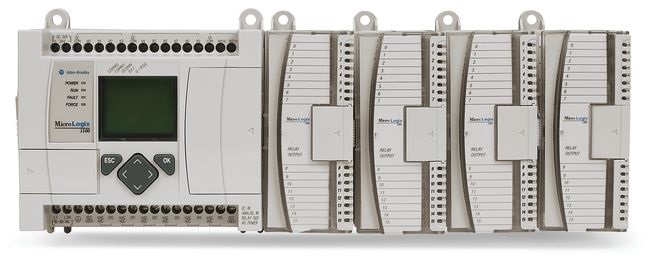

Page 17: 1762 Expansion I/O

Figure 1 — 1766-MM1 Memory Module 44536 1762 Expansion I/O 1762 expansion I/O can be connected to the MicroLogix 1400 controller, as shown below. A maximum of seven I/O modules, in any combination, can be connected to a controller. See Appendix H to determine how much heat a certain combination generates.

-

Page 18: Communication Cables

1762-IT4 4-Channel Thermocouple/mV Input Module Communication Cables Use only the following communication cables with the MicroLogix 1400 controllers. These cables are required for Class I Div. 2 applications. • 1761-CBL-AM00 Series C or later • 1761-CBL-AP00 Series C or later •…

-

Page 19: Communication Options

RS-232/485 communication port (Channel 0), an Ethernet port (Channel 1) and a non-isolated RS-232 communication port (Channel 2). The Channel 0 and Channel 2 ports on the MicroLogix 1400 can be connected to the following: • operator interfaces, personal computers, etc. using DF1 Full Duplex point-to-point •…

-

Page 20

Chapter 1 Hardware Overview information, but also includes the data table memory map and data table monitor screen using a standard web browser. See Chapter 4 for more information on connecting to the available communication options. Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 21: Install Your Controller

Chapter Install Your Controller This chapter shows you how to install your controller. The only tools you require are a flat or Phillips head screwdriver and drill. Topics include: • agency certifications • compliance to European Union Directives • installation considerations •…

-

Page 22: Low Voltage Directive

EN 61131-2 Programmable Controllers, Part 2 — Equipment Requirements and Tests. For specific information required by EN 61131-2, see the appropriate sections in this publication, as well as the following Allen-Bradley publications: • Industrial Automation Wiring and Grounding Guidelines for Noise Immunity, publication 1770-4.1 •…

-

Page 23: Safety Considerations

WARNING: Do not place the MicroLogix 1400 Programmable Controller in direct sunlight. Prolonged exposure to direct sunlight could degrade the LCD display and have adverse effects on the controller.

-

Page 24: Disconnecting Main Power

Chapter 2 Install Your Controller Use only the following communication cables in Class I, Division 2 hazardous locations. Environment Classification Communication Cables Class I, Division 2 Hazardous Environment 1761-CBL-AC00 Series C or later 1761-CBL-AM00 Series C or later 1761-CBL-AP00 Series C or later 1761-CBL-PM02 Series C or later 1761-CBL-HM02 Series C or later 2707-NC9 Series C or later…

-

Page 25: Power Distribution

If the power source cannot supply this inrush current, the source voltage may sag momentarily. The only effect of limited inrush current and voltage sag on the MicroLogix 1400 is that the power supply capacitors charge more slowly. However, the effect of a…

-

Page 26: Loss Of Power Source

Chapter 2 Install Your Controller voltage sag on other equipment should be considered. For example, a deep voltage sag may reset a computer connected to the same power source. The following considerations determine whether the power source must be required to supply high inrush current: •…

-

Page 27: Preventing Excessive Heat

Install Your Controller Chapter 2 Preventing Excessive Heat For most applications, normal convective cooling keeps the controller within the specified operating range. Ensure that the specified temperature range is maintained. Proper spacing of components within an enclosure is usually sufficient for heat dissipation. In some applications, a substantial amount of heat is produced by other equipment inside or outside the enclosure.

-

Page 28: Using Emergency-Stop Switches

Chapter 2 Install Your Controller When you use the master control relay to remove power from the external I/O circuits, power continues to be provided to the controller’s power supply so that diagnostic indicators on the processor can still be observed. The master control relay is not a substitute for a disconnect to the controller.

-

Page 29: Schematic (Using Iec Symbols)

Install Your Controller Chapter 2 Schematic (Using IEC Symbols) 230V AC Disconnect Fuse 230V AC Circuits Isolation Operation of either of these contacts will Transformer remove power from the external I/O Master Control Relay (MCR) circuits, stopping machine motion. 115V AC Cat.

-

Page 30: Schematic (Using Ansi/Csa Symbols)

Chapter 2 Install Your Controller Schematic (Using ANSI/CSA Symbols) 230V AC Disconnect Fuse 230V AC Output Circuits Isolation Operation of either of these contacts will Transformer remove power from the external I/O Master Control Relay (MCR) circuits, stopping machine motion. 115V AC or Cat.

-

Page 31: Using The Battery

4. Use a screwdriver as in step 1 to remove the memory module in the future. Using the Battery The MicroLogix 1400 controller is equipped with a replaceable battery (catalog number 1747-BA). The Battery Low indicator on the LCD display of the controller shows the status of the replaceable battery.

-

Page 32: Connecting The Battery Wire Connector

Chapter 2 Install Your Controller WARNING: When you connect or disconnect the battery an electrical arc can occur. This could cause an explosion in hazardous location installations. Be sure that the area is nonhazardous before proceeding. For Safety information on the handling of lithium batteries, including handling and disposal of leaking batteries, see Guidelines for Handling Lithium Batteries, publication AG…

-

Page 33: Controller Mounting Dimensions

Install Your Controller Chapter 2 Controller Mounting Dimensions 44516 1766-L32BWA, 1766-L32AWA, 1766-L32BXB, 1766-L32BWAA, 1766-L32AWAA, 1766-L32BXBA Dimension Measurement 90 mm (3.5 in.) 180 mm (7.087 in.) 87 mm (3.43 in.) Controller and Expansion The controller mounts horizontally, with the expansion I/O extending to the right of the controller.

-

Page 34: Mounting The Controller

Chapter 2 Install Your Controller Mounting the Controller MicroLogix 1400 controllers are suitable for use in an industrial environment when installed in accordance with these instructions. Specifically, this equipment is intended for use in clean, dry environments (Pollution degree 2…

-

Page 35: Din Rail Mounting

Install Your Controller Chapter 2 DIN Rail Mounting The maximum extension of the latch is 14 mm (0.55 in.) in the open position. A flat-blade screwdriver is required for removal of the controller. The controller can be mounted to EN50022-35×7.5 or EN50022-35×15 DIN rails. DIN rail mounting dimensions are shown below.

-

Page 36: Panel Mounting

Mount to panel using #8 or M4 screws. To install your controller using mounting screws: 1. Remove the mounting template from inside the back cover of the MicroLogix 1400 Programmable Controllers Installation Instructions, publication 1766-IN001. 2. Secure the template to the mounting surface. (Make sure your controller is spaced properly.

-

Page 37: 1762 Expansion I/O Dimensions

DIN rail mounting area of the module against the DIN rail. The latch momentarily opens and locks into place. Use DIN rail end anchors (Allen-Bradley part number 1492-EA35 or 1492-EAH35) for vibration or shock environments. The following illustration shows the location of the end anchors.

-

Page 38: Panel Mounting

Chapter 2 Install Your Controller End anchor End anchor 44974 1762 expansion I/O must be mounted horizontally as illustrated. For environments with greater vibration and shock concerns, use the panel mounting method described below, instead of DIN rail mounting. Panel Mounting Use the dimensional template shown below to mount the module.

-

Page 39: Connecting Expansion I/O

Install Your Controller Chapter 2 Connecting Expansion I/O The expansion I/O module is attached to the controller or another I/O module by means of a flat ribbon cable after mounting, as shown below. 44975 Use the pull loop on the connector to disconnect modules. Do not pull on the ribbon cable.

-

Page 40

Chapter 2 Install Your Controller Notes: Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 41: Wire Your Controller

Chapter Wire Your Controller This chapter describes how to wire your controller and expansion I/O. Topics include: • wire requirements • using surge suppressors • grounding the controller • wiring diagrams • sinking and sourcing wiring diagrams • controller I/O wiring •…

-

Page 42: Wire Without Spade Lugs

The diameter of the terminal screw head is 5.5 mm (0.220 in.). The input and output terminals of the MicroLogix 1400 controller are designed for a 6.35 mm (0.25 in.) wide spade (standard for #6 screw for up to 14 AWG) or a 4 mm (metric #4) fork terminal.

