- Manuals

- Brands

- CUMMINS Manuals

- Engine

- 6BT5.9

Manuals and User Guides for CUMMINS 6BT5.9. We have 2 CUMMINS 6BT5.9 manuals available for free PDF download: Shop Manual, Service Manual

CUMMINS 6BT5.9 Shop Manual (462 pages)

Brand: CUMMINS

|

Category: Engine

|

Size: 15.03 MB

Table of Contents

-

Foreword

2

-

Table of Contents

3

-

Cummins 22-Group System Exploded Diagram

4

-

How to Use the Manual

5

-

Generic Symbols

6

-

Introduction

8

-

Section Contents

8

-

About the Manual

9

-

General Safety Instructions

10

-

General Repair Instructions

11

-

General Cleaning Instructions

12

-

Glossary of Terms

13

-

Engine and Component Identification

15

-

Engine Identification

16

-

Industrial Engine Nomenclature

17

-

Automotive Engine Nomenclature

17

-

Injection Pump Dataplate

18

-

General Engine Specifications

20

-

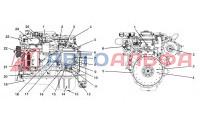

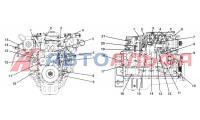

Engine Diagram-Automotive Engine

23

-

Inlet Side

23

-

Rear View

23

-

Turbocharger Side View

24

-

Front View

24

-

Engine Disassembly and Assembly

25

-

Engine Disassembly and Assembly-Service Tools

29

-

Engine Disassembly Check List

31

-

Engine Disassembly

32

-

Steam Cleaning the Engine

32

-

Engine Weight

32

-

Rollover Stand-Engine Mounting

32

-

Oil-Draining

33

-

Lifting Bracket Removal-Rear

33

-

Drive Beit-Removal

33

-

Fan Pulley-Removal

34

-

Vibration Damper/Crankshaft Pulley-Removal

34

-

Belt Tensioner-Removal

34

-

Fan Hub-Removal

35

-

Alternator-Removal

35

-

Thermostat-Removal

36

-

Turbocharger-Removal

36

-

Exhaust Manifold-Removal

38

-

Fuel Filter-Removal

38

-

Fuel Filter Head-Removal

39

-

KSB (Remote Mounted)-Removal

39

-

Fuel Lines-Removal

40

-

High Pressure Fuel Line-Removal

40

-

Fuel Drain Manifold-Removal

41

-

Low Pressure Fuel Lines-Removal

42

-

Dipstick-Removal

43

-

Manifold Cover-Removal

43

-

Aftercooler-Removal

43

-

Valve Covers-Removal

44

-

Injector Nozzles-Removal

44

-

Rocker Levers-Removal

45

-

Push Rods-Removal

45

-

Cylinder Head-Removal

46

-

Front Cover-Removal

46

-

Water Pump-Removal

47

-

Flywheel-Removal

47

-

Flywheel Housing-Removal

47

-

Accessories-Removal

48

-

Injection Pump-Removal (Rotary Type Pumps)

48

-

Gear Lash-Check

48

-

Locking the Pump

49

-

Drive Gear-Removal

50

-

Injection Pump-Removal (In-Line)

