-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

3.568.5275.300

Electropneumatic Smart Positioner

IM-P343-35 CH Issue 1

Printed in the UK

SP500

5. Installation

8. Programming

flow chart

9. Programming and

commissioning

11. Default values and

program settings

12. Glossary of

display data

IM-P343-35

CH Issue 1

© Copyright 2010

1

Related Manuals for Spirax Sarco SP500

Summary of Contents for Spirax Sarco SP500

-

Page 1

3.568.5275.300 IM-P343-35 CH Issue 1 SP500 Electropneumatic Smart Positioner Installation and Maintenance Instructions 1. Index 2. Safety information 3. Technical information 4. Options 5. Installation 6. Electrical connections 7. Quick start procedure 8. Programming flow chart 9. Programming and commissioning 10. Maintenance 11. Default values and program settings 12. Glossary of… -

Page 2: Table Of Contents

— setting of valve functions TUNE — setting of valve tune functions — automatic operation STRVL and RTIME — valve diagnostics RETRN — return to SP500 MENU in main menu 10. Maintenance and 10.1 Air supply quality troubleshooting 10.2 Fitting replacement filter plug kit 11.

-

Page 3: Safety Information

IP65 (see BS EN 60534-1 1998). 2.2 Electrical safety requirements The SP500 is a class III product which must only be powered from Safe Extra Low Voltage (SELV) sources whether by virtue of a 4 — 20 mA control signal or from a separate power supply.

-

Page 4: Technical Information

3. Technical information 3.1 Description The SP500 smart valve positioner is loop powered from a 4 — 20 mA input signal to provide accurate adaptive positional control of pneumatic actuated linear and quarter turn valves. Precise control is maintained through valve position feedback that automatically varies the pneumatic output pressure to overcome the effects of stem friction and flow forces to maintain desired valve position.

-

Page 5: Options

No. Features indicates all is OK ! Indicates a delay in positioning, this disappears when the position is reached Indicates that the value displayed is a percentage Indicates that the value displayed is the input current measured in mA Indicates that the value displayed is a time measured in seconds Indicates that you’re accessing the main programming menus…

-

Page 6

3.3 Materials Part Material Finish Case and cover Die cast aluminium Anti-corrosive paint to RAL5010 Magnet bracket Die cast aluminium 3.4 Programmable functions Autostroke Automatic commissioning routine Valve type 2-port or 3-port Selectable 0 to 100% or 100% to 0% % travel depending on valve / actuator configuration Control action… -

Page 7

4. Options 4.1 Pressure gauge block An optional pressure gauge block (Figure 3) can be fitted onto the SP500 positioner which includes two pressure gauges indicating air supply pressure and output air signal pressure to the actuator. The pressure gauge block can be retrospectively fitted using 2 off M5 socket head screws. -

Page 8: Electrical Connections

4.2 Retransmission and travel switches option board An option board can be fitted in the positioner to add valve position retransmission functionality and software travel switches functionality. The board generates a 4-20 mA current signal which represents the actual valve position. Moreover 2 output terminals are available to be configured as software travel switches.

-

Page 9

Rotate the mainboard and insert the option board (as shown in Figures 6, 7, 8 and 9). Rotate the mainboard to the initial position, fix it with the 4 screws, close the positioner and switch on the power supply and air supply. Fig. -

Page 10

4.3 External power supply option board The SP500 can host an option board for 24 V power supply. It’s a 4 wiring diagram: 2 wires for current loop and 2 wires for power supply through a 24 V external voltage. This reduces dramatically the voltage drop on the current loop. The drop is 7 V when the unit is powered by the loop (2 wires), it falls to 1 V when the 4 wires configuration is used. -

Page 11

Rotate the mainboard and insert the option board (as shown in Figures 12 and 13). Fig. 12 Fig. 13 Remove the Jumper J4 (Figure 14). Fig. 14 IM-P343-35 CH Issue 1… -

Page 12

Fig. 15 Insert the power supply option board. Collocate Jumper J4 as shown in Figures 15 and 16. Fig. 16 Rotate the mainboard to the initial position, fix it with the 4 screws, close the positioner and switch on the power supply and air supply. Once the option board is mounted, the positioner shall be powered according to the 4 wires connection diagram, refer to Section 6.2.3, ‘4 wires electrical connection’. -

Page 13: Maintenance

VDI / VDE 3845 compliant mounting kit for rotary actuators. 5.1.2 The SP500 has an enclosure rating of IP65 and should be installed in a location that will not exceed its ambient temperature limits of -10°C minimum and +80°C maximum.

