- Manuals

- Brands

- MTU Manuals

- Engine

- 12V2000G series

- Operating instructions manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Operating Instructions

Diesel engine

12V2000Gx6x

16V2000Gx6x

MS15054/00E

Related Manuals for MTU 12V2000G series

Summary of Contents for MTU 12V2000G series

-

Page 1: Operating Instructions

Operating Instructions Diesel engine 12V2000Gx6x 16V2000Gx6x MS15054/00E…

-

Page 2

All information in this publication was the latest information available at the time of going to print. MTU Friedrichshafen GmbH reserves the right to change, delete or supplement the information provided as and when required. -

Page 3: Table Of Contents

Table of Contents 1 Safety 3.10 Engine data 12V/16V2000Gx6S, 3H, standby operation mode, special 1.1 Important provisions for all products qualifications, EPA Nonroad T2 (40CFR89) 1.2 Personnel and organizational requirements and EPA Stationary EMERG T2 (40CFR60) 1.3 Transport (provisional) 1.4 Safety regulations for startup and operation 3.11 Firing order 1.5 Safety precautions when working on the 3.12 Engine –…

-

Page 4

7.12.4 Engine coolant – Filling 7.12.5 Engine coolant pump – Relief bore check 8.1 List of abbreviations 7.12.6 Engine coolant – Sample extraction and 8.2 MTU contact persons/service partners analysis 7.13 Low-Temperature Circuit 9 Appendix B 7.13.1 Charge-air coolant – Filling 9.1 Special Tools… -

Page 5: Safety

Nameplate, model designation or serial number can be found on the product. All EU-certified engines delivered by MTU come with a second nameplate. When operating the machine in the EU: The second nameplate must be affixed in a prominent position as described in the accompanying specifi- cations.

-

Page 6

The maintenance schedules of the manufacturer must be observed over the entire life cycle of the product. Replacing components with emission labels Emission labels are attached to all MTU engines. These must remain on the engine throughout its operational life. -

Page 7: Personnel And Organizational Requirements

1.2 Personnel and organizational requirements Organizational measures of the user/manufacturer This manual must be issued to all personnel involved in operation, maintenance, repair, or transportation. Keep this manual handy in the vicinity of the product such that it is accessible to operating, maintenance, repair, and transport personnel at all times.

-

Page 8: Transport

Only set down engine on a firm, level surface. Make sure that the consistency and load-bearing capacity of the ground or support surface is adequate. Never set down engines onto the oil pan unless expressly permitted by MTU on an engine-specific base. 8 | Safety | MS15054/00E 2015-09…

-

Page 9: Safety Regulations For Startup And Operation

1.4 Safety regulations for startup and operation Safety regulations for startup Install the product correctly and carry out acceptance in accordance with the manufacturer’s specifications before putting the product into service. All necessary approvals must be granted by the relevant authorities and all requirements for initial startup must be fulfilled.

-

Page 10: Safety Precautions When Working On The Engine

1.5 Safety precautions when working on the engine Safety regulations prior to maintenance and repair work Have maintenance or repair work carried out by qualified and authorized personnel only. Allow the product to cool down to less than 50 °C (risk of explosion for oil vapors, fluids and lubricants, risk of burning).

-

Page 11

Never bend lines and avoid damaging lines, particularly the fuel lines. Ensure that all retainers and dampers are installed correctly. Ensure that O-rings are not installed in a slanted/twisted condition. Ensure that all fuel injection and pressurized oil lines are installed with enough clearance to prevent contact with other components. -

Page 12

During hydraulic installation/removal of components, ensure that no persons are in the direct vicinity of the component being pressed. Working with batteries Observe the safety instructions of the battery manufacturer when working with batteries. Gases released from the battery are explosive. Avoid sparks and naked flames. Do not allow battery acids to come into contact with skin or clothing. -

Page 13: Fire Prevention And Environmental Protection, Fluids And Lubricants, Auxiliary Materials

The safety data sheet may be obtained from the relevant manufacturer or from MTU. Take special care when using hot, chilled or caustic materials.

-

Page 14: Compressed Air

Lead • Adopt suitable measures to avoid the formation of lead dust. • Switch on extraction system. • When working with lead or pastes containing lead, avoid direct contact to the skin and do not inhale lead vapors. • Wash relevant areas after contact with lead or lead-containing substances. Compressed air Observe special safety precautions when working with compressed air: •…

-

Page 15: Standards For Safety Notices In The Text

1.7 Standards for safety notices in the text DANGER In the event of immediate danger. Consequences: Death, serious or permanent injury! • Remedial action. WARNING In the event of a situation involving potential danger. Consequences: Death, serious or permanent injury! •…

-

Page 16: General Information

2 General Information 2.1 Engine side and cylinder designations 1 Left engine side (A-side) 3 Right engine side (B-side) 2 Engine free end in accord- 4 Engine driving end in ac- ance with DIN ISO 1204 cordance with (KGS = Kupplungsgegen- DIN ISO 1204 (KS = Kup- seite) plungsseite)

-

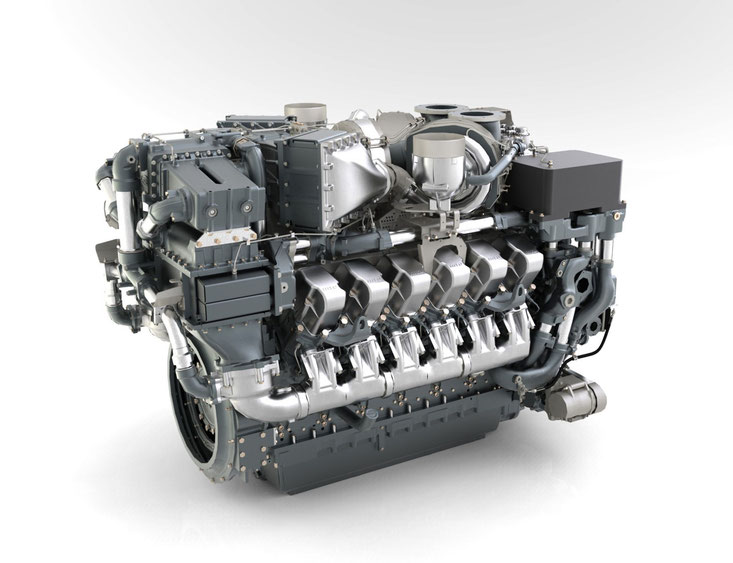

Page 17: Engine — Overview

2.2 Engine – Overview 12V2000Gx6S Also valid for 16V engines 1 Air intake/air supply 6 Engine coolant pump 11 Exhaust turbocharger 2 Charge-air line 7 Charge-air coolant pump 12 Fuel system (high pressure) 3 Monitoring, control and reg- 8 Exhaust pipe 13 Starting equipment ulation system 9 LP fuel system…

-

Page 18: Sensors And Actuators — Overview

2.3 Sensors and actuators – Overview Sensors and actuators – Driving end Overview also applies to 12 V and 16 V engines. Monitoring of Item Name Intake air temperature Table 3: Sensors and actuators – Driving end Sensors and actuators – A-side Overview also applies to 12 V and 16 V engines.

-

Page 19

Monitoring of Item Name B5.1 Oil pressure after oil filter Oil temperature B48.1 HP fuel, A-side M8.1 Fuel pump pressure, A-side Table 4: Sensors and actuators – A-side MS15054/00E 2015-09 | General Information | 19… -

Page 20

Sensors and actuators – Free end Monitoring of Item Name B5.3 Oil pressure before oil filter (optional) Table 5: Sensors and actuators – Free end 20 | General Information | MS15054/00E 2015-09… -

Page 21

Sensors and actuators – B-side Monitoring of Item Name Charge-air coolant temperature Charge-air pressure XF70 Fuel filter level monitor (optional) XF57 Coolant level, low temperature XF33 Coolant level, high temperature Coolant temperature EIL, electronic label Coolant temperature XF46 Leak fuel level (optional) M8.2 Fuel pump pressure, B-side B34.3… -

Page 22: Technical Data

3 Technical Data 3.1 Engine data 12V/16V2000Gx6S, 3B, continuous operation, variable load, ICXN, optimized fuel consumption (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 23

Performance data Rated engine speed 1800 1800 1800 1800 Continuous power ISO 3046 (10% over- load possible) (power range DIN 6280, ISO 8528) General conditions (for maximum power) Intake depression (new filter) mbar Intake depression, max. mbar Exhaust overpressure mbar Exhaust gas overpressure, max. -

Page 24

Coolant temperature after engine, limit 2 L °C Coolant antifreeze content, max. Pressure loss in engine-external cooling system, max. Coolant system (LT circuit) Coolant temperature before charge-air °C cooler (at engine inlet from cooling equipment) Coolant antifreeze content, max. Pressure loss in engine-external cooling system, max. -

Page 25

Capacities Engine coolant capacity, engine side Liters (without cooling equipment) Charge-air coolant, engine side Liters Engine oil capacity, initial filling (standard Liters oil system) (option: max. operating incli- nations) Oil change quantity, max. (standard oil Liters system) (option: max. operating inclina- tions) Weights / main dimensions Engine weight, dry (basic engine configu-… -

