E5CSL/E5CWL

Temperature Controller

EN

Instruction Manual

Thank you for purchasing the OMRON E5CSL/E5CWL

Temperature Controller. This manual describes the functions,

performance, and application methods needed for optimum use

of the product.

Please observe the following items when using the product.

knowledge of electrical systems.

this manual to ensure correct use.

OMRON CORPORATION

©

All Rights Reserved

2113603-9B

Wiring

Model Number Legends

Dimensions (mm)

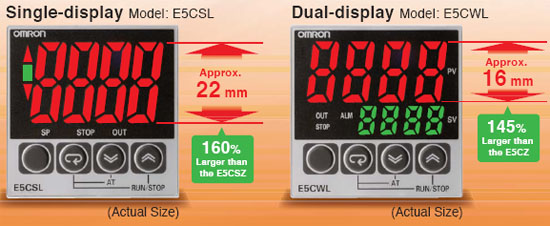

Models with Single Display Models with Dual Display

E5CSL-

E5CWL-

1

1 3

1

2 3

1

Control output

R

Relay output: 250 VAC, 3 A

Q

Voltage output (for driving SSR): 12 VDC, 21 mA

2

Alarm (E5CWL only)

1

Relay output: 250 VAC, 1 A (resistive load)

Sensor type

3

Package Contents

P

Platinum resistance thermometer (Pt100)

Front Panel Part Names and Functions

(1)

(5)

(3)

(7)

(6)

(4)

(6)

(7)

(9)

(10)

(9)

(8)

(11)

(8)

(12)

(13)

E5CSL

(14)

Operation Menu

Parameter Operations

POWER ON

Press

+

for at least

Press

for less

3 seconds.

than 1 second.

Press

Protect

Operation

+

Level

Level

for at least

1 second.

Operation/

25

o

a

p

t

Adjustment

PV/SP

Protect

SP

M

Initial

M

inpt

Setting

Protect

100

M

Set Point

Operation

*E5CSL only

o

k

p

t

SP

Protect

M

Alarm Value

al-1

*E5CWL only

M

r-s

RUN/STOP

Procedure for Changing E5CSL Settings

Press the U or D

setting is to be changed. The parameter setting display will appear.

Use the U or D

Example: Changing the Input Type from 0 to 1

in-t

0

U

D

U

Input Type

Parameter Setting

Parameter Display

Display

Parameter Tables

Step 1

Initial Setting Level: Used to set basic specifications.

Parameter name

Description

Display

in-t

Input Type

Set the input sensor type.

d-u

Temperature Unit

Set the unit for temperature input to Celsius (°C) or Fahrenheit (°F).

cntl

PID ON/OFF

Set either 2-PID control or ON/OFF control.

Set the time-proportional control period for the control output.

cp

Control Period

(Displayed only when PID control is selected.)

orev

Direct/Reverse Operation

Set either reverse option (heating control) or direct operation (cooling control).

alt1

Alarm Type

Set the alarm type.*E5CWL only.

Step 2

Operation Level: Used to monitor the process value and to set the set point, alarm value, etc.

Display

Parameter name

Description

PV/SP

Monitor the process value and set the set point.

al-1

Alarm value

Set the alarm value. The location of the decimal point depends on the input type. *E5CWL only.

*1

r-s

RUN/STOP

Start and stop control operation.

Step 3

Adjustment Level: Used to tune parameters and set control parameters.

Parameter name

Description

Display

l.adj

Adjustment Level

This display indicates that you have moved to Adjustment Level.

at

AT Execute/Cancel

Starts and stops autotuning. (Displayed only when PID control is selected.)

ins

Set a compensation value for the temperature input in increments of 0.1°C or 0.1°F.

Temperature Input Shift

p

Set the proportional band in increments of 0.1°C or 0.1°F.(Displayed only when PID control is selected.)

i

Integral Time

Set the integral time in increments of 1 s. (Displayed only when PID control is selected.)

d

Derivative Time

Set the derivative time in increments of 1 s. (Displayed only when PID control is selected.)

of-r

Manual Reset Value

Set the manipulated value to use for P or PD control (I = 0). The offset will be canceled.

Set the hysteresis to use to achieve stable operation when switching the control output

hys

Hysteresis

ON/OFF during ON/OFF control. (Displayed only when ON/OFF control is selected.)