50

-

Fuel Transfer Pump-Removal

52

-

Tappet Cover-Removal

52

-

Side Oil Fill-Removal

53

-

Oil Cooler-Removal

53

-

Water Inlet Connection-Removal

53

-

Oil Pan-Removal

54

-

Suction Tube-Removal

54

-

Rear Seal Housing-Removal

54

-

Camshaft-Removal

55

-

Measuring Gear Lash

55

-

Valve Tappets-Removal

56

-

Lube Pump-Removal

56

-

Measuring Backlash

56

-

Timing Pin Housing-Removal

58

-

Gear Housing-Removal

58

-

Balancer-Removal

59

-

Measuring the End Play

59

-

Locking the Balancer

59

-

Removing the Balancer

60

-

Piston and Rod Assemblies-Removal

61

-

Crankshaft-Removal

63

-

Turbocharger Drain Tube-Removal

65

-

Cylinder Block-Removing from the Rollover Stand

65

-

Engine Assembly

65

-

Cylinder Block-Prepare for Assembly

65

-

Valve Tappets-Installation

66

-

Crankshaft-Installation

66

-

Piston and Rod Assemblies-Installation

71

-

Piston Grading for 1994 Automotive Applications Only

71

-

Dial Indicator

72

-

Piston Protrusion

74

-

Piston and Connecting Rod Assemblies-Installation

74

-

Gear Housing-Installation

78

-

Lube Pump-Installation

79

-

Camshaft-Installation

80

-

Camshaft End Play-Measuring

82

-

Camshaft Gear Backlash-Measuring

83

-

Timing Pin-Installation

83

-

Crankshaft End Play-Measuring

90

-

Rear Seal-Installation

90

-

Suction Tube-Installation

91

-

Oil Pan-Installation

92

-

Oil Pan Sealing Surfaces-Sealants

92

-

Oil Cooler-Installation

93

-

Side Oil Fill-Installation

93

-

Fuel Transfer Pump-Installation

93

-

Tappet Cover-Installation

94

-

Injection Pump-Installation

95

-

Locked Timed Injection Pump-Installation

96

-

Injection Pumps-Unlocking

98

-

Chisel, Hammer

99

-

Unlocked CAV Injection Pump-Installation

100

-

Unlocked Stanadyne DB4 Injection Pump-Installation

101

-

Unlocked Bosch VE and P7100 Injection Pump-Installation

104

-

Disengage the TDC Pin

107

-

Pump Gear Backlash Limit

107

-

Injection Pump Installation

108

-

Accessories-Installation

112

-

Flywheel Housing-Installation

113

-

Flywheel-Installation

113

-

Water Pump-Installation

114

-

Front Cover-Installation

115

-

Cylinder Head-Installation

116

-

Push Rods-Installation

117

-

Rocker Levers-Installation

118

-

Cylinder Head-Tightening

119

-

Valve Clearance-Adjustment

121

-

Valve Stem to Rocker Lever Clearance

122

-

Injector Nozzles-Installation

123

-

Valve Covers-Installation

124

-

Manifold Cover-Installation

124

-

Aftercooler-Installation

125

-

Fuel Lines-Installation

125

-

Infection Pump Supply Line-Installation

125

-

Fuel Drain Manifold-Installation

126

-

Injection Pump Vent Line-Installation

126

-

High Pressure Fuel Lines-Installation

127

-

KSB (Remote Mounted)-Installation

128

-

Fuel Filter Head-Installation

128

-

Exhaust Manifold-Installation

129

-

Turbocharger-Installation

130

-

Thermostat-Installation

133

-

Vibration Damper-Installation

134

-

Fan Hub-Installation

134

-

Beit Tensioner-Installation

135

-

Water Inlet Connection-Installation

135

-

Alternator-Installation

135

-

Drive Belt-Installation

137

-

Oil Filter-Installation

137

-

Rollover Stand-Engine Removal

137

-

Starter-Installation

138

-

Cylinder Block

139

-

Cylinder Block-Exploded View

141

-

Cylinder Block-General Information

144

-

Cylinder Block-Service Tools

145

-

Cylinder Block Group Inspection Checklist

146

-

Cylinder Block-Precheck before Disassembly

147

-

Cylinder Block-Disassembly

147

-

Cylinder Block-Cleaning

149

-

Cylinder Block-Inspection

152

-

Cylinder Block-De-Glazing

154

-

Expansion and Pipe Plug-Installation

157

-

Camshaft Expansion Plug-Installation

159

-

Camshaft Bushing-Installation

160

-

Dipstick Tube-Replacement

162

-

Cylinder Block-Storing

162

-

Crankshaft-Cleaning

163

-

Crankshaft-Inspection

163

-

Crankshaft Gear-Replacement

164

-

Determining Mam Bearing Clearance

164

-

Camshaft-Cleaning

166

-

Camshaft and Gear-Inspection

166

-

Camshaft Lobe Pitting Reuse Criteria

167

-

Camshaft Lobe Edge Deterioration (Breakdown) Criteria

168

-

Camshaft Gear-Replacement

171

-

Camshaft Gear-Removal

171

-

Camshaft Gear-Installation (Heated Gear Method)

171

-

Camshaft Gear-Installation (with Special Tool 3823589)

173

-

Camshaft Capscrew-Installation

175

-

Rubber Element Vibration Damper-Cleaning and Inspection

176

-

Piston and Connecting Rod-Disassembly

178

-

Piston, Pin and Connecting Rod-Cleaning

178

-

Piston Inspection

179

-

Piston Pin-Inspection

180

-

Connecting Rod-Inspection

181

-

Rod Bearing Clearance-Checking

181

-

Piston and Connecting Rod-Assembly

182

-

Piston Ring Gap-Checking

183

-

Piston Rings-Installation

184

-

Balancer-Disassembly

185

-

Balancer-Assembly

188

-

Gear Housing and Timing Pin Assembly-Inspection

194

-

Gear Housing-Disassembly

195

-

Fuel Pump Stud-Replacement

195

-

Data Plate-Replacement

196

-

Cylinder Head

198

-

Cylinder Head-Service Tools

199

-

Cylinder Head Exploded View

200

-

General Information

202

-

Cylinder Head-Precheck before Disassembly

203

-

Cylinder Head-Disassembly

203

-

Cylinder Head-Cleaning

204

-

Valve-Inspection

206

-

Valve Guide Inspection

208

-

Cylinder Head Combustion Face Inspection

208

-

Valve Seat Inspection

208

-

Cylinder Head Cracks-Reuse Guidelines

209

-

Valve Spring Inspection

209

-

Cup Plug Replacement

210

-

Valves-Grinding

212

-

Valve Seats-Grinding

213

-

Calculating the Grinding Depth

213

-

Valve Depth

214

-

Seat Angle

214

-

Gauge Block

214

-

Seat Grinding Depth Limit

215

-

Valve Seat Width Limit

216

-

Cylinder Head-Assembly

218

-

Valve Spring Compressor

218

-

Rocker Levers

220

-

Rocker Lever Assembly-Exploded View

221

-

Rocker Lever Assembly-General Information

223

-

Rocker Levers-Disassembly

224

-

Rocker Levers and Pedestals-Cleaning

225

-

Rocker Lever-Inspection

225

-

Rocker Lever Pedestals-Inspection

226

-

Rocker Levers-Assembly

226

-

Tappets and Push Rods

228

-

Tappets and Push Rods-Exploded View

229

-

Tappets and Push Rods-General Information

230

-

Valve Tappets-Inspection

231

-

Push Rods-Inspection

231

-

Fuel System

233

-

Service Tools-Injection Pump

234

-

Exploded View-Fuel System

235

-

Injection Pump-General Information

236

-

Injection Pump-Identification

236

-

KSB Electrical Solenoid Style-General Information

238

-

Cold Start Timing Advance System (KSB)-Electrical Solenoid Style

238

-

VE Pump Timing Advance Principles (Without KSB)

239

-

VE Pump Timing Advance Principles (with Electrical Solenoid KSB Installed)