-

Page 43: Using Surge Suppressors

Wire Your Controller Chapter 3 When using spade lugs, use a small, flat-blade screwdriver to pry the finger-safe cover from the terminal blocks as shown below. Then loosen the terminal screw. Finger-safe cover 44528 Using Surge Suppressors Because of the potentially high current surges that occur when switching inductive load devices, such as motor starters and solenoids, the use of some type of surge suppression to protect and extend the operating life of the controllers output contacts is required.

-

Page 44: Recommended Surge Suppressors

Output Device Output Device Surge Suppressor RC Network Varistor Recommended Surge Suppressors Use the Allen-Bradley surge suppressors shown in the following table for use with relays, contactors, and starters. Recommended Surge Suppressors Device Coil Voltage Suppressor Catalog Number Type Bulletin 100/104K 700K 24…48V AC…

-

Page 45: Grounding The Controller

Wire Your Controller Chapter 3 Recommended Surge Suppressors Device Coil Voltage Suppressor Catalog Number Type Bulletin 100C, (C09 — C97) 24…48V AC 100-FSC48 110…280V AC 100-FSC280 380…480V AC 100-FSC480 12…55V AC, 12…77V DC 100-FSV55 56…136V AC, 78…180V DC 100-FSV136 137…277V AC, 181…250V DC 100-FSV277 278…575V AC 100-FSV575…

-

Page 46: Wiring Diagrams

Wiring Diagrams The following illustrations show the wiring diagrams for the MicroLogix 1400 controllers. Controllers with DC inputs can be wired as either sinking or sourcing inputs. (Sinking and sourcing does not apply to AC inputs.) Refer to Sinking and Sourcing Wiring Diagrams on page 36.

-

Page 47: Terminal Block Layouts

Wire Your Controller Chapter 3 This symbol denotes a protective earth ground terminal which provides a low impedance path between electrical circuits and earth for safety purposes and provides noise immunity improvement. This connection must be made for safety purposes on AC-powered controllers.

-

Page 48

Chapter 3 Wire Your Controller ATTENTION: The 24V DC sensor supply of the 1766-L32BWA and 1766-L32BWAA controllers should not be used to power output circuits. It should only be used to power input devices, for example, sensors and switches. See Master Control Relay on page 13 for information on MCR wiring in output circuits. -

Page 49

Wire Your Controller Chapter 3 Wire Types and Sizes Solid wire Cu-90⋅C (194⋅F) 14…22 AWG Stranded wire Cu-90⋅C (194⋅F) 16…22 AWG Wiring torque = 0.791Nm (7 in-lb) rated. Output Terminal Grouping Outputs Output Terminal Controllers Output Group Description Voltage Terminal 1766-L32BWA Group 0 Isolated relay output… -

Page 50: Sinking And Sourcing Wiring Diagrams

Chapter 3 Wire Your Controller Sinking and Sourcing Any of the MicroLogix 1400 DC embedded input groups can be configured as sinking or sourcing depending on how the DC COM is wired on the group. Wiring Diagrams Type Definition Sinking Input The input energizes when high-level voltage is applied to the input terminal (active high).

-

Page 51

Wire Your Controller Chapter 3 Figure 7 — 1766-L32BWA/L32BWAA Sinking Input Wiring Diagram +DCa +DCb +DCc 24V DC Sensor Power -DCa -DCb -DCc DC OUT — 24V + COM 0 COM 1 COM 2 IN10 IN11 1766-L32BWAA only +DCd -DCd COM 3 IN12 IN13… -

Page 52: Controller I/O Wiring

To help reduce the effects of environmental noise, install the MicroLogix 1400 system in a properly rated (for example, NEMA) enclosure. Make sure that the MicroLogix 1400 system is properly grounded.

-

Page 53: Wiring Your Analog Channels

Wire Your Controller Chapter 3 Wiring Your Analog Analog input circuits can monitor voltage signals and convert them to serial digital data. Channels Sensor 2 (V) Voltage Sensor 0 (V) Voltage Input Terminal Block I/10 COM 3 I/13 I/15 I/17 I/19 IV0(+) IV2(+)

-

Page 54: Analog Channel Wiring Guidelines

Chapter 3 Wire Your Controller Figure 13 — Analog Output Voltage Load O/10 O/11 Output Terminal Block Voltage Load 44680 Analog Channel Wiring Guidelines Consider the following when wiring your analog channels: • The analog common (COM) is connected to earth ground inside the module.

-

Page 55: Minimizing Electrical Noise On Analog Channels

Several specific steps can be taken to help reduce the effects of environmental noise on analog signals: • install the MicroLogix 1400 system in a properly rated enclosure, for example, NEMA. Make sure that the MicroLogix 1400 system is properly grounded.

-

Page 56: Grounding Your Analog Cable

Chapter 3 Wire Your Controller Grounding Your Analog Cable Use shielded communication cable (Belden #8761). The Belden cable has two signal wires (black and clear), one drain wire, and a foil shield. The drain wire and foil shield must be grounded at one end of the cable. Foil Shield Black Wire Insulation…

-

Page 57

Wire Your Controller Chapter 3 Figure 16 — 1762-IQ8 Wiring Diagram +DC (sinking) -DC (sourcing) IN 0 IN 1 IN 2 IN 3 24V DC IN 4 IN 5 IN 6 IN 7 Common connected internally. -DC (sinking) +DC (sourcing) 44571 Figure 17 — 1762-IQ16 Wiring Diagram +DC (Sinking) -

Page 58

Chapter 3 Wire Your Controller Figure 18 — 1762-IQ32T Wiring Diagram 44920 Figure 19 — 1762-OA8 Wiring Diagram OUT 0 OUT 1 OUT 2 OUT 3 OUT 4 OUT 5 OUT 6 OUT 7 44573 Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 59

Wire Your Controller Chapter 3 Figure 20 — 1762-OB8 Wiring Diagram +VDC OUT 0 OUT 1 OUT 2 OUT 3 OUT 4 OUT 5 24V DC (source) OUT 6 OUT 7 DC COM 44574 Figure 21 — 1762-OB16 Wiring Diagram VDC+ OUT 0 OUT 1… -

Page 60

Chapter 3 Wire Your Controller Figure 22 — 1762-OB32T Wiring Diagram 44925 Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 61

Wire Your Controller Chapter 3 Figure 23 — 1762-OV32T Wiring Diagram 44915 Figure 24 — 1762-OW8 Wiring Diagram L1 VAC1 + VAC-VDC 1 OUT 0 L2 DC1 COM OUT 1 OUT 2 OUT3 L1 VAC2 + VAC-VDC2 OUT 4 OUT 5 L2 DC2 COM OUT 6 OUT 7… -

Page 62

Chapter 3 Wire Your Controller Figure 25 — 1762-OW16 Wiring Diagram VAC-VDC OUT 0 OUT 1 OUT 2 OUT 3 OUT 4 OUT 5 OUT 6 OUT 7 VAC-VDC OUT 8 OUT 9 OUT 10 OUT 11 OUT 12 OUT 13 OUT 14 OUT 15 44577… -

Page 63

Wire Your Controller Chapter 3 Figure 26 — 1762-OX6I Wiring Diagram L1-0 L1 OR +DC OUT0 N.C. L2 OR -DC OUT0 N.O. L1 OR +DC L1-1 OUT1 N.C. OUT1 N.O. L2 OR -DC L1-2 L1 OR +DC OUT2 N.C. L2 OR -DC OUT2 N.O. -

Page 64: Analog Wiring

Select the input type, current or voltage, using the switches located on the module’s circuit board and the input type/range selection bits in the Configuration Data File. Refer to MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001. You can access the switches through the ventilation slots on the top of the module.

-

Page 65

Wire Your Controller Chapter 3 channel 0; switch 2 controls channel 1. The factory default setting for both switch 1 and switch 2 is Current. Switch positions are shown below. Ch0 Ch1 Switch Location Voltage (OFF) Current (ON) Default Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 66

The output type selection, current or voltage, is made by wiring to the appropriate terminals, Iout or Vout, and by the type/range selection bits in the Configuration Data File. Refer to MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001. -

Page 67

Wire Your Controller Chapter 3 Figure 28 — 1762-IF2OF2 Terminal Block Layout IN 0 (+) IN 0 (-) IN 1 (+) IN 1 (-) V Out 0 I Out 0 V Out 1 I Out 1 Common connected internally. Figure 29 — Differential Sensor Transmitter Types IN 0 (+) Analog Sensor IN 0 (-) -

Page 68

Select the input type, current or voltage, using the switches located on the module’s circuit board and the input type/range selection bits in the Configuration Data File. Refer to MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001. You can access the switches through the ventilation slots on the top of the module. -

Page 69

Wire Your Controller Chapter 3 Figure 31 — 1762-IF4 Terminal Block Layout IN 0 (+) IN 0 (-) IN 1 (+) IN 1 (-) IN 2 (+) IN 2 (-) IN 3 (+) IN 3 (-) Commons internally connected. Figure 32 — Differential Sensor Transmitter Types IN 0 (+) Analog Sensor IN 0 (-) -

Page 70

Chapter 3 Wire Your Controller Figure 33 — Sensor/Transmitter Types 2-Wire Transmitter Transmitter Module Power IN + Supply IN — Transmitter 3-Wire Transmitter Signal Supply Module Power IN + Supply IN — Transmitter 4-Wire Transmitter Module Signal Supply Power IN + Supply IN — All power supplies rated N.E.C. -

Page 71

Wire Your Controller Chapter 3 1762-OF4 Wiring I out 0 Current Load I out 1 I out 2 I out 3 V out 0 Voltage Load V out 1 V out 2 V out 3 Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 72

Chapter 3 Wire Your Controller Notes: Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 73: Communication Connections

The Ethernet communication channel, Channel 1, allows your controller to be connected to a local area network for various devices providing 10 Mbps/100 Mbps transfer rate. MicroLogix 1400 controllers support Ethernet/IP with CIP explicit messaging (message exchange), BOOTP/DHCP Client, HTTP Server, SMTP Client, DNS Client, SNMP Server, Socket Interface with CIP Generic messaging, Modbus TCP Client/Server and DNP3 over IP.

