-

#1

На этом сайте наконец то нашел руководство по ремонту Ямаха профессионал. www.moto-m0t0.ru .Там Ямахи за 2014 и 2016 год, но мне на ямаху 2012 года подошла. Могу отправить на электронную почту , Бесплатно!

-

#2

На проф 2 скинь если не сложно

-

#3

На проф 2 скинь если не сложно

К сожалению на профиль 2 не получается скачать

-

#4

На этом сайте наконец то нашел руководство по ремонту Ямаха профессионал. www.moto-m0t0.ru .Там Ямахи за 2014 и 2016 год, но мне на ямаху 2012 года подошла. Могу отправить на электронную почту , Бесплатно!

Доброго времени суток! Вы бы не могли мне помочь скинуть монуал по ремонту ямахи на мой ник? Буду очень Вам признателен!!!

-

#5

Доброго времени суток! Вы бы не могли мне помочь скинуть монуал по ремонту ямахи на мой ник? Буду очень Вам признателен!!!

На проф 2 скинь если не сложно

-

13,3 MB

Просмотры: 2.023

-

#6

На этом сайте наконец то нашел руководство по ремонту Ямаха профессионал. www.moto-m0t0.ru .Там Ямахи за 2014 и 2016 год, но мне на ямаху 2012 года подошла. Могу отправить на электронную почту , Бесплатно!

Скинь и мне пожалуйста setnorm@mail.ru

-

#7

Здра

На этом сайте наконец то нашел руководство по ремонту Ямаха профессионал. www.moto-m0t0.ru .Там Ямахи за 2014 и 2016 год, но мне на ямаху 2012 года подошла. Могу отправить на электронную почту , Бесплатно!

Здравствуйте, скиньте мне на электронку, если не сложно. Буду очень благодарен

-

#8

Здравствуйте, скиньте мне на электронку, если не сложно. Буду очень благодарен[/QUOTE]

Привет,пришли адрес электронной почты на этот номер,89140819413,я с Анадыря.

-

#9

Ватсап,Канчаланская группа,скинул туда.

-

#10

Огромное с

Ватсап,Канчаланская группа,скинул туда.

Огромное спасибо, как раз я там и живу. Как только появится интернет нормальный я сразу же скачаю

Описание конструкции снегохода Yamaha.

- Год издания: —

- Страниц: 65

- Формат: PDF

- Размер: 6,9 Mb

Руководство на английском языке по техническому обслуживанию и ремонту снегохода Yamaha BR250F.

- Год издания: 1981

- Страниц: 191

- Формат: PDF

- Размер: 8,7 Mb

Руководство по эксплуатации и техническому обслуживанию снегоходов Yamaha BR250TG и Yamaha VK540EG.

- Год издания: 2001

- Страниц: 88

- Формат: PDF

- Размер: 8,7 Mb

Дополнение к руководству по техническому обслуживанию и ремонту снегохода Yamaha ET300E.

- Год издания: 1980

- Страниц: 8

- Формат: PDF

- Размер: 790 Kb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha FX Nytro моделей FX10/RFX10 различных модификаций.

- Год издания: 2007-2012

- Страниц: 94/118/122

- Формат: PDF

- Размер: 32,0 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha FX Nytro модели FX10 различных модификаций.

- Год издания: 2007-2011

- Страниц: 92/104

- Формат: PDF

- Размер: 18,5 Mb

Руководство на английском языке по техническому обслуживанию и ремонту снегохода Yamaha FX Nytro модели FX10 различных модификаций.

- Год издания: 2007

- Страниц: 410

- Формат: PDF

- Размер: 13,5 Mb

Руководство по эксплуатации и техническому обслуживанию снегоходов Yamaha MM700/VT700/VX700ER.

- Год издания: 2001

- Страниц: 100

- Формат: PDF

- Размер: 9,2 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha MM600/MM700/SX600/VT600/VT700/VX600/VX700 различных модификаций.

- Год издания: 1998-2002

- Страниц: —

- Формат: PDF

- Размер: 32,0 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha PZ50/RPZ50 Venture различных модификаций.

- Год издания: 2006/2012

- Страниц: 110/120

- Формат: PDF

- Размер: 11,7 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha PZ50 Phazer, Venture различных модификаций.

- Год издания: 2006-2009

- Страниц: 88/92/98/104

- Формат: PDF

- Размер: 21,6 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту снегохода Yamaha PZ50 Phazer, Venture различных модификаций.

- Год издания: 2006-2007

- Страниц: 424/114

- Формат: PDF

- Размер: 21,2 Mb

Руководство на английском языке по техническому обслуживанию и ремонту снегоходов Yamaha PZ500C и Yamaha VT500XLC.

- Год издания: 1998

- Страниц: 209

- Формат: PDF

- Размер: 6,0 Mb

Руководство на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha PZ 500D/PZ500MLD/VT500XLD.

- Год издания: 1999

- Страниц: 83

- Формат: PDF

- Размер: 2,4 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha RS10/RS90/RSG90/RST90 RS Vecror, RS Venture различных модификаций.

- Год издания: 2004/2011/2012

- Страниц: 100/108/162

- Формат: PDF

- Размер: 31,0 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha RS90/RSG90/RST90 RS Vector, RS Venture различных модификаций.

- Год издания: 2004-2011

- Страниц: —

- Формат: PDF

- Размер: 63,5 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту снегоходов Yamaha RS90/RSG90/RST90 RS Venture различных модификаций.

- Год издания: 2004/2006/2008

- Страниц: 414/202/299

- Формат: PDF

- Размер: 37,1 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha RX10/RXW10 Apex различных модификаций.

- Год издания: 2001-2012

- Страниц: —

- Формат: PDF

- Размер: 28,6 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha RX90/RXW90 Apex различных модификаций.

- Год издания: 2002-2010

- Страниц: —

- Формат: PDF

- Размер: 48,2 Mb

Руководство на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha SRX700G.

- Год издания: 2001

- Страниц: 84

- Формат: PDF

- Размер: 6,6 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha SXV60/SXV70/VT60/VT70 различных модификаций.

- Год издания: 2003

- Страниц: 113/127

- Формат: PDF

- Размер: 10,5 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha SXV60/SXV70/VT60/VT70 различных модификаций.

- Год издания: 2001-2005

- Страниц: —

- Формат: PDF

- Размер: 48,3 Mb

Сборник руководств по эксплуатации и техническому обслуживанию снегоходов Yamaha VK10/VK10D RS Viking.

- Год издания: 2007/2012

- Страниц: 98/108

- Формат: PDF

- Размер: 15,6 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha VK10L и Yamaha VK10X.

- Год издания: 2005/2007

- Страниц: 98/88

- Формат: PDF

- Размер: 7,9 Mb

Дополнение к руководству по техническому обслуживанию и ремонту снегоходов Yamaha VK10L/VK10W.

- Год издания: 2005-2006

- Страниц: 360/103

- Формат: PDF

- Размер: 12,2 Mb

Руководство по эксплуатации и техническому обслуживанию снегоходов Yamaha VK540E/VK540EC.

- Год издания: 2012

- Страниц: 82

- Формат: PDF

- Размер: 3,2 Mb

Сборник руководств на английском языке по эксплуатации и техническому обслуживанию снегоходов Yamaha VK540EG/VK540EK.

- Год издания: 2001/2004

- Страниц: 76

- Формат: PDF

- Размер: 4,8 Mb

Руководство на английском языке по техническому обслуживанию и ремонту снегохода Yamaha VK540EK.

- Год издания: 2000

- Страниц: 211

- Формат: PDF

- Размер: 4,9 Mb

Руководство по эксплуатации и техническому обслуживанию снегохода Yamaha VT500XL.

- Год издания: 2001

- Страниц: 84

- Формат: PDF

- Размер: 8,2 Mb

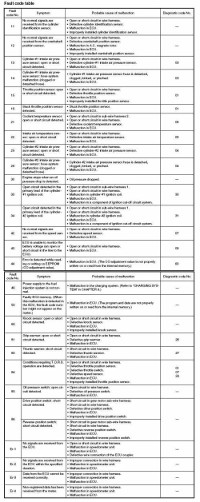

Коды неисправностей Yamaha.

- Год издания: —

- Страниц: 11

- Формат: JPG

- Размер: 1,7 Mb

-

Page 1

SUPPLEMENTARY SERVICE MANUAL… -

Page 2

OE001 son inspecting or repairing the snowmobile. NOTICE CAUTION: This manual was written by the Yamaha Mo- tor Company primarily for use by Yamaha A CAUTION indicates special precautions dealers and their qualified mechanics. It is that must be taken to avoid damage to the not possible to put an entire mechanic’s… -

Page 3

OE031 ILLUSTRATED SYMBOLS (Refer to the illustration) Illustrated symbols 1 to 9 are designed as thumb tabs to indicate the chapter’s number and content. 1 General information 2 Periodic inspection and adjustment 3 Chassis 4 Power train 5 Engine overhaul 6 Cooling system 7 Carburetion 8 Electrical… -

Page 4: Table Of Contents

CONTENTS GENERAL INFORMATION ….ENGINE ……MACHINE IDENTIFICATION .