Step 4

Protect Level: Used to set parameters to restrict key operations.

Display

Parameter name

Description

oapt

Operation/Adjustment Protect

Set protection for Operation Level and Adjustment Level.

inpt

Initial Setting Protect

Set protection for Initial Setting Level.

okpt

*2: The setting cannot be changed during autotuning. Autotuning will be stopped if you move to Initial Setting Level or stop control operation.

Displays during Autotuning

E5CSL: The current deviation indicator will flash.

E5CWL: The AT Execute/Cancel characters on display No. 1 and the PV/SP characters on display No. 2 will flash.

Safety Precautions

Indicates a potentially hazardous situation which, if not avoided, is

CAUTION

likely to result in minor or moderate injury or property damage. Read

this manual carefully before using the product.

Warning Symbols

CAUTION

Do not touch the terminals while power is being supplied.

Doing so may occasionally result in minor injury due to electric shock.

Do not allow pieces of metal, wire clippings, or fine metallic shavings or filings from installation to enter the

product. Doing so may occasionally result in electric shock, fire, or malfunction.

Do not use the product where subject to flammable or explosive gas. Otherwise, minor injury from explosion may

occasionally occur.

Never disassemble, modify, or repair the product or touch any of the internal parts. Minor electric shock, fire, or

malfunction may occasionally occur.

If the output relays are used past their life expectancy, contact fusing or burning may occasionally occur. Always

consider the application conditions and use the output relays within their rated load and electrical life expectancy.

The life expectancy of output relays varies considerably with the output load and switching conditions.

Tighten the terminal screws to between 0.74 and 0.90 N·m. Loose screws may occasionally result in fire.

Set the parameters of the product so that they are suitable for the system being controlled. If they are not

suitable, unexpected operation may occasionally result in property damage or accidents.

A malfunction in the Temperature Controller may occasionally make control operations impossible or prevent

alarm outputs, resulting in property damage. To maintain safety in the event of malfunction of the Temperature

Controller, take appropriate safety measures, such as installing a monitoring device on a separate line.

Suitability for Use

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination

CL1

of the products in the customer’s application or use of the product. Take all necessary steps to determine the suitability

See also product catalog for Warranty and Limitation of Liability.

48×48

64

4

60

58

Adapter

Solderless terminal size: M3.5

Terminal Cover: E53-COV19 (sold separately)

*The dimensions are the same for the E5CSL.

Front Panel: E53-COV20 (sold separately)

(1)

(2)

(10)

(11)

(12)

(13)

E5CWL

(14)

Press

for at least 1 second.

Press

for at least 3 seconds.

Adjustment

Initial Setting

Level

Level

Adjustment

l.adj

i

n

—

t

Input Type

Level

M

M

AT Execute/

Temperature

at

d-u

Cancel

Unit

M

M

Temperature

i

n

s

cntl

PID ON/OFF

Input Shift

M

M

Proportional

p

cp

Control Period

M

M

Direct/Reverse

i

oreV

Integral Time

Operation

M

M

Derivative

d

alt1

Alarm Type

Time

*E5CWL only

M

Manual Reset

of-r

Value

M

hys

Hysteresis

d-u

1

1

After

M

2 seconds

Setting confirmed.

Next Parameter Display

Setting/monitoring range

Default

*Refer to table on the right.

0 or 8

c(°C)/f(°F)

°C

ON/OFF

onof/pid

20 or 2 (s)

0.5, 1 to 99

or-r (reverse control)

Or-r

or-d (direct control)

(reverse control)

*Refer to table on the right.

2 (Deviation upper limit)

Setting/monitoring range

Default

SV: 0 (°C)

-1999 to 9999

0 (°C)

run/stop

RUN

Setting/monitoring range

Default

*1*2

off/on

OFF

-199.9 to 999.9

0.0 (°C)

0.1 to 999.9

8.0 (°C)

0 to 3999

233 (s)

0 to 3999

40 (s)

0.0 to 100.0

50.0 (%)

0.1 to 999.9

1.0 (°C)

Setting/monitoring range

Default

0

*Refer to table on the right.

1

*Refer to table on the right.

0

*Refer to table on the right.

Precautions for Safe Use

Be sure to observe the following precautions to prevent operation failure, malfunction, or adverse affects on

the performance and functions of the product. Not doing so may occasionally result in unexpected events.