-

Page 74: Default Communication Configuration

Chapter 4 Communication Connections For more information on MicroLogix 1400 communications, refer to the MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001. Default Communication The MicroLogix 1400 communication Channel 0 has the following default communication configuration. Configuration For Channel 0, the default configuration is present when: •…

-

Page 75: Changing Communication Configuration

Communication Connections Chapter 4 mode. Hold down the OK key more than 5 seconds to toggle the communication mode on the Main Menu screen. The Communication Toggle Functionality only affects the communication configuration of Channel 0. Changing Communication Configuration Follow the procedure below to change from the user-defined communication configuration to the default communications mode and back.

-

Page 76

Chapter 4 Communication Connections 2. Press the OK key on the LCD keypad. The Advanced Settings Menu screen is displayed. 3. Select DCOMM Cfg using the Up and Down keys, and then press the OK key. 4. The DCOMM Configuration screen is displayed. In this example, the current status is Disable. -

Page 77: Connecting To The Rs-232 Port

6. Press the ESC key to return to the Advanced Set Menu screen, as shown in step 3. Connecting to the RS-232 There are two ways to connect the MicroLogix 1400 programmable controller to your personal computer using the DF1 protocol: using a point-to-point Port connection, or using a modem.

-

Page 78: Making A Df1 Point-To-Point Connection

MicroLogix controllers and the 1747-DPS1 network port . Making a DF1 Point-to-Point Connection You can connect the MicroLogix 1400 programmable controller to your personal computer using a serial cable (1761-CBL-PM02) from your personal computer’s serial port to the controller’s Channel 0. The recommended protocol for this configuration is DF1 Full-Duplex.

-

Page 79: Using A Modem

(1) Series C or later cables are required for Class I Div 2 applications. Using a Modem You can use modems to connect a personal computer to one MicroLogix 1400 controller (using DF1 Full-Duplex protocol), to multiple controllers (using DF1 Half-Duplex protocol), or Modbus RTU Slave protocol via Channel 0, as shown in the following illustration.

-

Page 80

Chapter 4 Communication Connections MicroLogix 1400 Channel 0 to Modem Cable Pinout When connecting MicroLogix 1400 Channel 0 to a modem using an RS-232 cable, the maximum that the cable length may be extended is 15.24 m (50 ft). DTE Device… -

Page 81

Communication Connections Chapter 4 Constructing Your Own Null Modem Cable If you construct your own null modem cable, the maximum cable length is 15.24m (50 ft) with a 25-pin or 9-pin connector. Refer to the following typical pinout: Optical Isolator Modem 9-Pin 25-Pin… -

Page 82: Connecting To A Df1 Half-Duplex Network

Chapter 4 Communication Connections Connecting to a DF1 Half-Duplex Network When a communication port is configured for DF1 Half-Duplex Slave, available parameters include the following: DF1 Half-Duplex Configuration Parameters Parameter Options Baud Rate 300, 600, 1200, 2400, 4800, 9600, 19.2 KBps, 38.4 KBps Parity none, even Node Address…

-

Page 83

Communication Connections Chapter 4 DF1 Half-Duplex Master-Slave Network Use the following diagram for DF1 Half-Duplex Master-Slave protocol without hardware handshaking. SLC 5/03 MicroLogix 1400 processor Master 1761-CBL-AM00 or 1761-CBL-HM02 1761-CBL-AP00 or 1761-CBL-PM02 DF1 Slave radio modem or lease line AIC+… -

Page 84: Connecting To A Rs-485 Network

MicroLogix 1400 controllers to the RS-485 network. Network You can connect a MicroLogix 1400 controller to your RS-485 network directly without using an external optical isolator, such as Advanced Interface Converter (AIC+), catalog number 1761-NET-AIC, as shown in the illustrations below, because Channel 0 is isolated within the controller.

-

Page 85: Dh-485 Configuration Parameters

Communication Connections Chapter 4 DH-485 Configuration Parameters When MicroLogix communications are configured for DH-485, the following parameters can be changed: DH-485 Configuration Parameters Parameter Options Baud Rate 9600, 19.2 KBps Node Address 1…31 decimal Token Hold Factor 1…4 See Software Considerations on page 215 for tips on setting the parameters listed above.

-

Page 86

Chapter 4 Communication Connections DH-485 Network with a MicroLogix 1400 Controller AIC+ AIC+ TERM TERM PanelView SHLD SHLD CHS GND CHS GND DC SOURCE DC SOURCE CABLE CABLE EXTERNAL EXTERNAL SLC 5/04 PanelView 550 DH-485 Network AIC+ AIC+ AIC+ AIC+… -

Page 87: Recommended Tools

Communication Connections Chapter 4 Typical 3-Node Network (Channel 0 Connection) PanelView 550 PanelView MicroLogix 1400 RJ45 port 1761-CBL-AS09 or 1761-CBL-AS03 TERM 1747-CP3 or SHLD CHS GND 1761-CBL-AM00 1761-CBL-AC00 or 1761-CBL-HM02 DC SOURCE CABLE EXTERNAL 44599 Recommended Tools To connect a DH-485 network to additional devices, you need tools to strip the shielded cable and to attach the cable to the AIC+ Advanced Interface Converter.

-

Page 88: Connecting The Communication Cable To The Dh-485 Connector

Use these instructions for wiring the Belden #3106A or #9842 cable. (See Cable Selection Guide on page 77 if you are using standard Allen-Bradley cables.) Connecting the Communication Cable to the DH-485 Connector A daisy-chained network is recommended.

-

Page 89: Grounding And Terminating The Dh-485 Network

Communication Connections Chapter 4 Multiple Cable Connection When connecting multiple cables to the DH-485 connector, use the following diagram. to Previous Device to Next Device Connections using Belden #3106A Cable For this Wire/Pair Connect this Wire To this Terminal Shield/Drain Non-jacketed Terminal 2 — Shield Blue…

-

Page 90: Connecting The Aic

Shield ChassisGround Connecting the AIC+ You can connect a MicroLogix 1400 controller to a DH-485 network via Channel 0 directly without using an optical isolator, such as AIC+, catalog number 1761-NET-AIC, because Channel 0 is isolated. However, you need to use an AIC+ to connect your PC or other MicroLogix Family products, such as MicroLogix 1200, to a DH-485 network.

-

Page 91: Cable Selection Guide

SLC 5/03 or SLC 5/04 processors, ch 0 port 2 external 1761-CBL-PM02 2 m (6.5 ft) MicroLogix 1000, 1200, or 1500 ch 0 port 1 external MicroLogix 1400 ch 2 port 2 external PanelView 550 through NULL modem port 2 external adapter DTAM Plus / DTAM Micro…

-

Page 92

Port 1 on another AIC+ port 1 external MicroLogix 1400 ch 2 port 2 external External power supply required unless the AIC+ is powered by the device connected to port 2, then the selection switch should be set to cable. -

Page 93

Communication Connections Chapter 4 External power supply required unless the AIC+ is powered by the device connected to port 2, then the selection switch should be set to cable. 1761-CBL-PM02 Series C (or equivalent) Cable Wiring Diagram 6 8 7 44605 Programming Controller… -

Page 94: Recommended User-Supplied Components

If you are making a cable to connect to port 2, you must configure your cable to connect to the Allen-Bradley cable shown above. In the 1761-CBL-PM02 cable, pins 4 and 6 are jumpered together within the DB-9 connector.

-

Page 95: Safety Considerations

Communication Connections Chapter 4 Safety Considerations This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or non-hazardous locations only. WARNING: EXPLOSION HAZARD AIC+ must be operated from an external power source. This product must be installed in an enclosure. All cables connected to the product must remain in the enclosure or be protected by conduit or other means.