-

Page 5: General Information

MACHINE IDENTIFICATION/IMPORTANT INFORMATION INFO 1E001 GENERAL INFORMATION MACHINE IDENTIFICATION FRAME SERIAL NUMBER The frame serial number 1 is located on the right-hand side of the frame (just below the front of the seat). ENGINE SERIAL NUMBER The engine serial number 1 is located on the right-hand side of the crankcase.

-

Page 6: Power Train

Adjust the V-belt position by removing or adding a spacer 2 on each adjusting bolt. For this adjustment, consult a Yamaha deal- er or another qualified mechanic. CAUTION: As the V-belt wears, adjustment may be necessary.

-

Page 7

INSP DRIVE V-BELT 2. Adjust the position of the V-belt by re- moving or adding a spacer 1 on each adjusting bolt 2 . V-belt height adjustment To move V-belt up: Add spacer To move V-belt down: Reduce spacer 3. Tighten: S Adjusting bolt Adjusting bolt: 10 Nm (1.0 mSkg, 7.2 ftSlb) -

Page 8: Brake Pad Inspection

INSP BRAKE PAD INSPECTION/SLID RUNNER INSPECTION BRAKE PAD INSPECTION 1. Apply the brake lever. 2. Inspect: S Brake pad Wear indicator 1 nearly contacts the brake disc ! Replace the brake pads as a set. Wear limit a : 4.7 mm (0.185 in) SLIDE RUNNER INSPECTION 1.

-

Page 9: Tuning

INSP CLUTCH TUNING W White S Silver Blue CLUTCH P Pink R Red O Orange High altitude Y Yellow G Green Specifications Model: VX500SXB 4,500 X 7,000 ft X 3,500 ft 3,000 X 5,000 ft 6,500 X 10,000 ft Elevation Idle speed Approx.

-

Page 10

INSP CLUTCH W white S Silver Blue P Pink R Red O Orange Y Yellow G Green Specifications Model: VX700ER X 3,500 ft 3,000 X 5,000 ft 4,500 X 7,000 ft 6,500 X 10,000 ft Elevation Idle speed Approx. 1,600 r / min Clutch Approx. -

Page 11

INSP CLUTCH 2E331 The clutch may require tuning depending upon the area of operation and desired han- dling characteristics. The clutch can be tuned by changing engagement and shifting speed. Clutch engagement speed is defined as the engine speed where the machine first begins to move from a complete stop. -

Page 12: Gear Selection

INSP GEAR SELECTION GEAR SELECTION The reduction ratio of the driven gear to the drive gear must be set according to the snow conditions. If there are many rough surfaces unfavorable snow conditions, drive/driven gear ratio should be increased. If the surfaces are fairly smooth or better snow conditions exist, decrease the ratio.

-

Page 13

INSP GEAR SELECTION 3 Secondary spring Spring rate Wire Free No. of Parts No. NSmm/ rad Color gauge length Standard coils (kgmm/ rad) (mm) (mm) 90508-500B1 6003 (613) BROWN 90508-536A9 7147 (729) VX500 90508-556A2 8314 (848) GREEN VX700 90508-556A7 9460 (965) SILVER 4 Secondary spring twist angle Seat… -

Page 14

INSP GEAR SELECTION 6 Primary spring Spring rate Wire Outside Free Preload No. of Standard Parts No. N / mm Color gauge diameter length (kg) coils (kg / mm) (mm) (mm) (mm) 90501-481J1 9.8 (1.0) 196.1 (20) S-B-S 5.16 85.4 90501-487G8 14.7 (1.5) 147 (15) -

Page 15: Front Suspension

INSP FRONT SUSPENSION FRONT SUSPENSION Spring preload (700) 1. Adjust: S Turn the adjusting ring 1 to the proper position. Spring adjuster position Softer z ! Harder Preload Standard CAUTION: Be sure that the left and right spring preload is the same. Spring preload (500) 1.

-

Page 16: Rear Suspension

INSP REAR SUSPENSION REAR SUSPENSION Stopper band 1. Adjust: S Stopper band tension CAUTION: Be sure that the left and right length is the same. NOTE: This adjustment affects the handling charac- teristics of the machine. Adjustment steps: S Loosen the locknut 1 . S Turn the adjusting nut 2 in or out to adjust the stopper band tension.

-

Page 17

INSP REAR SUSPENSION Spring preload (500) 1. Adjust: S Turn the spring seat 1 in or out. Spring seat Standard Shorter z ! Longer distance Harder z ! Softer Preload Length Max. Min. (front) 172 mm 182 mm 192 mm (6.77 in) (7.17 in) (7.56 in) Length Max. -

Page 18: Chassis

CHAS CHASSIS SKI (500) 10 Nm (1.0 mSkg, 7.2 ftSlb) 21 Nm (2.1 mSkg, 15 ftSlb) 48 Nm (4.8 mSkg, 35 ftSlb) : ESSO beacon 325 grease or Aeroshell grease #7A Order Job name/Part name Q’ty Remarks Ski removal Remove the parts in the order below. Cotter pin Ski column lower bracket Ski stopper…

-

Page 19: Inspection

CHAS SKI/FRONT SUSPENSION INSPECTION 1. Inspect: S Ski 1 S Ski runner 2 S Ski column lower bracket 3 S Ski handle 4 S Ski stopper 5 Wear/cracks/damage ! Replace. S Mounting bolt 6 S Collar 7 Wear/damage ! Replace. FRONT SUSPENSION This shock absorber contains highly com- pressed nitrogen gas.

-

Page 20: Installation

CHAS FRONT SUSPENSION INSTALLATION 1. Install: S Control rod 1 S Nut 2 S Joint 3 a Set length Left hand Model Set length (mm) angle (_) 460.2 ± 0.5 mm VX500 94 ± 1 (18.11 ± 0.0197 in) Upper 458.7 ±…

-

Page 21: Power Train

POWR SECONDARY SHEAVE ASSEMBLY 1. Install: S Secondary sheave spring 1 S Bolts 2 (along with the shims) Bolt: 10 Nm (1.0 mSkg, 7.2 ftSlb) 2. Install: S Stopper S Sliding sheave Screw (stopper): 6.5 Nm (0.65 mSkg, 4.6 ftSlb) 3.

-

Page 22: Drive Chain Housing

POWR DRIVE CHAIN HOUSING DRIVE CHAIN HOUSING WITHOUT REVERSE MODEL (500) 10 Nm (1.0 mSkg, 7.2 ftSlb) 24 Nm (2.4 mSkg, 17 ftSlb) 48 Nm (4.8 mSkg, 35 ftSlb) 60 Nm (6.0 mSkg, 43 ftSlb) Order Job name/Part name Q’ty Remarks Drive chain housing removal Remove the parts in the order below.

-

Page 23: Installation

POWR DRIVE CHAIN HOUSING INSTALLATION During installation, pay attention to the fol- lowing point: A Make sure that the bearing seals face towards the drive chain, as shown. B Properly install the rubber seal onto the drive chain housing, making sure that these are no gaps.

-

Page 24: Drive Chain Housing And Jackshaft Installation

POWR DRIVE CHAIN HOUSING DRIVE CHAIN HOUSING AND JACKSHAFT INSTALLATION 1. Install: S Drive chain housing S Jackshaft Installation steps: D Install the drive chain housing 1 . D Tighten the bolts 2 . Bolt (drive chain housing): 48 Nm (4.8 mSkg, 35 ftSlb) D Temporarily tighten the nuts 3 .

-

Page 25: With Reverse Model (700)

POWR DRIVE CHAIN HOUSING WITH REVERSE MODEL (700) 10 Nm (1.0 mSkg, 7.2 ftSlb) 24 Nm (2.4 mSkg, 17 ftSlb) 48 Nm (4.8 mSkg, 35 ftSlb) 60 Nm (6.0 mSkg, 43 ftSlb) Order Job name/Part name Q’ty Remarks Drive chain housing removal Remove the parts in the order below.

-

Page 26

POWR DRIVE CHAIN HOUSING Order Job name/Part name Q’ty Remarks Reverse drive gear Spring Chain tensioner Roller Collar Spring Journal Reverse driven gear Washer Forward driven sprocket Collar Counter gear Drive sprocket Drive chain Collar Washer Plate Shaft Drive chain housing For installation, reverse the removal procedure. -

Page 27: Installation

POWR DRIVE CHAIN HOUSING/JACKSHAFT INSTALLATION During installation, pay attention to the fol- lowing point: A Properly install the rubber seal onto the drive chain housing, making sure that these are no gaps. B Make sure that the bearing seals face towards the drive chain, as shown.