240

-

Warm Engine Operation (more than 90°F IMT), Retarded Timing

242

-

KSB Electrical Solenoid Style-Inspection

244

-

KSB Electrical Solenoid-Inspection

244

-

KSB Electrical Solenoid Style Wiring Harness-Inspection

246

-

Injection Pump Repairs-Bosch VE

247

-

Delivery Valve Holder/Sealing Washer-Replacement

248

-

Shutdown Solenoid-Replacement

249

-

Shutdown Lever/Spring-Replacement

250

-

Overflow Adapter/Sealing Ring-Replacement

251

-

Fuel Inlet Adapter/Seal-Replacement

252

-

Injection Pump Timing-Bosch VE

253

-

Injection Pump Repairs-Lucas CAV DPA

257

-

Back Leakage Valve-Replacement/Inspection

258

-

Bleed Screws/Sealing Washers-Replacement

260

-

Vent Fitting/Sealing Washer-Inspection/Replacement

261

-

Fuel Inlet Fitting/Sealing Washer-Replacement

262

-

Control Lever-Replacement

262

-

Inspect the Lever Components

263

-

Automatic Timing Advance-Disassembly

265

-

Timing Advance Components-Inspection

266

-

Timing Advance-Assembly

267

-

Injection Pump Repairs

271

-

Injection Pump Timing-Stanadyne DB4

271

-

Return Connection Replacement, Stanadyne DB4

272

-

Shutoff Solenoid Replacement, Stanadyne DB4

273

-

Speed Droop Adjustment off Engine-Stanadyne DB4

275

-

Injection Pump Timing-Nippondenso EP9

276

-

Seals Replacement, Nippondenso EP9

278

-

Shut down Lever or Spring Replacement, Nippondenso EP9

278

-

Pressure Relief Valve and Sealing Washer Replacement, Bosch P7100

280

-

Seal Replacement, Bosch P7100

282

-

Fuel Inlet Banjo Connector Replacement, Bosch P7100

282

-

Fuel Shut off Solenoid Replacement, Bosch P7100

283

-

Fuel Shut off Solenoid Adjustment, Bosch P7100

283

-

Fuel Shut off Solenoid Bracket Replacement, Bosch P7100

284

-

Fuel Pump Shut off Lever Replacement, Bosch P7100

284

-

Throttle Lever Replacement, Bosch P7100

285

-

Shutdown Solenoid Inspection, Bosch P7100

286

-

Wiring Guidelines

286

-

Solenoid Resistance Check

286

-

Solenoid Voltage Check

287

-

Injectors

288

-

Injector-Service Tools

289

-

Injector Group-Exploded View

290

-

General Information-Injectors

291

-

Fuel Transfer Pump-General Information

292

-

Fuel Transfer Pump-Identification

292

-

Injector-Disassembly

294

-

Injector-Clean and Inspect

295

-

Nozzle Cleaning Kit

296

-

Injector-Assembly

297

-

Injector-Testing

299

-

Chatter Test

300

-

Fuel Transfer Pump-Cleaning and Inspecting

300

-

Fuel Transfer Pump-Piston Style Rebuild

301

-

Cleaning

302

-

Assembly

302

-

Fuel Lines-Clean and Inspect

303

-

High Pressure Fuel Lines

303

-

Fuel Drain Manifold

304

-

Low Pressure Fuel Lines

305

-

Lubrication Oil System

307

-

Oil Pan and Suction Tube-Exploded View

308

-

Oil Pan and Suction Tube-General Information

309

-

Oil Pan and Suction Tube-Cleaning and Inspection

310

-

Lubricating Oil Cooler-Exploded View

311

-

General Information-Lubrication System

312

-

Pressure Regulator Valve-Disassembly

313

-

Pressure Regulator Valve-Inspection

313

-

Pressure Regulator Valve-Assembly

314

-

Filter Bypass Valve-Replace

314

-

Oil Cooler-Cleaning

315

-

Oil Cooler-Inspection

315

-

Lubricating Oil Pump-Exploded View

317

-

Lubrication Oil Pump-General Information

318

-

Oil Pump-Inspection

319

-

Cooling System

322

-

Water Pump-Exploded View

323

-

Water Pump-General Information

324

-

Water Pump-Inspection

325

-

Belt Tensioner and Fan Hub-Exploded View

326

-

Belt Tensioner and Fan Hub-General Information

327

-

Fan Hub-Inspection

328

-

Fan Hub-Disassembly

328

-

Fan Hub Assembly

329

-

Belt Tensioner-Inspection

331

-

Thermostat Housing Assembly-Exploded View

332

-

Thermostat Housing Assembly-General Information

333

-

Thermostat-Inspection

334

-

General Information about Fans

335

-

Drive Units

336

-

Accessory Drive Adapter-Exploded View

337

-

Drive Units-General Information

338

-

Accessory Drive-Cleaning

339

-

Accessory Drive-Inspection

339

-

Accessory Drive Adaptor-Disassembly

339

-

Accessory Drive Adaptor-Assembly

340

-

Air Intake System

342

-

Air Intake System-Exploded View

343

-

Air Intake System-General Information

345

-

Turbocharger-Cleaning and Inspection for Reuse

346

-

Inspection

346

-

Aftercooler Assembly-Cleaning and Inspection for Reuse

347

-

Pressure Test the Aftercooler Core

348

-

Aftercooler Assembly-Rebuild

348

-

Air Transfer Pipe-Cleaning and Inspection for Reuse

348

-

Air Crossover Tube-Cleaning and Inspection for Reuse

349

-

Charge Air Cooler (CAC)-Cleaning and Inspection for Reuse

349

-

Charge Air Cooler (CAC)-Pressure Testing

350

-

Exhaust System

352

-

Exhaust Manifold-Exploded View

353

-

Exhaust Manifold Inspection

355

-

Turbocharger Mounting Stud Replacement

355

-

Air Equipment

356

-

Air Equipment-General Information

357

-

Air Compressor-Cleaning and Inspection for Reuse

358

-

Power Steering Coupling (if Applicable)

358

-

Power Steering Adapter

359

-

Electrical Equipment

360

-

Electrical Equipment-General Information

361

-

Alternator Inspection

362

-

Starter Inspection

362

-

Engine Testing

363

-

Engine Testing-Service Tools

364

-

Engine Testing-Engine Side Views

366

-

Engine Testing-General Information

368

-

Blowby Measurement

369

-

Engine Dynamometer Test-Installation of the Engine

370

-

Engine Dynamometer Test-Engine Run-In

376

-

Engine Dynamometer Test-Performance Checking

380

-

Chassis Dynamometer-Operation

382

-

General Engine Test Procedures-(Chassis Dynamometer)

384

-

Engine Run-In Procedure-(Chassis Dynamometer)

387

-

Engine Run-In Procedure “In Chassis”-(On-And Off-Highway Vehicles)

389

-

Engine-Painting

390

-

Engine Storage-Short Term

391

-

Removing the Engine from Short-Term Storage

393

-

Engine Storage-Long Term

393

-

Removing the Engine from Long-Term Storage

396

-

Mounting Adaptations

400

-

Flywheel Housing

401

-

Flywheel and Ring Gear

401

-

Front Support

401

-

Flywheel and Ring Gear Inspection

402

-

Ring Gear Replacement

402

-

Flywheel Housing Inspection

403

-

Flywheel Housing Assembly

403

-

Wet Clutch Application

404

-

Front Support-Cleaning and Inspection

405

-

Engine Component Specifications

406

-

Specifications-General Information

407

-

Engine Component Torque Values

408

-

Component Specifications and Torque Values

411

-

Engine Assembly-Specifications

411

-

Engine Assembly-Capscrew Torque Values

415

-

Cylinder Block-Rebuild Specifications

421

-

Cylinder Block-Torque Values

427

-

Cylinder Head-Rebuild Specifications

428

-

Cylinder Head-Torque Values

430

-

Tappet and Push Rods

431

-

Lubricating Oil System-Specifications

434

-

Fan Hub-Specifications

436

-

Thermostat, Coolant Operating Temperature

436

-

Combustion Air System

436

-

Compressed Air System Torque Values

438

-

Electrical System

439

-

Engine Testing-Test Specifications

440

-

Drive Belt Tension

441

-

Weight and Measures-Conversion Factors

443

-

Newton-Meter to Foot-Pound Conversion Chart

444

-

Capscrew Markings and Torque Values-U.S. Customary

445

-

Capscrew Markings and Torque Values

446

-

Pipe Plug Torque Values

447

-

Tap-Drill Chart-U.S. Customary & Metric

448

-

Service Literature

449

-

Additional Service Literature

450

-

Service Literature Ordering Location

451

-

Service Literature Order Form

452

-

Component Manufacturers

454

-

United States and United Kingdom Offices

455

-

Index

458

-

Cummins Customized Parts Catalog

461

Advertisement

CUMMINS

DGBA

Service Manual

CUMMINS 6BT5.9 Service Manual (108 pages)