-

Page 96: Powering The Aic

1761-NET-AIC, 1761-NET-ENI, and the 1761-NET-ENIW, these controllers provide the power for the interface converter modules. The MicroLogix 1400 does not provide 24V DC communication power through communication ports. Instead these pins are used to provide RS-485 communications directly. Any AIC+, ENI, or ENIW not connected to a MicroLogix 1000, 1200, or 1500 controller requires a 24V DC power supply.

-

Page 97: Connecting To Ethernet

Connecting to Ethernet You can connect directly a MicroLogix 1400 to an Ethernet network via the Ethernet port (Channel 1). You do not need to use an Ethernet interface card, such as the Ethernet Interface (ENI) and (ENIW), catalog number 1761-NET-ENI and 1761-NET-ENIW, to connect your MicroLogix 1400 controller to an Ethernet network.

-

Page 98: Ethernet Connections

End view of RJ 45 Plug Looking into a RJ45 Jack 1 2 3 4 5 6 7 8 8 7 6 5 4 3 2 1 For more information on using ethernet cables with MicroLogix 1400, see. Rockwell Automation Publication 1766-UM001I-EN-P — June 2015…

-

Page 99: Using The Lcd

Chapter Using the LCD This chapter describes how to use the LCD and keypad on the MicroLogix 1400 controller. Topics include: • operating principles • I/O status display • monitoring user defined target files • using the mode switch • using a user defined LCD screen •…

-

Page 100: Operating Principles

Chapter 5 Using the LCD LCD and Keypad Feature Description LCD Screen Keypad (ESC, OK, Up, Down, Left, and Right Buttons) Operating Principles MicroLogix 1400 LCD Menu Structure Tree Startup Screen User defined? Main Menu I/O Status Monitoring Integer Long Integer…

-

Page 101

Using the LCD Chapter 5 LCD Default Startup Screen You can customize this Startup screen in your application program by defining a ASCII data file that contains the bitmap format image to display on the Startup screen and specifying the CBL element of the LCD Function File to the address of this ASCII file. -

Page 102

LCD display. For more information on how to create and use a customized Startup screen, refer to the LCD Function File described in the MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001. After the default Startup screen or your customized Startup screen is displayed… -

Page 103: Main Menu And Default Screen

Using the LCD Chapter 5 Main Menu and Default Screen The Main menu consists of five menu items: I/O Status, Monitoring, Mode Switch, User Display, and Advanced Set. LCD Main Menu Rockwell Automation Publication 1766-UM001I-EN-P — June 2015…

-

Page 104

Chapter 5 Using the LCD Main Menu Items Menu Item Description For details, refer to I/O Status Displays the I/O Status screen, which shows the I/O status of the I/O Status on page 93 embedded digital I/O. Monitoring Allows you to view and change the data value of a bit and an Monitor User Defined Target Files on page 95 integer file. -

Page 105: Operating Buttons

Using the LCD Chapter 5 Operating Buttons Button Function Cursor Buttons Move cursor Select menu item Choose file numbers, values, etc. Next menu level, store your entry, apply the changes Previous menu level, cancel your entry 44612 Using Menus to Choose Values Press •…

-

Page 106: Cursor Display

Chapter 5 Using the LCD Cursor Display There are two different cursor types: Selection cursor (the symbol “ ”) is displayed left to the selected item. • Move cursor with the up/down arrows Full block navigation is shown as a flashing block: •…

-

Page 107: Setting Values

Down arrow = decrement I/O Status The MicroLogix 1400 provides I/O status indicators on the LCD screen. You can view the status of inputs and outputs on the I/O Status screen on the LCD, as shown below. The I/O status indicators on this screen are updated every 100 ms to reflect the current I/O status in real time, regardless of controller scan time.

-

Page 108: Viewing I/O Status

TO element in the LCD Function File. For more information, refer to the LCD Function File described in the MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001.

-

Page 109: Monitor User Defined Target Files

IMPORTANT in the TUF element, as well as the appropriate number of elements, exist in the MicroLogix 1400 user program. The data protection for a file depends on the LCD edit disable setting. When LCD Edit Disable is set (1: Checked) in file properties, the corresponding data file is considered read-only by and the “Protected!”…

-

Page 110: Monitoring A Bit File

Chapter 5 Using the LCD LCD Edit Disable is clear (0: Unchecked), the “UnProtected!” message is displayed and the corresponding data file is editable from the LCD keypad. Although you cannot change protected data from the LCD keypad, the IMPORTANT control program or other communication devices do have access to this data.

-

Page 111

Using the LCD Chapter 5 • LCD Edit Disable is set to unchecked(disable) • The TUF element of the LCD Function File is set to 3 to specify the bit file B3 as the target bit file to monitor on the LCD, as shown in the screen capture below. -

Page 112

Chapter 5 Using the LCD Follow these steps to view and change the data values of the bit file B3. 1. On the Main Menu screen, select Monitoring by using the Up and Down keys on the LCD keypad. 2. Press the OK key on the LCD keypad. The File Number prompt is displayed. -

Page 113

Using the LCD Chapter 5 7. Press OK to apply the changes. Then, the new value OFF (0) is applied. Note that the target bit, “0/0” in this example, is flashing. The cursor is moved automatically to the target bit position. You can identify this change of data value is reflected to your RSLogix 500/RSLogix Micro programming software. -

Page 114: Monitoring Integer Files

Chapter 5 Using the LCD 8. Now, we will view an example of the data value of a protected property. If LCD Edit Disable is set to checked (enable), the “Protected!” message will be displayed and this data file cannot be edited from the LCD. 9.

-

Page 115

Use your programming software to ensure that the integer file you IMPORTANT specify in the TUF element, as well as the appropriate number of elements, exists in the MicroLogix 1400 user program. The example table below shows how the LCD uses the configuration information with integer file number 7 (LCD:0.TUF=7). -

Page 116

Chapter 5 Using the LCD • The TUF element of the LCD Function File is set to 7 to specify the integer file N7 as the target integer file to monitor on the LCD, as shown in the screen capture below. •… -

Page 117

Using the LCD Chapter 5 4. The current data value (ON) of the N7:0 word is displayed. Note that the target word “0”, which is right next to “N7:”, is flashing, which means the cursor is at the target word position. 5. -

Page 118

Chapter 5 Using the LCD 8. Press the Left key once. Then, press the Down key once. The sign digit will change to “-”, as shown below. Note that “-” is still flashing, which means the cursor is still at the data value position. 9. -

Page 119: Monitoring Double Integer Files

Using the LCD Chapter 5 10. Now, we will view an example of the data value of a protected property. If LCD Edit Disable is set to checked (enable), the “Protected!” message will be displayed and this data file cannot be edited by the LCD. 11.

-

Page 120

Chapter 5 Using the LCD File and download your application program to the controller. The TUF element can only be changed by a program download. The value stored in the TUF element identifies the double integer file with which the LCD will interface. Valid double integer files are L9, and L10 through L255. When the LCD reads a valid double integer file number, it can access up to 256 words (0 to 255) on the LCD screen. -

Page 121

Using the LCD Chapter 5 • LCD Edit Disable is set to unchecked(disable) • The TUF element of the LCD Function File is set to 9 to specify the integer file L9 as the target file to monitor on the LCD, as shown in the screen capture below. -

Page 122

Chapter 5 Using the LCD 1. On the Main Menu screen, select Monitoring by using the Up and Down keys on the LCD keypad. 2. Then, press the OK key on the LCD keypad. The File Number prompt is displayed. 3. -

Page 123

Using the LCD Chapter 5 6. Press the Left key twice. Then, the cursor will position at the third digit. Press the Up key three times to change the third digit to 3. 7. Press the Left key once. Then, press the Up key once. The second digit will change to «1». -

Page 124

Chapter 5 Using the LCD 10. You can identify this change of data value is reflected to your RSLogix 500/RSLogix Micro programming software. After changing the data value of a target double word, press the OK key to apply the changes or press the ESC key to discard the changes. 11. -

Page 125: Monitor Floating Point Files

105. However, you will not be able to edit floating point files from the LCD. The Protected! message is displayed on the LCD for floating point files. MicroLogix 1400 Series A controllers display an «Unprotected!» message but you will not be able to edit the corresponding data file.

-

Page 126: Using The Mode Switch

Instruction Set Reference Manual, publication 1766-RM001. Using the Mode Switch The MicroLogix 1400 provides the controller mode switch on the LCD. The possible positions of the mode switch are PROGRAM, REMOTE, and RUN. You can change mode switch position using the Mode Switch screen on the LCD, as shown below.