-

Page 28: Brake

POWR BRAKE BRAKE 1.5 Nm (0.15 mSkg, 1.1 ftSlb) 6 Nm (0.6 mSkg, 4.3 ftSlb) Order Job name/Part name Q’ty Remarks Brake caliper disassembly Disassembly the parts in the order below. Cap bolt Retaining pin Pad spring Brake pads Shim 1 Shim 2 Bleed screws Oil seals…

-

Page 29: Brake Pad Replacement

POWR BRAKE CAUTION: Disc brake components rarely require disas- sembly. DO NOT: D Disassemble components unless abso- lutely necessary. D Use solvents on internal brake compo- nents. D Use contaminated brake fluid for clean- ing. Use only clean brake fluid. D Allow brake fluid to come in contact with the eyes, otherwise eye injury may occur.

-

Page 30

POWR BRAKE 2. Install: S Brake pads S Pad spring Installation steps: S Connect a suitable hose 1 tightly to the caliper bleed screw 2 . Put the other end of this hose into an open container. S Loosen the caliper bleed screw and push the pistons into the caliper with the finger. -

Page 31: Slide Rail Suspension

POWR SLIDE RAIL SUSPENSION SLIDE RAIL SUSPENSION 71 Nm (7.1 mSkg, 51 ftSlb) Order Job name/Part name Q’ty Remarks Slide rail suspension removal Remove the parts in the order below. Tension adjuster Loosen. Blind caps Bolts Washer Slide rail suspension For installation, reverse the removal procedure.

-

Page 32

POWR SLIDE RAIL SUSPENSION 4 Nm (0.4 mSkg, 2.9 ftSlb) 15 Nm (1.5 mSkg, 11 ftSlb) 30 Nm (3.0 mSkg, 22 ftSlb) 49 Nm (4.9 mSkg, 35 ftSlb) 71 Nm (7.1 mSkg, 50 ftSlb) 24 Nm (2.4 mSkg, 17 ftSlb) Order Job name/Part name Q’ty… -

Page 33

POWR SLIDE RAIL SUSPENSION 24 Nm (2.4 mSkg, 17 ftSlb) 49 Nm (4.9 mSkg, 35 ftSlb) 71 Nm (7.1 mSkg, 50 ftSlb) Order Job name/Part name Q’ty Remarks Suspension wheels Collar Wheel brackets Circlips Suspension wheels Bushings Shaft Rear suspension bracket Spacers Bushings Collar… -

Page 34

POWR SLIDE RAIL SUSPENSION 49 Nm (4.9 mSkg, 35 ftSlb) 71 Nm (7.1 mSkg, 50 ftSlb) Order Job name/Part name Q’ty Remarks Rear shock absorber Bushings Collar Pull rod Collars Bushings Collars (700) Suspension wheels Control rods Bushings Screw Bushings –30–… -

Page 35

POWR SLIDE RAIL SUSPENSION 24 Nm (2.4 mSkg, 17 ftSlb) 71 Nm (7.1 mSkg, 50 ftSlb) 75 Nm (7.5 mSkg, 54 ftSlb) Order Job name/Part name Q’ty Remarks Rear pivot arm Bushings Collar Collar Rear pivot arm bracket Collar Circlips Suspension wheels Wheel bracket Rear axle… -

Page 36: Front Axle And Track

POWR FRONT AXLE AND TRACK FRONT AXLE AND TRACK 27 mm INSTALLATION (1.06 in) Reverse the “REMOVAL” procedure. Note the following points. 1. Install: S Sprocket wheels S Guide wheels 60 mm 132.6 mm 201.4 mm (2.36 in) (5.22 in) (7.93 in) NOTE: 164.1 mm…

-

Page 37: Engine

ENGINE ASSEMBLY ENGINE ENGINE ASSEMBLY 90 Nm (9.0 mSkg, 65 ftSlb) 60 Nm (6.0 mSkg, 43 ftSlb) Order Job name/Part name Q’ty Remarks Engine removal Remove the parts in the order below. Exhaust pipe Carburetor Refer to “CARBURETOR”. Recoil starter Refer to “RECOIL STARTER”.

-

Page 38

ENGINE ASSEMBLY 23 Nm (2.3 mSkg, 17 ftSlb) 60 Nm (6.0 mSkg, 43 ftSlb) 90 Nm (9.0 mSkg, 65 ftSlb) 23 Nm (2.3 mSkg, 17 ftSlb) Order Job name/Part name Q’ty Remarks Engine removal Remove the parts in the order below. Exhaust pipe Carburetor Refer to “CARBURETOR”. -

Page 39: Cylinder Head And Cylinder

CYLINDER HEAD AND CYLINDER CYLINDER HEAD AND CYLINDER INSPECTION 1. Measure: S Piston-to-cylinder clearance Measurement steps: 1st step: S Measure the cylinder bore “C” with a cylinder bore gauge 1 . NOTE: Measure the cylinder bore “C” parallel to, and at right angles to the crankshaft. Then find the average of the measurements.

-

Page 40

CYLINDER HEAD AND CYLINDER 2nd step: S Measure the piston skirt diameter “P” with a micrometer from distance a . a 500: 25 mm (0.98 in) 700: 15 mm (0.59 in) from the piston bottom edge. Piston size P 500: 67.930 X 67.935 mm (2.6745 X 2.6746 in) Standard 700: 70.425 X 70.430 mm… -

Page 41: Heat Exchanger

COOL HEAT EXCHANGER COOLING SYSTEM HEAT EXCHANGER 1. Measure: S Filler cap opening pressure Cap opens at pressure below the speci- fied pressure ! Replace. Cap opening pressure: 95 X 125 kPa (0.95 X 1.25 kg/cm 13.58 X 17.87 psi) Measurement steps: D Attach the cooling system tester (90890-01325, YU-24460-01) to the…

-

Page 42: Carburetion

CARB CARBURETORS CARBURETION CARBURETORS * Intake silencer D First, remove the throttle cable from the cable guide on the steering column. D Adjust the throttle cable free play while the cable is in the cable guide. D After adjusting the throttle cable free play, properly install the upper and lower intake silencer plates and seal.

-

Page 43

CARB CARBURETORS * Intake silencer D First, remove the throttle cable from the cable guide on the steering column. D Adjust the throttle cable free play while the cable is in the cable guide. D After adjusting the throttle cable free play, properly install the upper and lower intake silencer plates and seal. -

Page 44

CARB CARBURETORS Order Job name/Part name Q’ty Remarks Carburetor separation Separation the parts in the order below. Coolant hoses Starter cable holder Collar Spring Screw Loosen Starter rod Spring Starter levers Breather hoses Top covers Gaskets Throttle shaft connecting screws Connecting plate (upper) Connecting plate (lower) For assembly, reverse the separation… -

Page 45: Assembly

CARB CARBURETORS ASSEMBLY 1. Measure: S Float height a Out of specification ! Adjust. Float height: 22.3 ± 2.0 mm (0.878 ± 0.080 in) 13.3 ± 2.0 mm (0.524 ± 0.080 in) Measurement and adjustment steps: S Hold the carburetor in an upside down position.

-

Page 46: Specifications

Maximum torque r/min Starting system Recoil hand starter Electric and recoil hand starter Lubrication system: Separate lubrication (YAMAHA AUTOLUBE) Engine oil: Type YAMALUBE 2-cycle oil Tank capacity 3.0 L (2.6 Imp gt, 3.2 Us gt) Drive chain housing oil: Type Gear oil API “GL-3”…

-

Page 47

SPEC GENERAL SPECIFICATIONS Model VX500SXB VX700ER Carburetor: Type/quantity TM36 TM33 Manufacturer MIKUNI Spark plug: Type BR9ES Manufacturer 0.7 X 0.8 mm (0.028 X 0.031 in) Transmission: Primary reduction system V-Belt 3.8 X 1.0 : 1 Primary reduction ratio Clutch type Automatic centrifugal engagement Secondary reduction system… -

Page 48: Maintenance Specifications

SPEC MAINTENANCE SPECIFICATIONS MAINTENANCE SPECIFICATIONS ENGINE Model VX500SXB VX700ER Cylinder head: 23.3 X 23.9 cm 22.9 X 23.5 cm Volume (with spark plug) <Warp limit> <0.03 mm (0.0012 in)> * Lines indicate straight edge measurement. Cylinder: Material Aluminum alloy with dispersion coating 68.00 X 68.02 mm 70.50 X 70.52 mm…