Detector Controls

Brand: CUMMINS

|

Category: Inverter

|

Size: 4.04 MB

Table of Contents

-

Table of Contents

3

-

Important Safety Instructions

5

-

Safety Precautions

7

-

Introduction

7

-

Ac Control

9

-

General

9

-

Standard Control Panel Components

9

-

Optional Control Panel Components

9

-

Automatic Voltage Regulator (AVR) Adjustments

10

-

Principle of Generator Operation

15

-

-

Engine Control

17

-

Control Panel

17

-

Standard Control Panel Components

17

-

Optional Control Panel Components

18

-

Control Box Interior

20

-

Engine Control Monitor (A11)

20

-

Engine Sensors

22

-

Auxiliary Control Components

26

-

Sequence of Operation

32

-

-

Troubleshooting

33

-

The Engine Does Not Crank

34

-

The Engine Cranks but Does Not Start

36

-

The Engine Runs until Fault Shutdown (Red Shutdown Lamp On)

38

-

The Engine Lacks Power or Stable Speed

40

-

Amber Warning Lamp on

42

-

The Green Run Lamps Stay off but the Set Runs Normally

43

-

There Is no Output Voltage (Engine Speed Is Stable)

44

-

Output Voltage Is too High or too Low

48

-

Output Voltage Is Unstable

49

-

The Field Circuit Breaker Keeps Tripping

50

-

The Phase Currents Are Unbalanced

51

-

Wiring Diagrams

91

-

Advertisement

Related Products

-

CUMMINS 6IRQ9AE

-

CUMMINS 6CT8.3

-

CUMMINS 6CTA8.3

-

CUMMINS 6 MDKBJ

-

CUMMINS RBAB 6kW

-

CUMMINS 485ST

-

CUMMINS 4BT3.9

-

CUMMINS 5.9

-

CUMMINS B Series 1991

-

CUMMINS B Series 1994

CUMMINS Categories

Portable Generator

Engine

Inverter

Controller

Switch

More CUMMINS Manuals

Эти двигатели просты в обслуживании, надежны и имеют высокий показатель эксплуатационной рентабельности. Двигатель Cummins серии B устанавливается на средние грузовики, автобусы, легкую строительную технику.

Экологический стандарт:

Евро-1

Тип двигателя:

дизельный с турбонаддувом

Мощность, кВт (лс):

95 (130)

при частоте вращения, об/мин:

2200

Максимальный крутящий момент, Н·м:

526

при частоте вращения, об/мин:

1600

Гарабиты (ДхШхВ), мм:

1017x632x958

Масса двигателя, нетто, кг:

432

Применяемость:

КАМАЗ, НЕФАЗ, ПАЗ, КАВЗ, ГАЗ, и другие

Руководство по ремонту и эксплуатации двигателя Cummins серии 6BT5.9-C130

Полный список моделей

Эти двигатели просты в обслуживании, надежны и имеют высокий показатель эксплуатационной рентабельности. Двигатель Cummins серии B устанавливается на средние грузовики, автобусы, легкую строительную технику.

Серия:

ISB5.9

Экологический стандарт:

Евро-1

Тип двигателя:

дизельный с турбонаддувом

Количество цилиндров:

6

Расположение:

рядное

Мощность, кВт (лс):

95 (130)

при частоте вращения, об/мин:

2200

Максимальный крутящий момент, Н·м:

526

при частоте вращения, об/мин:

1600

Объем, л:

5,9

Диаметр цилиндра:

102

Ход поршня:

120

Степень сжатия:

17.1:1

Гарабиты (ДхШхВ), мм:

1017x632x958

Масса двигателя, нетто, кг:

432

Применяемость:

и другие

- Manuals

- Brands

- CUMMINS Manuals

- Engine

- B5.9 Series

Manuals and User Guides for CUMMINS B5.9 Series. We have 3 CUMMINS B5.9 Series manuals available for free PDF download: Service Manual, Installation Manual, Operation And Maintenance Manual

CUMMINS B5.9 Series Service Manual (741 pages)

Brand: CUMMINS

|

Category: Engine

|

Size: 54.8 MB

Table of Contents

-

Product View

2

-

Table of Contents

4

-

Introduction

6

-

Section Contents

6

-

Introduction

7

-

B3.9, B4.5, B4.5 RGT, and

7

-

About the Manual

8

-

General Information

8

-

General Information

9

-

How to Use the Manual

9

-

Symbols

10

-

Illustrations

11

-

General Safety Instructions

12

-

General Repair Instructions

14

-

Welding on a Vehicle with an Electronic Controlled Fuel System

15

-

-

Abrasive Pads and Abrasive Paper

16

-

Definition of Clean

16

-

General Cleaning Instructions

16

-

Gasket Surfaces

17

-

Solvent and Acid Cleaning

17

-

Plastic Bead Cleaning

18

-

Steam Cleaning

18

-

Fuel System

19

-

Acronyms and Abbreviations

21

-

-

General Information

21

-

Fuel System — Group 05

24

-

Service Tools

28

-

AFC Assembly (005-001)

30

-

Engine Fuel Heater, Electric (005-008)

30

-

Preparatory Steps

30

-

Initial Check

30

-

Finishing Steps

32

-

Measure

33

-

Fuel Consumption (005-010)

33

-

Fuel Flow (005-011)

36

-

Pressure Test

36

-

Fuel Injection Pumps, In-Line (005-012)

38

-

-

Fuel System — Group

39

-

Fuel Injection Pump (In-Line Type)

41

-

Prime

49

-

Fuel Injection Pump, In-Line, Spill Port Timing (005-013)

50

-

Injection Pumps — Venting

50

-

Time

50

-

QD Contact Cleaner, Part Number 3824510

56

-

Plunger Lift Timing

57

-

Fuel Injection Pump, Rotary (005-014)

66

-

Fuel Injection Pump (Distributor Type)

67

-

Advance Timing Mechanism

68

-

Distributor-Type Pump Governor

68

-

Manual Shutdown Levers

68

-

Electrical Shutoff Valves

69

-

Front Gear Train

70

-

Rotary Distributor Type Fuel Injection Pumps

70

-

Bosch® VE

71

-

Lucas CAV DPA Pump and Delphi DP210

71

-

Stanadyne DB4 Pump

71

-

Rear Gear Train

72

-

Tier 2/Stage II Timing Adjustment

80

-

Fuel Pump Control Lever and Spring (005-018)

85

-

Fuel Pump High Idle Speed (005-028)

85

-

Fuel Pump Idle Speed (005-029)

85

-

Bosch® RSV Governor

87

-

Bosch® RQV and RQV-K Governor

88

-

Fuel Pump Support Bracket (005-033)

88

-

Bosch®; and Stanadyne Rotary Pumps

89

-

Four-Cylinder

89

-

In-Line Fuel Injection Pumps

89

-

Fuel Pump Timing (005-037)

91

-

CAV DPA/DPS Fuel Injection Pump Timing

97

-

Bosch® VE Pumps with Round Mounting Holes

98

-

Bosch® VE Pumps with Slotted Mounting Holes

98

-

Fuel Shutoff Valve (005-043)