Page 26: Standby Current, Fuel Stop Power (Ifn)

3.2 Engine data 12V/16V2000Gx6S, 3D, standby current, fuel stop power (IFN), optimized fuel consumption (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 27

Performance data Rated engine speed 1800 1800 1800 1800 Fuel stop power ISO 3046 1097 1371 General conditions (for maximum power) Intake depression (new filter) mbar Intake depression, max. mbar Exhaust overpressure mbar Exhaust gas overpressure, max. mbar Model-related data (basic design) Engine with exhaust turbocharging (ETC) and charge-air cooling (CAC) Uncooled exhaust lines… -

Page 28

Coolant system (HT circuit) Coolant temperature (at engine connec- °C tion: outlet to cooling equipment) Coolant temperature after engine, limit 1 L °C Coolant temperature after engine, limit 2 L °C Coolant antifreeze content, max. Pressure loss in engine-external cooling system, max. -

Page 29

General operating data Cold start capability: air temperature °C (w/o start aid. w/o preheating) — (case A) Coolant preheating: preheating tempera- °C ture (min.) Firing speed, from Firing speed, to Capacities Engine coolant capacity, engine side Liters (without cooling equipment) Charge-air coolant, engine side Liters Engine oil capacity, initial filling (standard… -

Page 30: Engine Data 12V/16V2000Gx6S, 3F, Standby Operation Mode, Unlimited, Icxn, Optimized Fuel Consumption (Provisional)

3.3 Engine data 12V/16V2000Gx6S, 3F, standby operation mode, unlimited, ICXN, optimized fuel consumption (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 31

Exhaust overpressure mbar Exhaust gas overpressure, max. mbar Model-related data (basic design) Engine with exhaust turbocharging (ETC) and charge-air cooling (CAC) Combustion method: direct fuel injection Direction of rotation: c.c.w. (facing driving end) Cylinder arrangement: V-angle Degrees (°) Bore Stroke Displacement, cylinder Liters 2.233… -

Page 32

Lube oil system Lube oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil temperature before engine, limit 1 °C Lube oil temperature before engine, limit 2 °C Lube oil operating pressure upstream of engine, from Lube oil operating pressure before engine, to Lube oil operating pressure before engine, warning Lube oil operating pressure before engine, shutdown… -

Page 33: Engine Data 12V/16V2000Gx6S, 3G, Continuous Operation, Time-Limited, Icxn, Optimized Fuel Consumption (Provisional)

3.4 Engine data 12V/16V2000Gx6S, 3G, continuous operation, time-limited, ICXN, optimized fuel consumption (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 34

Exhaust overpressure mbar Exhaust gas overpressure, max. mbar Model-related data (basic design) Engine with exhaust turbocharging (ETC) and charge-air cooling (CAC) Combustion method: direct fuel injection Direction of rotation: c.c.w. (facing driving end) Cylinder arrangement: V-angle Degrees (°) Bore Stroke Displacement, cylinder Liters 2.233… -

Page 35

Lube oil system Lube oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil temperature before engine, limit 1 °C Lube oil temperature before engine, limit 2 °C Lube oil operating pressure upstream of engine, from Lube oil operating pressure before engine, to Lube oil operating pressure before engine, warning Lube oil operating pressure before engine, shutdown… -

Page 36: Engine Data 12V/16V2000Gx6S, 3H, Standby Operation Mode, Special Qualifications, Optimized Fuel Consumption (Provisional)

3.5 Engine data 12V/16V2000Gx6S, 3H, standby operation mode, special qualifications, optimized fuel consumption (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 37

General conditions (for maximum power) Intake depression (new filter) mbar Intake depression, max. mbar Exhaust overpressure mbar Exhaust gas overpressure, max. mbar Model-related data (basic design) Engine with exhaust turbocharging (ETC) and charge- air cooling (CAC) Uncooled exhaust lines Operating method: Four-stroke cycle, diesel, single- action Combustion method: direct fuel injection Cooling method: conditioned water… -

Page 38

Coolant system (LT circuit) Coolant temperature before charge-air cooler (at en- °C gine inlet from cooling equipment) Coolant antifreeze content, max. Pressure loss in engine-external cooling system, max. L Lube oil system Lube-oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil temperature before engine, limit 1 °C… -

Page 39

Weights / main dimensions Engine weight, dry (basic engine configuration acc. to 2710 3180 3180 scope of delivery specification) Sound Exhaust noise, not attenuated — DL (sound power lev- dB(A) el LW, ISO 6798, +3 dB(A) tolerance) Engine surface noise with attenuated intake noise (fil- dB(A) ter) — DL (sound power level LW, ISO 6798, +2 db(A) tolerance) -

Page 40: Engine Data 12V/16V2000Gx6S, 3B, Continuous Operation, Variable Load, Icxn, Epa Nonroad T2 (40Cfr89) (Provisional)

3.6 Engine data 12V/16V2000Gx6S, 3B, continuous operation, variable load, ICXN, EPA Nonroad T2 (40CFR89) (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 41

Performance data Rated engine speed 1800 1800 1800 1800 Continuous power ISO 3046 (10% over- load possible) (power range DIN 6280, ISO 8528) General conditions (for maximum power) Intake depression (new filter) mbar Intake depression, max. mbar Exhaust overpressure mbar Exhaust gas overpressure, max. -

Page 42

Coolant temperature after engine, limit 2 L °C Coolant antifreeze content, max. Pressure loss in engine-external cooling system, max. Coolant system (LT circuit) Coolant temperature before charge-air °C cooler (at engine inlet from cooling equipment) Coolant antifreeze content, max. Pressure loss in engine-external cooling system, max. -

Page 43

Capacities Engine coolant capacity, engine side Liters (without cooling equipment) Charge-air coolant, engine side Liters Engine oil capacity, initial filling (standard Liters oil system) (option: max. operating incli- nations) Oil change quantity, max. (standard oil Liters system) (option: max. operating inclina- tions) Weights / main dimensions Engine weight, dry (basic engine configu-… -

Page 44: Engine Data 12V/16V2000Gx6S, 3D, Standby Current, Fuel Stop Power (Ifn), Epa Nonroad T2 (40Cfr89) (Provisional)

3.7 Engine data 12V/16V2000Gx6S, 3D, standby current, fuel stop power (IFN), EPA Nonroad T2 (40CFR89) (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 45

Reference condition Intake air temperature °C Charge air coolant temperature °C Barometric pressure mbar 1000 1000 1000 1000 Site altitude above sea level Performance data Rated engine speed 1800 1800 1800 1800 Fuel stop power ISO 3046 1097 1371 General conditions (for maximum power) Intake depression (new filter) mbar Intake depression, max. -

Page 46

Air / exhaust Charge-air pressure before cylinder — CP bar abs Coolant system (HT circuit) Coolant temperature (at engine connec- °C tion: outlet to cooling equipment) Coolant temperature after engine, limit 1 L °C Coolant temperature after engine, limit 2 L °C Coolant antifreeze content, max. -

Page 47

General operating data Cold start capability: air temperature °C (w/o start aid. w/o preheating) — (case A) Coolant preheating: preheating tempera- °C ture (min.) Firing speed, from Firing speed, to Capacities Engine coolant capacity, engine side Liters (without cooling equipment) Charge-air coolant, engine side Liters Engine oil capacity, initial filling (standard… -

Page 48: Engine Data 12V/16V2000Gx6S, 3F

3.8 Engine data 12V/16V2000Gx6S, 3F, standby operation mode, unlimited, ICXN, EPA Nonroad T2 (40CFR89) and EPA Stationary EMERG T2 (40CFR60) (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 49

General conditions (for maximum power) Intake depression (new filter) mbar Intake depression, max. mbar Exhaust overpressure mbar Exhaust gas overpressure, max. mbar Model-related data (basic design) Engine with exhaust turbocharging (ETC) and charge-air cooling (CAC) Combustion method: direct fuel injection Direction of rotation: c.c.w. -

Page 50

Coolant system (LT circuit) Coolant temperature before charge-air cooler (at engine inlet °C from cooling equipment) Coolant antifreeze content, max. Pressure loss in engine-external cooling system, max. Lube oil system Lube oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil temperature before engine, limit 1 °C… -

Page 51

Sound Exhaust noise, not attenuated — DL (sound power level LW, ISO dB(A) 6798, +3 dB(A) tolerance) Engine surface noise with attenuated intake noise (filter) — DL dB(A) (sound power level LW, ISO 6798, +2 db(A) tolerance) MS15054/00E 2015-09 | Technical Data | 51… -

Page 52: Engine Data 12V/16V2000Gx6S, 3G, Continuous Operation, Time-Limited, Icxn, Epa Nonroad T2 (40Cfr89) (Provisional)

3.9 Engine data 12V/16V2000Gx6S, 3G, continuous operation, time-limited, ICXN, EPA Nonroad T2 (40CFR89) (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 53

Exhaust overpressure mbar Exhaust gas overpressure, max. mbar Model-related data (basic design) Engine with exhaust turbocharging (ETC) and charge-air cooling (CAC) Combustion method: direct fuel injection Direction of rotation: c.c.w. (facing driving end) Cylinder arrangement: V-angle Degrees (°) Bore Stroke Displacement, cylinder Liters 2.233… -

Page 54

Lube oil system Lube oil operating temperature before engine, from °C Lube oil operating temperature before engine, to °C Lube oil temperature before engine, limit 1 °C Lube oil temperature before engine, limit 2 °C Lube oil operating pressure upstream of engine, from Lube oil operating pressure before engine, to Lube oil operating pressure before engine, warning Lube oil operating pressure before engine, shutdown… -

Page 55: Engine Data 12V/16V2000Gx6S, 3H

3.10 Engine data 12V/16V2000Gx6S, 3H, standby operation mode, special qualifications, EPA Nonroad T2 (40CFR89) and EPA Stationary EMERG T2 (40CFR60) (provisional) Legend CP Ref. value: Continuous power. Continuous driving power under standard conditions FSP Ref. value: Fuel stop power. Maximum engine power. In some applications, continuous power not pos- sible (adjustment reserve) A Design value.