-

Page 14

5.2 Sequence for mounting an SP500 positioner to a linear actuator Fig. 17 Pillar mounting kit for a linear actuator 5.2.1 Loosely attach the magnet bracket (2) to the valve / actuator connector (refer to Figures 17 and 18). Be sure it is positioned horizontally (as shown in Figure 18). -

Page 15

PN1000 Fig. 20 Bracket markings 5.2.3 If you’re not using a Spirax Sarco actuator, slide the bracket till the distance ‘A’ between the center of the magnet and the inner side of the mounting plate is 25 mm (Figure 21). -

Page 16

Fig. 22 Pillar actuator assembly Mounting plate Assembled Yoke actuator Fig.23 Yoke actuator assembly 5.2.5 Locate the protection plate onto the back of the SP500 positioner housing and fix in place (Figures 24 and 25). Protection plate Assembled Fig. 24 Fig. -

Page 17

5.2.6 5.2.7 Attach the positioner mounting plate to the Adjust the vertical position of the SP500 positioner as shown in Figures 26 and 27. positioner and mounting plate assembly, by sliding it up or down on the pillar style actuators,… -

Page 18

5.3 Sequence for mounting an SP500 positioner to a rotary actuator 5.3.1 Assembly for fitting an SP500 on to a ¼ turn valve. Fig. 30 Mounting kit IM-P343-35 CH Issue 1… -

Page 19

Fig. 32 Fig. 31 Fig. 33 IM-P343-35 CH Issue 1… -

Page 20

Fig. 34 Assembled Fig. 35 IM-P343-35 CH Issue 1… -

Page 21

5.3.2 Adjust the magnet orientation as illustrated in Figures 36 and 37 and tighten the bolt to fix the magnet into position. There should be a distance of between 5 and 14 mm between the magnet and the positioner. Refer to Figure 36 for actuator with clockwise rotation. Refer to Figure 37 for actuator with anti-clockwise rotation. -

Page 22

/ regulator is fitted in the mains air supply to the positioner. The filter / regulator should have a coalescing filter such as a Spirax Sarco type MPC2, or suitable compressed air pipework is used. -

Page 23

Systems: Installation design and practice or local equivalent. 6.2 Wiring diagrams 6.2.1 Terminal block MENU MANUAL AUTOS AUTOMATIC TUNE SP500 Fig. 39 Pole Description 24 V power supply option board 24 V external power supply (PWS) 4-20 mA current signal input… -

Page 24

6.2.2 Single loop applications The SP500 is loop powered using the 4 — 20 mA input signal source providing a minimum signal of 3.6 mA can be maintained. Minimum current 3.6 mA Maximum current 30 mA Maximum voltage drop < 7 V… -

Page 25

6.2.4 Travel switches- and 4-20 mA retransmission wiring digrams 2 k 22 k Travel switches 1 2 k 22 k Travel switches 2 Fig. 43 Software switches Example of customers external application wiring. 4 — 20 mA retransmit Fig. 44 4 — 20 mA retransmit Table 1 Ratings Supply… -

Page 26: Quick Start Procedure

Provide a minimum input signal of 3.6 mA to the positioner. SET-UP NOW should be displayed. 7.1.3 Ensure that upstream isolation valves are closed. key for 3 seconds to advance to SP500 MENU. Press and hold The display will count down the 3 seconds. 7.1.4 Press to advance to MANOP.

-

Page 27

7.2 3-port valves (with travel setting (TRAVL) 0 — 100%, refer to Figures 27 and 28) Proceed as above up to Section 7.1.9. 7.2.1 key once to advance to SET On completion of a successful autostroke press the in main menu. 7.2.2 key once to advance to VALVE TYPE. -

Page 28: Programming Flow Chart

Mounting position check Software SP500 (CALIB) version MENU (Ver X.XX) Manual operation From RETRN C-CAL (MCTL) (To SP500 MENU) MANOP % Travel (TRAVL Autostroke activate AUTOS 0-100% / (AUTOS) 100-0%) Note: SET, TUNE, and RUN can Valve type Actuator type…

-

Page 29

3 seconds enter Enter Clear stored values (RESET) Auto return Recall stored values (RETRN) Retain temporary values (RTAIN) Minimum Maximum Displayed % Minimum Maximum travel travel travel range range (MIN-T) (MAX-T) (DTRVL)† (MIN-R) (MAX-R) † Only if MIN-T / MAX-T not 0 / 100% Control action (CTRLA) Characterisation… -

Page 30: Programming And Commissioning

The positioner fitted to this control valve requires programming. A minimum input signal of 3.6 mA is required to power the positioner. To program the positioner it is necessary to enter SP500 MENU and carry out an autostroke commissioning routine (AUTOS) prior to putting the control valve into automatic operation.