-

Page 49

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Crankshaft: 61.95 X 62.00 mm 55.95 X 56.00 mm Crank width “A” (2.439 X 2.440 in) (2.203 X 2.205 in) 179.85 X 180.15 mm 291.75 X 292.30 mm Crank width “B” (7.080 X 7.093 in) (11.486 X 11.508 in) Crankshaft deflection “C”… -

Page 50

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Carburetor: Type/Quantity TM36/2 pcs. TM33/3 pcs. Manufacturer MIKUNI I.D. mark 8CJ10 8CH10 Main jet (M.J) #151.3 #1 : #145 #2, 3 : #143.8 Main air jet (M.A.J) ø2.5 – Pilot jet (P.J) Jet needle (J.N) 8CFY14-56-2 6DGM5-3 Needle jet (N.J) -

Page 51

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Thermostat: 50 X 55_C Opening temperature (122_F X 132_F) Valve lift 8 mm/70_C (159_F) –47–… -

Page 52: Power Train

SPEC MAINTENANCE SPECIFICATIONS POWER TRAIN Model VX500SXB VX700ER Transmission: Type V-belt automatic 3.8 X 1.0 : 1 Range of ratio 4,000 ± 200 r/min Engagement r/min 7,800 ± 250 r/min 8,300 ± 250 r/min Shift r/min 267 X 270 mm Sheave center distance “A”…

-

Page 53

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Rivet: Outer Part number 90261-06034 90261-06015 Material Steel Size 13.9 mm (0.55 in) 10.3 mm (0.40 in) Quantity 3 pcs Hole quantity 3 pcs Inner Part number 90261-06028 90261-06034 Material Aluminum Steel Size 10.3mm (0.40in) 13.9 mm (0.55 in) Quantity 3 pcs… -

Page 54

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Track: Part number 8AB-47110-10 8CH-47110-00 Width 381 mm (15.0 in) Length 3,072 mm (120.9 in) Pitch 64 mm (2.52 in) Number of links Height “B” 16 mm (0.63 in) 25 X 30 mm Deflection at 10 kg (22 lb) (0.98 X 1.18 in) Slide rail suspension: Front travel… -

Page 55

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Shock absorber: Damping force Front 3,320N ± 460N/0.3m/s 720 N ± 150N/0.3m/s Extension 1,110N ± 225N/0.3m/s 1,020 N ± 210N/0.3m/s Compression Rear 1,950N ± 264N/0.3m/s 2,206 N ± 657N/0.3m/s Extension 1,380N ± 235N/0.3m/s 726 N ± 216N/0.3m/s Compression Slide runner: Thickness… -

Page 56: Chassis

SPEC MAINTENANCE SPECIFICATIONS CHASSIS Model VX500SXB VX700ER Frame: Frame material Aluminum Seat height 685 mm (26.8 in) 730 mm (28.7 in) Luggage box location Rear side of seat Steering: Lock-to-lock angle (left) 29.6_ (R ski) 34.8_ (L ski) 29.4_ (R ski) 34.7_ (L ski) (right) 34.8_ (R ski) 29.6_ (L ski) 34.7_ (R ski) 29.4_ (L ski)

-

Page 57: Electrical

18_ at 4.500 r/min 24_ at 4.500 r/min Advanced type Electrical type Ignition coil: Model/Manufacturer 8AB-00/YAMAHA 8DG-00/YAMAHA Minimum spark gap 3 mm (0.118 in) or more 0.2 Ω ± 20% at 20_C (68_F) 0.06 Ω ± 20% at 20_C Primary coil resistance (68_F) 4.9 kΩ…

-

Page 58

SPEC MAINTENANCE SPECIFICATIONS Model VX500SXB VX700ER Rectifier/regulator: Model/manufacturer 8CR-00/MATSUSHITA 13.8 X 14.8 V No load regulated voltage 14.0 X 15.0 V Battery: (for electric model) Specific gravity – 1.280 Type – GM18Z-3A Electric starter system: (for electric model) Type – Bendix Starter motor: (for electric model) Model/manufacturer… -

Page 59

SPEC MAINTENANCE SPECIFICATIONS High altitude settings VX500SXB Tempera- – 40_C – 29_C – 18_C – 7_C 15_C ture (– 40_F) (– 20_F) (0_F) (20_F) (40_F) (60_F) Altitude 0 X 100 m MJ#155 MJ#153.8 MJ#152.5 MJ#151.3 MJ#150 (0 X 330 ft) JN-2.0 JN-2.0 JN-2.0… -

Page 60

SPEC MAINTENANCE SPECIFICATIONS High altitude settings VX700ER Tempera- – 40_C – 29_C – 18_C – 7_C 15_C ture (– 40_F) (– 20_F) (0_F) (20_F) (40_F) (60_F) Altitude MJ#1 #148.8 MJ#1 #147.5 MJ#1 #146.3 MJ#1 #145.0 MJ#1 #143.8 MJ#2#3 #147.5 MJ#2#3 #146.3 MJ#2#3 #145.0 MJ#2#3 #143.8 MJ#2#3 #142.5… -

Page 61

SPEC MAINTENANCE SPECIFICATIONS Tightening torque: Tightening torque Parts to be tightened Parts to be tightened Remarks Remarks mSkg ftSlb Crankcase (first) Tighten the bolts in two Crankcase (final) stages. Engine bracket (front) and frame 500 Engine bracket (front) and frame Engine bracket damper (front) Engine bracket and engine Engine bracket upper and lower (rear) -

Page 62

SPEC MAINTENANCE SPECIFICATIONS Tightening torque Parts to be tightened Parts to be tightened Remarks Remarks mSkg ftSlb Sliding frame and slide runner Slide rail suspension mounting bolt Rear pivot arm and bracket Apply LOCTITE Shock absorber and rear pivot arm Rear pivot arm and rod Rear suspension bracket and rod Control rod and sliding frame… -

Page 63

SPEC MAINTENANCE SPECIFICATIONS –59–… -

Page 64: Cable Routing <500

SPEC CABLE ROUTING CABLE ROUTING <500> –60–…

-

Page 65

SPEC CABLE ROUTING CABLE ROUTING <For 500> 1 Oil pump cable 2 Throttle cable 3 Fasten the wire harness. Do not fasten the throttle cable and oil pump cable. 4 Fasten the throttle cable and oil pump cable with a plastic clamp. Route the cable along the side of the handle holder. -

Page 66

SPEC CABLE ROUTING –62–… -

Page 67

SPEC CABLE ROUTING 35 To the conduction 36 Voltage regulator 37 Rectifire regulator 38 Fasten the wire harness with a plastic clamp. 39 Rectifire regulator (ECC model) 40 Brake hose holder 41 Fasten the wire harness with a plastic clamp. 42 To reverse gear 43 Fasten the wire harness, fuel breather hose and oil… -

Page 68

SPEC CABLE ROUTING –64–… -

Page 69

SPEC CABLE ROUTING 1 Wire lead (electrical starter model) 2 Carburetor switch coupler 3 Fasten the throttle cable and oil pump cable with a plastic clamp. 4 Air temperature sensor coupler (ECC model) 5 Coolant hose 6 Starter relay lead 7 Starter relay sub lead (electrical starter model) 8 Fasten the wire harness,… -

Page 70

SPEC CABLE ROUTING –66–… -

Page 71

SPEC CABLE ROUTING 32 Solenoid coupler (ECC model) 33 Ignition coil 34 Carburetor heating lever 35 Coolant hose 36 Speedometer cable 37 Fasten the throttle cable, water temperature sensor lead, carburetor switch lead and solenoid lead with a plastic clamp. 38 Water temperature sensor coupler 39 Under 50 mm (1.97 in) -

Page 72

SPEC CABLE ROUTING –68–… -

Page 73

SPEC CABLE ROUTING 1 Make sure that the oil tank cap and oil breather hose do not touch each other. 2 Route the fuel breather hose along the upper of the main harness. 3 Route the oil breather hose along the upper of the main harness. -

Page 74: Cable Routing <700

SPEC CABLE ROUTING CABLE ROUTING <700> –70–…

-

Page 75

SPEC CABLE ROUTING CABLE ROUTING <For 700> 1 Oil pump cable 2 Throttle cable 3 Do not fasten the throttle cable and oil pump wire with a plastic clamp. 4 Thumb warmer coupler 5 Engine stop switch coupler 6 Holder 7 Grip warmer coupler 8 Brake light switch coupler 9 Head light switch coupler… -

Page 76

SPEC CABLE ROUTING –72–… -

Page 77

SPEC CABLE ROUTING 37 DC back buzzer (reverse model) 38 Voltage regulator 39 Rectifier regulator 40 DC back buzzer coupler 41 Fasten the wire harness with a plastic clamp. 42 Brake hose holder 43 Fasten the wire harness with a plastic clamp. 44 To reverse gear 45 Fasten the wire harness, fuel breather hose and oil… -