-

Page 56

Performance data Rated engine speed 1800 1800 1800 Fuel stop power ISO 3046 1097 1371 General conditions (for maximum power) Intake depression (new filter) mbar Intake depression, max. mbar Exhaust overpressure mbar Exhaust gas overpressure, max. mbar Model-related data (basic design) Engine with exhaust turbocharging (ETC) and charge- air cooling (CAC) Uncooled exhaust lines… -

Page 57

Coolant system (HT circuit) Coolant temperature (at engine connection: outlet to °C cooling equipment) Coolant temperature after engine, limit 1 °C Coolant temperature after engine, limit 2 °C Coolant antifreeze content, max. Pressure loss in engine-external cooling system, max. L Coolant system (LT circuit) Coolant temperature before charge-air cooler (at en- °C… -

Page 58

Engine oil capacity, initial filling (standard oil system) Liters (option: max. operating inclinations) Oil change quantity, max. (standard oil system) (op- Liters tion: max. operating inclinations) Oil pan capacity at dipstick mark «min.» (standard oil Liters system) Oil pan capacity at dipstick mark «max.» (standard oil Liters system) Weights / main dimensions… -

Page 59: Firing Order

3.11 Firing order Firing order Number of cylinders Firing order A1-B5-A5-B3-A3-B6-A6-B2-A2-B4-A4-B1 A1-B5-A3-A5-B2-B8-A2-A8-B3-A7-B4-B6-A4-A6-B1-B7 A1-B6-A3-B4-A5-B2-A7-B1-A9-B3-A8-B5-A6-B7-A4-B9-A2-B8 MS15054/00E 2015-09 | Technical Data | 59…

-

Page 60: Engine — Main Dimensions

3.12 Engine – Main dimensions Dimensions Item Length (A) for 12V approx. 1885.2 mm Length (A) for 16V approx. 2235.2 mm Width (B) for 12V approx. 1588.3 mm Width (B) for 16V approx. 1568.4 mm Height (C) for 12V approx. 1420.2 mm Height (C) for 16V approx.

-

Page 61: Operation

4.1 Putting the engine into operation after extended out-of-service periods (>3 months) Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. Putting into operation after long out-of-service periods (>3 months) Item Action Engine Depreserve (→…

-

Page 62: Putting The Engine Into Operation After Scheduled Out-Of-Service-Period

4.2 Putting the engine into operation after scheduled out-of- service-period Preconditions ☑ Engine is stopped and starting disabled. Putting into operation Item Action Lube oil system Check engine oil level (→ Page 130). Coolant circuit Check engine coolant level (→ Page 135), check charge-air coolant level (→…

-

Page 63: Starting The Engine

4.3 Starting the engine Preconditions ☑ Engine with no load. DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Before cranking the engine with starter system, make sure that there are no persons in the engine’s danger zone.

-

Page 64: Operational Checks

4.4 Operational checks DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine’s danger zone. WARNING High level of engine noise when the engine is running. Risk of damage to hearing! •…

-

Page 65: Emission Label — Check

Checking emission label Note: If there are any irregularities, notify your MTU Service contact person without delay. Check that emission labels are present (several are possible). Does the label on the engine match the label document in the Business Portal/Equipment? Check emission label for intactness.

-

Page 66: Engine Shutdown

4.6 Engine shutdown Preconditions ☑ Engine is not connected to load. CAUTION Shutting down from full-load operation may cause hot water to escape from the expansion tank. Risk of scalding! • Allow engine to cool down. • Wear protective clothing, protective gloves, and safety goggles / safety mask. NOTICE Stopping the engine when it is running at full load subjects it to extreme thermal and mechanical stress- Overheating of and, therefore, damage to components is possible!

-

Page 67: Emergency Engine Stop

4.7 Emergency engine stop CAUTION Shutting down from full-load operation may cause hot water to escape from the expansion tank. Risk of scalding! • Allow engine to cool down. • Wear protective clothing, protective gloves, and safety goggles / safety mask. NOTICE An emergency stop causes extreme stress to the engine plant.

-

Page 68: After Stopping The Engine

4.8 After stopping the engine Preconditions ☑ MTU Preservation and Represervation Instructions (A001070/..) are available. NOTICE Engine coolant with inadequate freeze protection. Water remaining in the pressure sensors freezes at temperatures below 0 °C. Risk of sensor damage! • Remove pressure sensors and shake off residual water.

-

Page 69: Plant — Cleaning

4.9 Plant – Cleaning Preconditions ☑ Engine is stopped and starting disabled. ☑ No operating voltage is applied. Special tools, Material, Spare parts Designation / Use Part No. Qty. High-pressure cleaning unit Cleaner (Hakupur 50/136) X00056700 WARNING Compressed air gun ejects a jet of pressurized air. Risk of injury to eyes and damage to hearing, risk of rupturing internal organs! •…

-

Page 70: Maintenance

5 Maintenance 5.1 Maintenance task reference table [QL1] The maintenance tasks and intervals for this product are defined in the Maintenance Schedule. The Mainte- nance Schedule is a stand-alone publication. The task numbers in this table provide reference to the maintenance tasks specified in the Maintenance Schedule.

-

Page 71: Troubleshooting

6 Troubleshooting 6.1 Troubleshooting Engine does not turn when starter is actuated Component Cause Action Battery Low or faulty Charge or replace (see manufacturer’s documentation). Cable connections faulty Check if cable connections are properly secured (see manufacturer’s documen- tation). Starter Engine cabling or starter faulty Check if cable connections are properly secured, contact Service.

-

Page 72

Faulty Contact Service. Charge-air temperature too high Component Cause Action Engine coolant Engine coolant treatment incorrect Check (MTU test kit). Intercooler Contaminated Contact Service. Engine room Air-intake temperature too high Check fans and intake/exhaust lines. Charge-air pressure too low Component… -

Page 73

Blue exhaust gas Component Cause Action Engine oil Too much engine oil in the engine Drain engine oil (→ Page 131). Oil separator of crankcase breather con- Replace (→ Page 104). taminated Exhaust turbocharger, Faulty Contact Service. cylinder head, piston rings, cylinder liner White exhaust gas Component… -

Page 74: Engine Control Unit — Ecu9 Fault Messages

6.2 Engine Control Unit – ECU9 fault messages 5 – HI T-Charge Air Yellow alarm; warning Cause Corrective action Charge-air temperature too high 1. Check coolant cooler and intercooler. (Level 1). 2. Contact Service if no malfunction can be detected. 6 –…

-

Page 75

23 – LO Coolant Level Red alarm; emergency stop Cause Corrective action Coolant level too low. 1. Check coolant circuit for leaks. Check coolant level in expansion tank, top up as necessary. 2. Contact Service if no malfunction can be detected. 25 –… -

Page 76

44 – LO Coolant Level Intercooler Red alarm; emergency stop Cause Corrective action Intercooler coolant level too low. 1. Check coolant circuit for leaks. 2. Check coolant level in expansion tank, top up as necessary. 3. Contact Service if no malfunction can be detected. 51 –… -

Page 77

65 – LO P-Fuel Yellow alarm; warning Cause Corrective action Fuel inlet pressure too low (Level 1. Check fuel lines for leakage. 2. Drain fuel prefilter (→ Page 120). 3. Replace filter element of fuel prefilter (→ Page 121). 4. Replace fuel filter and, if required, intermediate fuel filter (→… -

Page 78

83 – LO P-Fuel (Common Rail) Yellow alarm; warning Cause Corrective action Rail pressure < set value; HP fuel 1. Check wiring of HP fuel control block. control block faulty or leakage in 2. Check high-pressure system for leaks. HP fuel system. 3. -

Page 79

94 – LO T-Preheat Yellow alarm; warning Cause Corrective action Preheating temperature too low 1. Extend preheating period. (Level 1); coolant temperature too 2. Check preheater. low for engine start. 95 – AL Prelubrication Fault Yellow alarm; warning Cause Corrective action Oil priming fault u Contact Service. -

Page 80

122 – HI T-ECU Yellow alarm; warning Cause Corrective action u Check engine room ventilation. Temperature of the electronics too high. 141 – AL Power too high Yellow alarm; warning Cause Corrective action The average power rate over the last 24 hours of engine operation has exceeded the set maximum value. -