-

Page 127: Controller Modes

Using the LCD Chapter 5 Controller Modes The table below shows the possible controller modes when the mode switch positions at PROGRAM, REMOTE, or RUN. For example, if the Mode Switch is at RUN and you want to test a control program with running it for a single scan, you have to first change mode switch position to REMOTE before you run the control program in the remote test single scan mode with your RSLogix 500/RSLogix Micro programming software.

-

Page 128

Chapter 5 Using the LCD • How to forcibly set Mode Switch to PROG when the controller is powered up: Press ESC key for 5 seconds when the controller is powered up. The following LCD screen appears if it’s successfully done. Note that I/O output status may be changed for some programs. -

Page 129: Using A User Defined Lcd Screen

Main Menu screen, as shown in step Using a User Defined LCD The MicroLogix 1400 controller allows you to use user defined LCD screens instead of the default built-in screens. Screen To use a user defined screen, you need to create a group of appropriate instructions using the LCD instruction in your application program.

-

Page 130: User Defined Lcd Screen

Chapter 5 Using the LCD User Defined LCD Screen Follow these steps to display the user defined screen implemented in your application program. 1. On the Main Menu screen, select User Display by using the Up and Down keys on the LCD keypad, as shown below. If the menu items shown in the figure below are not displayed on the Main Menu screen, you need to scroll down the screen by pressing the Down key.

-

Page 131: Configuring Advanced Settings

Using the LCD Chapter 5 If a user defined screen is used in your application program, the LCD screen is displayed, as shown below, according to the specific instructions used in your program. 3. Hold down the ESC key more than 3 seconds to return to the Main Menu screen, as shown below.

-

Page 132: Changing Key In Mode

Chapter 5 Using the LCD Changing Key In Mode Key In Modes There are two Key In modes, Continuous and Discrete. The Key In mode has an effect only when you change the data value of a trim pot on a trim pot screen, either Trim Pot 0 or Trim Pot 1 screen.

-

Page 133

Using the LCD Chapter 5 1. On the Main Menu screen, select Advance Set by using the Up and Down keys on the LCD keypad. If the menu items shown in the figure below are not displayed on the Main Menu screen, you need to scroll down the screen by pressing the Down key. -

Page 134: Using Communications Toggle Functionality

7. Press the ESC key to return to the Advanced Set Menu screen, as shown in step Using Communications The MicroLogix 1400 provides the Communications Toggle Functionality, which allows you to change from the user-defined communication configuration Toggle Functionality to the default communications mode and back to the user defined communication configuration on Channel 0.

-

Page 135

Using the LCD Chapter 5 1. On the Main Menu screen, select Advanced Set by using the Up and Down keys on the LCD keypad, as shown below. If the menu items shown in the figure below are not displayed on the Main Menu screen, you need to scroll down the screen by pressing the Down key. -

Page 136: Configuring The Ip Address

Chapter 5 Using the LCD 5. When an IP address is not yet assigned to your controller, only the MAC address that is assigned to your controller, represented as XXXXXXXXXXXX below, is displayed. A MAC address is a 12-digit hexadecimal number. Your controller ships with a unique MAC address assigned in the factory.

-

Page 137

Using the LCD Chapter 5 1. On the Main Menu screen, select Advanced Set by using the Up and Down keys on the LCD keypad, as shown below. If the menu items shown in the figure below are not displayed on the Main Menu screen, you need to scroll down the screen by pressing the Down key. -

Page 138

Chapter 5 Using the LCD 4. The password screen is displayed. Press Up, Down, Left and Right keys to enter the Master password up to a maximum of 10 digits. In this example, the current Master password is allocated as «1234». 5. -

Page 139

Using the LCD Chapter 5 7. If the password is correct, the Ethernet network type screen is displayed as below. Press Up or Down key to select the appropriate Ethernet mode. If you press the OK key at the static mode, the IP address flashes. 8. -

Page 140: Configuring The Ethernet Port

Chapter 5 Using the LCD 10. After configuring the Gateway address, press the OK key. The Primary DNS is displayed. 11. After configuring the Primary DNS, press the OK key. The Secondary DNS is displayed. To exit the Network configuration Menu, press the ESC key on the LCD keypad at any time.

-

Page 141

Using the LCD Chapter 5 2. Press the OK key on the LCD keypad. The Advanced Settings Menu screen is displayed. 3. If ENET Cfg is selected, press the OK key. If not, select ENET Cfg using the Up and Down keys, and then press the OK key. 4. -

Page 142: Configuring Ethernet Protocol Setup

Chapter 5 Using the LCD 6. If the Master password is correct, the last configuration is displayed. In this example, the auto negotiation function is enabled and the 10/100Mbps link configuration is shown. 7. Press Up and Down key to select auto disable menu, then press the OK key. The fourth line on the LCD flashes.

-

Page 143

Using the LCD Chapter 5 1. On the Main Menu screen, select Advanced Set by using the Up and Down keys on the LCD keypad, as shown below. If the menu items shown in the figure below are not displayed on the Main Menu screen, you need to scroll down the screen by pressing the Down key. -

Page 144

Chapter 5 Using the LCD 5. The password screen is displayed. Press Up, Down, Left and Right keys to enter a Master password up to a maximum of 10 digits. In this example, the current Master password is allocated as «1234». After entering the Master password, press the OK key on the LCD keypad. -

Page 145: Using Trim Pots

Using Trim Pots Trim Pot Operation The MicroLogix 1400 controller provides two trimming potentiometers (trim pots, POT0 and POT1) which allow modification of integer data within the controller. The data value of each trim pot can be used throughout the control program for timers, counters, analog presets, depending upon the requirements of the application.

-

Page 146: Changing Data Value Of A Trim Pot

Chapter 5 Using the LCD Changing Data Value of a Trim Pot Follow these steps to change the data value of a trim pot, either POT0 or POT1. 1. On the Main Menu screen, select trim pot Set by using the Up and Down keys on the LCD keypad.

-

Page 147: Trim Pot Configuration In Lcd Function File

Trim Pot Configuration in LCD Function File The configuration for Trim Pots in the LCD Function File, including trim pot low and high values for data value range, is described in the MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001.

-

Page 148: Viewing System Information

Chapter 5 Using the LCD Viewing System The System Information screen of the LCD allows you to identify the system information for your controller. Information Follow these steps to view the system information for your controller. 1. On the Main Menu screen, select Advanced Set by using the Up and Down keys on the LCD keypad, as shown below.

-

Page 149: Viewing Fault Code

Using the LCD Chapter 5 Viewing Fault Code The Fault Code screen of the LCD displays the fault code when a fault occurs. When a fault occurs, the Fault Code screen is not displayed automatically. Only the FAULT LED on the controller flashes in red light. Therefore, you need to navigate into the Fault Code screen to identify the fault code on the LCD.

-

Page 150: Saving/Loading Communication Eeprom

Chapter 5 Using the LCD If a fault is occurred, its fault code is displayed, as shown below. For more information on a specific fault code, refer to the Online Help of your RSLogix 500/RSLogix Micro programming software. 5. Press the ESC key to return to the Advanced Set Menu screen, as shown in step Saving/Loading At the communication EEPROM screen, you can load/save user programs and…

-

Page 151

Using the LCD Chapter 5 3. Select Comms EEPROM using the Down key, and then press the OK key. 4. Select Store to MM to save user program and data, and then press the OK key. 5. If your controller is in a non-executing mode, skip to the next step. Otherwise switch your controller to a non-executing mode. -

Page 152

Chapter 5 Using the LCD 6. The usual method for using a memory module is to reuse the device. Select Reuse Device or Write Only by pressing the Up or Down keys. Once set to Write Only mode, write protection cannot be removed. If a IMPORTANT change is required, use a different memory module. -

Page 153: Loading Communication Eeprom

Using the LCD Chapter 5 Loading communication EEPROM Follow these steps to load user programs and data from the memory module to the controller’s memory. 1. Select Load from MM to load user programs and data. 2. If your controller is in a non-executing mode, skip to the next step. Otherwise switch your controller to a non-executing mode.

-

Page 154: Configuring Contrast Value

Chapter 5 Using the LCD Configuring contrast value 1. On the Main Menu screen, select Advanced Set by using the Up and Down keys on the LCD keypad. If the menu items shown are not displayed on the Main Menu screen, scroll down by pressing the Down key.

-

Page 155: Configuring The Backlight

Using the LCD Chapter 5 Configuring the backlight 1. On the Main Menu screen, select Advanced Set by using the Up and Down keys on the LCD keypad. If the menu items shown are not displayed on the Main Menu screen, scroll down by pressing the Down key.

-

Page 156: Protocol Configuration

Chapter 5 Using the LCD Protocol Configuration The following section provides a step-by-step guide on how to change the Modbus Node address. Modbus RTU Slave Node Address The user can set the Modbus RTU Slave Node address for Channel 0 or 2. The node address change will only be applicable after a power cycle.