(1) The product is designed for indoor use only. Do not use the product outdoors or in any of the following

locations.

Places directly subject to heat radiated from heating equipment.

Places subject to splashing liquid or oil atmosphere.

Places subject to direct sunlight.

Places subject to dust or corrosive gas (in particular, sulfide gas and ammonia gas).

Places subject to intense temperature change.

Places subject to icing and condensation.

Places subject to vibration and large shocks.

(2) Use/store within the rated temperature and humidity ranges.

Provide forced-cooling if required.

(3) To allow heat to escape, do not block the area around the product.

Do not block the ventilation holes on the product.

(4) Be sure to wire properly with correct polarity of terminals.

(5) Use specified size (M3.5, width 7.2 mm or less) crimped terminals for wiring. To connect bare wires to

the terminal block, use copper braided or solid wires with a rated temperature of over 70°C and a

gauge of AWG24 to AWG14 (equal to a cross-sectional area of 0.205 to 2.081 mm

length is 5 to 6 mm.) Up to two wires of same size and type, or two crimped terminals can be inserted

into a single terminal.

(6) Do not wire the terminals which are not used.

(7) Allow as much space as possible between the controller and devices that generate a powerful high-

frequency or surge.

Separate the high-voltage or large-current power lines from other lines, and avoid parallel or common

wiring with the power lines when you are wiring to the terminals.

(8) Use this product within the rated load and power supply.

(9) Make sure that the rated voltage is attained within two seconds of turning ON the power using a switch

or relay contact. If the voltage is applied gradually, the power may not be reset or output malfunctions

may occur.

(10) Make sure that the Controller has 30 minutes or more to warm up after turning ON the power before

starting actual control operations to ensure the correct temperature display.

(11) A switch or circuit breaker should be provided close to this unit.

The switch or circuit breaker should be within easy reach of the operator, and must be marked as a

disconnecting means for this unit.

(12) Do not use paint thinner or similar chemical to clean with. Use standard grade alcohol.

(13) Design system (control panel, etc) considering the 2 second of delay that the controller’s output to be

set after power ON.

(14) The output may turn OFF when shifting to certain levels. Take this into consideration when performing

control.

(15) The number of non-volatile memory write operations is limited.

Installation (mm)

Individual Mounting

44.8×44.8

+0.6

45

0

+0.6

45

0

60 min.

Insert the Controller through the hole in the panel. Push the adapter on from the

rear to secure the Controller.

Make sure that the surrounding temperature does not exceed the allowable

operating temperature given in the specifications, especially when two or more

Controllers are mounted.

(1) Display No. 1

Displays the process value (PV) or parameter. For the E5CSL,

the set point or parameter setting is also displayed.

(2) Display No. 2

Displays the set point (SP) or parameter setting.

(3) Deviation Indicators

Show the relation between the process value and the set point.

Lit: The process value is more than 5°C/°F higher than the set point.

Lit: The process value is more than 5°C/°F lower than the set point.

Lit: The process value is within 5°C/°F of the set point.

The relevant deviation indicator will flash during autotuning.

(4) SP

Lit while the set point is displayed on display No. 1 (E5CSL only).

(5) ALM

Lit while the alarm is ON. Not lit while the alarm is OFF.

(6) OUT

Lit while the control output is ON. Not lit while the control output is OFF.

(7) STOP

Not lit during operation. Lit while operation is stopped.

(8) O

(9) M

Alarms

Positive alarm

Setting

Alarm type

value (X)

0

No alarm

ON

1

Deviation upper/lower limit

OFF

ON

2

Deviation upper limit

OFF

ON

3

Deviation lower limit

OFF

ON

4

Deviation upper/lower range

OFF

Deviation upper/lower limit

ON

5

OFF

Deviation upper limit standby

ON

6

OFF

Deviation lower limit standby

ON

7

OFF

ON

8

Absolute value upper limit

OFF

0

ON

9

Absolute value lower limit

OFF

0

Absolute value upper limit

ON

10

OFF

0

Absolute value lower limit

ON

11

OFF

0

Do not set.

12

The default alarm type is 2.