Page 81

184 – AL CAN PU Data Flash Error Yellow alarm; warning Cause Corrective action u Contact Service. A programming error occurred when attempting to copy a received PU data module into the Flash module. 186 – AL CAN1 Bus Off Yellow alarm;… -

Page 82

203 – SD T-Charge Air Yellow alarm; warning Cause Corrective action u Check sensor B9 and wiring, replace as necessary (→ Page 162). Charge air temperature sensor faulty. 205 – SD T-Coolant Intercooler Yellow alarm; warning Cause Corrective action Coolant pressure sensor of u Check sensor B26 and wiring, replace as necessary (→… -

Page 83

220 – SD Level Coolant Water Yellow alarm; warning Cause Corrective action Coolant level sensor faulty. 1. Check sensor F33 and wiring, replace as necessary (→ Page 162). 2. Fault is rectified when electronics are switched back on. 221 – SD P-Diff Lube Oil Yellow alarm;… -

Page 84

230 – SD Crankshaft Speed Yellow alarm; warning Cause Corrective action Crankshaft sensor faulty. 1. Check sensor B13 and wiring, replace as necessary (→ Page 162). 2. Fault is rectified when engine is restarted, contact Service if this is not the case. 231 –… -

Page 85

270 – SD Frequency Input Yellow alarm; warning Cause Corrective action Frequency input faulty. 1. Check speed setting transmitter and wiring, replace as necessary (→ Page 162). 2. Fault is rectified when engine is restarted. 321 – AL Wiring Cylinder A1 Yellow alarm;… -

Page 86

325 – AL Wiring Cylinder A5 Yellow alarm; warning Cause Corrective action Short circuit in cylinder A5 1. Check injector wiring. injector wiring. Result: Misfiring. 2. Rectify injector solenoid valve short circuit (positive to negative) (e.g. by exchanging injectors). 3. Fault is rectified when engine is restarted. 326 –… -

Page 87

331 – AL Wiring Cylinder B1 Yellow alarm; warning Cause Corrective action Short circuit in cylinder B1 1. Check injector wiring. injector wiring. Result: Misfiring. 2. Rectify injector solenoid valve short circuit (positive to negative) (e.g. by exchanging injectors). 3. Fault is rectified when engine is restarted. 332 –… -

Page 88

336 – AL Wiring Cylinder B6 Yellow alarm; warning Cause Corrective action Short circuit in cylinder B6 1. Check injector wiring. injector wiring. Result: Misfiring. 2. Rectify injector solenoid valve short circuit (positive to negative) (e.g. by exchanging injectors). 3. Fault is rectified when engine is restarted. 337 –… -

Page 89

343 – AL Open Load Cylinder A3 Yellow alarm; warning Cause Corrective action Open circuit in cylinder A3 1. Check injector wiring, exclude disruption in solenoid valve (e.g. by injector wiring. Result: Misfiring. injector replacement). 2. Fault is rectified after each working cycle. 344 –… -

Page 90

349 – AL Open Load Cylinder A9 Yellow alarm; warning Cause Corrective action Open circuit in cylinder A9 1. Check injector wiring, exclude disruption in solenoid valve (e.g. by injector wiring. Result: Misfiring. injector replacement). 2. Fault is rectified after each working cycle. 351 –… -

Page 91

356 – AL Open Load Cylinder B6 Yellow alarm; warning Cause Corrective action Open circuit in cylinder B6 1. Check injector wiring, exclude disruption in solenoid valve (e.g. by injector wiring. Result: Misfiring. injector replacement). 2. Fault is rectified after each working cycle. 357 –… -

Page 92

363 – AL Stop Injector Power Stage Red alarm; Self-restoring Cause Corrective action Internal electronic fault, 1. Start Engine Control Unit self-test. electronics possibly faulty. 2. Replace ECU in case of fault; if self-test diagnoses “Electronics OK” check for additional fault messages (e.g. wiring fault). 365 –… -

Page 93

390 – AL MCR exceeded Yellow alarm; warning Cause Corrective action DBR/MCR function: MCR (continuous maximum rate) was exceeded. 400 – AL Open Load Digital Input 1 Yellow alarm; warning Cause Corrective action Line disruption at digital input 1. u Check wiring (→ Page 162). 401 –… -

Page 94

407 – AL Open Load Digital Input 8 Yellow alarm; warning Cause Corrective action u Check wiring (→ Page 162). Line disruption at digital input 8. 408 – AL Open Load Emerg. Stop Input ESI Yellow alarm; warning Cause Corrective action u Check wiring (→… -

Page 95

415 – LO P-Coolant Intercooler Yellow alarm; warning Cause Corrective action Coolant pressure in intercooler 1. Check coolant level in expansion tank, top up as necessary. too low (Level 1). 2. Check coolant circuit for leaks. 3. Check coolant pump. 416 –… -

Page 96

444 – SD U-PDU Yellow alarm; warning Cause Corrective action u Replace Engine Control Unit. Sensor of injector output stage faulty. 445 – SD P-Ambient Air Yellow alarm; warning Cause Corrective action Ambient air pressure sensor u Replace Engine Control Unit (sensor is in the ECU). faulty. -

Page 97

472 – AL Stop SD Red alarm; emergency stop Cause Corrective action u Contact Service. Shutdown channels sensor fault. 474 – AL Wiring FO Yellow alarm; warning Cause Corrective action u Contact Service. Wire break or short circuit at FO channel. -

Page 98

536 – AL Wiring PWM_CM1 Yellow alarm; warning Cause Corrective action u Check wiring to connected device or check connected device Wire break or short circuit on channel PWM_CM1. (actuator/sensor), replace as necessary. 549 – AL Power Cut-Off detected Entered in fault memory only. Cause Corrective action The operating voltage of the… -

Page 99

602 – AL CAN Engine Start Lock Yellow alarm; warning Cause Corrective action Start interlock initiated by plant. 1. Check plant configuration. 2. Restart engine (→ Page 63). 610 – AL Wiring HP Control Block 1 Yellow alarm; warning Cause Corrective action Wire break or short circuit at PWM u Check wiring or HP fuel control block, replace as necessary . -

Page 100

836 – AL Nominal Speed Setting Fail Yellow alarm; warning Cause Corrective action u Check wiring (CAN MD). Active analog speed setting faulty. 851 – AL Extern Start and HD too high Entered in fault memory only Cause Corrective action u Contact Service. -

Page 101

1131 – AL Short Circuit Analog Output 2 Yellow alarm; warning Cause Corrective action u Check wiring. The value output at analog output 2 deviates excessively from the value read back. MS15054/00E 2015-09 | Troubleshooting | 101… -

Page 102: Task Description

7 Task Description 7.1 Engine 7.1.1 Engine – Cranking manually Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Barring tool F6792910 Ratchet F30006212 DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •…

-

Page 103: Engine — Barring With Starting System

7.1.2 Engine – Barring with starting system Preconditions ☑ External pushbutton “Bar engine without starting” is provided. DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Before cranking the engine with starter system, make sure that there are no persons in the engine’s danger zone.

-

Page 104: Crankcase Breather

7.2 Crankcase Breather 7.2.1 Crankcase breather – Oil mist fine separator replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine oil Oil mist fine separator (→ Spare Parts Catalog) O-ring (→…

-

Page 105: Valve Drive

7.3 Valve Drive 7.3.1 Valve clearance – Check and adjustment Preconditions ☑ Engine is stopped and starting disabled. ☑ Engine coolant temperature is max. 40 °C. ☑ Valves are closed. Special tools, Material, Spare parts Designation / Use Part No. Qty.

-

Page 106: Adjusting Valve Clearance

Checking valve clearance at two crankshaft positions Check TDC position of piston in cylinder 1 side A: • When the rocker arms are relieved on cylinder 1 side A, the piston is at firing TDC. • When the rocker arms are loaded on cylinder 1 side A, the piston is at overlap TDC. Check valve clearance with engine cold (at max.

