1. General;

2. Configuration;

3. Specifications;

4. Consumable Parts;

5. External Views and Internal Structures;

6. Adjustments;

7. Simulations;

8. User Programs (The user programs allow the parameters of certain functions to be set, changed, or canceled as desired);

8.1 List of user programs;

8.2 Setting the user programs;

8.3 Toner cartridge life;

9. Trouble Code List for Sharp AR-5516 / AR-5520.;

10. Maintenance;

11. Disassembly and Assembly;

12. Flash ROM Version up Procedure;

13. Electrical Section.

Download Sharp AR-5516 / AR-5520. Service Manual

Все материалы на сайте представлены исключительно для ознакомления. Все торговые марки и права на публикуемые материалы принадлежат их владельцам.

All materials on the site are presented solely for information. All trademarks and copyrights in the published materials belong to their respective owners.

AR-5516 AR-5516S

AR-5516D

AR-5520 AR-5520S

AR-5520D

(With RSPF installed)

CODE : 00ZAR5520/S1E

DIGITAL COPIER

AR-5520 AR-5516

AR-5520S AR-5516S MODEL AR-5520D AR-5516D

|

CONTENTS |

|||||

|

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 1 |

— 1 |

|||

|

[ 2 ] CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

— 1 |

|||

|

[ 3 ] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

— 1 |

|||

|

[ 4 ] CONSUMABLE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

— 1 |

|||

|

[ 5 ] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . |

5 |

— 1 |

|||

|

[ 6 |

] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

— 1 |

||

|

[ 7 |

] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

— 1 |

||

|

[ 8 |

] USER PROGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

— 1 |

||

|

[ 9 |

] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

— 1 |

||

|

[10] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

— 1 |

|||

|

[11] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . |

11 |

— 1 |

|||

|

[12] FLASH ROM VERSION UP PROCEDURE . . . . . . . . . . . . . . |

12 |

— 1 |

|||

|

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

— 1 |

Parts marked with “

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used for SHARP CORPORATION after sales service only.

The contents are subject to change without notice.

CONTENTS

[1] GENERAL

1.Note for servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] CONFIGURATION

1.System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] SPECIFICATIONS

1.Copy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] CONSUMABLE PARTS

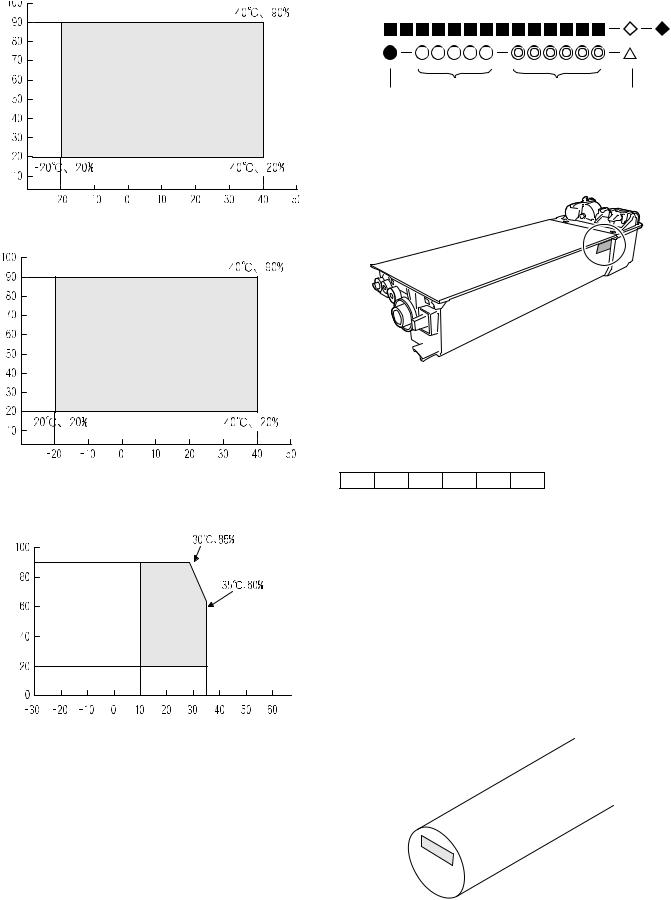

1.Supply system table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 2.Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 3. Production number identification . . . . . . . . . . . . . . . . . . . 4-3

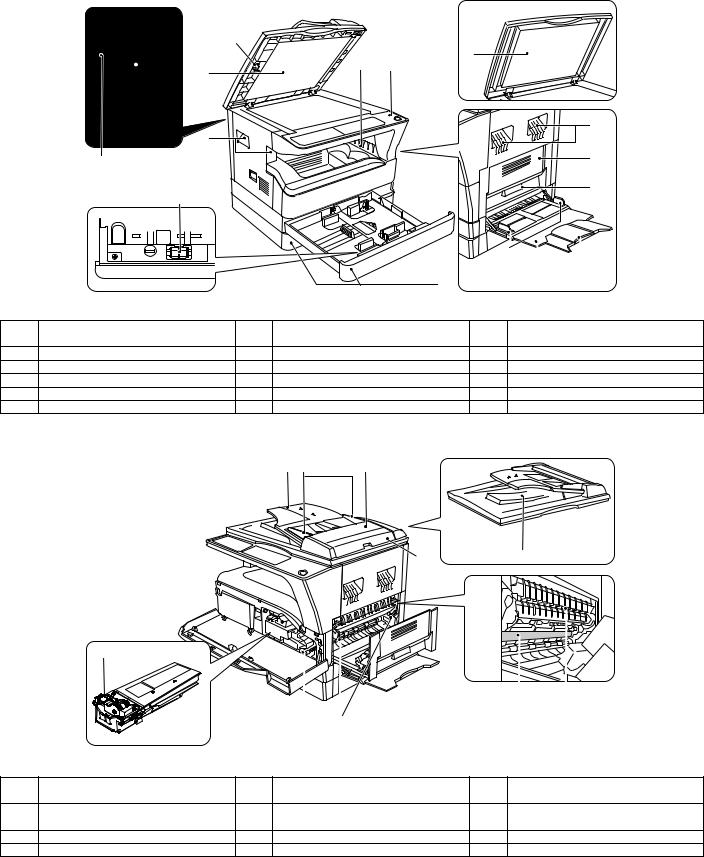

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES

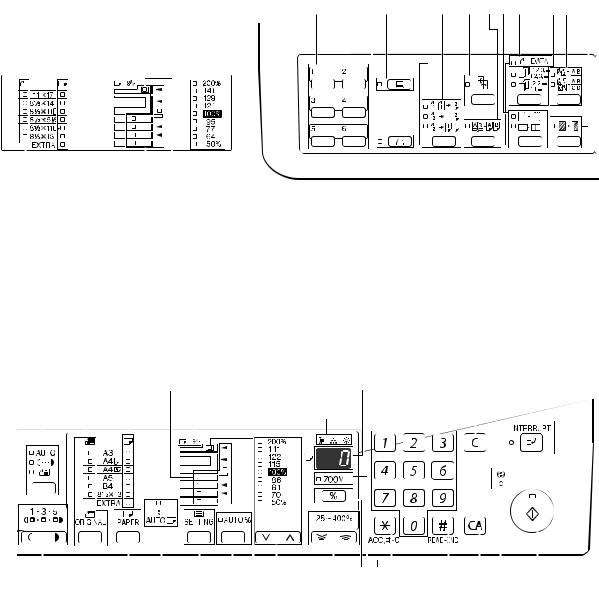

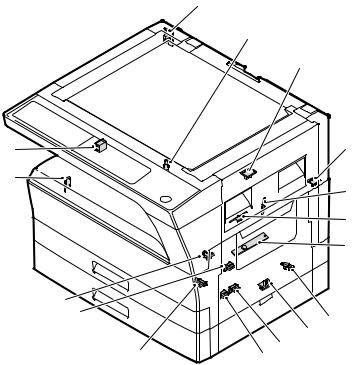

1.Appearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 2.Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 3.Operation Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 4.Motor, solenoid, clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 5.Sensor, switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4 6.PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5 7.Cross sectional view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

[6] ADJUSTMENTS

1.Adjustment item list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 2.Copier adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] SIMULATIONS

1.Entering the simulation mode . . . . . . . . . . . . . . . . . . . . . . 7-1 2.Canceling the simulation mode . . . . . . . . . . . . . . . . . . . . . 7-1 3.List of simulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 4.Contents of simulations. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

[8] USER PROGRAMS

1.List of user programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 2.Setting the user programs . . . . . . . . . . . . . . . . . . . . . . . . 8-4 3.Toner cartridge life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

[9] TROUBLE CODE LIST

1.Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 2.Details of trouble codes . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] MAINTENANCE

1.Maintenance table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1 2.Maintenance display system . . . . . . . . . . . . . . . . . . . . . . 10-2 3.Note for replacement of consumable parts . . . . . . . . . . . 10-2

[11] DISASSEMBLY AND ASSEMBLY

1.High voltage section/Duplex transport section. . . . . . . . . 11-1 2.Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2 3.Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4 4.Paper exit section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6 5.MCU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8 6.Optical frame unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8 7.LSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9 8.Tray paper feed section/Paper transport section . . . . . . 11-9 9.Bypass tray section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11 10.Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13 11.Developing section . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14 12.Process section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15 13.Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

[12] FLASH ROM VERSION UP PROCEDURE

1.Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1 2.Download procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1 3.Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

[13] ELECTRICAL SECTION

1.Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1 2.Actual wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

[1] GENERAL

1. Note for servicing

|

Pictogram |

|

|

The label ( |

) in the fusing area of the machine indicates the |

following:

A. Warning for servicing

•The fusing area is hot. Exercise care in this area when removing misfed paper.

•Do not look directly at the light source. Doing so may damage your eyes.

B. Cautions for servicing

•Do not switch the machine rapidly on and off. After turning the machine off, wait 10 to 15 seconds before turning it back on.

•Machine power must be turned off before installing any supplies. •Place the machine on a firm, level surface.

•Do not install the machine in a humid or dusty location.

•When the machine is not used for a long time, for example, during prolonged holidays, turn the power switch off and remove the power cord from the outlet.

•When moving the machine, be sure to turn the power switch off and remove the power cord from the outlet.

•Do not cover the machine with a dust cover, cloth or plastic film while the power is on. Doing so may prevent heat dissipation, damaging the machine.

•Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous laser radiation exposure.

•The socket-outlet shall be installed near the machine and shall be easily accessible.