-

Page 31

9.2.1 VER -.— software version Programming notes To view the version of the embedded software (VER-.—) press key. key to return to SP500 MENU. The display will automatically return to Press SP500 MENU after 10 seconds. IM-P343-35 CH Issue 1… -

Page 32

9.2.2 CALIB — mounting position calibration Programming notes To access CALIB press and hold key for 3 seconds. The display will count down the 3 seconds. You are now in calibrate mode. The LCD shows in % the magnet position in respect to the sensor board of the positioner, without any offset or scale up or down. -

Page 33

Resetting to default values (refer to Section 9 for default values) should be used if it is intended to use the positioner on a different control valve. If the SP500 positioner has been moved on its mounting or is to be fitted on a different control valve it will be necessary to undertake a new autostroke (AUTOS). -

Page 34

9.3 MANOP 3 second enter Manual operation C-CAL MANOP (MCTL) Fig. 47 Programming notes Press and hold key for 3 seconds to enter manual control mode (MCTL). The display will count down the 3 seconds. Press the key to enter the current calibration mode (C-CAL). Press return to MANOP. -

Page 35

12 mA 100% 20 mA 20 mA In this way a perfect match is achieved between the setpoint of the PLC and the setpoint of the of the SP500 (i.e. the input current read by the SP500). IM-P343-35 CH Issue 1… -

Page 36

AUTOS — automatic autostroke commissioning % Travel 3 second (TRAVL Autostroke activate enter AUTOS 0-100% / (AUTOS) 100-0%) Fig. 48 Programming notes AUTOS provides access to: 1. Autostroke commissioning (AUTOS). 2. % travel display (TRAVL). AUTOS Autostroke provides an automatic commissioning routine which will take approximately 1 to 3 minutes to complete. -

Page 37

9.4.1 TRAVL — % travel display Programming notes Press key to access TRAVL. Provides selection of valve travel display with option of 0 — 100% or 100 — 0%. Default is 0 — 100%. keys to toggle selection. key to return to AUTOS. Press Commissioning notes The selection of… -

Page 38

Display = 0% Display = 100% Fig. 51 2-port valve normally open — TRAVL setting = 100% to 0% Display = 100% Display = 0% Fig. 52 2-port valve normally closed — TRAVL setting = 100% to 0% IM-P343-35 CH Issue 1… -

Page 39

100% 100% TRAVEL setting = 0 to 100% TRAVEL setting = 0 to 100% DISPLAY = 0% DISPLAY = 100% TRAVL setting = 100 to 0% TRAVL setting = 100 to 0% DISPLAY = 100% DISPLAY = 0% Fig. 53 3-port valve and spring extend actuator 100% 100% TRAVEL setting = 0 to 100%… -

Page 40

SET — setting of valve functions Valve type Actuator type (VALVE 2-PORT / (ACT) VALVE 3-PORT) Maximum range Control action (MAX-R) (CTRLA) Minimum travel Minimum range (MIN-R) (MIN-T) Displayed % Maximum travel travel (MAX-T) (DTRVL)† † Only if MIN-T / MAX-T not 0 / 100% Fig. -

Page 41

9.5.1 VALVE — valve type Programming notes Provides selection between 2-port and 3-port valves. Default is 2-port valve. Default values for travel limit settings (MIN-T and MAX-T) and early vent / inflate settings (S-MIN and S-MAX) will depend on the valve type (2-port or 3-port) and control action (direct or reverse) as follows: 2-port 3-port… -

Page 42

9.5.3 CTRLA — direct or reverse control action Programming notes Provides selection of direct (dIRCT) (4 — 20 mA) or reversed (REV) (20 — 4 mA) valve positioning control action. Press keys to select desired action. Default action is dIRCT. Default values for travel limit settings (MIN-T and MAX-T) and early shut-off vent / inflate settings (S-MIN and S-MAX) will depend on the valve type (2-port or 3-port) and control action (direct or reverse) as follows:… -