-

Page 107

Tighten locknut (1) with torque wrench to the specified tightening torque, using an Allen wrench to hold the adjusting screw (2) to prevent it from turning. Name Size Type Lubricant Value/Standard Locknut M12x1 Tightening torque 50 Nm +5 Nm Insert feeler gauge between valve bridge and rocker arm to verify that the gauge just passes through the gap. -

Page 108: Cylinder Head Cover — Removal And Installation

7.3.2 Cylinder head cover – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 8–40 Nm F30043446 Torque wrench, 0.5–5 Nm 0015384230 Ratchet adapter F30027340 Engine oil Gasket (→…

-

Page 109: Injector

7.4 Injector 7.4.1 Injector ‒ Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Injector (→ Spare Parts Catalog) Screw for hold-down clamp (→ Spare Parts Catalog) Replacing injector Remove injector and install new one (→ Page 110). MS15054/00E 2015-09 | Task Description | 109…

-

Page 110: Injector — Removal And Installation

7.4.2 Injector – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Press-fitting tool F6790085 Puller F6790636 Fuel suction device F30378207 Torque wrench, 20-100 Nm F30026582 Torque wrench, 0.5–5 Nm 0015384230 Ratchet adapter F30027340…

-

Page 111

WARNING Compressed air gun ejects a jet of pressurized air. Risk of injury to eyes and damage to hearing, risk of rupturing internal organs! • Never direct air jet at people. • Always wear safety goggles/face mask and ear defenders. Preparatory steps Shut off fuel supply line. -

Page 112

Remove screw (3). Take off hold-down clamp (2). Note: Support ring on injector must likewise be re- moved if it does not come out with the injec- tor. Use the puller to pull out injector (1). After removal, seal all openings with suitable covers. -

Page 113

Installing pressure pipe neck Note: Minimize contamination! Visually inspect HP line (1) and replace if nec- essary. Note: Pressure pipe neck may be reused twice at most. Visually check sealing surfaces and pins on pressure pipe neck for plastic deformation and replace if necessary. -

Page 114

Tighten union nut (2) on pressure pipe neck (3) to specified torque using a torque wrench. Name Size Type Lubricant Value/Standard Retaining screw Tightening torque 50 Nm +5 Nm Installing fuel line Coat thread and shoulder of union nuts on HP fuel line (1) with engine oil. Note: Position fuel line, ensuring it is free of tension. -

Page 115

Fitting gasket and connecting injector cable Place gasket on cylinder head, ensuring correct installation position. Name Size Type Lubricant Value/Standard Union nut Tightening torque (Engine oil) 37 Nm +3 Nm Push cable lugs under the terminals (arrowed) on the injector and tighten to specified torque using a torque wrench. -

Page 116: Injector Functions

7.4.3 Injector functions Preconditions ☑ Engine is stopped and starting disabled. Note: The engine will lose its emissions certification of the drift correction parameters (CDC) are not reset. Resetting drift correction parameters (CDC) with DiaSys® Note: After successful installation of DiaSys®, document can be found here: C:DiaSysDoku auf ihrem Service- (→…

-

Page 117: Fuel System

7.5 Fuel System 7.5.1 Fuel system – Venting Preconditions ☑ Engine is stopped. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6-50 Nm F30027336 Ring socket, 22 mm F30038494 WARNING Fuels are combustible and explosive. Risk of fire and explosion! •…

-

Page 118: Fuel — Draining

7.5.2 Fuel – Draining Preconditions ☑ Engine is stopped and starting disabled. WARNING Fuels are combustible and explosive. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. • Wear protective clothing, protective gloves, and safety glasses / facial protection. WARNING Liquid or gaseous media, e.g.

-

Page 119: Fuel Filter

7.6 Fuel Filter 7.6.1 Fuel filter – Replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Filter wrench F30379104 Easy-change filter (→ Spare Parts Catalog) WARNING Fuels are combustible and explosive. Risk of fire and explosion! •…

-

Page 120: Fuel Prefilter – Draining

7.6.2 Fuel prefilter – Draining Preconditions ☑ Engine is stopped and starting disabled (non-switchable fuel prefilters only). DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine’s danger zone. WARNING Fuels are combustible and explosive.

-

Page 121: Fuel Prefilter – Filter Element Replacement

7.6.3 Fuel prefilter – Filter element replacement Preconditions ☑ Engine is stopped and starting disabled (non-switchable fuel prefilters only). Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6-50 Nm F30027336 Ratchet adapter F30027340 Diesel fuel Filter parts kit (→…

-

Page 122

Replacing fuel prefilter Close fuel supply. Unscrew filter cover (1). Remove filter element (3) from filter hous- ing (4). Install new O-ring (2) on filter cover (1). Coat new O-ring (2) with fuel. Insert new filter element (3) into filter hous- ing (4). -

Page 123: Fuel Prefilter – Venting

7.6.4 Fuel prefilter – Venting Preconditions ☑ Engine is stopped and starting disabled (non-switchable fuel prefilters only). DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine’s danger zone. WARNING Fuels are combustible and explosive.

-

Page 124: Air Filter

7.7 Air Filter 7.7.1 Air filter – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Air filter (→ Spare Parts Catalog) Filter insert (→ Spare Parts Catalog) Filter element (→ Spare Parts Catalog) Air filter – Replacement Remove air filter(s) and install new one(s) (→…

-

Page 125: Air Filter – Removal And Installation

7.7.2 Air filter – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Air filter – Removal and installa- tion Release clamp (2). Remove air filter (1) and clamp (2) from con- necting flange of intake housing (3). Clean the connecting flange of the intake housing (3) and check it for free passage.

-

Page 126: Air Intake

7.8 Air Intake 7.8.1 Service indicator – Signal ring position check Preconditions ☑ Engine is stopped and starting disabled. Checking signal ring position If the signal ring is completely visible in the control window (2), replace air filter (→ Page 124). After installation of new filter, press reset button (1).

-

Page 127: Starting Equipment

7.9 Starting Equipment 7.9.1 Electric starter ‒ Overview 1 Starter 4 Gasket 7 Nut 2 Gasket 5 Stud 3 Flange 6 Washer MS15054/00E 2015-09 | Task Description | 127…

-

Page 128: Starter – Removal

7.9.2 Starter – Removal Preconditions ☑ Engine is stopped and starting disabled. DANGER Electric voltage supply for operation. Danger of burns and fatal electric shock! • Make certain that the power supply to the product is switched off before starting work. Secure against unintentional switching on! WARNING The component is very heavy and may fall or tip over if unstable.

-

Page 129: Starter ‒ Installation

7.9.3 Starter ‒ Installation Preconditions ☑ Engine is stopped and starting disabled. DANGER Electric voltage supply for operation. Danger of burns and fatal electric shock! • Make certain that the power supply to the product is switched off before starting work. Secure against unintentional switching on! WARNING The component is very heavy and may fall or tip over if unstable.

-

Page 130: Lube Oil System, Lube Oil Circuit

7.10 Lube Oil System, Lube Oil Circuit 7.10.1 Engine oil – Level check Preconditions ☑ Engine is stopped and starting disabled. Oil level check prior to engine start Withdraw oil dipstick from guide tube and wipe it. Insert oil dipstick into guide tube up to the stop, withdraw after approx.

-

Page 131: Engine Oil – Change

7.10.2 Engine oil – Change Preconditions ☑ Engine is stopped and starting disabled. ☑ Engine is at operating temperature. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine oil Sealing ring (→…

-

Page 132: Oil Filtration / Cooling

7.11 Oil Filtration / Cooling 7.11.1 Engine oil filter – Replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Filter wrench F30379104 Engine oil Oil filter (→ Spare Parts Catalog) WARNING Hot oil.

-

Page 133: Centrifugal Oil Filter – Cleaning And Filter Sleeve Replacement

7.11.2 Centrifugal oil filter – Cleaning and filter-sleeve replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 8–40 Nm F30043446 Ratchet F30027340 Cold cleaner(Hakutex 60) X00056750 Filter sleeve (→…

-

Page 134

Use torque wrench to tighten nut (2) to specified tightening torque. Name Size Type Lubricant Value/Standard Tightening torque 8 Nm + 1 Nm Fit housing cover (1). Screw on nuts (4). Use torque wrench to tighten nuts (4) crosswise to specified tightening torque. Name Size Type… -

Page 135: Circuit

7.12 Coolant Circuit, General, High-Temperature Circuit 7.12.1 Engine coolant – Level check Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. WARNING Coolant is hot and under pressure. Risk of injury and scalding! •…

-

Page 136: Engine Coolant – Change

7.12.2 Engine coolant – Change Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant Engine coolant change Drain engine coolant (→ Page 137). Fill with engine coolant (→ Page 138). 136 | Task Description | MS15054/00E 2015-09…

-

Page 137: Engine Coolant – Draining

7.12.3 Engine coolant – Draining Preconditions ☑ Engine is stopped and starting disabled. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down. • Wear protective clothing, gloves, and goggles / safety mask. Preparatory steps Provide a suitable container to catch the coolant.

-

Page 138: Engine Coolant – Filling

7.12.4 Engine coolant – Filling Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant WARNING Coolant is hot and under pressure.

-

Page 139

Final steps Start the engine and operate it at idle speed for some minutes. Check coolant level, top up coolant if necessary (→ Page 135). MS15054/00E 2015-09 | Task Description | 139… -

Page 140: Engine Coolant Pump – Relief Bore Check

7.12.5 Engine coolant pump – Relief bore check DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine’s danger zone. WARNING High level of engine noise when the engine is running.

-

Page 141: Engine Coolant – Sample Extraction And Analysis

Draw off precipitated corrosion inhibitor oil from expansion tank and dispose of oil. Draw off approx. 1 liter coolant and drain into a clean container. Using the equipment and chemicals from the MTU test kit, examine coolant for: • antifreeze concentration;…

-

Page 142: Low-Temperature Circuit

7.13 Low-Temperature Circuit 7.13.1 Charge-air coolant – Filling Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant Sealing ring (→ Spare Parts Catalog) WARNING Coolant is hot and under pressure.