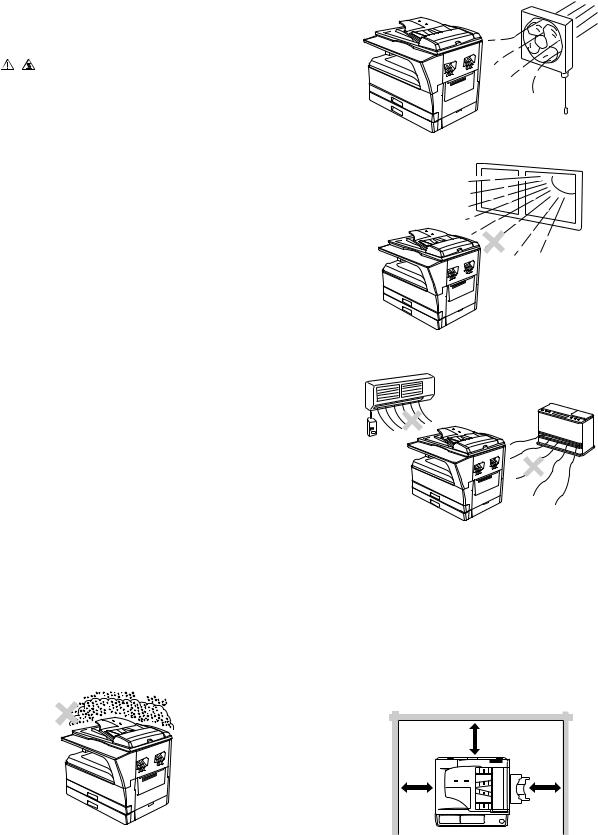

C. Note for installation place

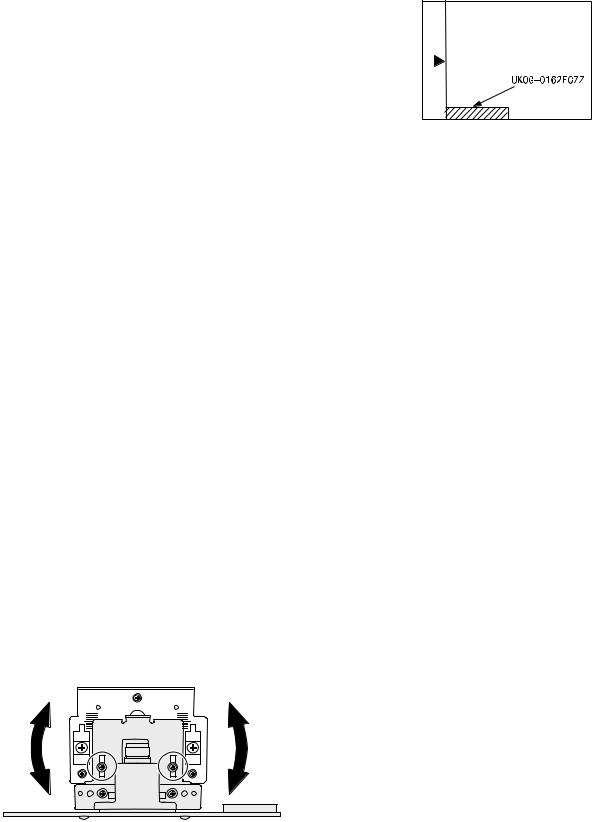

Improper installation may damage the machine. Please note the following during initial installation and whenever the machine is moved.

Caution : If the machine is moved from a cool place to a warm place, condensation may form inside the machine. Operation in this condition will cause poor copy quality and malfunctions. Leave the machine at room temperature for at least 2 hours before use.

Do not install your machine in areas that are:

•damp, humid, or very dusty

•poorly ventilated

•exposed to direct sunlight

•subject to extreme temperature or humidity changes, e.g., near an air conditioner or heater.

The machine should be installed near an accessible power outlet for easy connection and disconnection.

Be sure to connect the power cord only to a power outlet that meets the specified voltage and current requirements. Also make certain the outlet is properly grounded.

Note : Connect the machine to a power outlet which is not used for other electric appliances. If a lighting fixture is connected to the same outlet, the light may flicker.

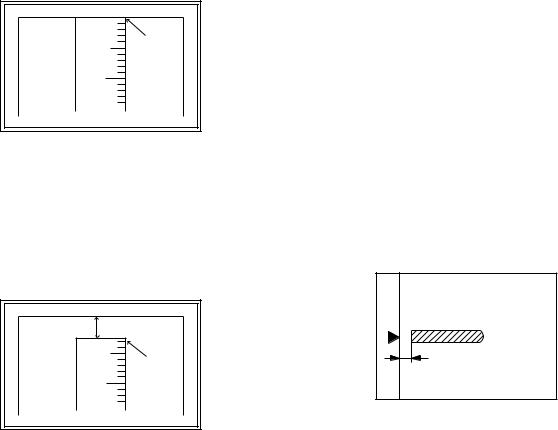

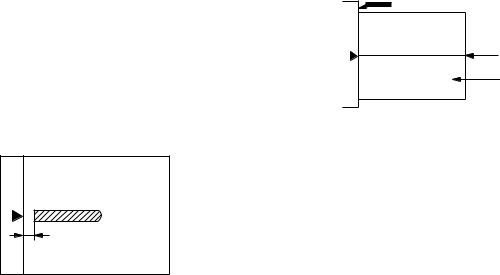

Be sure to allow the required space around the machine for servicing and proper ventilation.

|

20 cm (8″) |

|

|

20 cm |

20 cm |

|

(8″) |

(8″) |

AR-5520 GENERAL 1-1

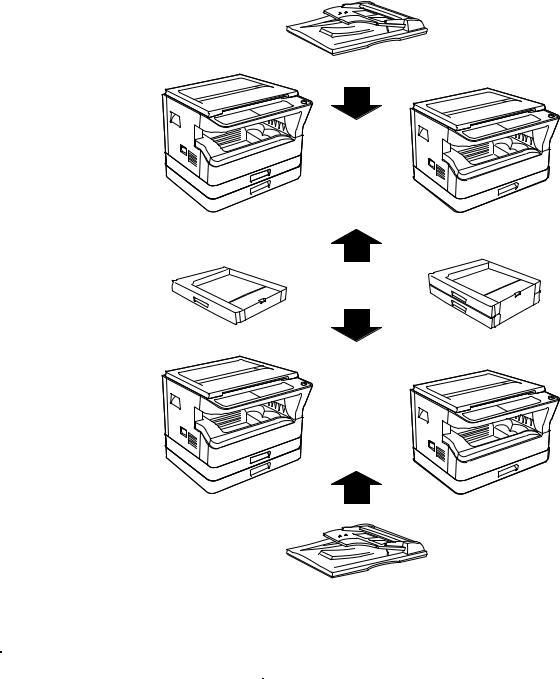

[2] CONFIGURATION

1. System Configurations

AR-SP10

|

AR-5520/AR-5520S |

AR-5516/AR-5516S |

AR-RP10

|

Model |

AR-5520 / AR-5520S |

AR-5520D |

Remark |

||

|

Option |

AR-5516 /AR-5516S |

AR-5516D |

|||

|

AR-RP10 |

Duplex document auto feeder (RSPF) |

X |

O |

||

|

AR-SP10 |

Document auto feeder (SPF) |

O |

X |

||

|

AR-D34 |

1-stage paper feed unit |

O |

O |

||

|

AR-D35 |

2-stage paper feed unit |

O |

O |

||

|

O:Option installation enable |

X: Option installation disable |

AR-5520 CONFIGURATION 2-1

[3] SPECIFICATIONS

1. Copy mode

A. Type

|

Type |

Desk-top |

|

Paper exit |

Wing less |

B. Machine composition

|

AR-5516 / AR-5516S / AR-5516D |

16-CPM multi function model |

|

AR-5520 / AR-5520S / AR-5520D |

20-CPM multi function model |

(1) Option

|

Machine |

Model |

|

|

250 sheets paper feed unit |

AR-D34 |

|

|

250 sheets x 2 paper feed unit |

AR-D35 |

|

|

SPF |

AR-SP10 |

AR-5520/ AR-5520S |

|

AR-5516 /AR-5516S |

||

|

RSPF |

AR-RP10 |

AR-5520D/ AR-5516D |

C. Copy speed

(1) Engine speed (ppm)

|

Paper size |

AR-5520 / AR-5520S |

AR-5516 / AR-5516S |

|

|

AR-5520D |

AR-5516D |

||

|

A4/ 8.5”x11” |

20ppm |

16ppm |

|

|

A4R |

14ppm |

12ppm |

|

|

8.5”x11”R |

15ppm |

12ppm |

|

|

A5/ 5.5”x8.5” |

20ppm |

16ppm |

|

|

B5/ 16K |

20ppm |

16ppm |

|

|

B5R |

16ppm |

14ppm |

|

|

16KR |

15ppm |

14ppm |

|

|

8.5×13” |

12ppm |

11ppm |

|

|

B4/ 8.5”x14 |

12ppm |

10ppm |

|

|

A3 |

11ppm |

9ppm |

|

|

11”x17” |

10ppm |

9ppm |

|

|

8K |

11ppm |

10ppm |

|

(2) Document replacement speed (Copy mode)

|

Copy mode |

AR-5520 / AR-5520S |

AR-5516 / AR-5516S |

||

|

AR-5520D |

AR-5516D |

|||

|

S to S |

20cpm |

(100%) |

16cpm |

(100%) |

|

S to D |

9cpm |

(45%) |

9cpm |

(56%) |

|

D to D |

8cpm |

(40%) |

8cpm |

(50%) |

S to S : Tray1 A4/8.5”X11” document 11 sheets (11 pages), copy 1 set S to D : Tray1 A4/8.5”X11” document 22 sheets (22 pages), copy 1 set D to D : Tray1 A4/8.5”X11” document 11 sheets (22 pages), copy 1 set

(3) Job efficiency

|

Copy mode |

AR-5520 / AR-5520S |

AR-5516 / AR-5516S |

|

|

AR-5520D |

AR-5516D |

||

|

S to S |

19cpm (95%) |

15cpm (94%) |

|

|

S to D |

11cpm (55%) |

10cpm (63%) |

|

|

D to D |

10cpm (50%) |

10cpm (63%) |

|

S to S : Tray1 A4/8.5”X11” document 10 sheets (10 pages), copy 5 sets S to D : Tray1 A4/8.5”X11” document 10 sheets (10 pages), copy 5 sets D to D : Tray1 A4/8.5”X11” document 10 sheets (20 pages), copy 5 sets

(4) First copy time

|

Tray |

Content |

|

1st tray |

7.2 sec or less |

|

2nd tray |

8.5 sec or less |

|

3rd tray |

9.5 sec or less |

|

4th tray |

10.5 sec or less |

|

Bypass tray |

7.5 sec or less |

600x300dpi, AE mode, A4/Letter, single surface copy with OC, in polygon ready state