-

Page 157

Using the LCD Chapter 5 3. Select the Protocol Cfg using the Up and Down arrow keys, and then press the OK key. 4. Select the Modbus RTU Sl and then press the OK key. 5. The Modbus RTU Slave screen is displayed. Channel 0 is selected below. 6. -

Page 158

Chapter 5 Using the LCD 7. If the channel selected is not configured with the Modbus RTU Slave driver, then Modbus Not Configured is displayed, as shown below. 8. If channel 0 is configured with the Modbus RTU Slave driver with node address 100, the following screen will appear as shown. -

Page 159

Using the LCD Chapter 5 Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 160

Chapter 5 Using the LCD Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 161: Real-Time Clock Operation

For more information on “Real-Time Clock Function File” and “Memory Module Information File”, refer to the MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001. One type of memory module is available for use with the MicroLogix 1400 controller. Catalog Number Function…

-

Page 162: Rtc Battery Operation

Chapter 6 Using Real-Time Clock and Memory Modules RTC Battery Operation The real-time clock uses the same replaceable battery that the controller uses. The RTC Function File features a battery low indicator bit (RTC:0/BL), which shows the status of the replacement battery. When the battery is low, the indicator bit is set (1).

-

Page 163: User Program , User Data, Datalog And Recipe Back-Up

(run or test) mode. To enable this feature, set the S:2/9 bit in the system status file. See “Status System File” in the MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, Publication 1766-RM001 for more information.

-

Page 164: Removal/Insertion Under Power

If a memory module is installed while the MicroLogix 1400 is executing, the memory module is not recognized until either a power cycle occurs, or until the controller is placed in a non-executing mode (program mode, suspend mode or fault condition).

-

Page 165: Editing User

At least one download is required before you can start online editing. Editing User If you are using a MicroLogix 1400 from out-of-box state or after clearing processor memory or a firmware upgrade, at least one download is required before starting online edits. If not, an error occurs and programming software will go offline due to a default image mismatch between programming software (RSLogix500) and the MicroLogix 1400.

-

Page 166: Types Of Online Editing

LCD screen in the RUN mode. This prevents the use of the online editing feature. Types of Online Editing The type of online editing is dependent on the MicroLogix 1400 processor’s mode switch position in LCD display and the processor’s mode. There are two types of online editing: •…

-

Page 167: Edit Functions In Runtime Online Editing

Online Editing Chapter 7 ATTENTION: Use the online editing function while in the RUN mode to make minor changes to the ladder program. We recommend developing your program offline since ladder rung logic changes take effect immediately after testing your edits. Improper machine operation may occur, causing personnel injury or equipment damage.

-

Page 168

Chapter 7 Online Editing Notes: Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 169: Specifications For Inputs

Appendix Specifications General Specifications Description 1766-L32AWA/A 1766-L32BWA/A 1766-L32BXB/A Dimensions 90 x 180 x 87 mm HxWxD 3.5 x 7.08 x 3.43 in. Shipping weight 0.9 kg (2.0 lbs) Number of I/O 24 inputs (20 digital and 4 analog) and 14 outputs (12 digital and 2 analog) Power supply voltage 100…240V AC (-15%, +10%) at 47…63 Hz 24V DC (-15%, +10%) Class 2 SELV…

-

Page 170

Appendix A Specifications Description 1766-L32AWA/A 1766-L32BWA/A, 1766-L32BXB/A Inputs 0 through 11 Inputs 12 and higher (12 high-speed DC inputs) (8 standard DC inputs) Off-State Leakage Current 2.5 mA max. 0.1 mA max 1.5 mA max. Nominal Impedance 12 kΩ at 50 Hz 2.0 kΩ… -

Page 171

Specifications Appendix A Relay and FET Outputs Description 1766-L32AWA/A, 1766-L32BXB/A 1766-L32BWA/A Maximum controlled load 1440 VA 1080 VA Maximum Continuous Current: Current per channel and group 2.5 A per channel 2.5 A per channel common 8A max channel 8…11 common Current per at 150V max 28 A or total of per-point… -

Page 172

Appendix A Specifications Figure 1 — MicroLogix 1400 DC Input Power Requirements for 1766-L32BXB/A Unit 1766-L32BXB/A Typical Power Requirements Calculated Expansion I/O Power Load (Watts) Figure 2 — 1766-L32BXB, 1766-L32BXBA FET Output Maximum output current (temperature dependent): FET Current per Point FET Total Current 1.75… -

Page 173

Specifications Appendix A AC Input Filter Settings Nominal Filter Setting (ms) ON Delay (ms) OFF Delay (ms) Minimum Maximum Minimum Maximum High-Speed DC Input Filter Settings (Inputs 0 to 11) Nominal Filter Setting (ms) ON Delay (ms) OFF Delay (ms) Maximum Counter Frequency (Hz) 50% Duty Cycle Minimum… -

Page 174: Working Voltage

Appendix A Specifications Working Voltage Working Voltage for 1766-L32AWA/A Description Recommendation Power Supply Input to Backplane Verified by one of the following dielectric tests: 1836V AC for 1 second or 2596V DC for 1 second Isolation 265V AC Working Voltage (IEC Class 2 reinforced insulation) Input Group to Backplane Isolation Verified by one of the following dielectric tests:1517V AC for 1 second or 2145V DC for 1 second 132V AC Working Voltage (IEC Class 2 reinforced insulation)

-

Page 175: Expansion I/O Specifications

Specifications Appendix A Expansion I/O Digital I/O Modules Specifications General Specifications Specification Value Dimensions 90 mm (height) x 87 mm (depth) x 40.4 mm (width) height including mounting tabs is 110 mm 3.54 in. (height) x 3.43 in. (depth) x 1.59 in. (width) height including mounting tabs is 4.33 in.

-

Page 176

Appendix A Specifications (2) Conducted Immunity frequency range may be 150 kHz to 30 MHz if the Radiated Immunity frequency range is 30…1000 MHz. Input Specifications Specification 1762-IA8 1762-IQ8 1762-IQ16 1762-IQ32T 1762-IQ8OW6 Shipping weight, approx. 209 g (0.46 lbs.) 200 g (0.44 lbs.) 230 g (0.51 lbs.) 200g (0.44 lbs.) 280g (0.62 lbs.) -

Page 177

Specifications Appendix A Input Specifications Specification 1762-IA8 1762-IQ8 1762-IQ16 1762-IQ32T 1762-IQ8OW6 Vendor I.D. code Product type code Product code (1) Sinking/Sourcing Inputs — Sourcing/sinking describes the current flow between the I/O module and the field device. Sourcing I/O circuits supply (source) current to sinking field devices. -

Page 178

Appendix A Specifications Output Specifications Specification 1762-OA8 1762-OB8 1762-OB16 1762-OB32T 1762-OV32T Output group to Verified by one of the Verified by one of the following dielectric tests: Verified by one of the following dielectric tests: backplane isolation following dielectric 1200V AC for 1 s or 1697V DC for 1 s. 1200V AC for 2 s or 1697V DC for 2 s. -

Page 179

Specifications Appendix A Output Specifications Specification 1762-OW8 1762-OW16 1762-OX6I 1762-IQ8OW6 Continuous current per 7 A (Also see “Relay common, max. Contact Ratings” on page 157.) Continuous current per 16 A 16 A 30A (Also see Module module, max. Load Ratings 1762-OX6I on page 166.) Surge current, max. -

Page 180

Appendix A Specifications (1) The continuous current per module must be limited so the module power does not exceed 1440VA. (2) 6 A in ambient temperatures above 40 °C (104.°F) (3) Surge Suppression – Connecting surge suppressors across your external inductive load will extend the life of the relay contacts. -

Page 181: Analog Modules

Specifications Appendix A Analog Modules Common Specifications Specification 1762-IF2OF2, 1762-IF4, 1762-IR4, 1762-IT4 and 1762-OF4 Dimensions 90 mm (height) x 87 mm (depth) x 40 mm (width) height including mounting tabs is 110 mm 3.54 in. (height) x 3.43 in. (depth) x 1.58 in. (width) height including mounting tabs is 4.33 in.