-

Page 143

Charge-air coolant – Filling Fill treated coolant through filling line or through filler neck of coolant expansion tank until coolant level reaches marking plate. Install plug screws of filling points with new sealing rings. Check proper condition of breather valve (1), clean sealing faces if required. Fit breather valve (1) and close it. -

Page 144: Charge-Air Coolant – Draining

7.13.2 Charge-air coolant – Draining Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Sealing ring (→ Spare Parts Catalog) Sealing ring (→ Spare Parts Catalog) WARNING Coolant is hot and under pressure. Risk of injury and scalding! •…

-

Page 145: Charge-Air Coolant – Change

7.13.3 Charge-air coolant – Change Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant Charge-air coolant – Change Drain charge-air coolant (→ Page 144). Fill with charge-air coolant (→ Page 142). MS15054/00E 2015-09 | Task Description | 145…

-

Page 146: Charge-Air Coolant – Level Check

7.13.4 Charge-air coolant – Level check Preconditions ☑ Engine is stopped and starting disabled. ☑ MTU Fluids and Lubricants Specifications (A001061/..) are available. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down.

-

Page 147: Charge-Air Coolant Pump – Relief Bore Check

7.13.5 Charge-air coolant pump – Relief bore check DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine’s danger zone. WARNING High level of engine noise when the engine is running.

-

Page 148: Intercooler – Checking Condensate Drain For Coolant Discharge And Obstructions

7.13.6 Intercooler – Checking condensate drain for coolant discharge and obstructions Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Sealing ring (→ Spare Parts Catalog) WARNING Compressed air gun ejects a jet of pressurized air. Risk of injury to eyes and damage to hearing, risk of rupturing internal organs! •…

-

Page 149: Belt Drive

7.14 Belt Drive 7.14.1 Drive belt – Condition check Preconditions ☑ Engine is stopped and starting disabled. ☑ Guard is removed. Drive belt – Condition check Item Findings Action Drive belt A Singular cracks None Drive belt B Cracks on entire circumference Replace (→…

-

Page 150: Drive Belt – Tension Check

7.14.2 Drive belt – Tension check Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Tester Y4345711 Belt tension tester, 150–600 N Y20097429 Measuring depression depth with preload measuring device Note: The frequency measurement procedure is the preferred one because it provides more exact measurement results.

-

Page 151

Measured value Belt length ‒ Application Measured value Operating tension (used belt) Initial installation (new belt) Drive belt 1800 mm – Fan Frequency: 88 ±1 Hz Frequency: 77 ±1 Hz Drive belt 1520 mm – Fan Frequency: 104 ±1 Hz Frequency: 92 ±1 Hz Table 11: Set-point values ‒… -

Page 152: Drive Belt ‒ Tension Adjustment

7.14.3 Drive belt ‒ Tension adjustment Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 20–100 Nm F30026582 Ratchet adapter F30027340 Torque wrench, 40–200 Nm F30027337 Ring socket, 24 mm F30501562 Engine oil Drive belt ‒…

-

Page 153: Drive Belt – Replacement

7.14.4 Drive belt – Replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Ring socket, 24 mm F30501562 Drive belt (→ Spare Parts Catalog) Replacing fan drive belt Remove protective cover from cooler. Remove protective grill from fan.

-

Page 154: Battery-Charging Generator

7.15 Battery-Charging Generator 7.15.1 Battery-charger drive – Drive belt replacement Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Tester Y4345711 Belt tension tester, 150–600 N Y20097429 Engine oil Drive belt (→…

-

Page 155

Measured value Belt ‒ Application Measured value Operating tension (used belt) Initial installation (new belt) Drive belt – Battery-charging gen- Depression depth: 7.8 mm Depression depth: 8.9 mm erator Test force: 60 N Test force: 60 N Table 13: Set-point values ‒ Measurement with preload measuring device Tighten screws (1). -

Page 156: Fuel Supply System

7.16 Fuel Supply System 7.16.1 Differential pressure gage – Check WARNING Fuels are combustible and explosive. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. • Wear protective clothing, protective gloves, and safety glasses / facial protection. Checking differential pressure gage Switch on fuel treatment system (optional).

-

Page 157: Coolant Level Sensor – Check

7.16.2 Coolant level sensor – Check Preconditions ☑ Plant has been put out of operation. WARNING Fuels are combustible and explosive. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. • Wear protective clothing, protective gloves, and safety glasses / facial protection. Checking coolant level sensor Drain coolant slowly.

-

Page 158: Pump Capacity – Check

7.16.3 Pump capacity – Check WARNING Fuels are combustible and explosive. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. • Wear protective clothing, protective gloves, and safety glasses / facial protection. Checking pump capacity Install suitable pressure gage in the intake connection of the pump.

-

Page 159: Engine Governor

7.17 Engine Governor 7.17.1 Engine control system – Overview 1 Connector X2 3 Connector X3 5 Screw 2 Engine control system 4 Washer 6 Damper MS15054/00E 2015-09 | Task Description | 159…

-

Page 160: Engine Governor – Removal And Installation

7.17.2 Engine governor – Removal and installation Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine governor (→ Spare Parts Catalog) Resilient mount (→ Spare Parts Catalog) NOTICE Wrong engine governor installed. Engine damage! •…

-

Page 161: Engine Governor Plug Connections – Check

7.17.3 Engine governor plug connections – Check Preconditions ☑ Engine stopped and starting disabled. ☑ Electronic engine management system is de-energized. NOTICE Insertion of unsuitable test probe, e.g. test prod. The contacts in the plug connection can be bent! • Carry out check of plug connection only with test connectors. Checking plug connections at engine governor Check all plug connections for secure seating.

-

Page 162: Wiring (General) For Engine/Gearbox/Unit

7.18 Wiring (General) for Engine/Gearbox/Unit 7.18.1 Engine cabling – Check Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Solvent (isopropyl alcohol) X00058037 Engine cabling – Check Check securing screws of cable clamps on engine and tighten loose screw connections. Ensure that cables are securely seated in clamps and cannot move freely.

-

Page 163: Accessories For (Electronic) Engine Governor / Control System

7.19 Accessories for (Electronic) Engine Governor / Control System 7.19.1 Engine governor and connector – Cleaning Preconditions ☑ Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Solvent (isopropyl alcohol) X00058037 NOTICE Insertion of unsuitable test probe, e.g.

-

Page 164: List Of Abbreviations

Abgasturbolader Exhaust turbocharger (ETC) Backup Data Module Baureihe Series Betriebsstoffvorschrift Fluids and Lubricants Specifications, MTU Publication No. A01061/.. Controller Area Network Data bus system, bus standard Controllable Pitch Propeller Deutsches Institut für Normung e. V. At the same time identifier of German standards (DIN = “Deutsche Industrie-Norm”)

-

Page 165

Explanation Abbrevia- Meaning tion Monitoring and Control System Message Microprocessor Unit, Microprocessing Unit Oberer Totpunkt Top dead center (TDC) Panel Control panel PCU/PMU Propeller Control Unit Propeller controller Peripheral Interface Module Priming Pump Control Remote Control System Redundancy Lost Alarm: Redundant CAN bus failure Sea Acceptance Test Sensor Defect Alarm: Sensor failure… -

Page 166: Mtu Contact Persons/Service Partners

Local support Experienced and qualified specialists place their knowledge and expertise at your disposal. For locally available support, go to the MTU Internet site: http://www.mtu-online.com 24h hotline With our 24h hotline and the outstanding flexibility of our service staff, we are always ready to assist you –…

-

Page 167: Special Tools

9 Appendix B 9.1 Special Tools Angular screw driver Part No.: F30453001 Qty.: Used in: 7.3.1 Valve clearance – Check and adjustment (→ Page 105) Barring device Part No.: F6792910 Qty.: Used in: 7.3.1 Valve clearance – Check and adjustment (→…

-

Page 168

Belt tension tester, 150–600 N Part No.: Y20097429 Qty.: Used in: 7.14.2 Drive belt – Tension check (→ Page 150) Qty.: Used in: 7.15.1 Battery-charger drive – Drive belt replacement (→ Page 154) Crowfoot wrench, 19 mm Part No.: F30027424 Qty.: Used in: 7.4.2 Injector –… -

Page 169

Filter wrench Part No.: F30379104 Qty.: Used in: 7.6.1 Fuel filter – Replacement (→ Page 119) Qty.: Used in: 7.11.1 Engine oil filter – Replacement (→ Page 132) Fuel suction device Part No.: F30378207 Qty.: Used in: 7.4.2 Injector – Removal and installation (→ Page 110) High-pressure cleaning unit Part No.: Qty.:… -

Page 170

MTU test kit Part No.: 5605892099/00 Qty.: Used in: 7.12.6 Engine coolant – Sample extraction and analysis (→ Page 141) Plug-in open-end wrench, 19 mm Part No.: F30453236 Qty.: Used in: 7.4.2 Injector – Removal and installation (→ Page 110) Press-fitting tool Part No.:… -

Page 171

Ratchet Part No.: F30006212 Qty.: Used in: 7.1.1 Engine – Cranking manually (→ Page 102) Qty.: Used in: 7.3.1 Valve clearance – Check and adjustment (→ Page 105) Ratchet Part No.: F30027340 Qty.: Used in: 7.11.2 Centrifugal oil filter – Cleaning and filter-sleeve re- placement (→… -