100

-

Bosch® a Pump with RSV Governor

102

-

-

Lucas CAV DPA or DPS

103

-

Stanadyne DB4

103

-

Voltage Checking

103

-

Bosch® VE

104

-

Delivery Valves (Back Leakage Valves on Lucas CAV Pumps)

104

-

Bosch® P Pump with RQVK Governor

107

-

-

Install

107

-

Stanadyne DB4

108

-

Bosch® a Pump with RSV Governor

109

-

Bosch® P Pump with RQVK Governor

111

-

Fuel Lift Pump (005-045)

112

-

Cold Start Timing Advance System (KSB) Remote (005-046)

116

-

Wax-Motor Style

116

-

Electrical Solenoid-Style KSB

117

-

KSB Hardware Definition

117

-

Remote Mounted KSB

117

-

Wax Motor Style KSB

117

-

Electrical Solenoid Style

118

-

Wax Motor-Style KSB

118

-

Assemble

122

-

Test

122

-

Resistance Check

123

-

Adjust

125

-

Speed Droop Governor (005-058)

125

-

Stanadyne DB4 (Generator Application) Speed Droop Governor

125

-

Fuel Pump Back Leakage Valve (005-059)

126

-

Speed Droop Adjustment

126

-

Inspect for Reuse

127

-

Clean and Inspect for Reuse

128

-

Fuel Pump Pressure Regulator (005-060)

128

-

Cold Start Timing Advance System Temperature Switch (005-069)

129

-

Cold Start Timing Advance System Pump Mounted (005-070)

132

-

Pump-Mounted KSB

133

-

Cold Start Timing Advance System (KSB)

134

-

Pump-Mounted Wax Motor-Style KSB

135

-

Injectors and Fuel Lines — Group 06

140

-

Injectors and Fuel Lines

142

-

-

Service Tools

142

-

AFC Air Tube (006-001)

144

-

Air in Fuel (006-003)

146

-

Fuel Drain Line Restriction (006-012)

148

-

Drain

149

-

Fuel Filter (Spin-On Type) (006-015)

149

-

Low Pressure Fuel Line(S)

153

-

Fuel Filter Head (006-017)

154

-

Fuel Inlet Restriction (006-020)

157

-

Fuel Manifold (Drain) (006-021)

158

-

Distributor-Type Pump

159

-

In-Line Pump

160

-

-

Install

161

-

Fuel Supply Lines (006-024)

162

-

Remove

162

-

Install

165

-

Low Pressure Fuel Line(S)

165

-

Injector (006-026)

167

-

Rust-Penetrating Solvent

169

-

O-Rings and Sealing Washers

172

-

Chatter Test

174

-

Leakage Test

174

-

-

Canister Type

188

-

Drain

188

-

Fuel-Water Separator (006-043)

188

-

Fuel Return Overflow Valve (006-044)

189

-

-

Spin-On Type

189

-

General Information

190

-

Injector Supply Lines (High Pressure) (006-051)

190

-

Finishing Steps

197

-

Fuel Connector (Headmounted) (006-052)

197

-

Preparatory Steps

198

-

Remove

198

-

Lubricating Oil System — Group 07

202

-

Lubricating Oil System

204

-

-

Service Tools

204

-

Clean and Inspect for Reuse

206

-

Engine Oil Heater (007-001)

206

-

Finishing Steps

207

-

Install

207

-

Lubricating Oil Cooler (007-003)

208

-

Clean and Inspect for Reuse

210

-

Finishing Steps

212

-

Lubricating Oil Dipstick (007-009)

213

-

General Information

214

-

Lubricating Oil Dipstick Tube (007-011)

214

-

Preparatory Steps

214

-

Remove

214

-

Lubricating Oil Filter (Spin-On) (007-013)

216

-

Remove

216

-

Finishing Steps

217

-

Install

217

-

Lubricating Oil Pan (007-025)

217

-

Clean and Inspect for Reuse

220

-

Six-Cylinder

222

-

Finishing Steps

224

-

Lubricating Oil Pressure Regulator (Main Rifle) (007-029)

224

-

Clean and Inspect for Reuse

225

-

Finishing Steps

226

-

Install

226

-

Lubricating Oil Pump (007-031)

227

-

Remove

228

-

Install

231

-

Lubricating Oil Suction Tube (Block-Mounted) (007-035)

233

-

Clean and Inspect for Reuse

234

-

Finishing Steps

235

-

-

Lubricating Oil System — Group 07

236

-

Drain

238

-

Fill

238

-

Lubricating Oil Contamination (007-044)

240

-

General Information

245

-

Low-Lubricating Oil Pressure

245

-

Lubricating Oil Pressure Regulating Valve

245

-

Lubricating Oil System Diagnostics (007-048)

245

-

Lubricating Oil Coolers

246

-

Lubricating Oil Filter Bypass Valve

246

-

Bearings and Lubricating Oil Pump

247

-

Incorrect Lubricating Oil Pump

247

-

Lubricating Oil Gauge

247

-

Lubricating Oil Suction Tube

247

-

Lubricating Oil Leaks

248

-

Lubricating Oil Pressure Sensor, OEM (007-052)

249

-

Lubricating Oil and Filter Analysis (007-083)

250

-

Cooling System

252

-

-

Service Tools

256

-

Drive Belt, Cooling Fan (008-002)

258

-

Coolant Heater (008-011)

261

-

Coolant Thermostat (008-013)

267

-

Cooling System (008-018)

276

-

Flush

278

-

Cooling System — Air or Combustion Gas Test (008-019)

282

-

Combustion Gas Leak

283

-

Fan, Shutter, or Heater Air Control Valve

283

-

Air Compressor

284

-

Combustion Gas Leak Test Kit, Part Number 3822985

285

-

Cooling System Diagnostics (008-020)

288

-

Water Pump

290

-

Radiator, Fans, and Shutters

291

-

Gauges, Overfueling, and Loading

293

-

Fan Clutch, Electric (008-026)

294

-

Fan Hub, Belt Driven (008-036)

298

-

Fan Shroud Assembly (008-038)

301

-

Fan Spacer and Pulley (008-039)

301

-

Fan, Cooling (008-040)

304

-

Radiator (008-042)

305

-

Pressure Caps

306

-

Radiator Hoses (008-045)

306

-

Radiator Pressure Cap (008-047)

306

-

Radiator Shutter Assembly (008-049)

308

-

Heat Exchanger (008-053)

309

-

Sea Water Pump (008-057)

311

-

-

General Information

315

-

Water Pump (008-062)

315

-

Initial Check

316

-

Install

318

-

Coolant Temperature Sensor (008-070)

319

-

Preparatory Steps

319

-

Remove

319

-

Water Inlet Connection (008-082)

321

-

Cooling Fan Belt Tensioner (008-087)

323

-

Sea Water Hoses (008-104)