Input type: Thermocouple

Input

Setting

Setting range (°C)

Setting range (°F)

0

200 to 1300

300 to 2300

1

20.0 to 500.0

0.0 to 900.0

2

100 to 850

100 to 1500

3

20.0 to 400.0

0.0 to 750.0

200 to 400

4

300 to 700

T

199.9 to 400.0

199.9 to 700.0

5

R

6

0 to 1700

0 to 3000

S

7

0 to 1700

0 to 3000

The default input type is 0.

Input type: Platinum Resistance Thermometer

Input

Setting

Setting range (°C)

Setting range (°F)

8

200 to 850

300 to 1500

Pt100

9

199.9 to 500.0

199.9 to 900.0

The default input type is 8.

Troubleshooting

Display

Meaning

s.err

Check the wiring of inputs, disconnections, short circuits

*1

Input error

(S.ERR)

and input type.

e111

RAM memory error

Turn the power OFF then back ON again.

(E111)

e111/sum

Non-volatile memory

Press the U and D

*3

(E111)/(SUM)

memory error

initialize the settings and clear the non-volatile memory error.

The control output and the alarm output will turn OFF when an error occurs.

(For s.err, the alarm output will be processed for a high temperature error.)

If the input value exceeds the display limit (-1999 to 9999) but it is still within the control range,

[[[[ will be displayed for values under -1999.

Under these conditions, the control output and alarm output will operate normally.

*1: This error is displayed only when the process value and set point are displayed.

*2: If the display does not change, the Controller needs to be repaired.

If operation returns to normal, then noise may have caused the problem. Check for noise.

*3: On the E5CSL, e111 and sum will alternate on the display at 1-second intervals.

On the E5CWL, e111 will be displayed on display No. 1 and sum will be displayed on display No. 2.

2

). (The stripping

Connections

Control Output

Side-by-side Mounting

Relay output: 250 VAC, 3 A (resistive load)

+1.0

0

Voltage output (for driving SSR): 12 VDC, 21 mA

Control output

+0.6

45

0

A

DO NOT

Recommended panel thickness is 1 to 5 mm.

USE

Pt input

TC input

The voltage output (control output) is not electrically isolated from the internal

wiring. One or the other of the control output terminals must therefore be left

ungrounded when using a grounded thermocouple thermometer. (If both are

grounded, measurements will be unreliable due to sneak current.)

(10) D

(11) U

(12) O+M

Press these keys for at least 3 seconds in Operation Level or Adjustment Level to go to Protect Level.

Press these keys for at least 1 second in Protect Level to return to Operation Level.

(13) M+D

Press these keys for at least 2 seconds to start or stop autotuning.*1

(14) M+U

Press these keys for at least 2 seconds to start or stop operation.*2

*1: These keys are disabled when starting and stopping autotuning has been disabled with operation control key protection.

*2: These keys are disabled when starting and stopping operation has been disabled with operation control key protection.

Deviation/ab

Deviation Alarm

Negative alarm

solute value

Use a deviation alarm to link the alarm to the SP.

value (X)

alarm

If the SP is changed, the alarm operating point will also change.

Output OFF

Set this difference.

X

X

Deviation

Always ON

alarm

SP

X

X

Deviation

ON

Absolute Value Alarm

OFF

alarm

SP

SP

Use an absolute value alarm when the alarm is not linked to the SP.

X

X

Deviation

ON

Set the alarm operating point as the temperature (absolute value).

OFF

alarm

SP

SP

X

X

Deviation

Always OFF

alarm

SP

X

X

Deviation

Always OFF

alarm

SP

X

X

The alarm is blocked until the first safe-state is reached.

Deviation

ON

OFF

alarm

Unwanted alarm during start-up are prevented.

SP

SP

X

X

Deviation

ON

alarm

OFF

SP

SP

X

X

Absolute

ON

OFF

value alarm

Alarm value

0

X

X

Absolute

ON

value alarm

OFF

0

X

X

Absolute

ON

value alarm

OFF

0

Absolute

X

X

ON

value alarm

OFF

0

Operation is started (power is turned ON or operation is switched from stop to run).

The alarm value is changed.

The temperature input offset is changed.

The set point is changed.

Protection

Operation/Adjustment Protection

Initial Setting Protection

Setting

Level

0

2

1

3

Initial Setting Level

Process value

Operation

PV/SP

Default: 1

Level

: Can be displayed and changed.

Others (Alarm Value)

: Display or changing to another level is not possible.