Page 172

Ring socket, 24 mm Part No.: F30501562 Qty.: Used in: 7.14.3 Drive belt ‒ Tension adjustment (→ Page 152) Qty.: Used in: 7.14.4 Drive belt – Replacement (→ Page 153) Socket wrench Part No.: F30030450 Qty.: Used in: 7.3.1 Valve clearance – Check and adjustment (→… -

Page 173

Torque wrench, 20-100 Nm Part No.: F30026582 Qty.: Used in: 7.3.1 Valve clearance – Check and adjustment (→ Page 105) Qty.: Used in: 7.4.2 Injector – Removal and installation (→ Page 110) Torque wrench, 20–100 Nm Part No.: F30026582 Qty.: Used in: 7.14.3 Drive belt ‒… -

Page 174

Torque wrench, 8–40 Nm Part No.: F30043446 Qty.: Used in: 7.3.2 Cylinder head cover – Removal and installation (→ Page 108) Qty.: Used in: 7.11.2 Centrifugal oil filter – Cleaning and filter-sleeve re- placement (→ Page 133) Torque wrench, 0.5–5 Nm Part No.: 0015384230 Qty.:… -

Page 175: Index

9.2 Index Crankcase breather – Oil mist fine separator Actuators – Replacement 104 – Overview 18 Cylinder After stopping the engine 68 – Designation 16 Air filter Cylinder head cover – Installation 125 – Installation 108 – Removal 125 – Removal 108 –…

-

Page 176

– Filter sleeve Main dimensions – Replacement 133 – Engine 60 Engine oil filter Maintenance schedule – Replacement 132 – Maintenance task reference table [QL1] 70 Engine oil level MTU contact persons 166 – Check 130 176 | Appendix B | MS15054/00E 2015-09… -

Page 177

Operational checks 64 Transport 8 Overview Troubleshooting 71 – Actuators 18 – Electric Valve clearance – Starter 127 – Adjustment 105 – Engine 17 – Check 105 – Engine governor 159 – Sensors 18 Plant – Cleaning 69 Pump – Charge-air coolant –…

- Manuals

- Brands

- MTU Manuals

- Engine

- 12V 2000 G23

- Use and maintenance manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Related Manuals for MTU 12V 2000 G23

Summary of Contents for MTU 12V 2000 G23

-

Page 1

Use and maintenance manual Diesel Engine 12V 2000 G23/43/63/83 16V 2000 G23/43/63/83 18V 2000 G63/83 Réf. constructeur : M015560/00E Réf. GPAO : 33522055801… -

Page 2

ã 2003 Copyright MTU Friedrichshafen GmbH Tout droit réservé pour cet ouvrage dans son intégralité. Toute utilisation ou exploitation requiert au préalable l’accord écrit de MTU Friedrichshafen GmbH. Ceci s’applique notamment à la reproduction, la diffusion, la modification, la traduction, l’archivage sur microfiches, la mémorisation et / ou le traitement sur des systèmes électroniques, y compris les bases de données et les services en ligne. -

Page 3

Safety Safety, accident prevention and environmental protection instructions Product Summary Engine layout, technical data Operation Task descriptions Maintenance and Servicing Maintenance schedule Troubleshooting Malfunctions, causes, measures Task Description Inspection and maintenance tasks Annex Abbreviations Index… -

Page 5

The Commissioning Note information serves as a basis for the contractually agreed logistic support (warranty, spare parts, etc.). Veuillez séparer la carte “Signalisation de mise en service“ et la renvoyer à la MTU Friedrichshafen GmbH. Les informations concernant la signalisation de mise en service constituent la base pour l’assistance en exploitation contractuelle (garantie, rechanges, etc.). -

Page 6

¡A rellenar en letras de imprenta! Scrivere in stampatello! Favor preencher com letras de forma! Motornr.: Auftragsnr.: Inbetriebnahmemeldung Engine No.: MTU works order No.: No du moteur: No de commande: No de motor: No de pedido: Motore N.: N. commessa: Commissioning Note No. -

Page 7

Amendment Service! Any changes in contents will be sent to you in the form of an amendment, provided you complete the reverse of this receipt card and return it to us. Postcard MTU Friedrichshafen GmbH Department SCT 88040 Friedrichshafen GERMANY… -

Page 8

Date Name Please mark all filed amendments here. Please use block capitals! Receipt Amendment No. Publication number: M015560/00E Name …………Manufacturer …………Department …………….Telephone….. Street …………Postal box number ……….(Postal code) City ……….Country ………… -

Page 9: Table Of Contents

1.6 Standards for warning notices in the publication ……. . 1 – 09 M015560/00E 03-05 © MTU…

-

Page 10

1 – II Table of Contents M015560/00E 03-05 © MTU… -

Page 11: Safety

Modifications or Conversions Modifications made by the customer to the engine may affect safety. MTU will accept no liability or warranty claims for any damage caused by unauthorized modifications or conversions. Spare parts Only genuine MTU spare parts must be used to replace components or assemblies. In the event of any damage caused by the use of other spare parts, no liability nor warranty claims vis-à-vis the engine manufacturer will be accepted.

-

Page 12: Personnel And Organizational Requirements

Depending on the kind of work, use additional protective equipment, e.g. protective goggles, gloves, helmet, apron. Work clothing must be tight fitting so that it does not catch on rotating or projecting components. Do not wear jewelry (e.g. rings, chains etc.). M015560/00E 03-05 © MTU…

-

Page 13: Transport

Place the engine only on an even, firm surface. Ensure appropriate consistency and load-bearing capacity of the ground or support surface. Never place an engine on the oil pan, unless expressively authorized by MTU on a case-to-case basis to do so. M015560/00E 03-05…

-

Page 14: Safety Precautions When Working On The Engine

In order to prevent back injuries when lifting heavy components adults, depending on age and sex, should only lift weights between max. 10 kg and 30 kg, therefore: • Use lifting gear or seek assistance. M015560/00E 03-05 © MTU…

-

Page 15

It is not necessary to remove the connector and the connections when carrying out welding operation on MTU electronics if the master switch for power supply is switched from «ON» to «OFF» and the wire is disconnected from the negative and positive poles on the battery. -

Page 16

5 mW, and in which the beam axis and surface are designed to prevent any risk to the eyes. Operation of electrical equipment When operating electrical equipment, certain components of this equipment are live. Noncompliance with the warning instructions given for this equipment may result in serious injury or damage to property. M015560/00E 03-05 © MTU… -

Page 17: Auxiliary Materials, Fire Prevention And Environmental Protection

Only fuels of the specified quality required to achieve emission limits must be used. In Germany, the VAwS (= regulations governing the use of materials that may affect water quality) is applicable, which means work must only be carried out by authorized specialist companies (MTU is such a company). Auxiliary materials Use only fluids and lubricants that have been tested and approved by MTU.

-

Page 18

• Do not blow dirty clothing with compressed air when being worn on the body. Used oil Used oil may contain health-threatening combustion residues. Rub barrier cream into hands! Wash hands after contact with used oil. M015560/00E 03-05 © MTU… -

Page 19: Standards For Warning Notices In The Publication

ANSI Z535, which begin with one of the above signal words according to the degree of danger: Warning notices 1. Read and become acquainted with all cautions and symbols before operating or repairing this product. 2. Pass on all safety instructions to your operating, maintenance, repair and transport personnel! M015560/00E 03-05 © MTU…

-

Page 20

1 – 10 Safety M015560/00E 03-05 © MTU… -

Page 21

……… . 2 – 70 M015560/00E 03-05 © MTU… -

Page 22

2 – II Table of Contents M015560/00E 03-05 © MTU… -

Page 23: Engine Layout

040 Cylinder head 140 Exhaust system free end (couplings) 050 Valve gear 170 Starting equipment 500 Monitoring and control systems, 070 HP fuel system 180 Lube oil system general electric devices 080 LP fuel system 200 Cooling system M015560/00E 03-05 © MTU…

-

Page 24

2 – 02 Engine Layout Engine model designation Key to the engine model designations 812/16/18V 2000 Gxy 8/12/16/18 Number of cylinders Cylinder configuration: V engine 2000 Series Application Application segment (2, 4, 6,Design index (0,1, 2,…) M015560/00E 03-05 © MTU…

-

Page 25: Engine Side And Cylinder Designations

The cylinders of each bank are numbered consecutively, starting with No. 1 at the driving end. The numbering of engine components is also from the driving end, starting with No. 1. KGS = Free end KS = Driving end Right side Left side M015560/00E 03-05 © MTU…

-

Page 26: Main Engine Dimensions

18V 2000 Gxy Length (A) approx. 2020 mm approx. 2365 mm approx. 2400 mm Width (B) approx. 1580 mm approx. 1580 mm approx. 1580 mm Height (C) approx. 1690 mm approx. 1925 mm approx. 1605 mm M015560/00E 03-05 © MTU…

-

Page 27: Engine Data

Fuel stop power ISO 3046 FSP GENERAL CONDITIONS (for maximum power) Number of cylinders Intake air depression (new filter) mbar (design) Intake air depression (limit mbar value) Exhaust backpressure (design) mbar Exhaust backpressure (limit mbar value) M015560/00E 03-05 © MTU…