D. Document

|

Max. document size |

A3, 11″ X 17″ |

|

Document reference position |

Left side center |

|

Detection (Platen) |

None |

E. Paper feed

(1) Paper feed section details

|

Item |

1st tray |

2nd tray |

Bypass tray |

|

|

Paper capacity |

250 |

250 |

100 sheets |

|

|

sheets |

sheets |

|||

|

Paper size detection |

No |

|||

|

(Paper size is set with |

||||

|

the system setting.) |

||||

|

Paper type setting |

No |

No |

No |

|

|

(Heavy |

||||

|

paper setting |

||||

|

is enabled.) |

||||

|

Paper size changing method |

The paper |

guide is set |

by the user. |

|

|

Paper when shipping |

AB series |

A4 |

A4 |

— |

|

Size setting |

Inch series |

8 1/2” x11” |

8 1/2” x11” |

— |

|

Remaining paper quantity |

Only empty detection available |

|||

|

detection |

||||

(2) Feedable paper

|

Paper size |

1st tray |

2nd tray |

Bypass |

|

|

tray |

||||

|

A3 |

297×420 |

Yes |

Yes |

Yes |

|

B4 |

257×364 |

Yes |

Yes |

Yes |

|

A4 |

297×210 |

Yes |

Yes |

Yes |

|

A4-R |

210×297 |

Yes |

Yes |

Yes |

|

B5 |

257×182 |

Yes |

Yes |

Yes |

|

B5R |

182×257 |

Yes |

Yes |

Yes |

|

A5 |

210×148.5 |

Yes |

N/A |

Yes |

|

A5R |

148.5×210 |

N/A |

N/A |

Yes |

|

A6R |

105×148.5 |

N/A |

N/A |

Yes |

|

B6R |

128.5×182 |

N/A |

N/A |

Yes |

|

Ledger 11 x 17 in |

279.4×431.8 |

Yes |

Yes |

Yes |

|

Legal 8.5x14in. |

215.9×355.6 |

Yes |

Yes |

Yes |

|

Foolscap 8.5 x 13 in |

215.9×330.2 |

Yes |

Yes |

Yes |

|

Letter 11×8.5in |

279.4×215.9 |

Yes |

Yes |

Yes |

|

Letter-R 8.5x11in |

215.9×279.4 |

Yes |

Yes |

Yes |

|

Executive-R 7.25×10.5in. |

184.2×266.7 |

N/A |

N/A |

Yes |

|

Invoice 8.5×5.5 in. |

215.9×139.7 |

Yes |

N/A |

Yes |

|

Invoice-R 5.5×8.5 in |

139.7×215.9 |

N/A |

N/A |

Yes |

|

8K |

270×390 |

Yes |

Yes |

Yes |

|

16K |

270×195 |

Yes |

Yes |

Yes |

|

16KR |

195×270 |

Yes |

Yes |

Yes |

|

COM10 |

104.8×241.3 |

N/A |

N/A |

Yes |

|

COM9 |

98.4×225.4 |

N/A |

N/A |

Yes |

|

C5 |

162×229 |

N/A |

N/A |

Yes |

|

DL |

110×220 |

N/A |

N/A |

Yes |

|

Postcard |

100×148 |

N/A |

N/A |

Yes |

|

Return postcard |

200×148 |

N/A |

N/A |

Yes |

|

Long format No. 3 |

120.1×235 |

N/A |

N/A |

Yes |

|

Monarch |

98.4×190.5 |

N/A |

N/A |

Yes |

|

Western format No. 2 |

114×162 |

N/A |

N/A |

Yes |

|

Western format No. 4 |

105×235 |

N/A |

N/A |

Yes |

AR-5520 SPECIFICATIONS 3-1

(3)Types of feedable paper

|

Types of paper |

1st tray |

2nd tray |

Bypass tray |

||

|

Thin paper |

56-59g/m2 |

Yes |

Yes |

Yes |

|

|

15-15.9lbs |

|||||

|

Plain paper |

60-90g/m2 |

Yes |

Yes |

Yes |

|

|

16-24lbs |

(Multi paper feed enable) |

||||

|

Heavy paper |

91-105g/m2 |

N/A |

N/A |

Yes |

|

|

16-24lbs |

(Multi paper feed enable) |

||||

|

106-128g/m2 |

Yes |

||||

|

Heavy paper |

N/A |

N/A |

(A4 or less) |

||

|

24.1-33.5lbs |

|||||

|

(Multi paper feed enable) |

|||||

|

129-200g/m2 |

Yes |

||||

|

Heavy paper |

N/A |

N/A |

(A4 or less) |

||

|

33.6-53.2lbs |

|||||

|

(Only single paper feed) |

|||||

|

Heavy paper |

201-256g/m2 |

N/A |

N/A |

N/A |

|

|

53.3-68lbs |

|||||

|

Envelope |

75-90g/m2 |

N/A |

N/A |

Yes |

|

|

20-24lbs |

|||||

|

Postcard |

N/A |

N/A |

Yes |

||

|

OHP film |

N/A |

N/A |

Yes |

||

|

Label sheet |

N/A |

N/A |

Yes |

||

|

Tab paper 20 |

N/A |

N/A |

Yes |

||

F. Multi copy

|

Max. number of multi copy |

999 sheets |

G. Warm-up time

|

Warm-up time |

45 sec |

|

Pre-heat |

Available |

|

Jam recovery |

Within 45 sec |

H. Copy magnification ratio

|

Fixed |

AB system: |

|

magnification |

50,70,86,100,141,200% |

|

ratio |

|

|

Inch system: |

|

|

50,64,78,100,129,200% |

|

|

Zooming |

25 ~ 400% |

|

SPF/RSPF(50 ~ 200%) |

|

|

Independent |

Available (25 ~ 400%) |

|

zooming(vertical) |

SPF/RSPF(50 ~ 200%) |

|

Independent zooming |

Available (25 ~ 400%) |

|

(horizontal) |

SPF/RSPF(50 ~ 200%) |

I. Print density

|

Density mode |

Auto / Text / Photo |

|

No. of manual |

5 steps (Text / Photo) |

|

adjustment |

|

|

Resolution |

Writing: 600 x 600dpi |

|

Reading: 600 (main) x 600 (sub) (PHOTO mode) |

|

|

600 (main) x 300 (sub) (AUTO exposure |

|

|

mode) |

|

|

Gradation |

Reading: 256 gradations |

|

Writing: Binary |

|

|

Toner save mode |

Set by the user program |

J. Void width

|

Void area |

Lead edge 1 ~ 4mm, |

||

|

rear edge 4mm or less, |

|||

|

Total of both sides: 6mm or less |

|||

|

Image loss |

OC |

Same size |

3.0mm or less |

|

Enlargement |

1.5mm or less |

||

|

Reduction |

6.0mm or less |

||

|

SPF/RSPF |

Same size |

4.0mm or less |

|

|

Enlargement |

3.0mm or less |

||

|

Reduction |

8.0mm or less |

||

K. Auto duplex

|

Standard/ |

Standard provision (AR-5520D / AR-5516D only) |

|

Option |

(D→ D / D → S enable only when RSPF is installed) |

|

Not available for AR-5520 / AR-5520S / AR-5516/ AR- |

|

|

5516S |

|

L. Paper exit / finishing

|

Paper exit section |

Face down 250 sheets |

|

capacity |

|

|

Full detection |

None |

|

Finishing |

None |

|

Electronic sort |

A4/ 8.5″ x 11″ standard document (6% |

|

capacity |

coverage) 160 sheets |

|

Offset function |

None |

|

Staple function |

None |

M. Additional functions

|

AR-5520S |

AR-5520 |

AR-5520D |

|||||

|

AR-5516S |

AR-5516 |

AR-5516D |

|||||

|

APS |

O |

||||||

|

AMS |

O |

||||||

|

Auto tray |

O |

||||||

|

switching |

|||||||

|

Memory copy |

O |

||||||

|

Rotation copy |

O |

||||||

|

E-sort (Sorting |

O |

||||||

|

function) |

X |

Single surface, A4, 6% document, Max. |

|||||

|

160 sheets |

|||||||

|

E-sort (Grouping |

X |

O |

|||||

|

function) |

|||||||

|

Rotation sort |

X |

||||||

|

Prevention of sky |

X |

||||||

|

shot |

|||||||

|

Independent |

O |

||||||

|

zooming |

|||||||

|

1 set 2 copy |

O |

||||||

|

Disable in enlargement copy or when SPF/RSPF is |

|||||||

|

used. |

|||||||

|

Binding margin |

O |

||||||

|

X |

Default AB series: 10mm (5, 10, 15, 20mm) |

||||||

|

Inch series: 1/2 inch (1/4, 1/2, 3/4, 1 inch) |

|||||||

|

Edge erase |

O |

||||||

|

X |

Default AB series: 10mm (5, 10, 15, 20mm) |

||||||

|

Inch series: 1/2 inch (1/4, 1/2, 3/4, 2 inch) |

|||||||

|

Center erase |

O |

||||||

|

X |

Default AB series: 10mm (5, 10, 15, 20mm) |

||||||

|

Inch series: 1/2 inch (1/4, 1/2, 3/4, 3 inch) |

|||||||

|

Black/white |

X |

||||||

|

reverse |

|||||||

|

2in1/4in1 |

X |

O |

|||||

|

Offset |

X |

||||||

|

Preheating |

O |

The conditions are set by the user program. |

|||||

|

Auto shut-off |

O |

The conditions are set by the user program. |

|||||

|

User |

O |

||||||

|

programming |

|||||||

|

Total counter |

O |

Supports Total counter |

and Copy counter. |

||||

|

Coin vendor |

O |

(Supports I/F only.) |

|||||

|

support |

|||||||

|

Auditor support |

O |

(Supports I/F only.) |

|||||

|

Duplex |

X |

O |

|||||

|

Toner save |

O (Set according to the destination) |

||||||

|

Department |

O (Copy: 20 Dept.) |

||||||

|

management |

|||||||

|

O : Available X |

: Not available |

AR-5520 SPECIFICATIONS 3-2

N. Other specifications

|

Photoconductor type |

OPC (Organic Photo Conductor) |

|

Photoconductor drum dia. |

30mm |

|

Copy lamp |

Cold cathode fluorescent lamp (CCFL) |

|

Developing system |

Dry 2-component magnetic brush |

|

development |

|

|

Charging system |

Saw teeth charging |

|

Transfer system |

(+) DC corotron |

|

Separation system |

(-) DC corotron |

|

Fusing system |

Heat roller |

|

Cleaning system |

Contact blade |

O. Package form

P. External view

|

AR-5520S/AR-5520/ |

AR-5516S/AR-5516/ |

||

|

AR-5520D |

AR-5516D |

||

|

External dimensions |

590mm(W) x 550mm(D) |

590mm(W) x 550mm(D) |

|

|

(With the bypass tray |

|||

|

x 555mm(H) or less |

x 470mm(H) or less |

||

|

closed) |

|||

|

Occupying area |

|||

|

(With the bypass tray |

883mm(W) x 550mm(D) or less |

||

|

opened) |

|||

|

Weight |

|||

|

(Excluding |

35.9Kg |

30.9Kg |

|

|

developer) |

|||

Q. Power source

|

Voltage |

100 — 127V 220 — 240V |

|

Frequency |

50/60Hz common |

R. Power consumption

|

Max. power consumption |

1200W |

||

|

* EnergyStar conformity |

|||

|

Average power consumption in |

Less than 550W |

||

|

operation |

|||

|

Power consumption when |

5W(Not include option) |

||

|

standby |

|||

|

Energy consumption efficiency |

Less than 25W |

||

|

S. Digital performance |

|||

|

Resolution |

Reading |

600 x 600dpi (PHOTO mode) |

|

|

600 x 300dpi (AUTO exposure mode) |

|||

|

Writing |

600 x 600dpi |

||

|

Gradation |

Reading |

256 gradations |

|

|

Writing |

Binary |

||

|

Memory |

AR-5520S/5516S : 16MB |

||

|

AR-5520/5516/5520D/5516D : 64MB |

|||

|

Hard disk |

None |

||

T. Printing function

(1) Platform

|

Item |

Content |

|

Support platform |

IBM PC/AT compatible machine |

(2) Support OS

|

OS |

Support |

|

Windows 95 |

X |

|

Windows 98/Me |

X |

|

Windows NT 4.0 SP5 |

X |

|

Windows 2000 |

O |

|

Windows XP 32 |

O |

|

Windows XP 64 |

O (Web release only) |

|

Windows Server 2003 |

X |

|

Windows Vista 32 |

O |

|

Windows Vista 64 |

O (Web release only) |

AR-5520 SPECIFICATIONS 3-3

(3) Printer driver function (SPLC)