Adjustment Level

Default: 0

: Can be displayed and changed.

Operation Control

: Can only be displayed.

: Display or changing to another level is not possible.

AT Execute/Cancel (M+D)

RUN/STOP

Default: 0

: Operation control keys are enabled but operation control using

parameters is disabled.

: Operation control keys are disabled but operation control using

parameters is enabled.

: Operation control keys and operation control using parameters

are disabled.

Action

Conformance to EN/IEC Standards

This is a class A product.

In residential areas it may cause radio interference, in which case the user

*2

may be required to take adequate measures to reduce interference.

*2

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp The Netherlands

Phone 31-2356-81-300

FAX 31-2356-81-388

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg, IL 60173-5302 U.S.A

Phone 1-847-843-7900

FAX 1-847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Phone 65-6835-3011

FAX 65-6835-2711

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku, Kyoto 600-8530 JAPAN

Specifications

Power supply voltage

100 to 240 VAC, 50/60 Hz

Operating voltage range

85% to 110% of the rated voltage

Power consumption

Approx. 3.5 VA

Sensor type

Platinum resistance thermometer: Pt100

( 0.5% of indication value or 1 C, whichever is greater)

Indication accuracy

1 digit max.

(ambient temperature: 23°C)

R, S thermocouple at 200 C or less: 3 C 1 digit max.

100 C or less: 2 C 1 digit max.

Relay output: 250 VAC, 3 A (resistive load)

Control output

Voltage output (for driving SSR): 12 VDC

+25%/ 15%, 21 mA

Alarm output

Relay output: 250 VAC, 1 A (resistive load)

ON/OFF or 2-PID control

Control method

Electrical life of relay

100,000 operations

Sampling period

250 ms

Malfunction vibration

2

10 to 55 Hz, 20 m/s

Vibration resistance

10 to 55 Hz, 20 m/s

2

100 m/s

2

Malfunction shock

300 m/s

2

Shock resistance

Ambient temperature

Ambient humidity

25% to 85%

Storage temperature

Altitude

2,000 m max.

T2A, 250 VAC, time-lag, low-breaking capacity

Recommended fuse

Weight

Approx. 100 g (Controller only)

Front panel: IP50, Rear case: IP20,

Degree of protection

Terminal section: IP00

Installation category II,

Installation environment

pollution degree 2 (as per IEC 61010-1)

Non-volatile memory

Memory protection

(number of write operations: 100,000)

1

2

7

3

8

Alarm Output

Relay output: 250 VAC, 1 A

(resistive load)

4

9

Input power supply:

100 to 240 VAC,

5

10

50/60 Hz

Alarm

operating

Linked

point

Set the difference

SP

(deviation) from the SP.

Fixed

Alarm

Set the temperature (absolute value)

operating

at which to output an alarm.

point

0

Alarm hysteresis

(always 0.2 C/ F)

Process value

Time

Setting

Level

1

2

0

Do not set.

Setting

0

1

2

3

4

(M+U)

Терморегулятор Omron E5CWL — базовый электронный регулятор температуры, который используется в сушильных шкафах и печах под маркой СНОЛ. Прибор обладает двухстрочным дисплеем с отображением заданной и текущей температуры на экране. Отличительные особенности терморегулятора Omron E5CWL:

— автонастройка параметров прибора;

— напряжение питания 100-240AC;

— высокая частота дискретизации: 250 мс;

— 2 Пид регулирование;

— размер панели 48х48х60;

— работа с термопарами типа: «J», «K», «T»,»S», «R»;

— сверхчеткий семисегментный дисплей высотой их на экране размером 16,2 мм.

Инструкцию на русском языке к терморегулятору Omron E5CWL Вы можете запросить связавшись с нашими менеджерами.

| Модели регуляторов | |

| E5CWL-R1TC | тип датчика — термопара, релейный выход |

| E5CWL-R1P | тип датчика — термометр сопротивления, релейный выход |

| E5CWL-Q1TC | тип датчика — термопара, выход — напряжение |

| E5CWL-Q1P | тип датчика — термометр сопротивления, выход — напряжение |

Новые терморегуляторы Omron E5CSL и Omron E5CWL позволяют заметно снизить время настройки оборудования, т.к. позволяют пользователю сделать все настройки просто и быстро. Терморегуляторы E5CSL и E5CWL обеспечивают высокую производительность, что характерно всем терморегуляторам Омрон. Максимальная продолжительность и стабильность работы достигаются за счет функций автонастройки и ПИД-регулирования.