Page 43

Fig. 58 CTRL Control Action dIRCT or REV setting guidance Installed orientation At-rest position Control action 100% dIRCT 4 mA 20 mA 100% 100% 4 mA 20 mA 100% dIRCT 4 mA 20 mA 100% 100% (TRAVL) 0 — 100% 4 mA 20 mA 4 mA… -

Page 44

9.5.4 MIN-T — minimum travel setting Programming notes Enables the minimum valve travel to be set as a percentage of the maximum travel obtained during autostroke. Maximum setting is MAX-T less 33.3%. Default value is 0%. keys to alter the displayed value. Press key to accept the displayed value and advance to the maximum travel setting (MAX-T). -

Page 45

9.5.6 DTRVL — displayed travel percentage Programming notes The full mechanical limits of valve travel (0 to 100%) are measured during autostroke (AUTOS). It is possible to limit the minimum and maximum valve travel by programming MIN-T and MAX-T values, i.e. MAX-T maximum travel limit of 95% (Autostroke default value for 2-port valves). -

Page 46

9.5.7 MIN-R — minimum signal span range Programming notes Enables the minimum mA input signal span range to be set. The value set will correspond to the minimum travel setting. Default value is 4 mA. keys to alter the displayed value. Minimum difference between MIN-R and MAX-R is 4 mA. -

Page 47

9.6 TUNE — setting of valve tune functions Shut-off minimum Dead-band (S-MIN) (dBand) TUNE Travel switch 2 Shut-off maximum (TS2) (S-MAX) Normally closed Travel switch 1 Characterisation (TS1) (LIN / FAST / Normally open EQUAL) Time to close Time to open (T-dWN) (T-UP) Fig. -

Page 48

9.6.1 dbANd — deadband setting (positional sensitivity) Programming notes Dead-band provides adjustment of the valve positioning sensitivity relative to the input signal and is expressed as a % of the input signal span. Default value based on a 4 — 20 mA input signal span is 0.5% with a minimum setting of 0.2%. -

Page 49

9.6.3 S-MAX — valve shut-off maximum Programming notes Provides the facility to fully inflate the actuator at a pre-determined input signal. The value set is a percentage of the input signal span range, i.e. setting a value of 10% with an input span range of 4 — 20 mA (16 mA), will cause the valve to close with an input signal of 18.4 mA i.e. -

Page 50

9.6.5 T-UP — valve slow opening action Programming notes This function slows down the time taken for the valve to travel from 0 to 100% lift. The time displayed is the fastest travel time measured during autostroke (AUTOS). 4 seconds may be displayed if ACT is set to ‘ON’ (refer to Section 9.5.2, page 41). -

Page 51

9.6.7 TS1 and TS2 software travel switches Two switches are available TS1 and TS2. TS1 is normally open and TS2 is normally closed. Switching action is set as a % of valve travel (refer to Figures 61 and 62). TS1 — software configured travel switch 1 (normally open) Programming notes The switching point can be set as a percentage of the valve travel between 0 to100%. -

Page 52

TS2 — software configured travel switch 2 (normally closed) Programming notes The switching point can be set as a percentage of the valve travel between 0 to 100%. A value can be set outside the limits of the travel settings (MIN-T) and (MAX-T). -

Page 53

The valve will move to a position as dictated by the input control signal. To alter or check SET or TUNE values it is necessary to return to SP500 MENU. Press and key for 3 seconds to return to SP500 MENU. The display will count down the 3 seconds. -

Page 54

At any time during automatic operation the mA input signal can be displayed by pressing key. To return to SP500 MENU press and hold key for 3 seconds. The display will count down the 3 seconds. You will advance to RETRN with the option of AUTO (automatic operation) or VENT (venting air from actuator). -

Page 55

9.8 STRVL and RTIME — valve diagnostics Provides visibility of total number of valve strokes (STRVL) and total valve run time in hours (RTIME). 9.8.1 STRVL — total stem travel Programming notes The number displayed should be multiplied by a factor of 10 to obtain the total number of complete valve strokes. -

Page 56

Press and hold key for 3 seconds. The display will count down the 3 seconds. This provides the facility to return to SP500 MENU with the option of staying in automatic operation (AUTO) or venting the actuator (VENT). Use keys key to select and return to SP500 MENU. -