Page 78

SPEC CABLE ROUTING –74–… -

Page 79

SPEC CABLE ROUTING 1 Fasten the carburetor switch, water temperature sensor lead, coolant hose, wire lead and battery negative lead with a plastic clamp. 2 Clamp 3 Fasten the ignition coil and starter cable with a plastic clamp. 4 Fasten the wire lead, battery negative lead and coolant hose with a plastic clamp. -

Page 80

SPEC CABLE ROUTING –76–… -

Page 81

SPEC CABLE ROUTING 1 Wire harness 2 50 mm (1.97 in) 3 Make sure that the oil tank cap and oil breather hose do not touch each other. 4 Route the fuel breather hose along the upper of the main harness. -

Page 82

WIRING DIAGRAM VX500SXB CDI magneto Brake light switch Rectifier / regulator Tail / brake light Starter relay / fuse Speedometer assembly Battery Oil level indicator light Starter motor Water temp. indicator light Main switch High beam indicator light Engine stop switch Speedometer light Throttle switch Tachometer assembly… -

Page 83

WIRING DIAGRAM VX700ER CDI magneto Brake light switch Rectifier / regulator Tail / brake light Starter relay / fuse Speedometer assembly Battery Oil level indicator light Starter motor Water temp indicator light Main switch High beam indicator light Engine stop switch Speedometer light Throttle switch Tachometer assembly… -

Page 84

PRINTED IN USA PRINTED ON RECYCLED PAPER…

- Manuals

- Brands

- Yamaha Manuals

- Snowmobiles

- VK10W

- Supplementary service manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

SUPPLEMENTARY SERVICE MANUAL

VK10W

LIT-12618-02-57

8GS-28197-10

Related Manuals for Yamaha VK10W

Summary of Contents for Yamaha VK10W

-

Page 1

SUPPLEMENTARY SERVICE MANUAL VK10W LIT-12618-02-57 8GS-28197-10… -

Page 2

FOREWORD This Supplementary Service Manual has been prepared to introduce new service and new data for the VK10W. For complete information, on service procedures, it is necessary to use this Supple- mentary Service Manual together with following manual: RS90K, RS90RK, RSG90K, RS90MK, RST90K, RST90TFK SERVICE MANUAL:… -

Page 3: How To Use This Manual

If there is any question about a service procedure, it is imperative that you contact a Yamaha dealer for any service information changes that apply to this model. This policy is intended to provide the customer with the most satisfaction from his vehicle and to conform to federal environmental quality objectives.

-

Page 4: Chassis

ILLUSTRATED SYMBOLS (Refer to the illustration) INSP INFO Illustrated symbols 1 to 9 are designed as thumb tabs to indicate the chapter’s number and content. 1 General information 2 Periodic inspection and adjustment POWR 3 Chassis CHAS 4 Power train 5 Engine 6 Cooling system 7 Carburetion…

-

Page 5

INDEX GENERAL INFORMATION INFO PERIODIC INSPECTION AND INSP ADJUSTMENT CHASSIS CHAS POWER TRAIN POWR ENGINE COOLING SYSTEM COOL CARBURETION CARB – ELECTRICAL ELEC SPECIFICATIONS SPEC… -

Page 6: Table Of Contents

GENERAL INFORMATION ENGINE SPECIAL TOOLS ……….1 CAMSHAFTS…………. 38 FOR ELECTRICAL SERVICE ……1 INSTALLATION……….38 PERIODIC INSPECTION AND CARBURETION ADJUSTMENT CARBURETORS ……….43 THROTTLE POSITION SENSOR (T.P.S.) INTRODUCTION………..2 INSPECTION AND ADJUSTMENT ….. 44 PERIODIC MAINTENANCE CHART FOR THE EMISSION CONTROL SYSTEM….2 ELECTRICAL GENERAL MAINTENANCE AND LUBRICATION CHART……..3…

-

Page 7: General Information

SPECIAL TOOLS INFO GENERAL INFORMATION SPECIAL TOOLS Some special tools are necessary for a completely accurate tune-up and assembly. Using the correct special tool will help prevent damage that can be caused by the use of improper tools or improvised techniques. NOTE: •…

-

Page 8: Periodic Inspection And Adjustment

INTRODUCTION/PERIODIC MAINTENANCE CHART FOR INSP THE EMISSION CONTROL SYSTEM PERIODIC INSPECTION AND ADJUSTMENT INTRODUCTION This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable machine operation and a longer ser- vice life.

-

Page 9: General Maintenance And Lubrication Chart

INSP GENERAL MAINTENANCE AND LUBRICATION CHART GENERAL MAINTENANCE AND LUBRICATION CHART Every Initial Pre-opera- 1 month or Seasonally Item Remarks tion check 800 km or 4,000 km (Daily) (500 mi) (2,500 mi) (40 hr) (200 hr) Check oil level. Engine oil Replace.

-

Page 10

INSP GENERAL MAINTENANCE AND LUBRICATION CHART Every Initial Pre-opera- 1 month or Seasonally Item Remarks tion check 800 km or 4,000 km (Daily) (500 mi) (2,500 mi) (40 hr) (200 hr) Steering column bearing Lubricate with specified grease. Ski and front suspension Lubricate with specified grease. -

Page 11: Power Train

INSP DRIVE V-BELT POWER TRAIN DRIVE V-BELT WARNING When installing the new V-belt, make sure that it is positioned from 1.5 mm (0.06 in) above the edge of the secondary sheave to –0.5 mm (–0.02 in) below the edge a. If the V-belt is not positioned correctly, the clutch engagement speed will be changed.

-

Page 12

INSP DRIVE V-BELT 2. Adjust the position of the V-belt by removing or adding a spacer 1 on each adjusting bolt 2. V-belt position Adjustment More than 1.5 mm (0.06 in) above the Remove a spacer edge From 1.5 mm (0.06 in) above the edge to Not necessary –0.5 mm (–0.02 in) -

Page 13: Brake Pad Inspection

DRIVE V-BELT/BRAKE PAD INSPECTION/ INSP AIR BLEEDING (HYDRAULIC BRAKE SYSTEM) 6. Measure: • Drive V-belt circumference a Out of specification → Replace. V-belt circumference: 1,132 ~ 1,138 mm (44.6 ~ 44.8 in) BRAKE PAD INSPECTION 1. Apply the brake lever. 2.

-

Page 14: Drive Chain

AIR BLEEDING (HYDRAULIC BRAKE SYSTEM)/ INSP DRIVE CHAIN i. Repeat steps (e) to (h) until all of the air bubbles have disappeared from the fluid. j. Tighten the bleed screws. Bleed screw: 6 Nm (0.6 m · kg, 4.3 ft · lb) NOTE: If bleeding is difficult, it may be necessary to let the brake fluid settle for a few hours.

-

Page 15

INSP DRIVE CHAIN Checking steps: • Remove the rubber cap 1. • Check the oil level through the check window 2 located on the drive chain housing. • If the oil is below the minimum level mark a, remove the dipstick 3 and add sufficient oil to the maximum level mark b. -

Page 16

INSP DRIVE CHAIN Oil replacement Oil replacement steps: • Place the oil pan under the drain hole. • Remove the oil drain bolt (along with the gas- ket) 1 and drain the oil. CAUTION: Be sure to remove any oil from the heat protec- tor. -

Page 17: Tuning

INSP CLUTCH TUNING CLUTCH L Blue P Pink High altitude W White Y Yellow Specifications ~ 800 m 600 ~ 1,400 m 1,200 ~ 2,000 m 1,800 ~ 2,600 m 2,400 ~ 3,000 m È Elevation (~ 2,500 ft) (2,000 ~ 4,500 ft) (4,000 ~ 6,500 ft) (6,000 ~ 8,500 ft) (8,000 ~ 10,000 ft)

-

Page 18: Gear Selection

INSP CLUTCH/GEAR SELECTION The clutch may require tuning depending upon where the machine will be operated and the desired handling characteristics. The clutch can be tuned by changing the engagement and shifting speeds. Clutch engagement speed is defined as the engine speed at which the machine first begins to move from a complete stop.