Основные особенности:

- Простая настройка несколькими нажатиями кнопок управления

- Уникальная технология Omron 2-ПИД регулирования и Автонастройка

- Время цикла контроля 250 мс

- Большой цифровой дисплей 16,7 или 21,7 мм, различимый с расстояния 5 м

- Компактный размер корпуса (глубина 60 мм)

Регуляторы температуры Omron E5CSL и E5CWL разработаны с учетом особенностей и технических требований для задач регулирования температуры в простых печах и упаковочных машинах.

Термоконтроллеры E5CSL (один дисплей)

| Размер | Напряжение питания, В | Тип датчика | Аварийный выход | Управляющий выход | Модель |

|---|---|---|---|---|---|

| 1/16 DIN 48 х 48 х 60 (W х Н х D) |

100 — 240 | Термопара | нет | Релейный | E5CSL-RTC |

| Термометр сопротивления | E5CSL-RP | ||||

| Термопара | Напряжение (для управления твердотельными реле) | E5CSL-QTC | |||

| Термометр сопротивления | E5CSL-QP |

Термоконтроллеры E5CWL (два дисплея)

| Размер | Напряжение питания, В | Тип датчика | Аварийный выход | Управляющий выход | Модель |

|---|---|---|---|---|---|

| 1/16 DIN 48 х 48 х 60 (W х Н х D) |

100 — 240 | Термопара | 1 | Релейный | E5CWL-R1TC |

| Термометр сопротивления | E5CWL-R1P | ||||

| Термопара | Напряжение (для управления твердотельными реле) | E5CWL-Q1TC | |||

| Термометр сопротивления | E5CWL-Q1P |

Аксессуары для регуляторов температуры Омрон

| Клеммная крышка | E53-COV19 |

| Крышка лицевой панели | E53-COV20 |

| Адаптер | Y92F-45 |

* Изображения служат только для ознакомления,

см. техническую документацию

Добавить в корзину 1 шт.

на сумму 87 440 руб.

Номенклатурный номер: 8005889289

Страна происхождения: КИТАЙ

Бренд / Производитель: Omron

Описание

Industrial Automation and ControlsControllers — Process, Temperature

Контроллер температуры (RTD) 100 ~ 240 В переменного тока для монтажа на панели

Технические параметры

| Control Method | On/Off, Proportional (PID) |

| Display Characters — Height | 0.638″» (16.20mm) |

| Display Type | LED — Dual Color Characters |

| ECCN | EAR99 |

| HTSUS | 9032.10.0090 |

| Ingress Protection | IP50 — Dust Protected |

| Input Range | -200В°C ~ 850В°C |

| Moisture Sensitivity Level (MSL) | 1 (Unlimited) |

| Mounting Type | Panel Mount |

| Number of Characters Per Row | 4, 4 |

| Operating Temperature | -10В°C ~ 55В°C |

| Output Type | Relay (2) |

| Package | Box |

| Panel Cutout Dimensions | Square — 45.00mm x 45.00mm |

| RoHS Status | RoHS Compliant |

| Series | E5CWL -> |

| Termination Style | Screw Terminal |

| Type | Temperature Controller (RTD) |

| Voltage — Supply | 100 ~ 240VAC |

| Weight | 0.221 lb (100.24 g) |

Техническая документация

Сроки доставки

Доставка в регион Курск

| Магазин «ЧИП и ДИП» | 5 июля1 | бесплатно |

| ПВЗ Boxberry | 3 июля1 | бесплатно |

| ПВЗ СДЭК | 4 июля1 | бесплатно |

| ПВЗ Л-Пост | 4 июля1 | бесплатно |

| ПВЗ 5Post | 5 июля1 | бесплатно |

| Почта России | 12 июля1 | бесплатно |

| Курьер | 4 июля1 | 416 руб.2 |

| ТК DPD | 3 июля1 | 546 руб.2 |

| ТК «Деловые линии» | 4 июля1 | 824 руб.2 |

Цена и наличие в магазинах

| ул. Карла Маркса, 68, ТЦ «Мега Гринн», 1 этаж | нет в наличии |