Page 57

To change the filter proceed as follows: Ensure that the air supply to the positioner is isolated. Unscrew the filter plug (1) from the SP500 housing using a 5 mm hex. head socket key (refer to Figure 65). The replacement filter plug can now be fitted: Fit the ‘O’ ring (4) and filter (3) onto the filter plug (1) (refer to Figure 49). -

Page 58

11. Default values and program settings Programmed Main menu Sub-menu Setting options Default value value 2-PORT Valve type (2-PORT) 3-PORT (VALVE) Actuator type (ACT) Control action Direct (dIRCT) (dIRCT) (CTRLA) Reverse (REV) Minimum travel 0 to 66% (MIN-T) Maximum travel 33 to 100% 95% for 2-port (MAX-T) -

Page 59: Description

12. Glossary of display data 12.1 Main menu display functions Display Description SET UP Indicates that the SP500 positioner fitted to the valve has not been programmed or commissioned. Indicates that you have now entered the SP500 main menu. Provides access to: SP500 •…

-

Page 60: Port Valves

12.2 Sub-menu display functions Display Description VER x.xx Indicates the version of software embedded within the SP500 positioner. CALIb Provides facility for mounting position adjustment. RETRN Enables previously stored function values to be recalled. RTAIN Enables temporary changes made to function values to be retained.

-

Page 61: Sp500 Menu

Indicates the total number of valve strokes (x10). STRVL Value can be retained (RTAIN) or reset (RESET). Indicates the total run time of the SP500 in hours. RTIME Value can be retained (RTAIN) or reset (RESET) IM-P343-35 CH Issue 1…

-

Page 62

IM-P343-35 CH Issue 1… -

Page 63

IM-P343-35 CH Issue 1… -

Page 64

IM-P343-35 CH Issue 1…

В ранее вышедшей статье мы подробно рассказали об особенностях клапанов серии Spira-TrolTM и рассмотрели варианты их применения в различных процессах. Но, как известно, сам клапан это всего лишь часть устройства для регулирования потока среды, которое также включает в себя исполнительный механизм, например, пневматический привод, который, в свою очередь, может быть оснащен позиционером.

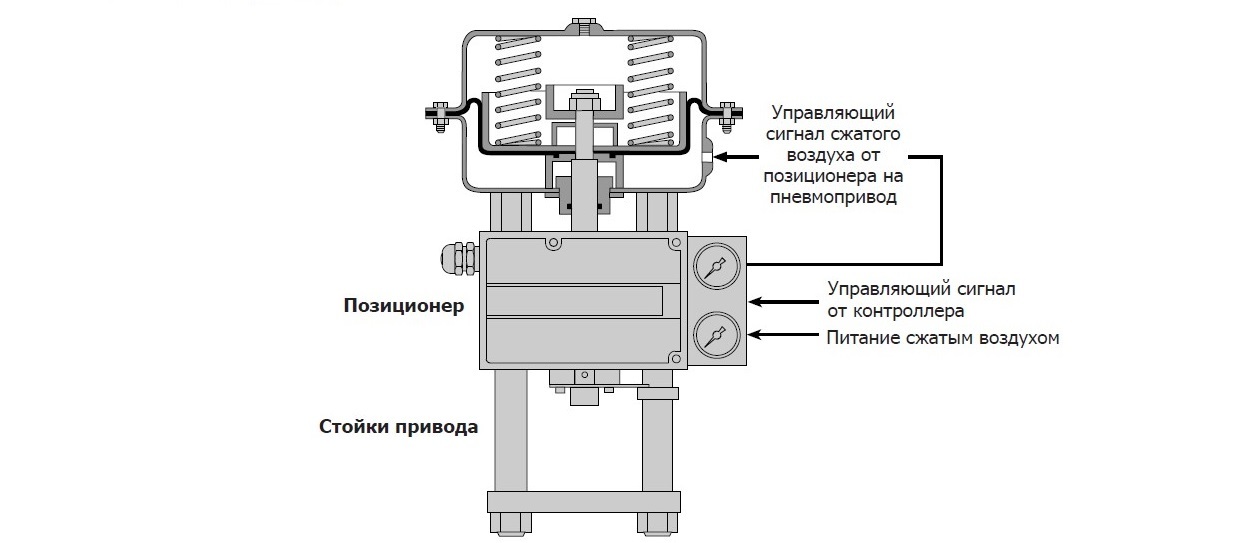

Позиционер – это дополнительное устройство, которое обычно монтируют на стойках пневмопривода и которое имеет бесконтактную или механическую связь со штоком привода/клапана для получения обратной связи о его положении. Электропневматический позиционер преобразует электрический сигнал в пневматический сигнал сжатого воздуха, который направляется в пневмопривод для перемещения штока клапана в требуемое положение.