|

Item |

SPLC |

|||

|

Common |

Default |

Button |

||

|

MIMIC |

Yes |

|||

|

Configuration |

Input Tray Options |

One Tray/ Two Tray/ Three Tray/ |

||

|

Four Tray |

||||

|

Set |

Paper |

Tray1/ Tray2/ Bypass Tray |

||

|

Tray |

Source |

|||

|

Status |

||||

|

Set Paper |

Not set/ A3/ A4-R/ A5-R/ A6-R/ B4/ |

|||

|

size |

B5-R/ B6-R/ Leger/ Letter-R/ |

|||

|

Legal/ Executive-R/ Invoice-R/ |

||||

|

Foolscap/ Folio/ Com10/ DL/ C5/ |

||||

|

8k/ 16k-R/ Custom paper |

||||

|

ROPM |

On/Off (The AR-5520S/5516S are |

|||

|

out of target.) |

||||

|

Status window |

Button |

|||

|

About |

Button |

|||

|

Main |

Copies |

1-999 |

||

|

Collate |

On/ Off |

|||

|

N-UP printing |

1/ 2/ 4 /6 up |

|||

|

User settings |

Button |

|||

|

Paper |

Paper size |

A3/ A4/ A5/ A6/ B4/ B5/ B6/ Leger/ |

||

|

Letter/ Legal/ Executive/ Invoice/ |

||||

|

Foolscap/ Folio/ Com10/ DL/ C5/ |

||||

|

8k/ 16k/ Custom paper |

||||

|

— Custom paper: |

||||

|

Width [100.0] -[297.0] |

||||

|

[3.94”] -[11.69”] |

||||

|

Length [148.0] -[431.8] |

||||

|

[5.83”] — [17.00”] |

||||

|

— Milimeters/ Inches |

||||

|

Fit to paper size |

On/Off |

|||

|

A3/ A4/ A5/ A6/ B4/ B5/ B6/ Leger/ |

||||

|

Letter/ Legal/ Executive/ Invoice/ |

||||

|

Foolscap/ Folio/ Com10/ DL/ C5/ |

||||

|

8k/ 16k |

||||

|

Image orientation |

Portrait/ Landscape/ Rotate 180 |

|||

|

degrees |

||||

|

Paper selection |

Auto select/ Tray1/ Tray2/ Bypass |

|||

|

Tray |

||||

|

Advanced |

Image quality |

Draft/ Normal/ Photo |

||

|

Text to Black, Vector |

On/Off |

|||

|

to Black |

||||

|

Watermark |

Watermark |

Top seclet/ Confidential/ Draft/ |

||

|

Original/ Copy |

||||

|

Text |

Yes |

|||

|

Size |

[6] — [300] |

|||

|

Angle |

[-90] — [90] |

|||

|

Grayscale |

[0] — [255] |

|||

|

Edit font |

Yes |

|||

|

On first page only |

On/Off |

|||

|

Center |

Button |

|||

|

Position |

X: [-50] — [50] |

|||

|

Y: [-50] — [50] |

||||

U. Scanner function (Except for AR-5520/AR-5516)

|

Type |

Flat bed scanner |

|

|

Scan system |

Document table/document feed unit |

|

|

Light source |

Yellow + Green CCFL |

|

|

Resolution |

Binary: 600 x 600 dpi |

|

|

Gray scale: 300 x 300 dpi |

||

|

Document |

Sheet/Book |

|

|

Effective scan range |

OC/SPF/RSPF: |

|

|

about 297(length) x 431(width) mm |

||

|

Scan speed |

OC/SPF/R-SPF: |

|

|

0.962msec/line(300 dpi) |

||

|

Input data |

1bit or 12bit |

|

|

Output data |

1bit or 8bit |

|

|

Scan color |

Black & white / binary / Gray scale |

|

|

Protocol |

TWAIN / WIA(XP only) * / STI |

|

|

Interface |

USB2.0 (High speed mode, full speed mode) |

|

|

Scanner utility |

Button Manager |

|

|

Drop-out color |

No |

|

|

Scanner button |

Provided (6) |

|

|

Supported OS |

USB connection:Windows 2000/XP/VISTA |

|

|

network connection:Windows 2000/XP/VISTA |

||

|

Void area |

Lead edge/rear edge (2.5mm) on the driver |

|

|

side Left/right: 3.0mm |

||

|

WHQL support |

No |

|

AR-5520 SPECIFICATIONS 3-4

[4] CONSUMABLE PARTS

1.Supply system table

A. USA/Canada/South and Central America(100V series)

AR-5516/AR-5520D

|

No. |

Name |

Product name |

Content |

Life |

Remark |

|

|

1 |

Toner cartridge(Black) |

AR-020MT |

Toner cartridge |

x10 |

160K(16Kx10) |

Life setting by A4 6% document |

|

(AR-020NT x 10) |

(Toner:Net 537g With IC) |

|||||

|

2 |

Developer |

AR-205MD |

Developer |

x10 |

500K(50×10) |

|

|

(AR-205ND x 10) |

(Net 300g) |

|||||

|

3 |

Drum KIT |

AR-205DR |

Drum |

x1 |

50K |

|

|

Drum fixing plate |

x1 |

|||||

B. South and Central America(200V series)

AR-5516/AR-5520D

|

No. |

Name |

Product name |

Content |

Life |

Remark |

|

|

1 |

Toner cartridge(Black) |

AR-020LT |

Toner cartridge |

x10 |

190K(19Kx10) |

Life setting by A4 6% document |

|

(AR-020T x 10) |

(Toner:Net 537g With IC) |

(In a toner save mode) |

||||

|

2 |

Developer |

AR-205LD |

Developer |

x10 |

500K(50×10) |

|

|

(AR-205DV x 10) |

(Net 300g) |

|||||

|

3 |

Drum KIT |

AR-205DM |

Drum |

x1 |

50K |

|

|

Drum fixing plate |

x1 |

|||||

C. Brazil

AR-5516/AR-5520D

|

No. |

Name |

Product name |

Content |

Life |

Remark |

|

|

1 |

Toner cartridge(Black) |

AR-020MTB |

Toner cartridge |

x10 |

190K(19Kx10) |

Life setting by A4 6% document |

|

(AR-020NTB x 10) |

(Toner:Net 537g With IC) |

(In a toner save mode) |

||||

|

2 |

Developer |

AR-205MD |

Developer |

x10 |

500K(50×10) |

|

|

(AR-205ND x 10) |

(Net 300g) |

|||||

|

3 |

Drum KIT |

AR-205DR |

Drum |

x1 |

50K |

|

|

Drum fixing plate |

x1 |

|||||

D. Europe

AR-5516/AR-5516S/AR-5520/AR-5520S/AR-5520D

|

No. |

Name |

Product name |

Content |

Life |

Remark |

|

|

1 |

Toner cartridge(Black) |

AR-020LT |

Toner cartridge |

x10 |

160K(16Kx10) |

Life setting by A4 6% document |

|

(AR-020T x 10) |

(Toner:Net 537g With IC) |

(In a toner save mode) |

||||

|

2 |

Developer |

AR-205LD |

Developer |

x10 |

500K(50×10) |

|

|

(AR-205DV x 10) |

(Net 300g) |

|||||

|

3 |

Drum KIT |

AR-205DM |

Drum |

x1 |

50K |

|

|

Drum fixing plate |

x1 |

|||||

E. Australia/New Zealand

AR-5516/AR-5516D/AR-5520/AR-5520S/AR-5520D

|

No. |

Name |

Product name |

Content |

Life |

||

|

1 |

Toner cartridge(Black) |

AR-020LT |

Toner cartridge |

x10 |

190K(19Kx10) |

Life setting by A4 6% document |

|

(AR-020T x 10) |

(Toner:Net 537g With IC) |

(In a toner save mode) |

||||

|

2 |

Developer |

AR-205LD |

Developer |

x10 |

500K(50×10) |

|

|

(AR-205DV x 10) |

(Net 300g) |

|||||

|

3 |

Drum KIT |

AR-205DM |

Drum |

x1 |

50K |

|

|

Drum fixing plate |

x1 |

|||||

AR-5520 CONSUMABLE PARTS 4-1

F. Middle East/Africa/Israel/Philippine/Other Distributor

AR-5516/AR-5516S/AR-5516D/AR-5520/AR-5520S/AR-5520D

|

No. |

Name |

Product name |

Content |

Life |

Remark |

||

|

1 |

Toner cartridge(Black) |

AR-021ET |

Toner cartridge |

x10 |

190K(19Kx10) |

Life setting by A4 6% document |

|

|

(AR-021FT |

x 10) |

(Toner:Net 537g With IC) |

(In a toner save mode) |

||||

|

2 |

Developer |

AR-205CD |

Developer |

x10 |

500K(50×10) |

||

|

(AR-205SD |

x 10) |

(Net 300g) |

|||||

|

3 |

Drum KIT |

AR-205DR |

Drum |

x1 |

50K |

||

|

Drum fixing plate |

x1 |

||||||

G. Taiwan

AR-5516/AR-5516S/AR-5516D/AR-5520/AR-5520S/AR-5520D

|

No. |

Name |

Product name |

Content |

Life |

Remark |

||

|

1 |

Toner cartridge(Black) |

AR-021ET |

Toner cartridge |

x10 |

160K(16Kx10) |

Life setting by A4 6% document |

|

|

(AR-021FT |

x 10) |

(Toner:Net 537g With IC) |

|||||

|

2 |

Developer |

AR-205CD |

Developer |

x10 |

500K(50×10) |

||

|

(AR-205SD |

x 10) |

(Net 300g) |

|||||

|

3 |

Drum KIT |

AR-205DR |

Drum |

x1 |

50K |

||

|

Drum fixing plate |

x1 |

||||||

H. Asia(Except the above)

AR-5516/AR-5516S/AR-5516D/AR-5520/AR-5520S/AR-5520D

|

No. |

Name |

Product name |

Content |

Life |

Remark |

||

|

1 |

Toner cartridge(Black) |

AR-020CT |

Toner cartridge |

190K(19Kx10) |

Life setting by A4 6% document |

||

|

(AR-020ST |

x 10) |

(Toner:Net 537g With IC) |

x10 |

(In a toner save mode) |

|||

|

2 |

Developer |

AR-205CD |

Developer |

x10 |

500K(50×10) |

||

|

(AR-205SD |

x 10) |

(Net 300g) |

|||||

|

3 |

Drum KIT |

AR-205DR |

Drum |

x1 |

50K |

||

|

Drum fixing plate |

x1 |

||||||

AR-5520 CONSUMABLE PARTS 4-2

2. Environmental conditions

A. Transport conditions

(1) Transport conditions

Temperature

|

(2) Storage conditions |

|

Humidity (%) |

Temperature

3. Production number identification

<Toner cartridge>

The label on the toner cartridge shows the date of production.

|

Production |

Serial |

Year/ |

Ver.No. |

|

place |

number |

Month/ |

|

|

Day |

<Drum cartridge>

The lot number, printed on the front side flange, is composed of 6 digits, each digit showing the following content:

|

1 |

2 |

3 |

4 |

5 |

6 |

B. Use conditions

1Alphabet

Indicates the model conformity code. A for this model.

|

2 |

Number |

||

|

Indicates the end digit of the production year. |

|||

|

(%) |

3 |

Number or X, Y, Z |

|

|

Use envi- |

Indicates the month of packing. |

||

|

Humidity |

ronment |

Indicates the day of the month of packing. |

|

|

X stands for October, Y November, and Z December. |

|||

|

conditions |

4/5 |

Number |

|

|

6 |

Alphabet |

||

|

Indicates the production factory. «A» for Nara Plant, “C“ for |

|||

|

SOCC |

Temperature

C. Life(packed conditions)

Photoconductor drum (36 months from the production month)

Developer, toner (24 months from the production month)

AR-5520 CONSUMABLE PARTS 4-3

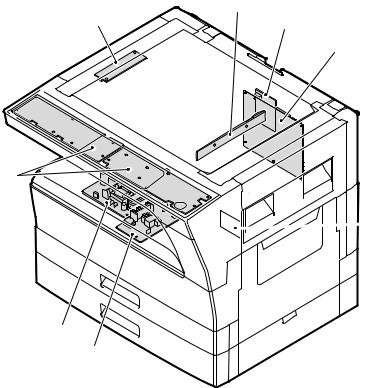

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

|

9 |

12 |

13 |

14 |

|||||

|

1 |

Glass cleaner |

2 |

Document feeder cover (when the SPF/ |

3 |

Document glass |

|||

|

(when the SPF/RSPF is installed) |

RSPF is installed) /document cover |

|||||||

|

4 |

Handles |

5 |

Power switch |

6 |

Operation panel |

|||

|

7 |

Paper output tray |

8 |

Front cover |

9 |

Paper trays |

|||

|

10 |

Side cover |

11 |

Side cover handle |

12 |

Bypass tray guides |

|||

|

13 |

Bypass tray |

14 |

Bypass tray extension |

15 |

Charger cleaner |

|||

|

16 |

USB 2.0 connector |

|||||||

2. Internal |

||||||||

|

17 18 |

19 |

22

|

24 |

25 |

26 |

27 |

||||

|

23 |

|||||||

|

17 |

Document feeder tray |

18 |

Original guides |

19 |

Feeding roller cover |

||

|

(when the SPF/RSPF is installed) |

(when the SPF/RSPF is installed) |

(when the SPF/RSPF is installed) |

|||||

|

20 |

Right side cover |

21 |

Exit area |

22 |

Toner cartridge lock release lever |

||

|

(when the SPF/RSPF is installed) |

(when the SPF/RSPF is installed) |

||||||

|

23 |

Toner cartridge |

24 |

Roller rotating knob |

25 |

Fusing unit release levers |

||

|

26 |

Photoconductive drum |

27 |

Fusing unit paper guide |

AR-5520 EXTERNAL VIEWS AND INTERNAL STRUCTURES 5-1

3. Operation Section

|

The indications of the operation panel may differ |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|||||||||||||||||

|

depending on the country and the region. |

||||||||||||||||||||||||||||

The example of a display of inch series.