327

-

-

Drive Units — Group 09

328

-

Accessory Drive (009-001)

330

-

Clean and Inspect for Reuse

330

-

Disassemble

331

-

Finishing Steps

334

-

Initial Check

334

-

Install

334

-

Hydraulic Pump Drive (009-016)

335

-

Remove

335

-

Accessory Drive Cover (009-039)

338

-

Clean

338

-

Preparatory Steps

338

-

Remove

338

-

Finishing Steps

339

-

Install

339

-

Air Intake System

340

-

Aftercooler (010-001)

346

-

-

Preparatory Steps

346

-

Remove

346

-

Air Crossover (010-019)

348

-

Air Intake Manifold (010-023)

349

-

Air Leaks, Air Intake and Exhaust Systems (010-024)

354

-

Damage from Nonfiltered Air

356

-

Turbocharger Engines — Air Leaks, Pressure Side

357

-

Charge-Air Cooler (010-027)

357

-

Temperature Differential Test

360

-

Air Intake Restriction (010-031)

361

-

Turbocharger (010-033)

362

-

Axial Clearance Check

363

-

Radial Clearance Check

364

-

Turbocharger Oil Drain Line (010-045)

371

-

Turbocharger Oil Supply Line (010-046)

373

-

Turbocharger Wastegate Actuator (010-050)

375

-

Calibrate

379

-

Turbocharger Wastegate Valve Body (010-055)

380

-

Intake Manifold Pressure (010-057)

381

-

Air Intake Manifold Heater (010-072)

382

-

Air Intake Heater Controller Interconnection Diagram

384

-

Cold Starting System

385

-

Grid Heater Component Connections

385

-

6B Industrial Grid Heater

387

-

Maintenance Check

389

-

Intake Manifold Air Heater Wiring Harness (010-122)

393

-

Intake Manifold Air Heater Temperature Sensor (010-123)

397

-

Intake Manifold Air Heater Element (010-124)

398

-

Intake Manifold Air Heater Control Module (010-125)

403

-

Post Heat Cycle

405

-

Post Heat Recycle

407

-

Intake Manifold Air Heater Solenoid Switch (010-126)

409

-

Intake Manifold Air Heater Speed Sensor (010-127)

411

-

Air Intake Connection Adapter (010-131)

414

-

Exhaust System

418

-

-

Exhaust System — Group

419

-

Exhaust Manifold, Dry (011-007)

421

-

Exhaust Restriction (011-009)

424

-

Compressed Air System

426

-

-

Compressed Air System — Group

427

-

Air Compressor Carbon Build up (012-003)

430

-

Air Compressor Coolant Lines (012-004)

431

-

Air Compressor Pin Bore Wear (012-010)

432

-

Air Compressor Unloader and Valve Assembly (012-013)

435

-

Air Compressor (012-014)

439

-

Compressor Timing Procedure

442

-

Air Governor (Air Compressor will Notpump) (012-017)

444

-

Air Governor (Air Compressor Pumps Continuously) (012-018)

445

-

Air Compressor Cylinder Head (Holset® SS191 Model) (012-101)

447

-

Air Leaks, Compressed Air System (012-019)

447

-

Air Compressor Seat Socket, Part Number 3823528

451

-

Valve Discs

452

-

Inlet Valve Seat

452

-

Exhaust Valve Seat

453

-

Inlet Valve Cage

453

-

Measure the Valve Guide Diameter

454

-

Measure the Top of the Cage to the Valve Stop

454

-

Exhaust Valve Stop

454

-

Unloader Pin

455

-

Valve Springs

455

-

Cylinder Head

456

-

Spring Data

456

-

Air Compressor Cylinder Head (Holset® QE Models) (012-104)

461

-

E-Type Air Compressor

461

-

E-Type System with Air Dryer

461

-

E-Type System Without Air Dryer

462

-

QE, European

473

-

Electrical Equipment

480

-

-

Electrical Equipment — Group

481

-

Alternator (013-001)

483

-

One Wire System, Typical Alternator (Delco-Remy™) with Combined Metri-Pack™ Connector

483

-

Three Wire System, Typical Alternator (Delco-Remy™)

484

-

One Wire System, Typical Alternator (Delco-Remy™)

484

-

Typical Alternator (Bosch™ K1)

485

-

Spool Mount

489

-

Hinge Mount

489

-

Bosch™ K1 Alternator

491

-

Alternator Bracket (013-003)

491

-

Alternator Pulley (013-006)

495

-

Batteries (013-007)

496

-

Battery Cables and Connections (013-009)

500

-

Starter Magnetic Switch (013-017)

501

-

Starter Switch (013-018)

503

-

Starter Solenoid (013-019)

505

-

Solenoid Control Circuit Voltage Drop on Delco® Starters

508

-

Starting Motor (013-020)

511

-

Cummins® Branded Starters

515

-

Non-Cummins® Branded Starters

515

-

Engine Testing

516

-

-

Engine Testing — Group

517

-

Engine Testing (Chassis Dynamometer) (014-002)

520

-

Engine Run-In (Chassis Dynamometer) (014-003)

526

-

Engine Run-In (Without Dynamometer) (014-004)

527

-

On-Highway Applications

527

-

Off-Highway Applications

528

-

Engine Lifting Fixture, Part Number 3822512

529

-

Engine Testing (Engine Dynamometer) (014-005)

529

-

Water Manometer, Part Number ST-1111-3

530

-

Air Inlet Restriction

530

-

Pressure Gauge, Part Number ST-1273

530

-

Exhaust Restriction

530

-

Blowby Checking Tool, Part Number 3822476

534

-

Vacuum Gauge, Part Number ST-434

534

-

Engine Run-In (Engine Dynamometer) (014-006)

535

-

Engine Testing (in Chassis) (014-008) Initial Check

539

-

B3.9, B5.9, and B4.5 Engines

539

-

Piston Ring Sealing

540

-

Intake and Exhaust Valve Sealing

540

-

B4.5 RGT Engines

541

-

Cylinder Head Gasket Sealing

541

-

Crankcase Blowby, Measure (014-010)

544

-

Blowby Conversion Table (5.61-MM [0.221-In] Orifice, Blowby Tool, Part Number 3822476)

546

-

Blowby Conversion Table (7.67-MM [0.302-In] Orifice, Blowby Tool, Part Number 3822566)

547

-

Midrange Blowby Specifications Chart

549

-

Engine Blowby Contribution

555

-

Turbocharger Blowby Contribution

556

-

Preferred Turbocharger Isolation Method

557

-

Air Compressor Blowby Contribution

561

-

Exhaust Brake Blowby Contribution

564

-

Base Engine Component Blowby Contribution

565

-

Air Compressor Is Malfunctioning

568

-

Piston or Piston Rings Are Worn or Damaged

569

-

Mounting Adaptations

570

-

Engine Support Bracket, Front (016-002)