-

Page 19

INSP GEAR SELECTION 1 Chain and sprocket part number È Parts name É Teeth & links Ê Parts no. Ë Standard 19 teeth 8FA-17682-90 20 teeth 8FA-17682-00 21 teeth 8FA-17682-10 Ì Drive sprocket 22 teeth 8FA-17682-20 23 teeth 8FA-17682-30 24 teeth 8FA-17682-40 38 teeth 8FB-47587-80… -

Page 20

INSP GEAR SELECTION 4 Secondary spring twist angle È Seat É Sheave 10° 40° 70° 100° 20° 50° 80° 110° 30° 60° 90° 120° 5 Torque cam (secondary spring seat) É Effects Ê Part no. Ë Cam angle Ì Identification mark Í… -

Page 21

INSP GEAR SELECTION 6 Primary spring Ì Spring rate Ð Outside Í Preload Ï Wire gauge Ò Free length Ë Parts No. Î Color Ñ No. of coils Ó Standard N/mm diameter N (kg) mm (in) mm (in) (kg/mm) mm (in) 90501-550A2 19.6 (2.00) 196 (20) -

Page 22

INSP GEAR SELECTION 7 Clutch weight É Weight g (oz) È Parts No. Ê Shape & ID mark Ë Standard without bush and rivets 8BU-17605-20 45.41 (1.603) 8CH-17605-10 35.32 (1.246) 8DG-17605-00 34.26 (1.208) 8DJ-17605-00 37.77 (1.332) 8DN-17605-10 39.76 (1.402) 8ES-17605-00 54.63 (1.928) 8FA-17605-10 63.81 (2.251) -

Page 23

INSP GEAR SELECTION 8 Weight rivets Ê Length Ë Weight È Parts No. É Material Ì Standard Í Effects mm (in) g (oz) √ (OUT) Î Increased force 90261-06033 Steel 17.2 (0.677) 4.5 (0.159) 90261-06034 Steel 13.9 (0.547) 3.6 (0.127) √… -

Page 24: High Altitude Tuning

INSP HIGH ALTITUDE TUNING HIGH ALTITUDE TUNING To attain the best performance in high altitude conditions, carefully tune the snowmobile as outlined below. Check STD settings • Carburetors • Spark plugs Adjust the main jet size according to the chart Test the main jet Adjust the size of the main jet Not OK…

-

Page 25: Power Train

POWR SHIFT LEVER POWER TRAIN SHIFT LEVER È: kg, 7.2 ft 10 Nm (1.0 m • • É: É 23 Nm (2.3 m kg, 17 ft • • É È É Q’ty Remarks Order Job name/Part name Shift lever assembly removal Remove the parts in the order listed below.

-

Page 26

POWR SHIFT LEVER È: kg, 17 ft 23 Nm (2.3 m • • É: 59 Nm (5.9 m kg, 43 ft • • È È É Q’ty Remarks Order Job name/Part name Shift lever disassembly Remove the parts in the order listed below. Shift lever stay Circlip Bearing… -

Page 27: Installation

POWR SHIFT LEVER INSTALLATION 1. Install: • Shift lever 1 • Shift lever stopper 2 • Shift guide 3 • Shift lever pin 4 • Spring Installation steps: • Install the shift lever 1 onto the shift lever stop- per 2. •…

-

Page 28: Drive Chain Housing

POWR DRIVE CHAIN HOUSING DRIVE CHAIN HOUSING Ï: È: Ì: kg, 4.3 ft kg, 13 ft kg, 31 ft 6 Nm (0.6 m 18 Nm (1.8 m 43 Nm (4.3 m • • • • • • Ð: É: Í: kg, 7.2 ft kg, 14 ft 55 Nm (5.5 m…

-

Page 29

POWR DRIVE CHAIN HOUSING È: Ì: Ï: kg, 4.3 ft kg, 13 ft kg, 31 ft 6 Nm (0.6 m 18 Nm (1.8 m 43 Nm (4.3 m • • • • • • Ð: É: Í: kg, 7.2 ft kg, 14 ft kg, 40 ft 10 Nm (1.0 m… -

Page 30

POWR DRIVE CHAIN HOUSING È: Ì: Ï: kg, 4.3 ft kg, 13 ft kg, 31 ft 6 Nm (0.6 m 18 Nm (1.8 m 43 Nm (4.3 m • • • • • • Ð: É: Í: kg, 7.2 ft kg, 14 ft kg, 40 ft 10 Nm (1.0 m… -

Page 31: Removal

POWR DRIVE CHAIN HOUSING REMOVAL 1. Remove: • Driven gear 1 NOTE: While holding the front axle assembly with spanner wrench 2, loosen the reverse driven gear bolt. INSPECTION 1. Inspect: • Drive chain housing • Drive chain housing cover Cracks/damage →…

-

Page 32

POWR DRIVE CHAIN HOUSING 2. Inspect: • Drive sprocket • Driven sprocket • Driven gear • Reverse drive gear • Counter gear • Low pinion gear • Low wheel gear • Low drive gear • Journal • Chain tensioner Pitting/wear/damage → Replace. •… -

Page 33: Installation

POWR DRIVE CHAIN HOUSING 5. Measure: • Brake disc thickness a Measure the brake disc thickness 1 ~ 3 mm (0.04 ~ 0.12 in) from the edge of the brake disc. Out of specification → Replace. Minimum thickness: 3.5 mm (0.14 in) INSTALLATION 1.

-

Page 34

POWR DRIVE CHAIN HOUSING Ó 0 ~ 1 mm (0 ~ 0.039 in) 3. Install: • Shift rod lock washer 1 NOTE: Bend a lock washer tab along a flat side of the bolt. 4. Adjust: • Shift rod length a Adjustment steps: •… -

Page 35: Secondary Shaft

POWR SECONDARY SHAFT SECONDARY SHAFT SECONDARY SHAFT AND DRIVE CHAIN HOUSING INSTALLATION 1. Install: • Secondary shaft È • Drive chain housing Installation steps: • Install the secondary shaft. • Tighten the bolt. Secondary shaft bolt: 30 Nm (3.0 m · kg, 22 ft · lb) •…

-

Page 36

POWR SECONDARY SHAFT 2. Measure: • Brake disc clearance a Out of the specification → Adjust. Brake disc clearance: 0.2 ~ 0.7 mm (0.008 ~ 0.028 in) 3. Adjust: • Brake disc clearance Adjustment steps: • Remove the circlip 8. •… -

Page 37: Brake

POWR BRAKE BRAKE È: kg, 4.3 ft 6 Nm (0.6 m • • É: kg, 13 ft 18 Nm (1.8 m • • Ê: kg, 35 ft 48 Nm (4.8 m • • È Ê È É Q’ty Remarks Order Job name/Part name Brake pad removal Remove the parts in the order listed below.

-

Page 38: Brake Pad Replacement

POWR BRAKE CAUTION: Disc brake components rarely require disas- sembly. DO NOT: • Do not disassemble components unless absolutely necessary. • Do not use solvents on internal brake compo- nents. • Do not use contaminated brake fluid for cleaning. • Use only clean brake fluid. •…

-

Page 39

POWR BRAKE 2. Install: • Brake pads • Pad spring Installation steps: • Connect a suitable hoses 1 tightly to the cali- per bleed screws 2. Put the other end of this hose into an open container. • Loosen the caliper bleed screws and push the pistons into the caliper with your finger. -

Page 40

POWR BRAKE Q’ty Remarks Order Job name/Part name Brake caliper and parking brake Remove the parts in the order listed below. removal Brake fluid Drain. Brake hose Brake caliper assembly Parking brake cable Spring Parking brake assembly Collar For installation, reverse the removal proce- dure. -

Page 41

POWR BRAKE È: 6 Nm (0.6 m kg, 4.3 ft • • É: 18 Nm (1.8 m kg, 13 ft • • È È É Q’ty Remarks Order Job name/Part name Brake caliper disassembly Remove the parts in the order listed below. Cap bolt Retaining pin Pad spring… -

Page 42: Brake Caliper Disassembly

POWR BRAKE BRAKE CALIPER DISASSEMBLY NOTE: Before disassembling a caliper, drain brake fluid from brake hose, master cylinder, brake caliper and brake reservoir of their brake fluid. 1. Remove: • Pistons • Piston seals 1 Removal steps: • Using a wood of piece 2, lock the right piston. •…

-

Page 43: Front Axle And Track

POWR FRONT AXLE AND TRACK FRONT AXLE AND TRACK 103.5 mm 121.5 mm 121.5 mm 103.5 mm (4.07 in) (4.78 in) (4.78 in) (4.07 in) INSTALLATION 1. Install: • Sprocket wheels • Guide wheels NOTE: • When pressing the sprocket wheels onto the front 32.5 mm 42 mm 58.5 mm…

-

Page 44: Engine

CAMSHAFTS ENGINE CAMSHAFTS INSTALLATION 1. Install: • Exhaust camshaft sprocket 1 • Intake camshaft sprocket 2 (with the special tool 3) Rotor holding tool: 90890-01235, YU-01235 • Camshaft sprocket bolts Camshaft sprocket bolt: 24 Nm (2.4 m · kg, 17 ft · lb) NOTE: Make sure that the holes a in the cylinder #3 cam and marks b and c on the camshaft sprockets are…