|

13 |

14 |

15 |

26 |

27 |

||||||||||||||||||||||||||

|

1 |

SCAN MENU key |

2 |

SCAN key / indicator |

3 |

ON LINE key/indicator |

|||||||||||||||||||||||||

|

(Except AR-5516S/AR-5520S) |

(Except AR-5516S/AR-5520S) |

|||||||||||||||||||||||||||||

|

4 |

ORIGINAL TO COPY key/indicators |

5 |

XY-ZOOM key / indicator |

6 |

DUAL PAGE COPY key / indicator |

|||||||||||||||||||||||||

|

(Except AR-5516/AR-5520/AR-5516S/ |

||||||||||||||||||||||||||||||

|

AR-5520S) |

||||||||||||||||||||||||||||||

|

7 |

ERASE key / indicators |

8 |

ORIGINAL DATA indicator |

9 |

SORT/GROUP key / indicators |

|||||||||||||||||||||||||

|

(Except AR-5516S/AR-5520S) |

(Except AR-5516S/AR-5520S) |

|||||||||||||||||||||||||||||

|

10 |

2 IN 1 / 4 IN 1 key / indicators |

11 |

MARGIN SHIFT key / indicator |

|||||||||||||||||||||||||||

|

(Except AR-5516S/AR-5520S) |

(Except AR-5516S/AR-5520S) |

|||||||||||||||||||||||||||||

|

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

||||||||||||||||||||||

|

21 |

22 |

24 |

25 |

26 |

27 |

28 |

29 30 31 |

32 |

33 |

34 |

35 |

|||||||||||||||

|

23 When there are two or more paper trays |

||||||||||||||||||||||||||

|

12 |

AUTO/TEXT/PHOTO key / indicators |

13 |

ORIGINAL key / ORIGINAL SIZE |

14 |

PAPER SIZE indicators |

|||||||||||||||||||||

|

indicators |

||||||||||||||||||||||||||

|

15 |

Paper feed location / misfeed location |

16 |

Alarm indicators |

17 |

Display |

|||||||||||||||||||||

|

indicators |

||||||||||||||||||||||||||

|

18 |

Numeric keys |

19 |

CLEAR key |

20 |

INTERRUPT key / indicator |

|||||||||||||||||||||

|

21 |

Light and Dark keys / indicators |

22 |

PAPER SELECT key |

23 |

AUTO PAPER SELECT indicator |

|||||||||||||||||||||

|

24 |

TRAY SETTING key |

25 |

AUTO IMAGE key / indicator |

26 |

SPF/RSPF indicator |

|||||||||||||||||||||

|

(when the SPF/RSPF is installed) |

||||||||||||||||||||||||||

|

27 |

PRESET RATIO selector keys / |

28 |

Zoom keys |

29 |

Copy ratio display key |

|||||||||||||||||||||

|

indicators |

||||||||||||||||||||||||||

|

30 |

ZOOM indicator |

31 |

Audit clear key |

32 |

READ-END key |

|||||||||||||||||||||

|

33 |

CLEAR ALL key |

34 |

POWER SAVE indicator |

35 |

START key / indicator |

AR-5520 EXTERNAL VIEWS AND INTERNAL STRUCTURES 5-2

4. Motor, solenoid, clutch

|

1 |

||

|

2 |

||

|

18 |

||

|

3 |

||

|

4 |

||

|

5 |

||

|

17 |

6 |

|

|

7 |

||

|

8 |

||

|

9 |

||

|

10 |

||

|

11 |

||

|

12 |

||

|

13 |

||

|

14 |

||

|

16 15 |

|

No. |

Name |

Code |

Function operation |

|

1 |

Mirror motor |

MRM |

Drives the optical mirror base (scanner unit). |

|

2 |

Toner motor |

TM |

Toner supply |

|

3 |

Duplex motor |

DPX |

Switchback operation and paper exit motor in duplex. |

|

4 |

Cooling fan motor |

CFM |

Cools the inside of the machine. |

|

5 |

Main motor |

MM |

Drives the machine. |

|

6 |

1st tray paper feed clutch |

CPFC1 |

Drive the pick up roller |

|

7 |

PS clutch |

RRC |

Drives the resist roller |

|

8 |

Paper feed solenoid |

CPSOL1 |

Solenoid for paper feed from tray |

|

9 |

Resist roller solenoid |

RRS |

Resist roller rotation control solenoid |

|

10 |

Bypass tray paper transport clutch |

MPTC |

Drives the bypass tray paper transport roller. |

|

11 |

Bypass tray paper feed clutch |

MPFC |

Drives the bypass tray paper feed roller. |

|

12 |

Bypass tray paper feed solenoid |

MPFS |

Bypass tray paper feed solenoid |

|

13 |

2nd tray transport clutch |

CPFC2 |

Drives the 2nd tray transport roller. |

|

14 |

2nd tray transport solenoid |

FSOL1 |

2nd tray transport solenoid |

|

15 |

2nd tray paper feed clutch |

CPFC1 |

Drives the 2nd tray paper feed roller. |

|

16 |

2nd tray paper feed solenoid |

PSOL2 |

2nd tray transport solenoid |

|

17 |

Exhaust fan motor |

VFM |

Cools the inside of the machine. |

|

18 |

Cooling fan motor |

CFM |

Cools the inside of the machine. |

AR-5520 EXTERNAL VIEWS AND INTERNAL STRUCTURES 5-3

5. Sensor, switch

|

1 |

|

|

2 |

|

|

3 |

|

|

16 |

4 |

|

15 |

5 |

|

6 |

|

|

7 |

14

|

13 |

8 |

||||

|

9 |

|||||

|

12 |

11 |

10 |

|||

|

No. |

Name |

Code |

Function operation |

||

|

1 |

Mirror home position sensor |

MHPS |

Detects the mirror (scanner unit) home position. |

||

|

2 |

Side door switch |

DSWR |

Side door open detection |

||

|

3 |

Paper exit sensor (paper exit side) |

POD1 |

Detects paper exit. |

||

|

4 |

Paper exit sensor (DUP side) |

PDPX |

Paper transport detection |

||

|

5 |

Thermistor |

RTH |

Fusing section temperature detection |

||

|

6 |

Thermostat |

Fusing section abnormally high temperature detection |

|||

|

7 |

Toner density sensor |

TCS |

Toner quantity detection |

||

|

8 |

2nd tray detection switch |

2nd tray detection |

|||

|

9 |

Bypass tray sensor |

MPED |

Bypass tray transport detection |

||

|

10 |

2nd tray door open/close sensor |

DRS2 |

2nd tray door open/close detection |

||

|

11 |

2nd tray door paper pass sensor |

PPD2 |

2nd tray paper entry detection |

||

|

12 |

2nd tray paper empty sensor |

CSS2 |

2nd tray paper empty detection |

||

|

13 |

Paper in sensor |

PIN |

Paper transport detection |

||

|

14 |

Tray empty |

Tray paper entry detection |

|||

|

15 |

Front cover SW |

Front cover open detection |

|||

|

16 |

Power switch |

MAIN SW |

Turns ON/OFF the main power source. |

AR-5520 EXTERNAL VIEWS AND INTERNAL STRUCTURES 5-4

6. PWB unit

2

3

7

6

5

|

No. |

Name |

Function operation |

|

1 |

Copy lamp Inverter PWB |

Copy lamp control |

|

2 |

CCD sensor PWB |

Image scanning |

|

3 |

Main control PWB |

Main control PWB |

|

4 |

2nd tray PWB |

2nd tray control |

|

5 |

High voltage PWB |

High voltage control |

|

6 |

Power PWB |