574

-

Engine Support Bracket, Rear (016-003)

576

-

Flexplate (016-004)

578

-

Mechanical

579

-

Electrical

579

-

Flywheel (016-005)

581

-

Bore Runout

587

-

Face Runout

588

-

Flywheel Housing (016-006)

590

-

All Applications

591

-

Face Alignment

596

-

Determine the Total Indicator Reading (TIR)

597

-

Bore Alignment

599

-

Flywheel Ring Gear (016-008)

606

-

Engine Mounts (016-010)

607

-

Propeller Shaft (016-025)

607

-

Out of Water

608

-

Specifications

609

-

Marine Vibration Isolator (016-026)

610

-

Miscellaneous

616

-

-

Miscellaneous — Group

617

-

Cup Plug (017-002)

620

-

Pipe Plug (017-007)

621

-

Straight Thread Plug (017-011)

623

-

Expansion Plug (017-015)

625

-

Coolant Passages

626

-

Service Literature

628

-

-

Service Literature

629

-

Additional Service Literature

630

-

Contact Information

631

-

Cummins Customized Parts Catalog

632

-

-

Specifications

634

-

Cylinder Block — Group 01 — Specifications

638

-

Cylinder Block — Group 01 — Torque Values

648

-

Cylinder Head — Group 02 — Specifications

654

-

Cylinder Head — Group 02 — Torque Values

657

-

Rocker Levers — Group 03 — Specifications

659

-

Rocker Levers — Group 03 — Torque Values

660

-

Cam Followers/Tappets — Group 04 — Specifications

663

-

Cam Followers/Tappets — Group 04 — Torque Values

664

-

Fuel System — Group 05 — Specifications

665

-

Fuel System — Group 05 — Torque Values

666

-

Injectors and Fuel Lines — Group 06 — Specifications

674

-

Injectors and Fuel Lines — Group 06 — Torque Values

675

-

Lubricating Oil System — Group 07 — Specifications

679

-

Lubricating Oil System — Group 07 — Torque Values

681

-

Cooling System — Group 08 — Specifications

682

-

Cooling System — Group 08 — Torque Values

683

-

Drive Units — Group 09 — Specifications

686

-

Drive Units — Group 09 — Torque Values

687

-

Air Intake System — Group 10 — Specifications

688

-

Air Intake System — Group 10 — Torque Values

689

-

Exhaust System — Group 11 — Specifications

692

-

Exhaust System — Group 11 — Torque Values

693

-

Compressed Air System — Group 12 — Specifications

694

-

Compressed Air System — Group 12 — Torque Values

696

-

Electrical Equipment — Group 13 — Specifications

699

-

Electrical Equipment — Group 13 — Torque Values

700

-

Mounting Adaptations — Group 16 — Specifications

702

-

Mounting Adaptations — Group 16 — Torque Values

703

-

General Engine

705

-

Fuel System

707

-

Lubricating Oil System

708

-

Cooling System Specifications

710

-

Air Intake System Specifications

711

-

Exhaust System Specifications

717

-

Electrical System Specifications

718

-

Compressed Air System Specifications

720

-

Engine Testing Specifications

722

-

Cummins®/Fleetguard® Filter Specifications

723

-

Fuel Recommendations and Specifications

724

-

Drive Belt Tension

725

-

Engine Component Torque Values

726

-

Capscrew Markings and Torque Values

727

-

Fraction, Decimal, Millimeter Conversions

729

-

Newton-Meter to Foot-Pound Conversions

730

-

Pipe Plug Torque Values

731

-

Tap-Drill Chart — U.S. Customary and Metric

732

-

Weights and Measures — Conversion Factors

733

-

Index

734

-

Advertisement

CUMMINS B5.9 Series Service Manual (724 pages)

Brand: CUMMINS

|

Category: Portable Generator

|

Size: 38.93 MB

CUMMINS B5.9 Series Installation Manual, Operation And Maintenance Manual (323 pages)

Brand: CUMMINS

|

Category: Engine

|

Size: 9.1 MB

Table of Contents

-

Table of Contents

4

-

Introduction

7

-

To the Owner and Operator

8

-

About the Manual

9

-

How to Use the Manual

10

-

Symbols

11

-

Illustrations

12

-

General Safety Instructions

13

-

General Repair Instructions

15

-

Welding on a Vehicle with an Electronic Controlled Fuel System

16

-

-

General Cleaning Instructions

17

-

Gasket Surfaces

18

-

Plastic Bead Cleaning

19

-

Fuel System

20

-

-

Acronyms and Abbreviations

22

-

-

Engine and System Identification

25

-

Operating Instructions

55

-

Maintenance Guidelines

56

-

Maintenance Procedures at Daily Interval

70

-

Maintenance Procedures at 250 Hours or 3 Months

70

-

Maintenance Procedures at 500 Hours or 6 Months

70

-

Maintenance Procedures at 1000 Hours or 1 Year

70

-

Maintenance Procedures at 2000 Hours or 2 Years

70

-

-

Section 3 — Maintenance Procedures at Daily Interval

74

-

Air Intake Piping

77

-

Maintenance Check

77

-

-

Air Tanks and Reservoirs

77

-

Maintenance Check

78

-

-

Crankcase Breather Tube

78

-

Drain

81

-

Canister Type

81

-

Spin-On Type

82

-

-

-

Lubricating Oil Level

82

-

Maintenance Check

82

-

-

-

Section 4 — Maintenance Procedures at 250 Hours or 3 Months

84

-

Air Cleaner Restriction

86

-

Maintenance Check

86

-

-

Air Compressor

87

-

Maintenance Check

87

-

-

Charge-Air Cooler

87

-

Charge-Air Piping

88

-

Maintenance Check

88

-

-

Closed Crankcase Ventilation Hoses

88

-

Fuel Pump

88

-

Maintenance Procedures — Overview

89

-

Radiator Pressure Cap

89

-

General Information

89

-

Inspect for Reuse

90

-

Pressure Test

90

-

-

-

Radiator Hoses

89

-

-

Section 5 — Maintenance Procedures at 500 Hours or 6 Months

92

-

Engine Coolant Antifreeze

94

-

Maintenance Check

94

-

-

Fuel Filter (Canister Type)

94

-

Preparatory Steps

94

-

Prime

95

-

Remove

95

-

-

Fuel Filter (Spin-On Type)