-

Page 182: Rockwell Automation Publication 1766-Um001I-En-P — June

Appendix A Specifications General Specifications Specification 1762-IF2OF2 1762-IF4 1762-OF4 1762-IR4 1762-IT4 Shipping weight, 240 g (0.53 lbs.) 235 g (0.517 lbs.) 260 g (0.57 lbs.) 220 g (0.53 lbs.) approx. (with carton) Bus current draw, max. 40 mA at 5V DC 40 mA at 5V DC 40 mA at 5V DC 40 mA at 5V DC…

-

Page 183

Specifications Appendix A Input Specifications Specification 1762-IF2OF2 1762-IF4 1762-IR4 1762-IT4 Number of inputs 2 differential (unipolar) 4 differential (bipolar) 4 input channels plus 1 CJC sensor Update time (typical) 2.5 ms 130, 250, 290, 450, 530 ms Input filter and cofiguration (selectable) dependent A/D converter type… -

Page 184

Appendix A Specifications Input Specifications 1762-IR4 Specification 1762-IR4 ·100 Ω Platinum 385 Input types ·200 Ω Platinum 385 ·500 Ω Platinum 385 ·1,000 Ω Platinum 385 ·100 Ω Platinum 3916 ·200 Ω Platinum 3916 ·500 Ω Platinum 3916 ·1,000 Ω Platinum 3916 ·10 Ω… -

Page 185

Specifications Appendix A Input Specifications 1762-IR4 Specification 1762-IR4 Maximum overload at input terminals ±35V DC continuous 25 Ω (Operating with >25 Ω will reduce accuracy.) Cable impedance, max. Channel to channel isolation ±10V DC (1) Accuracy is dependent upon the Analog/Digital converter filter rate selection, excitation current selection, data format, and input noise. (2) Open-circuit detection time is equal to channel update time. -

Page 186

Appendix A Specifications (1) (2) 1762-IT4 Repeatability at 25 °C (77 °F) Input Type Repeatability for 10 Hz Filter Thermocouple J ±0.1 °C [±0.18 °F] Thermocouple N (-110…1300 °C [-166…2372 °F]) ±0.1 °C [±0.18 °F] Thermocouple N (-210…-110 °C [-346…-166 °F]) ±0.25 °C [±0.45 °F] Thermocouple T (-170…400 °C [-274…752 °F]) ±0 .1 °C [±0.18 °F]… -

Page 187

Specifications Appendix A 1762-IT4 Accuracy Input Type With Autocalibration Enabled Without Autocalibration (2) (3) Accuracy for 10 Hz, 50 Hz and 60 Hz Maximum Temperature Drift Filters (max.) at 25 °C [77 °F] at 0…60 °C at 0…60 °C [32…140 °F] Ambient [32…140 °F] Ambient… -

Page 188

Appendix A Specifications Valid Input/Output Data Word Formats/Ranges for 1762-IF2OF2 Normal Operating Range Full Scale Range RAW/Proportional Data Scaled-for-PID 0…10V DC 10.5V DC 32760 16380 0.0V DC 4…20 mA 21.0 mA 32760 16380 20.0 mA 31200 15600 4.0 mA 6240 3120 0.0 mA Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 189: Micrologix 1400 Replacement Kits

Appendix Replacement Parts This chapter contains the following information: • a table of MicroLogix 1400 replacement parts • procedure for replacing the lithium battery MicroLogix 1400 The table below provides a list of replacement parts and their catalog number. Replacement Kits…

-

Page 190

Appendix B Replacement Parts Battery compartment Battery 1762 I/O expansion bus connector Battery wire connector Battery connector Battery wires 44522 Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 191: Battery Handling

Replacement Parts Appendix B Battery Handling Follow the procedure below to ensure proper battery operation and reduce personnel hazards. • Use only for the intended operation. • Do not ship or dispose of cells except according to recommended procedures. • Do not ship on passenger aircraft. ATTENTION: •…

-

Page 192

Appendix B Replacement Parts cargo-only aircraft, providing certain conditions are met. Transport by passenger aircraft is not permitted. A special provision of DOT-E7052 (11th Rev., October 21, 1982, par. 8-a) provides that: “Persons that receive cell and batteries covered by this exemption may reship them pursuant to the provisions of 49 CFR 173.22a in any of these packages authorized in this exemption including those in which they were received.”… -

Page 193: Disposal

Replacement Parts Appendix B Disposal ATTENTION: Do not incinerate or dispose of lithium batteries in general trash collection. Explosion or violent rupture is possible. Batteries should be collected for disposal in a manner to prevent against short-circuiting, compacting, or destruction of case integrity and hermetic seal.

-

Page 194

Appendix B Replacement Parts Notes: Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 195: Understanding The Controller Status Indicators

• analog expansion I/O diagnostics and troubleshooting • calling Rockwell Automation for assistance Understanding the The MicroLogix 1400 provides three groups of status indicators: • the status LEDs on the top of the controller, Controller Status Indicators • the status indicators on the LCD •…

-

Page 196: Status Indicators On The Lcd

Appendix C Troubleshooting Your System Controller LED Indicators Color Indicates FAULT No fault detected red flashing Application fault detected Controller hardware faulted FORCE No forces installed amber Forces installed amber flashing Forces installed in force files but forcing is disabled. Status Indicators on the LCD Figure 4 — Status Indicators on the LCD Status Indicators on the LCD…

-

Page 197: I/O Status Indicators On The Lcd

Troubleshooting Your System Appendix C When using a MicroLogix 1400 controller, the DCOMM LED applies only to Channel 0. I/O Status Indicators on the LCD Figure 5 — I/O Status Indicators on the LCD I/O LED screen on the LCD…

-

Page 198: Controller Error Recovery Model

Cycle power. Contact your local Allen-Bradley representative if the error LEDs on solid Error persists. Loose Wiring Verify connections to the controller. For error codes and Status File information, see MicroLogix 1400 Power LED on and Application fault Hardware/Software Programmable Controllers Instruction Set Reference Manual, Publication FAULT LED flashing Major Fault Detected 1766-RM001.

-

Page 199

Troubleshooting Your System Appendix C Identify the error code and Is the error Start description. hardware related? Refer to page 206 for Are the wire Tighten wire connections. probable cause and connections tight? recommended action. Does the Is the Power Clear Fault. -

Page 200: Analog Expansion I/O Diagnostics And Troubleshooting

Channel over-range or under-range conditions are reported in the module’s input data table. Module hardware errors are reported in the controller’s I/O status file. Refer to the MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001 for more information.

-

Page 201: Critical And Non-Critical Errors

Troubleshooting Your System Appendix C Critical and Non-Critical Errors Non-critical module errors are recoverable. Channel errors (over-range or under-range errors) are non-critical. Non-critical error conditions are indicated in the module input data table. Non-critical configuration errors are indicated by the extended error code. See Extended Error Codes for 1762-IF2OF2 on page 188.

-

Page 202: Error Codes

The type of error determines what kind of information exists in the extended error information field. These types of module errors are typically reported in the controller’s I/O status file. Refer to the MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001 for more information.

-

Page 203: Calling Rockwell Automation For Assistance

Troubleshooting Your System Appendix C Extended Error Codes for 1762-IF2OF2 Error Type Hex Equivalent Module Error Extended Error Error Description Code Information Code Binary Binary Hardware-Specific X210 0 0001 0000 Reserved Error Configuration Error X400 0 0000 0000 General configuration error; no additional information X401 0 0000 0001 Invalid input data format selected (channel 0)

-

Page 204

Appendix C Troubleshooting Your System • controller error codes (Refer to MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, Publication 1766-RM001 for error code information.) Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 205: Preparing For Firmware Upgrade

Appendix Using ControlFLASH to Upgrade Your Operating System The operating system (OS) can be upgraded through the Ethernet port of the controller. In order to download a new operating system, you must have the following: • ControlFLASH Upgrade Kit containing the new OS Go to http://www.ab.com/programmablecontrol/plc/micrologix/downloads.ht to download the upgrade kit.

-

Page 206: Prepare The Controller For Firmware Upgrade

Appendix D Using ControlFLASH to Upgrade Your Operating System Prepare the Controller for Firmware Upgrade 1. It is important that the SNMP server is enabled before the firmware upgrade begins. You can check if the SNMP server is enabled by looking at the Channel Configuration page for Channel 1 in RSLogix 500/RSLogix Micro.

-

Page 207: Using Controlflash For Firmware Upgrade

Using ControlFLASH to Upgrade Your Operating System Appendix D 2. Ensure that you complete the IP configuration for the OS firmware upgrade. Note the assigned IP address of the controller. If the IP address is not configured you can still perform the IP configuration using Static, BOOTP or DHCP settings.