AC power input/DC power control |

|

7 |

Operation main PWB |

Operation panel input/Display, operation panel section control |

|

8 |

USB I/F PWB |

Connect a USB device |

AR-5520 EXTERNAL VIEWS AND INTERNAL STRUCTURES 5-5

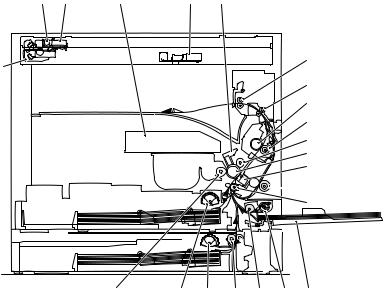

7. Cross sectional view

|

1 |

2 |

3 |

4 |

5 |

6

18

7 8

9

10

11

12

|

23 |

22 |

21 |

20 |

19 |

17 |

16 |

|

|

No. |

Name |

Function/Operation |

|||||

|

1 |

Copy lamp |

Image radiation lamp |

|||||

|

2 |

Copy lamp unit |

Operates in synchronization with No. 2/3 mirror unit to radiate documents |

|||||

|

sequentially. |

|||||||

|

3 |

LSU unit |

Converts image signals into laser beams to write on the drum. |

|||||

|

4 |

Lens unit |

Reads images with the lens and the CCD. |

|||||

|

5 |

MC holder unit |

Supplies negative charges evenly on the drum. |

|||||

|

6 |

Paper exit roller |

Used to discharge paper. |

|||||

|

7 |

Transport roller |

Used to transport paper. |

|||||

|

8 |

Upper heat roller |

Fuses toner on paper (with the teflon roller). |

|||||

|

9 |

Lower heat roller |

Fuses toner on paper (with the silicon rubber roller). |

|||||

|

10 |

Waste toner transport roller |

Transports waste toner to the waste toner box. |

|||||

|

11 |

Drum unit |

Forms images. |

|||||

|

12 |

Transfer charger unit |

Transfer images (on the drum) onto paper. |

|||||

|

13 |

DUP follower roller |

||||||

|

14 |

Duplex transport roller |

Transports paper for duplex . |

|||||

|

15 |

Resist roller |

Takes synchronization between the paper lead edge and the image lead edge. |

|||||

|

16 |

Bypass tray |

Bypass tray |

|||||

|

17 |

Bypass tray paper pick up roller |

Picks up paper in bypass tray. |

|||||

|

18 |

No. 2/3 mirror unit |

Reflects the images from the copy lamp unit to the lens unit. |

|||||

|

19 |

Bypass tray transport roller |

Transports paper from the bypass tray. |

|||||

|

20 |

2nd tray paper transport roller |

Transports paper from the 2nd tray. |

|||||

|

21 |

2nd tray paper pick up roller |

Picks up paper from the 2nd tray. |

|||||

|

(semi-circular roller) |

|||||||

|

22 |

1st tray paper feed roller |

Picks up paper from the 1st tray. |

|||||

|

(semi-circular roller) |

|||||||

|

23 |

MG roller |

Puts toner on the OPC drum. |

AR-5520 EXTERNAL VIEWS AND INTERNAL STRUCTURES 5-6

[6]ADJUSTMENTS

1.Adjustment item list

|

Section |

Adjustment item |

Adjustment procedure/SIM No. |

||

|

A |

Process |

(1) |

Developing doctor gap adjustment |

Developing doctor gap adjustment |

|

section |

||||

|

(2) |

MG roller main pole position adjustment |

MG roller main pole position adjustment |

||

|

(3) |

Developing bias voltage check |

|||

|

(4) |

Main charger voltage check |

|||

|

B |

Mechanism |

(1) |

Image position adjustment |

SIM-50 |

|

section |

||||

|

(2) |

Main scanning direction (FR direction) distortion balance |

No. 2/3 mirror base unit installing position adjustment |

||

|

adjustment |

||||

|

Copy lamp unit installing position adjustment |

||||

|

(3) |

Main scanning direction (FR direction) distortion adjustment |

Rail height adjustment |

||

|

(4) |

Sub scanning direction (scanning direction) distortion |

Winding pulley position adjustment |

||

|

adjustment |

||||

|

(5) |

Main scanning direction (FR direction) magnification ratio |

SIM 48-1 |

||

|

adjustment |

||||

|

(6) |

Sub scanning direction (scanning direction) magnification ratio |

OC mode in copying (SIM 48-1) |

||

|

adjustment |

||||

|

SPF mode in copying (SIM 48-5) |

||||

|

(7) |

Off center adjustment |

OC mode (SIM 50-12) |

||

|

SPF mode (SIM 50-12) |

||||

|

(8) |

SPF white correction pixel position adjustment |

SIM63-7 |

||

|

(required in an SPF model when replacing the lens unit) |

||||

|

C |

Image density |

(1) |

Copy mode |

SIM 46-1 |

|

adjustment |

||||

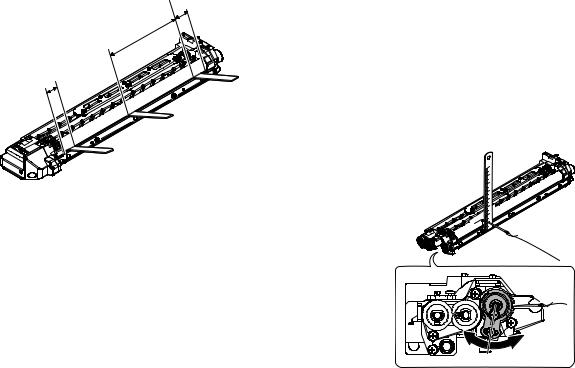

2.Copier adjustment

A.Process section

(1) Developing doctor gap adjustment

1)Loosen the developing doctor fixing screw A.

2)Insert a thickness gauge of 1.5mm to the three positions at 20mm and 150mm from the both ends of the developing doctor as shown.

OO

OO

OO

3)Push the developing doctor in the arrow direction, and tighten the developing doctor fixing screw. (Perform the same procedure for the front and the rear frames.)

4)Check the clearance of the developing doctor. If it is within the specified range, then fix the doctor fixing screw with screw lock.

*When inserting a thickness gauge, be careful not to scratch the developing doctor and the MG roller.

<Adjustment specification>

Developing doctor gap

Both ends (20mm from the both ends) : 1.5 +0.1— 0.15 mm

C (Center) (150mm from the both ends) :1.55 +0.15— 0.2 mm

(2) MG roller main pole position adjustment

1)Remove and separate the waste toner box and put the developing unit on a flat surface.

2)Tie a string to a needle or a pin.

3)Hold the string and bring the needle close to the MG roller horizontally. (Do not use paper clip, which is too heavy to make a correct adjustment.) (Put the developing unit horizontally for this adjustment.)

4)Do not bring the needle into contact with the MG roller, but bring it to a position 2 or 3mm apart from the MG roller. Mark the point on the MG roller which is on the extension line from the needle tip.

5)Measure the distance from the marking position to the top of the doctor plate of the developing unit to insure that it is 18mm.

If the distance is not within the specified range, loosen the fixing screw A of the main pole adjustment plate, and move the adjustment plate in the arrow direction to adjust.

AR-5520 ADJUSTMENT 6-1

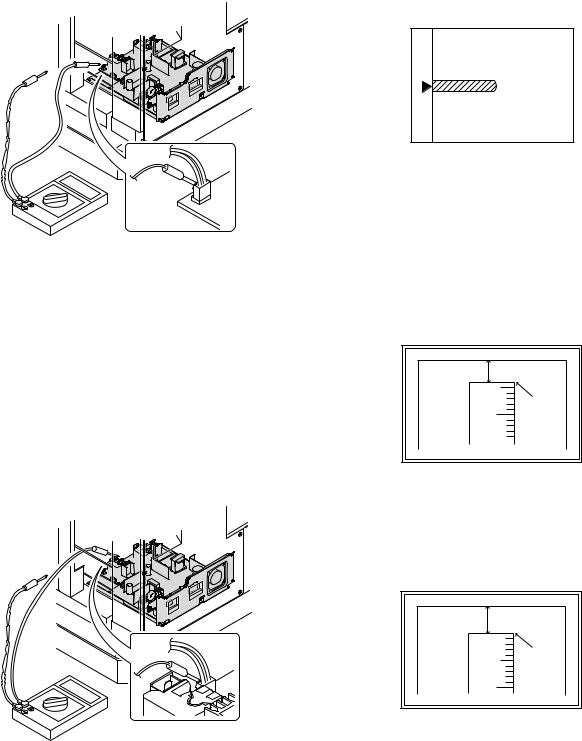

(3)Developing bias voltage check

Note:Use a digital multi-meter with an internal resistance of 10MΩ or more.