-

Page 28

Number of exhaust valves, per cylinder Standard flywheel housing flange (engine main PTO) Flywheel interface DISC 18″ 18″ 18″ 18″ 18″ COMBUSTION AIR / EXHAUST GAS Number of cylinders Charge air pressure before bar ABS cylinder FSP M015560/00E 03-05 © MTU… -

Page 29

Lube oil temperature before engine, alarm Lube oil temperature before engine, shutdown Lube oil operating press. bef. engine, from Lube oil operating press. bef. engine, to Lube oil pressure before engine, alarm Lube oil pressure before engine, shutdown M015560/00E 03-05 © MTU… -

Page 30

(standard oil system) (Option: max. operating inclinations) Oil pan capacity, dipstick mark liter min. (standard oil system) (Option: max. operating inclinations) Oil pan capacity, dipstick mark liter max. (standard oil system) (Option: max. operating inclinations) M015560/00E 03-05 © MTU… -

Page 31

ACOUSTICS Number of cylinders Exhaust noise, unsilenced FSP db(A) (sound power level LW, ISO 6798) Engine surface noise with db(A) attenuated FSP intake noise (filter) (sound power level LW, ISO 6798) M015560/00E 03-05 © MTU… -

Page 32: 12/16/18V 2000 Standby Operation: Application Group 3D, Air-Cooled Charge Air, Optimized Exhaust Emission (Epa 40 Cfr89 / Tier 1)

Fuel stop power ISO 3046 FSP 1000 1115 1250 GENERAL CONDITIONS (for maximum power) Number of cylinders Intake air depression (new filter) mbar (design) Intake air depression (limit mbar value) Exhaust backpressure (design) mbar Exhaust backpressure (limit mbar value) M015560/00E 03-05 © MTU…

-

Page 33

Number of exhaust valves, per cylinder Standard flywheel housing flange (engine main PTO) Flywheel interface DISC 18″ 18″ 18″ 18″ 18″ COMBUSTION AIR / EXHAUST GAS Number of cylinders Charge air pressure before bar ABS cylinder FSP M015560/00E 03-05 © MTU… -

Page 34

Lube oil temperature before engine, alarm Lube oil temperature before engine, shutdown Lube oil operating press. bef. engine, from Lube oil operating press. bef. engine, to Lube oil pressure before engine, alarm Lube oil pressure before engine, shutdown M015560/00E 03-05 © MTU… -

Page 35

(standard oil system) (Option: max. operating inclinations) Oil pan capacity, dipstick mark liter min. (standard oil system) (Option: max. operating inclinations) Oil pan capacity, dipstick mark liter max. (standard oil system) (Option: max. operating inclinations) M015560/00E 03-05 © MTU… -

Page 36

ACOUSTICS Number of cylinders Exhaust noise, unsilenced FSP db(A) (sound power level LW, ISO 6798) Engine surface noise with db(A) attenuated FSP intake noise (filter) (sound power level LW, ISO 6798) M015560/00E 03-05 © MTU… -

Page 37: 12/16/18V 2000 Continuous Operation With Variable Load: Application Group 3B, Air-Cooled Charge Air, Optimized Fuel Consumption

(10% overload CP cap., design power DIN 6280, ISO 8528) GENERAL CONDITIONS (for maximum power) Number of cylinders Intake air depression (new filter) mbar (design) Intake air depression (limit mbar value) Exhaust backpressure (design) mbar Exhaust backpressure (limit mbar value) M015560/00E 03-05 © MTU…

-

Page 38

Number of exhaust valves, per cylinder Standard flywheel housing flange (engine main PTO) Flywheel interface DISC 18″ 18″ 18″ 18″ 18″ COMBUSTION AIR / EXHAUST GAS Number of cylinders Charge air pressure before CP bar ABS cylinder (abs.) M015560/00E 03-05 © MTU… -

Page 39

Lube oil temperature before engine, alarm Lube oil temperature before engine, shutdown Lube oil operating press. bef. engine, from Lube oil operating press. bef. engine, to Lube oil pressure before engine, alarm Lube oil pressure before engine, shutdown M015560/00E 03-05 © MTU… -

Page 40

(standard oil system) (Option: max. operating inclinations) Oil pan capacity, dipstick mark liter min. (standard oil system) (Option: max. operating inclinations) Oil pan capacity, dipstick mark liter max. (standard oil system) (Option: max. operating inclinations) M015560/00E 03-05 © MTU… -

Page 41

ACOUSTICS Number of cylinders Exhaust noise, unsilenced CP db(A) (sound power level LW, ISO 6798) Engine surface noise with db(A) attenuated CP intake noise (filter) (sound power level LW, ISO 6798) M015560/00E 03-05 © MTU… -

Page 42: 12/16/18V Continuous Operation With Variable Load: Application Group 3B, Air-Cooled Charge Air, Optimized Exhaust Emission (Ta-Luft)

(10% overload CP cap., design power DIN 6280, ISO 8528) GENERAL CONDITIONS (for maximum power) Number of cylinders Intake air depression (new filter) mbar (design) Intake air depression (limit mbar value) Exhaust backpressure (design) mbar Exhaust backpressure (limit mbar value) M015560/00E 03-05 © MTU…

-

Page 43

Number of exhaust valves, per cylinder Standard flywheel housing flange (engine main PTO) Flywheel interface DISC 18″ 18″ 18″ 18″ 18″ COMBUSTION AIR / EXHAUST GAS Number of cylinders Charge air pressure before CP bar ABS cylinder (abs.) M015560/00E 03-05 © MTU… -

Page 44

Lube oil temperature before engine, alarm Lube oil temperature before engine, shutdown Lube oil operating press. bef. engine, from Lube oil operating press. bef. engine, to Lube oil pressure before engine, alarm Lube oil pressure before engine, shutdown M015560/00E 03-05 © MTU… -

Page 45

(standard oil system) (Option: max. operating inclinations) Oil pan capacity, dipstick mark liter min. (standard oil system) (Option: max. operating inclinations) Oil pan capacity, dipstick mark liter max. (standard oil system) (Option: max. operating inclinations) M015560/00E 03-05 © MTU… -

Page 46

ACOUSTICS Number of cylinders Exhaust noise, unsilenced CP db(A) (sound power level LW, ISO 6798) Engine surface noise with db(A) attenuated CP intake noise (filter) (sound power level LW, ISO 6798) M015560/00E 03-05 © MTU… -

Page 47: 12/16/18V Continuous Operation With Variable Load: Application Group 3B, Air-Cooled Charge Air, Optimized Exhaust Emission (Epa 40 Cfr89 / Tier 1)

DIN 6280, ISO 8528) GENERAL CONDITIONS (for maximum power) Number of cylinders Intake air depression (new filter) (design) mbar Intake air depression (limit value) mbar Exhaust backpressure (design) mbar Exhaust backpressure (limit value) mbar M015560/00E 03-05 © MTU…

-

Page 48

Number of exhaust valves, per cylinder Standard flywheel housing flange (engine main PTO) Flywheel interface DISC 18″ 18″ 18″ COMBUSTION AIR / EXHAUST GAS Number of cylinders Charge air pressure before CP cylinder (abs.) bar ABS M015560/00E 03-05 © MTU… -

Page 49

FUEL SYSTEM Number of cylinders Fuel pressure at supply connection to engine (when -0.3 -0.3 -0.3 engine is starting), min. admissible Fuel pressure at supply connection to engine (when +0.5 +0.5 +0.5 engine is starting), max. admissible M015560/00E 03-05 © MTU… -

Page 50

3500 scope of supply specification) ACOUSTICS Number of cylinders Exhaust noise, unsilenced CP (sound power level LW, db(A) ISO 6798) Engine surface noise with attenuated CP intake noise db(A) (filter) (sound power level LW, ISO 6798) M015560/00E 03-05 © MTU… -

Page 51: 12/16/18V 2000 Continuous Operation, Unrestricted: Application Group 3B, Air-Cooled Charge Air, Optimized Fuel Consumption, Optimized Exhaust Emission (Epa 40 Cfr89 / Tier 1)

POWER-RELATED DATA (power ratings are net brake power to ISO 3046) Number of cylinders Engine rated 1500 1500 1500 1800 1800 1800 speed Continuous power ISO 3046 (10% overload CP cap., design power DIN 6280, ISO 8528) M015560/00E 03-05 © MTU…

-

Page 52

(CAC) Exhaust piping, non-cooled Working method: four-cycle, diesel, single-acting Combustion method: direct fuel injection Cooling system: conditioned water Direction of rotation: c.c.w. (facing driving end) Number of cylinders Cylinder degrees configuration: V angle Bore Stroke M015560/00E 03-05 © MTU… -

Page 53

Standard flywheel housing flange (engine main PTO) Flywheel interface DISC 18″ 18″ 18″ 18″ 18″ 18″ COMBUSTION AIR / EXHAUST GAS Number of cylinders Charge air bar ABS pressure before CP cylinder (abs.) M015560/00E 03-05 © MTU… -

Page 54