-

Page 208

Appendix D Using ControlFLASH to Upgrade Your Operating System The Welcome to ControlFLASH dialog box is displayed. 2. Click the Next button. 3. Select the appropriate catalog number from the Catalog Number dialog box and click the Next button. Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 209

Using ControlFLASH to Upgrade Your Operating System Appendix D The AB_SNMP.DLL — Enter IP Address dialog box is displayed. 4. Type in the IP address for the processor. Use the IP address that was configured earlier, or use an available IP IMPORTANT address assigned to by your network administrator. -

Page 210

Appendix D Using ControlFLASH to Upgrade Your Operating System For the IP address to be configured using the ControlFLASH BOOTP server, the BOOTP settings should be enabled in the controller, see step 2 of Prepare the Controller for Firmware Upgrade on page 192. 8. -

Page 211

Using ControlFLASH to Upgrade Your Operating System Appendix D 9. Click the OK button. 10. Select the appropriate revision from the Firmware Revision dialog box and click the Next button. Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 212

Appendix D Using ControlFLASH to Upgrade Your Operating System The Summary dialog box is displayed. 11. Click the Finish button. The ControlFLASH dialog box is displayed. 12. Click the Yes button. If your computer has more than one Ethernet interface installed, the following dialog box displays the assigned IP addresses of each of the listed Ethernet interfaces. -

Page 213

Using ControlFLASH to Upgrade Your Operating System Appendix D 14. You may need to wait several seconds before the Progress dialog box is displayed. (A typical sequence is shown below). While the download is in progress, the RUN LED, FAULT LED and FORCE LED display a Walking Pattern (First RUN LED ON, then FAULT LED ON and then FORCE LED ON in sequence). -

Page 214

Appendix D Using ControlFLASH to Upgrade Your Operating System The LCD displays this screen: The Run, Fault and Force LEDs display a walking Pattern. Stage 3 The LCD displays this screen: At this stage the Power and Force LEDs are solid ON. After flashing of the controller, the LCD shows this screen: Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 215

Using ControlFLASH to Upgrade Your Operating System Appendix D 15. After the flashing is complete, the following dialog box prompts you to wait for the controller to reset, verify that the POWER LED is solid GREEN and verify the FAULT LED is turned OFF. 16. -

Page 216

Appendix D Using ControlFLASH to Upgrade Your Operating System The Update Status dialog box is displayed. If the update was successful, the status text box is green and has an appropriate message. If the update was not successful, the status text box is red and has an appropriate message. -

Page 217: Controlflash Error Messages

Using ControlFLASH to Upgrade Your Operating System Appendix D 18. Click the OK button. You are returned to the Welcome to ControlFLASH dialog box. 19. You can continue to upgrade additional controllers by clicking the Next button, or exit the program by clicking the Cancel button. If you click cancel, you are asked to verify that you want to end the update session.

-

Page 218

Appendix D Using ControlFLASH to Upgrade Your Operating System This error message is displayed if the ControlFLASH tool is unable to match the processor to the catalog number that was selected in the Catalog Number dialog box. To clear this error: 1. -

Page 219: Missing Or Corrupt Os State

Using ControlFLASH to Upgrade Your Operating System Appendix D To clear this error: 1. Connect the controller’s Ethernet port directly to the computer’s Ethernet port using a crossover cable, or disable or uninstall any firewall VPN or virus protection software running on the computer. 2.

-

Page 220: Recovering From Missing Or Corrupt Os State

Appendix D Using ControlFLASH to Upgrade Your Operating System • The POWER LED is solid ON and the RUN, FAULT and FORCE LEDs are blinking simultaneously. The LCD shows this information: • The POWER and FAULT LED are solid ON and the LCD shows this information: When the LCD displays the Fpga Corrupt information, the LEDs do not show the Walking pattern during the firmware upgrade process.

-

Page 221: Communication Interface

• Modbus RTU Master/Slave • ASCII • DNP3 Slave RS-232 Communication The communications port on Channel 0 of the MicroLogix 1400 controller utilizes a combined, isolated RS-232/485 interface. RS-232 and RS-485 are Interface Electronics Industries Association (EIA) standards that specify the electrical and mechanical characteristics for serial binary communication.

-

Page 222: Df1 Half-Duplex Protocol

RS-232 point-to-point communication is required. DF1 protocol controls message flow, detects and signals errors, and retries if errors are detected. Example DF1 Full-Duplex Connections For information about required network connecting equipment, see Chapter Communication Connections. MicroLogix 1400 Personal Computer Personal Computer Modem cable 1761-CBL-PM02 MicroLogix 1400…

-

Page 223

(including the master) on the DF1 Half-Duplex link. MicroLogix 1400 can act as the master or as a slave on a Half-Duplex network. When the MicroLogix 1400 is a slave device, a master device is required to “run”… -

Page 224: Considerations When Communicating As A Df1 Slave

Radio modems may be implemented in a point-to-point topology supporting either Half-Duplex or Full-Duplex communications, or in a multi-drop topology supporting Half-Duplex communications between three or more modems. MicroLogix 1400 also supports DF1 Radio Modem protocol. Rockwell Automation Publication 1766-UM001I-EN-P — June 2015…

-

Page 225: Communication Protocol

“Half-Duplex Modem”. MicroLogix 1400 controllers also support DCD (Data Carrier Detect) line for DF1 Radio Modem protocol. For other protocols, you can only access the DCD signal from your ladder logic. No other modem handshaking lines (such as Data Set Ready and Data Terminal Ready) are supported by MicroLogix 1400 controller.

-

Page 226: Dh-485 Configuration Parameters

Appendix E Connecting to Networks via RS-232/RS-485 Interface • maximum network segment of 1,219 m (4,000 ft.) The DH-485 protocol supports two classes of devices: initiators and responders. All initiators on the network get a chance to initiate message transfers. To determine which initiator has the right to transmit, a token passing algorithm is used.

-

Page 227: Important Dh-485 Network Planning Considerations

Connecting to Networks via RS-232/RS-485 Interface Appendix E Devices that Support DH-45 Network Catalog Description Installation Function Publication Number 1746-BAS BASIC Module SLC Chassis Provides an interface for SLC 500 devices to foreign devices. Program in 1746-UM004 BASIC to interface the 3 channels (2 RS232 and 1 DH-485) to printers, 1746-PM001 modems, or the DH-485 network for data collection.

-

Page 228

Appendix E Connecting to Networks via RS-232/RS-485 Interface (8000 ft.). For additional information on connections using the AIC+, refer to the Advanced Interface Converter (AIC+) User Manual, publication 1761-6.4. Planning Cable Routes Follow these guidelines to help protect the communication cable from electrical interference: •… -

Page 229

Connecting to Networks via RS-232/RS-485 Interface Appendix E Software Considerations Software considerations include the configuration of the network and the parameters that can be set to the specific requirements of the network. The following are major configuration factors that have a significant effect on network performance: •… -

Page 230

Appendix E Connecting to Networks via RS-232/RS-485 Interface Setting Node Addresses The best network performance occurs when node addresses are assigned in sequential order. Initiators, such as personal computers, should be assigned the lowest numbered addresses to minimize the time required to initialize the network. -

Page 231: Example Dh-485 Connections

Use a 1763-NC01 Series A or later cable to connect a MicroLogix 1400 controller to a DH-485 network. You can connect a MicroLogix 1400 controller to your DH-485 network directly without using a RS-232 to RS-485 converter and optical isolator, such as the AIC+, catalog number 1761-NET-AIC, as shown in the illustration below, because Channel 0 has isolation and RS-485 built-in.

-

Page 232

DC SOURCE DC SOURCE DC SOURCE CABLE CABLE CABLE CABLE EXTERNAL EXTERNAL EXTERNAL EXTERNAL MicroLogix Personal MicroLogix MicroLogix 1400 MicroLogix 1000 Computer 1200 1500 DH-485 Network Belden, shielded, twisted-pair cable Belden, shielded, twisted-pair cable AIC+ TERM 1763-NC01 SHLD CHS GND… -

Page 233: Modbus Communication Protocol

You can use ASCII by configuring the RS-232/485 port, channel 0 and the RS-232 port, Channel 2 for the ASCII driver. Refer to the MicroLogix 1400 Programmable Controllers Instruction Set Reference Manual, publication 1766-RM001 for detailed configuration information.

-

Page 234

Appendix E Connecting to Networks via RS-232/RS-485 Interface Notes: Rockwell Automation Publication 1766-UM001I-EN-P — June 2015… -

Page 235: Micrologix 1400 Distributed

The default communication protocol for the Ethernet Channel 1 in the MicroLogix 1400 is Ethernet/IP. To communicate with DNP3 over IP protocol in the MicroLogix 1400 Series B controller, the channel must be configured to use the DNP3 protocol. The MicroLogix 1400 Series A controller supports DNP3 protocol via Channel 0 and/or Channel 2 Serial ports.

-

Page 236

Appendix F MicroLogix 1400 Distributed Network Protocol (DNP3) In RSLogix 500/RSLogix Micro, open Channel Configuration in the MicroLogix 1400 project tree. There are 4 configurations related to DNP3 protocol in RSLogix 500/RSLogix Micro software: • Channel 0 configuration • Channel 2 configuration •… -

Page 237: Channel 0 And Channel 2 Link Layer Configuration

MicroLogix 1400 Distributed Network Protocol (DNP3) Appendix F Channel 0 and Channel 2 Link Layer Configuration Link Layer related configuration can be done in the Channel 0 and/or Channel 2 tab. Rockwell Automation Publication 1766-UM001I-EN-P — June 2015…

-

Page 238: Channel 1 Link Layer Configuration