1)Set the digital multi-meter range to DC700V.

2)Put the test rod of the digital multi-meter on the developing bias voltage output check pin.

3)Turn on the power, execute SIM25-1.

<Specification>

|

Mode |

Specification |

|

Developing bias voltage |

DC — 400±10V |

(4) Grid bias voltage check

Note:Use a digital multi-meter with an internal resistance of 10MΩ or more.

1)Set the digital multi-meter range to DC700V.

2)Put the test rod of the digital multi-meter on the grid bias voltage output check pin.

3)Turn on the power.

(The voltage is outputted in the grid bias High output mode during warming up, and in the grid bias Low output mode when warming up is completed.)

B.Mechanism section

Note: If a jam error or paper empty occurs during copying in the adjustment by the simulation, the image data are not saved, and therefore recopying is required.

(1) Image position adjustment

a.OC image lead edge position adjustment (SIM 50-1)

Note:In advance to this adjustment, the sub scanning magnification ratio adjustment must be performed.

1) Set a scale on the OC table as shown below.

2)Make a copy.

3)Check the copy output. If necessary, perform the following adjustment procedures.

4)Execute SIM 50-1.

5)Set the OC lead edge position set value (PHOTO indicator ON) to [1] The OC image scanning start position is shifted inside the document edge.

6)Set the 1st tray lead edge void adjustment value (TEXT indicator ON) * to [1]

The lead edge void becomes the minimum.

7)Set the 1st tray print start position value (AUTO, 1st tray indicator ON) to [1] and make a copy.

The print start position is shifted inside the document edge.

*The dimension varies depending on the model.

•1 step of the set value corresponds to about 0.1mm shift. •Calculate the set value from the formula below. R/0.1(mm) = Image loss set value

<R: Image loss measurement value (mm)>

*The scanning edge is set.

(A line may be printed by scanning the document edge.)

<Specification>

|

Mode |

Specification |

|

Grid bias LOW |

DC — 380±8V |

|

Grid bias HIGH |

DC — 525±10V |

Example: 4/0.1 = 40 = about 40

Note:If the set value is not obtained from the above formula, perform the fine adjustment.

AR-5520 ADJUSTMENT 6-2

9)Measure the distance H between the paper lead edge and the image print start position. Set the image print start position set value

(AUTO, 1st tray indicator ON) again.

•1 step of the set value corresponds to about 0.1mm shift. •Calculate the set value from the formula below. H/0.1(mm) = Image print start position set value

<H: Print start position measurement value (mm)>

*Fit the print edge with the paper edge, and perform the lead edge adjustment.

Example: 5/0.1 = 50 = about 50

Note:If the set value is not obtained from the above formula, perform the fine adjustment.

10) Set the lead edge void adjustment value (TEXT indicator ON)* again. •1 step of the set value corresponds to about 0.1mm shift.

•Calculate the set value from the formula below. B/0.05 (mm) = Lead edge void adjustment value <B: Lead edge void (mm)>

Example: When setting the lead edge void to 2.5mm :2.5 /0.05 = about 50

Note:If the set value is not obtained from the above formula, perform the fine adjustment.

*2nd tray lead edge void adjustment: Exposure display <<AUTO + TEXT + PHOTO>>

Bypass tray lead edge void adjustment: (TEXT indicator and PHOTO indicator ON)

<Duplex mode adjustment>

OC 2nd print surface (Auto duplex) lead edge position adjustment: SIM50-19 <<PHOTO>>

*For the adjustment procedure, set to S → D mode before execution.

Note:Before performing the 2nd print surface lead edge position adjustment and the lead edge void adjustment, be sure to perform the 1st print surface lead edge position adjustment in advance, and be sure to perform the 2nd print surface lead edge position adjustment and then the lead edge void adjustment in this sequence.

<Adjustment specification>

|

Adjustment |

SIM |

LED |

Set |

Spec |

Set |

|

mode |

value |

value |

range |

||

|

OC image lead |

SIM |

PHOTO |

R/0.1 |

Lead edge |

1 ~ 99 |

|

edge position |

50-1 |

||||

|

void: |

|||||

|

1st tray print |

AUTO |

B/0.1 |

|||

|

start position |

+ |

1 — 4mm |

|||

|

1st tray |

Image loss: |

||||

|

2nd tray print |

AUTO |

||||

|

3mm or |

|||||

|

start position |

+ |

||||

|

less |

|||||

|

2nd tray |

|||||

|

Bypass tray |

AUTO |

||||

|

print start |

+ |

||||

|

position |

Bypass |

||||

|

tray |

|||||

|

Lead edge void |

TEXT |

B/0.05 |

|||

|

OC 2nd print |

SIM |

PHOTO |

1 step: |

||

|

surface lead |

50-19* |

0.1mm shift |

|||

|

edge position |

|||||

|

adjustment |

|||||

*(Set to S → D mode for before execution)

b.SPF image lead edge position adjustment (SIM50-6)

1) Set a scale on the OC table as shown below.

Note: Since the printed copy is used as a test chart, put the scale in paralled with the edge lines.

2)Make a copy, Then use the copy output as an original to make an SPF copy again.

3)Check the copy output. If necessary, perform the following adjustment procedures.

4)Execute SIM 50-6.

5)Set the SPF lead edge position set value (AUTO indicator ON) so that the same image is obtained as that obtained in the previous OC image lead edge position adjustment.

<Adjustment specification>

|

Adjustment mode |

SIM |

LED |

Set value |

Spec value |

Set |

|

range |

|||||

|

SPF image lead |

SIM |

AUTO |

1 step: |

Lead edge |

1 ~ 99 |

|

edge position |

50-6 |

0.1mm shift |

void: |

||

|

(1st print surface) |

1 — 4mm |

||||

|

(2nd print surface) |

TEXT |

Image loss: |

|||

|

3mm or |

|||||

|

less |

|||||

AR-5520 ADJUSTMENT 6-3

c.Rear edge void adjustment (SIM50-1, SIM50-19)

1) Set a scale as shown in the figure below.

A4(8.5″ x 11″)

Paper rear edge

2)Set the document size to A4 (8.5″ x 11″), and make a copy at 100%.

3)If necessary, perform the following adjustment procedure.

Void amount (Standard value: 4mm or less)

Scale image

Paper rear edge

4)Execute SIM 50-1 and set the density mode to AUTO + TEXT + PHOTO (Rear edge void).The currently set adjustment value is displayed.

5)Enter the set value and press the [START] key. The correction value

is stored and a copy is made.

<Duplex mode adjustment>

*1st print surface (auto duplex) rear edge void adjustment: SIM50-19 <<AUTO>>

*2nd print surface (auto duplex) rear edge void adjustment: SIM50-19<<TEXT>>

*Set to S → D mode before execution.

Note:Before performing the 2nd print surface rear edge void adjustment, be sure to perform the 2nd print surface lead edge position adjustment. Never reverse the sequence.

<Adjustment specification>

|

Mode |

SIM |

LED |

Set value |

Specifi- |

Set |

|

cation |

range |

||||

|

Rear edge void |

SIM |

AUTO |

1 step: |

4mm or |

1 ~ 99 |

|

50-1 |

+ |

0.1mm shift |

less |

||

|

TEXT |

|||||

|

+ |

|||||

|

PHOTO |

|||||

|

1st print |

SIM |

AUTO |

|||

|

surface rear |

50-19* |

||||

|

edge void |

|||||

|

2nd print |

SIM |

TEXT |

|||

|

surface rear |

50-19* |

||||

|

edge void |

|||||

*Set to S → D mode before execution

d. Paper off center adjustment (SIM50-10)

1)Set a test chart (UKOG-0089CSZZ) on the document table.

2)Select a paper feed port and make a copy. Compare the copy and the test chart. If necessary, perform the following adjustment procedure.

3)Execute SIM 50-10. After completion of warm-up, shading is performed and the currently set off center adjustment value of each paper feed port is displayed.

4)Enter the set value and press the [START] key. The correction value is stored and a copy is made.

<Duplex mode adjustment>

*2nd print surface (auto duplex) off-center adjustment: SIM50-10 (TEXT, 1st tray indicator)

<Adjustment specification>

|

Mode |

SIM |

LED |

Set value |

Specifi- |

Set |

|

cation |

range |

||||

|

Paper off |

SIM |

AUTO |

Add 1: |

Single: |

1 ~ 99 |

|

center |

50-10 |

+ |

0.1mm shift |

Center |

|

|

Selected |

to R side. |

±2.0mm |

|||

|

tray ON |

|||||

|

Reduce 1: |

|||||

|

2nd print |

SIM |

TEXT |

Duplex: |

||

|

surface off- |

50-10 |

+ |

0.1mm shift |

Center |

|

|

center |

1st tray |

to L side. |

±2.5mm |

||

e.Side edge void area adjustment (SIM26-43)

Note:Before performing this adjustment, be sure to check that the paper off center adjustment (SIM 50-10) is completed.

1)Set a test chart (UKOG-0089CSZZ) on the document table.

2)Select a paper feed port and make two copies. Compare the 2nd copy and the test chart. If necessary, perform the following

adjustment procedure.

*The 1st copy does not show the void. Be sure to check the 2nd copy.

3)Execute SIM 26-43 and set the density mode to AUTO(right edge void) + TEXT (Left edge void).

The currently set adjustment value is displayed.

4)Enter the set value and press the [START] key. The correction value is stored.

<Adjustment specification>

|

ode |

SIM |

LED |

Set value |

Specifi- |

Set |

|

cation |

range |

||||

|

Left edge void |

SIM |

AUTO |

1 step: |

0 ~ 10mm |

1 ~ 99 |

|

26-43 |

(right |

0.5mm shift |

|||

|

edge) |

|||||

|

+ |

|||||

|

TEXT |

|||||

|

(left edge) |

|||||

*The void adjustment values on the right and the left must be the same.