-

Page 45

CAMSHAFTS 2. Install: • Exhaust camshaft 1 • Intake camshaft 2 (with the camshaft sprockets) Installation steps: • Turn the crankshaft clockwise. • When piston #3 is at TDC on the compression stroke, align the “I” mark a on the A.C. mag- neto rotor with the stationary pointer b on the A.C. -

Page 46

CAMSHAFTS 3. Install: • Dowel pins • Intake camshaft caps • Exhaust camshaft caps NOTE: • The “I” mark refers to the intake camshaft caps and the “E” mark refers to the exhaust camshaft cap. • Install the camshaft caps with the arrow mark a pointing towards the right side of the engine. -

Page 47

CAMSHAFTS 5. Install: • Timing chain tensioner Installation steps: • While lightly pressing the timing chain tensioner rod by hand, turn the tensioner rod fully clock- wise with a thin screwdriver 1. NOTE: Make sure that the tensioner rod has been fully set clockwise. -

Page 48

® • Apply Sealant (Quick Gasket ) or Yamaha bond No. 1215 2 onto the mating surfaces of the cylin- der head cover gasket and cylinder head. • Tighten the cylinder head cover bolts stages and… -

Page 49: Carburetion

CARB CARBURETORS CARBURETION CARBURETORS Q’ty Remarks Order Job name/Part name Carburetor separation Remove the parts in the order listed below. Sub-wire harness 3 Carburetor heating hose Fuel delivery hose Float chamber air vent hose Vacuum hose Spring Starter plunger link Connecting bolt Throttle position sensor Carburetor…

-

Page 50: Throttle Position Sensor (T

CARB CARBURETORS THROTTLE POSITION SENSOR (T.P.S.) INSPECTION AND ADJUSTMENT NOTE: Before adjusting the throttle position sensor, prop- erly adjust the idle speed. 1. Inspect: • Throttle position sensor Inspection steps: • Disconnect the throttle position sensor coupler. • Connect the pocket tester (Ω × 1k) to the throt- tle position sensor coupler.

-

Page 51

CARB CARBURETORS 2. Adjust: • Throttle position sensor angle Adjustment steps: • Disconnect the throttle position sensor coupler. • Connect the test coupler to the throttle position sensor. • Connect three dry cells (1.5 V × 3 pcs.) in series to the test coupler. -

Page 52: Electrical

– ELEC SIGNAL SYSTEM ELECTRICAL…

-

Page 53: Circuit Diagram

– ELEC SIGNAL SYSTEM SIGNAL SYSTEM CIRCUIT DIAGRAM 2 A.C. magneto 3 Rectifier/regulator 4 Main switch 5 Load control relay 6 Main fuse 9 Battery I Ignitor unit M Coolant temperature sensor P Frame ground T DC back buzzer U Gear position switch relay V Gear position switch W Brake light switch X Tail/brake light…

-

Page 54: Troubleshooting

– ELEC SIGNAL SYSTEM TROUBLESHOOTING BACK BUZZER DOES NOT SOUND. Check the signal fuse. FAULTY Replace the signal fuse. Check the battery. OUT OF SPECIFICATION Replace and/or charge the battery. Check the stator coil. OUT OF SPECIFICATION Replace the stator coil assembly. Check the main switch.

-

Page 55: Gear Position Switch

– ELEC SIGNAL SYSTEM GEAR POSITION SWITCH 1. Check: • Gear position switch 1 continuity Faulty → Replace. – Shift lever position Continuity DRIVE (D) or LOW (L) REVERSE GEAR POSITION SWITCH RELAY 1. Inspect: • Gear position switch relay 1 Inspection steps: •…

-

Page 56: Specifications

SPEC GENERAL SPECIFICATIONS SPECIFICATIONS GENERAL SPECIFICATIONS Model VK10W Model code number: 8GS1 (USA/Canada) 8GS2 (Europe) Dimensions: Overall length 3,270 mm (128.7 in) Overall width 1,200 mm (47.2 in) Overall height 1,380 mm (54.3 in) Weight: Dry weight 360 kg (794 lb)

-

Page 57

SPEC GENERAL SPECIFICATIONS Model VK10W Spark plug: Type NGK R CR8E Manufacture 0.7 ~ 0.8 mm (0.028 ~ 0.031 in) Transmission: Primary reduction system V-Belt Primary reduction ratio 3.8 ~ 1 : 1 Clutch type Automatic centrifugal engagement Secondary reduction system… -

Page 58: Maintenance Specifications

SPEC MAINTENANCE SPECIFICATIONS MAINTENANCE SPECIFICATIONS ENGINE Model VK10W Cylinder head: Volume (with spark plug) 22.82 ~ 23.62 cm (1.39 ~ 1.44 cu.in) <Warpage limit> 0.10 mm (0.0039 in) Lines indicate straight edge measurement. Cylinder: Material Aluminum alloy with dispersion coating Bore size 79.000 ~ 79.010 mm (3.1102 ~ 3.1106 in)

-

Page 59

SPEC MAINTENANCE SPECIFICATIONS Model VK10W Valves, valve seats, valve guides: Valve clearance (cold) Intake 0.15 ~ 0.22 mm (0.0059 ~ 0.0087 in) Exhaust 0.21 ~ 0.25 mm (0.0083 ~ 0.0098 in) Valve dimensions Valve head diameter A Intake 29.9 ~ 30.1 mm (1.1771 ~ 1.1850 in) Exhaust 25.9 ~ 26.1 mm (1.0197 ~ 1.0276 in) -

Page 60

SPEC MAINTENANCE SPECIFICATIONS Model VK10W Valve spring: Free length Intake 39.73 mm (1.56 in) <Limit> 37.74 mm (1.48 in) Exhaust 39.73 mm (1.56 in) <Limit> 37.74 mm (1.48 in) Installed length (valve closed) Intake 33.0 mm (1.30 in) Exhaust 33.0 mm (1.30 in) -

Page 61

SPEC MAINTENANCE SPECIFICATIONS Model VK10W Piston ring: Sectional sketch Top ring Ring type Barrel Dimensions (B × T) 1.00 × 2.80 mm (0.039 × 0.110 in) 2nd ring Ring type Taper Dimensions (B × T) 1.00 × 2.90 mm (0.039 × 0.114 in) Oil ring Dimensions (B ×… -

Page 62: Cooling System

SPEC MAINTENANCE SPECIFICATIONS Model VK10W Carburetor: Type/Quantity CVK40/3 Manufacturer KEIHIN I.D. mark 8ES1 02 Main jet (M.J) #148 Main air jet (M.A.J) Jet needle (J.N) N425-BSJ00 Needle jet (N.J) W9554-26538#6 Pilot jet (P.J) Pilot air jet (P.A.J) #120 Pilot outlet (P.O)

-

Page 63: Power Train

SPEC MAINTENANCE SPECIFICATIONS POWER TRAIN Model VK10W Transmission: Type V-belt automatic Range of ratio 3.8 ~ 1.0 : 1 Engagement speed r/min 2,200 ~ 2,600 r/min Shift r/min 8,250 ~ 8,750 r/min Sheave distance 267 ~ 270 mm (10.51 ~ 10.63 in) Sheave offset 13.5 ~ 16.5 mm (0.53 ~ 0.65 in)

-

Page 64

SPEC MAINTENANCE SPECIFICATIONS Model VK10W Hole position Sheave side-spring side (twist angle) 3-3 (60°) Spring rate 12.3 N/mm (1.25 kg/mm, 70.23 lb/in) Number of coils 5.53 Free length 75 mm (2.95 in) Torque cam angle 39° Drive chain: Type Borg Warner Automotive 23RH303-68ASM… -

Page 65

SPEC MAINTENANCE SPECIFICATIONS Model VK10W Shock absorber: Damping force Front Extension 540 N/0.3 m/s (55.1 kg/0.3 m/s, 121.4 lb/0.3 m/s) Compression 1,130 N/0.3 m/s (115.2 kg/0.3 m/s, 254.0 lb/0.3 m/s) Rear Extension 2,530 N/0.3 m/s (258.0 kg/0.3 m/s, 568.7 lb/0.3 m/s) Compression 690 N/0.3 m/s (70.4 kg/0.3 m/s, 155.1 lb/0.3 m/s) -

Page 66: Chassis

SPEC MAINTENANCE SPECIFICATIONS CHASSIS Model VK10W Frame: Frame material Monocoque (Aluminum & Steel) Seat height 716 mm (28.2 in) Luggage box location Under seat Steering: Lock-to-lock angle (left) 29.7° (R ski) 34.4° (L ski) (right) 34.4° (R ski) 29.7° (L ski)

-

Page 67: Electrical

SPEC MAINTENANCE SPECIFICATIONS ELECTRICAL Model VK10W Voltage 12 V Ignition system: Ignition timing (B.T.D.C.) 5° at 1,400 r/min Advanced type Digital type Ignition coil: Model/Manufacturer F6T558/MITSUBISHI Ignition spark gap 6.0 mm (0.24 in) 1.19 ~ 1.61 Ω at 20 °C (68 °F)