97

-

Drain

97

-

Install

98

-

Prime

99

-

General Information

99

-

Remove

101

-

-

Lubricating Oil and Filters

101

-

Drain

101

-

-

-

Section 6 — Maintenance Procedures at 1000 Hours or 1 Year

104

-

Cooling Fan Belt Tensioner

106

-

Maintenance Check

106

-

-

Fan Hub, Belt Driven

107

-

Maintenance Check

107

-

-

Overhead Set

109

-

Maintenance Procedures — Overview

109

-

Adjust

109

-

B3.9, B5.9, and B4.5 Engines

109

-

-

Finishing Steps

111

-

-

-

Section 7 — Maintenance Procedures at 2000 Hours or 2 Years

112

-

Air Compressor Discharge Lines

114

-

General Information

114

-

Maintenance Check

114

-

-

Adjustment, Repair, and Replacement

114

-

System Diagrams

114

-

-

Cooling System

115

-

Drain

115

-

Flush

116

-

-

Vibration Damper, Rubber

119

-

Inspect

119

-

-

Maintenance Procedures — Overview

119

-

Vibration Damper, Viscous

120

-

Inspect

120

-

-

-

Section a — Adjustment, Repair, and Replacement

122

-

Air in Fuel

124

-

General Information

124

-

-

Alternator

124

-

Initial Check

124

-

Install

127

-

-

Charge-Air Cooler

127

-

General Information

127

-

Initial Check

127

-

-

Cooling Fan Belt Tensioner

129

-

Inspect for Reuse

129

-

Install

129

-

Remove

129

-

-

Drive Belt, Cooling Fan

130

-

Inspect for Reuse

130

-

Install

131

-

Remove

131

-

-

Fan Spacer and Pulley

131

-

Inspect for Reuse

131

-

Preparatory Steps

131

-

Remove

132

-

-

Starting Motor

132

-

Finishing Steps

133

-

Install

133

-

Service Literature

157

-

Service Assistance

163

-

-

-

Section Ts — Troubleshooting Symptoms

214

-

Troubleshooting Symptoms

215

-

Troubleshooting Procedures and Techniques

216

-

General Information

216

-

-

Troubleshooting Symptoms Charts

217

-

General Information

217

-

Air Compressor Air Pressure Rises Slowly

218

-

Air Compressor Cycles Frequently

219

-

Air Compressor Noise Is Excessive

220

-

Air Compressor Pumping Excess Lubricating Oil into the Air System

221

-

Air Compressor will Not Maintain Adequate Air Pressure (Not Pumping Continuously

222

-

Air Compressor will Not Stop Pumping

223

-

Alternator Not Charging or Insufficient Charging

224

-

Alternator Overcharging

225

-

Coolant Contamination

226

-

Coolant Loss — External

227

-

Coolant Temperature above Normal — Gradual Overheat

228

-

Coolant Temperature above Normal — Sudden Overheat

230

-

Coolant Temperature below Normal

231

-

Engine Acceleration or Response Poor

232

-

Engine Difficult to Start or will Not Start (Exhaust Smoke

234

-

Engine Difficult to Start or will Not Start (no Exhaust Smoke

237

-

Engine Noise Excessive

239

-

Engine Noise Excessive — Combustion Knocks

241

-

Engine Power Output Low

242

-

Engine Runs Rough at Idle

245

-

Engine Runs Rough or Misfires

246

-

Engine Shuts off Unexpectedly or dies During Deceleration

247

-

Engine Speed Surges at Low or High Idle

248

-

Engine Speed Surges under Load or in Operating Range

249

-

Engine Starts but will Not Keep Running

250

-

Engine Vibration Excessive

251

-

Engine will Not Crank or Cranks Slowly (Air Starter

252

-

Engine will Not Crank or Cranks Slowly (Electric Starter

254

-

Engine will Not Reach Rated Speed (RPM

256

-

Engine will Not Shut off

258

-

Exhaust Smoke Excessive under Load

259

-

Fuel Consumption Excessive

260

-

Fuel in Coolant

261

-

Fuel in the Lubricating Oil

262

-

Fuel or Lubricating Oil Leaking from Exhaust Manifold

263

-

Intake Manifold Air Temperature above Specification

264

-

Intake Manifold Pressure (Boost) Is below Normal

266

-

Lubricating Oil Consumption Excessive

267

-

Lubricating Oil Contaminated

268

-

Lubricating Oil Loss

269

-

Lubricating Oil Pressure High

270

-

Lubricating Oil Pressure Low

271

-

Lubricating Oil Sludge in the Crankcase Excessive

273

-

Smoke, Black — Excessive

274

-

Smoke, White — Excessive

275

-

Turbocharger Leaks Engine Oil or Fuel

277

-

Maintenance Specifications

279

-

Warranty

307

-

All Engines United States and Canada Industrial (Off-Highway

308

-

All Engines International Industrial (Off-Highway

311

-

California Emission Control System Warranty, Off-Highway

313

-

Owner’s Warranty Responsibilities

315

-

-

-

Advertisement

Advertisement

Related Products

-

CUMMINS B3.3

-

CUMMINS B Series 1991

-

CUMMINS B Series 1994

-

CUMMINS B3.9 Series

-

CUMMINS B4.5 Series

-

CUMMINS B4.5 RGT

-

CUMMINS Big Cam III

-

CUMMINS Big Cam IV

-

CUMMINS B112

-

CUMMINS B109

CUMMINS Categories

Portable Generator

Engine

Inverter

Controller

Switch

More CUMMINS Manuals

Комментарии

15

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Дружище привет, нашел мануал по таким движкам если да то скинь мне, а то уже все перерыл не могу найти, у меня такой же на камазике 4308 стоит, проблема коленвал ходит вперед назад 2мм, хочу вскрыть потдон и поменять полукольца или что там стоит сам, а то наши местные моторюги за.бали уже кто говорит что что там нет полуколец и что нужно вкладыши менять кто есть и возможно шейки на валу подъело и люфт появился, короче пока сам не разберешься ну его нафиг этих кулибинов

Всем спасибо все нашел!

Там нет 5.9 12 клапанного. Спасибо!

Это клуб владельцев додж рам там вся нужная информация, а если нет то подскажут что и как;)

Я там просто не очень ориентируюсь.

В «Базе знаний» там лежат файлы: мануалы, реклама и т.д. Я наш BR/BE-шный мануал, в свое время, скачал там.

Как вариант: на торрентах можно поискать, их там есть.

Могу на почту выслать )))

9,06 Мб

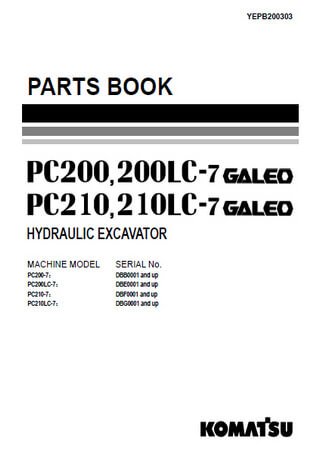

Каталог запчастей экскаваторов Komatsu PC200-7, PC200LC-7,

Формат: pdf

-

Год:

2004

-

Страниц:

536

-

Язык:

английский

-

Размер:

9,06 Мб

-

Категории:

Двигатель Cummins 6BTAA5.9