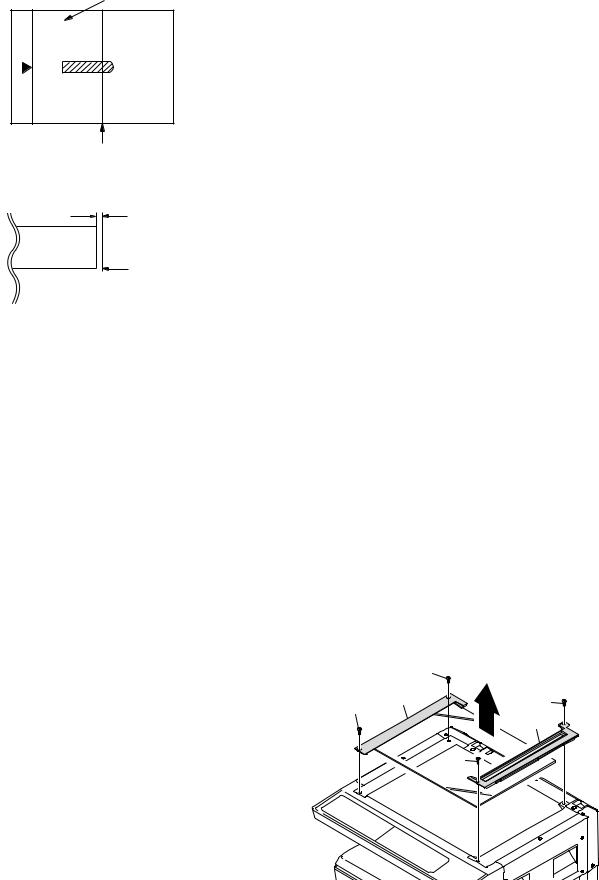

(2)Main scanning direction(FR direction) distortion balance adjustment

1) Remove the OC glass and the right cabinet.

AR-5520 ADJUSTMENT 6-4

2) Loosen the copy lamp unit wire fixing screw.

4)Loosen the set screw of the scanner drive pulley which is not in contact with No. 2/3 mirror base unit positioning plate.

5)Without moving the scanner drive pulley shaft, manually turn the scanner drive pulley until the positioning plate is brought into contact with No. 2/3 mirror base unit, then fix the scanner drive pulley.

Wire fixing screw

3)Manually turn the mirror base drive pulley and bring No. 2/3 mirror base unit into contact with the positioning plate. At that time, if the front frame side and the rear frame side of No. 2/3 mirror base unit are brought into contact with the positioning plate at the same time, the mirror base unit parallelism is proper. If one of them is in contact with the positioning plate, perform the adjustment of 4).

6)Put No. 2/3 mirror base unit on the positioning plate again, push the projections on the front frame side and the rear frame side of the copy lamp unit to the corner frame, and tighten the wire fixing screw.

AR-5520 ADJUSTMENT 6-5

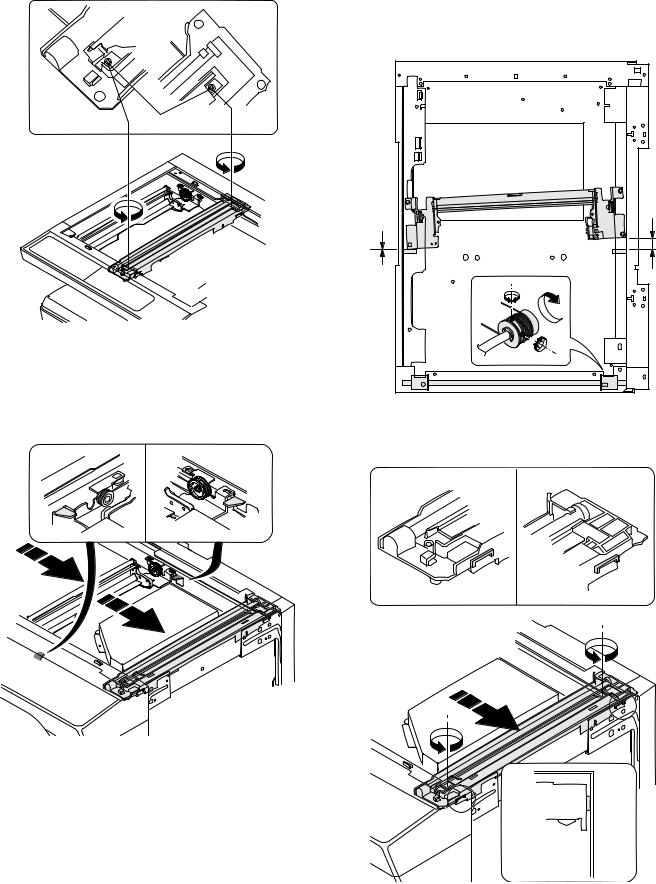

(3)Main scanning direction (FR direction) distortion adjustment

This adjustment must be performed in the following cases:

•When the mirror base drive wire is replaced.

•When the lamp unit, or No. 2/3 mirror holder is replaced.

•When a copy as shown is made.

Paper exit direction

1) Set A3 (11″ x 17″) white paper on the original table as shown below.

Allow a little space.

|

Glass holding plate |

A3 (11″ x 17″) white paper |

Fit the paper edge and

the glass holding plate edge.

2)Open the original cover and make a normal (100%) copy.

3)Measure the width of the black background at the lead edge and at the rear edge.

Paper exit direction

La: Lead edge black background width

Lb: Rear edge black background width

If the width (La) of the black background at the lead edge is equal that (Lb) at the rear edge, there is no need to execute the following procedures of 4) ~ 7).

4)Loosen the mirror base drive pulley fixing screw on the front frame side or on the rear frame side.

Turn the mirror base drive pulley on the front frame side in the arrow direction A.

(Do not move the mirror base drive pulley shaft.)

Turn the mirror base drive pulley on the front frame side in the arrow direction A.

(Do not move the mirror base drive pulley shaft.)

Rear side

A

B

Front side

5)Tighten the mirror base drive pulley fixing screw.

<Adjustment specification>

La = Lb

6)Execute the main scanning direction (FR) distartion balance adjustment previously described in 2) again.

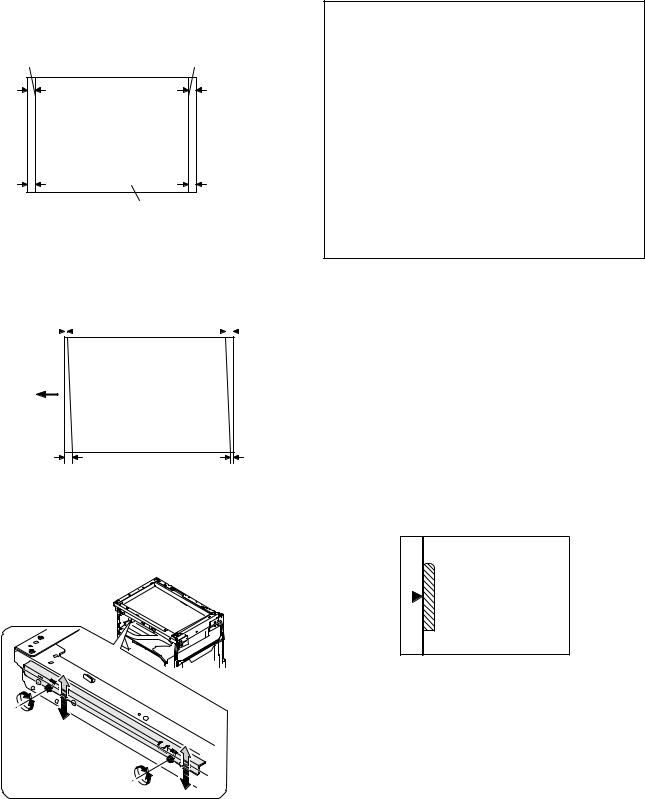

(4)Sub scanning direction (scanning direction) distortion adjustment

When there is no skew copy in the mirror base scanning direction and there is no horizontal error (right angle to the scanning direction), the adjustment can be made by adjusting the No. 2/3 mirror base unit rail height.

Before performing this adjustment, be sure to perform the horizontal image distortion adjustment in the laser scanner section.

This adjustment must be performed in the following cases:

•When the mirror base wire is replaced.

•When the copy lamp unit or No. 2/3 mirror unit is replaced.

•When the mirror unit rail is replaced or moved.

•When a following copy is made.

AR-5520 ADJUSTMENT 6-6

1)Making of a test sheet

Make test sheet by drawing parallel lines at 10mm from the both ends of A3 (11″ x 17″) white paper as shown below. (These lines must be correctly parallel to each other.)

|

Parallel line |

Parallel line |

|

10mm |

10mm |

White paper

2)Make a normal (100%) copy of the test sheet on A3 (11″ x 17″) paper. (Fit the paper edge with the glass holding plate edge.)

3)Measure the distances (La, Lb, Lc, Ld) at the four corners as shown below.

|

La |

Lc |

|||||

Paper exit direction

When La = Lb and Lc = Ld, no need to perform the procedures 4) and 5).

4)Move the mirror base F rail position up and down (in the arrow direction) to adjust.

Note:Do not adjust the rail on the rear side.

If the rail on the rear side is adjusted, a trouble may be caused. Only the rail on the front side can be adjusted.

Shift the mirror base B rail upward by the half of the difference of La — Lb.

Shift the mirror base B rail downward by the half of the difference of Lb — La.

Example: When La = 12mm and Lb = 9mm, shift the mirror base B rail upward by 1.5mm.

Shift the mirror base B rail downward by the half of the difference of Lc — Ld.

Shift the mirror base B rail downward by the half of the difference of Ld — Lc.

<Adjustment specification>

La = Lb, Lc = Ld

5)After completion of adjustment, manually turn the mirror base drive pulley, scan the mirror base A and mirror base B fully, and check that

the mirror bases are not in contact with each other.

*If the mirror base rail is moved extremely, the mirror base may be in contact with the frame or the original glass. Be careful to avoid this.

(5)Main scanning direction (FR direction) magnification ratio adjustment (SIM 48-1)

Note: Before performing this adjustment, be sure to check that the CCD unit is properly installed.

1) Put a scale on the original table as shown below.

2)Execute SIM 48-1.

3)After warm-up, shading is performed and the current set value of the main scanning direction magnification ratio is displayed on the display section in 2 digits.

4)Select the mode and press the [START] key again.

5)Manual correction mode (TEXT indicator ON) Enter the set value and press the [START] key. The set value is stored and a copy is made.

AR-5520 ADJUSTMENT 6-7

<Adjustment specification>

Note: A judgment must be made with 200mm width, and must not be made with 100mm width.

|

Mode |

Specification |

SIM |

Set value |

Set range |

|

Main scanning |

At normal: |

SIM 48-1 |

Add 1:0.1% |

1 ~ 99 |

|

direction |

±1.0% |

increase |

||

|

magnification |

Reduce 1: |

|||

|

ratio |

0.1% |

|||

|

decrease |

||||

(6)Sub scanning direction (scanning direction) magnification ratio adjustment (SIM 48-1, SIM 48-5)

a. OC mode in copying (SIM48-1)

Note:Before performing this adjustment, be sure to check that the CCD unit is properly installed.

1)Put a scale on the original table as shown below, and make a normal (100%) copy.

2)Compare the scale image and the actual image. If necessary, perform the following adjustment procedures.

3)Execute SIM 48-1.<<PHOTO>>

4)After warm-up, shading is performed and the current set value of the main scanning direction magnification ratio is displayed on the display section in 2 digits.