-

Page 68

SPEC MAINTENANCE SPECIFICATIONS Model VK10W T.P.S. (throttle position sensor): Manufacturer KEIHIN Resistance 4 ~ 6 kΩ at 20 °C (68 °F) (Blue – Black) 0 ~ 4 kΩ at 20 °C (68 °F) (Yellow – Black) Oil level switch: Model/Manufacturer… -

Page 69

SPEC MAINTENANCE SPECIFICATIONS Model VK10W Speed sensor: Model/Manufacture 8EK/NIPPON SEIKI Carburetor heater: Model/Manufacture 5FU/NIPPON THERMOSTAT Wattage 30 W 6 ~ 10 Ω at 20 °C (68 °F) Resistance… -

Page 70: High Altitude Settings

SPEC MAINTENANCE SPECIFICATIONS HIGH ALTITUDE SETTINGS Temperature –30 °C –10 °C 10 °C (–22 °F) (–14 °F) (50 °F) Altitude Idling speed (r/min) 0 ~ 200 m #150 #148 #148 1,400 (0 ~ 700 ft) 200 ~ 1,500 m #148 #148 #145 1,400…

-

Page 71

SPEC MAINTENANCE SPECIFICATIONS… -

Page 72: Tightening Torque

SPEC TIGHTENING TORQUE TIGHTENING TORQUE ENGINE Tightening torque Parts to be tightened Remarks m · kg ft · lb Spark plug Cylinder head bolt (M10 × 1.25) See NOTE. Cylinder head bolt Camshaft cap and cylinder head Apply the engine oil. Cylinder head cover Camshaft and camshaft sprocket Timing chain tensioner…

-

Page 73

SPEC TIGHTENING TORQUE Tightening torque Parts to be tightened Remarks m · kg ft · lb Primary sheave drive shaft assembly bolt Connecting rod and cap See NOTE. Balancer ® Balancer shaft bearing retainer Apply LOCTITE A.C. magneto rotor Apply the engine oil. A.C. -

Page 74: Power Train

SPEC TIGHTENING TORQUE POWER TRAIN Tightening torque Parts to be tightened Remarks m · kg ft · lb Primary sheave See NOTE. Spider and sliding sheave Left-hand thread. ® Apply LOCTITE Primary sheave cap and sliding sheave Roller and weight (primary sheave) ®…

-

Page 75

SPEC TIGHTENING TORQUE Tightening torque Parts to be tightened Remarks m · kg ft · lb ® Shaft and sliding frame Apply LOCTITE Shock absorber and front pivot arm Shock absorber and front suspension bracket ® Front pivot arm and sliding frame Apply LOCTITE ®… -

Page 76: Chassis

SPEC TIGHTENING TORQUE CHASSIS Tightening torque Parts to be tightened Remarks m · kg ft · lb Handlebar holder Steering column 1 (front) Steering column 1 (rear upper) Steering column 1 (rear lower) Steering column 2 (upper) Steering column 2 (lower) Steering column 2 and steering shaft ®…

-

Page 77: General Torque Specifications

GENERAL TORQUE SPECIFICATIONS/ SPEC DEFINITION OF UNITS GENERAL TORQUE General torque SPECIFICATIONS specifications (nut) (bolt) This chart specifies torque for standard fasteners m · kg ft · lb with standard I.S.O. pitch threads. Torque specifi- 10 mm 6 mm cations for special components or assemblies are 12 mm 8 mm included in the applicable sections of this book.

-

Page 78: Cable Routing

SPEC CABLE ROUTING…

-

Page 79

SPEC CABLE ROUTING CABLE ROUTING 1 Positive battery lead 2 Negative battery lead 3 Pass the wire harness (two leads) through the hole in the cover. 4 Wire harness 5 A.C. magneto lead 6 Negative battery lead coupler 7 Positive starter motor lead 8 Fasten the A.C. -

Page 80

SPEC CABLE ROUTING… -

Page 81

SPEC CABLE ROUTING Z Starter cable [ Brake hose Fuel sender lead coupler ] Fasten the ignition coil lead to the frame cross member with the plastic band, making sure to fas- ten the lead under the fuel hoses and to face the end of the band rearward. -

Page 82

SPEC CABLE ROUTING… -

Page 83

SPEC CABLE ROUTING x Pass the carburetor heater lead under the positive starter motor lead. y Be sure to install the positive bat- tery lead terminal so that it is fac- ing rearward. -

Page 84

SPEC CABLE ROUTING… -

Page 85

SPEC CABLE ROUTING 1 Headlight sub-wire harness 2 Fasten the headlight sub-wire harness at the white tape with the holder on the shroud. 3 Fasten the headlight sub-wire harness with the holder. 4 Shroud stopper 5 Pass the headlight sub-wire har- ness inside of the shroud stop- per. -

Page 86

SPEC CABLE ROUTING… -

Page 87

SPEC CABLE ROUTING 1 Right handlebar switch 2 Handlebar holder 3 Throttle cable 4 Pass all of the leads and cables through the guide, except the parking brake cable. Do not pass the brake hose through the guide. 5 Fasten the wire harness with the plastic band. -

Page 88

SPEC CABLE ROUTING… -

Page 89

SPEC CABLE ROUTING Y Pass the wire harness, brake hose, and parking brake cable through the guide. Do not pass the throttle cable and starter cable through the guide. Z Place the end of the plastic band between the frame cross mem- ber and the fuel tank. -

Page 90

SPEC CABLE ROUTING… -

Page 91

SPEC CABLE ROUTING 1 Headlight sub-wire harness 2 Oil tank outlet hose 3 Starter motor positive lead 4 Pass the starter motor positive lead behind the engine. 5 Gear position switch lead 6 To the tail/brake light 7 Route the wire harness to the front of the frame cross member bolts, making sure that the har- ness is not on the bolts. -

Page 92

SPEC CABLE ROUTING… -

Page 93

SPEC CABLE ROUTING 1 Fuel pumps 2 Face the ends of each clamp outward. 3 Fuel hoses 4 Coolant reservoir 5 Fasten the fuel tank breather hose, speed sensor lead and relay leads with the holder. Secure the frame cross member and the holder to the frame with the nut and bolt. -

Page 94

SPEC CABLE ROUTING… -

Page 95

SPEC CABLE ROUTING 1 To the starter motor 2 Starter motor positive lead 3 Negative battery lead 4 Positive battery lead 5 Ignitor unit 6 Ignitor unit bracket 7 Air filter case latch 8 Battery band 9 Battery cover 0 To the carburetor A Wire harness B Battery bracket… -

Page 96

SPEC CABLE ROUTING… -

Page 97

SPEC CABLE ROUTING 1 Forward 2 Wire harness 3 Battery bracket 4 To the air filter case 5 A.C. magneto lead 6 Route the crankcase breather hose inside of the wire harness, and then over the starter motor positive lead, and under the bat- tery bracket. -

Page 98

SPEC CABLE ROUTING… -

Page 99

SPEC CABLE ROUTING 1 Fasten the passenger grip warmer lead with the plastic band, making sure that the end of the band is on top of the pipe and facing rearward. The plastic band should not be visible when the passenger seat is installed. 2 Route the passenger grip warmer lead along the groove in the storage compartment. -

Page 100

WIRING DIAGRAM VK10W 2007 8GS-0F001-00 1 Pickup coil COLOR CODE 2 A.C. magneto B ….. Black 3 Rectifier/regulator Br …. Brown 4 Main switch Dg … Dark green 5 Load control relay G ….. Green 6 Main fuse Gy … Gray 7 Starter relay L…. -

Page 102

YAMAHA MOTOR CO., LTD. PRINTED IN U.S.A. 2006.07 CR… -

Page 103

WIRING DIAGRAM VK10W 2007 8GS-0F001-00 (BLACK) B/Y G/B G L/Y (BLACK) (BLACK) R/W B/W Br/B Br/R Lg Br/Y Y/R G R/L G/Y L Y/B Br/L B HEADLIGHT HEADLIGHT TAIL/BRAKE LIGHT SUB-WIRE (BLACK) WIRE HARNESS SUB-WIRE WIRE HARNESS SUB-WIRE WIRE HARNESS…

4-я Красноармейская, 2А

Санкт-Петербург, 190005

Email: info@lenmoto.ru

Телефон: +7 (921) 930-81-18

Телефон: +7 (911) 928-08-06

Компания ЛенМото

Запчасти, аксессуары, экипировка, тюнинг для мотоциклов, скутеров, квадроциклов, снегоходов, багги, гидроциклов, катеров и лодочных моторов.

Подпишитесь на наши новости

Подписаться