Часто задают вопрос: «В каком случае следует использовать позиционер?»

Рассматривать необходимость использования позиционера нужно в следующих обстоятельствах:

1. Когда требуется точное позиционирование штока клапана.

2. Когда нужно ускорить отклик клапана на изменение управляющего сигнала, что обеспечивается более высоким давлением воздуха управляющего сигнала, поступающего с позиционера на пневмопривод.

3. Для возможности работы клапана на более высоком перепаде давления на клапане (позиционер действует в качестве усилителя сигнала).

4. В случаях, когда трение в уплотнении штока клапана приводит к слишком сильному запаздыванию в реакции на изменение управляющего сигнала.

5. Для обеспечения линейности отклика при использовании нелинейного привода.

6. В случаях, когда изменения перепада давления в клапане могут приводить к изменению положения плунжера клапана.

Для систем регулирования большинство процессов с такими средами, как пар и вода, обычно используют либо электрические, либо пневматические привода. Пневматические более востребованные в технологических процессах благодаря быстродействию (по сравнению с электрическими) и возможности занимать безопасное положение при потере питания или управляющего сигнала под действием пружин.

Темой данной статьи будут являться электропневматические позиционеры, которые являются неотъемлемой частью системы регулирования. Мы опишем производимые нашей компанией позиционеры, их технические характеристики и отличительные особенности.

На сегодняшний день наша компания производит три различных электропневматических позиционера (нажмите на картинку, чтобы узнать больше о каждом продукте):

Модель ЕР500 – это по сути обновленная версия позиционера ЕР5, который имеет достаточно простую и надежную конструкцию. Данный тип электропневматического позиционера зарекомендовал себя как надежное и высокоточное устройство, которое востребовано на рынке.

Более подробно хотелось бы остановиться на типе SP400/500. Эта серия была специально разработана с учетом требований и пожеланий наших заказчиков.

Отличительными особенностями данной серии являются:

- простая и быстрая функция авто-настройки (запускается нажатием одной кнопки, длительность процедуры 1,5-2 минуты)

- для обеспечения контакта со штоком клапана используется бесконтактный датчик Холла, что позволяет обеспечит более точную обратную связь по положению клапана, исключает ошибки и выход из строя из-за нарушения механической связи;

- программируемые функции и встроенная клавиатура (для корректировки параметров не требует подключения сторонних устройств);

- электрические соединения с низким сопротивлением. Позиционер не требует внешних источников питания, достаточно питания от управляющего сигнала;

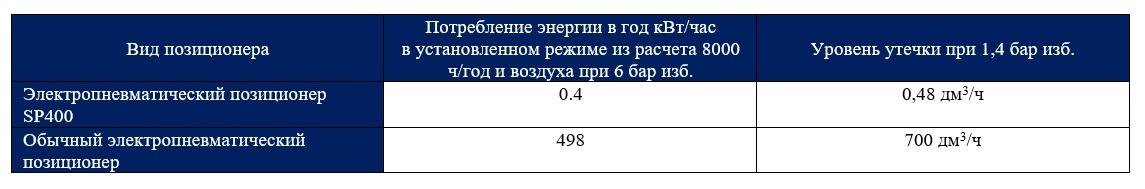

- цифровой контроль расхода сжатого воздуха – благодаря данному решению позиционер практически не потребляет воздух в стационарных режимах.

Таким образом позиционеры имеют очень низкую стоимость эксплуатации. Учитывая постоянно растущие цены на энергоносители значение потребления сжатого воздуха становится важнее с каждым годом.

- расширенное меню программируемых функций для более точного управления клапаном

- возможность установки (опционально) платы ретрансляции сигнала о фактическом положении клапана

- доступна версия с HART протоколом

Дополнительную информацию по электропневматических позиционерах производства Spirax Sarco вы можете найти на нашем сайте или позвонить по телефону 8 800 551-00-25.

Download Installation and maintenance instructions manual of Spirax Sarco SP500 Controller, Valve Positioners for Free or View it Online on All-Guides.com.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

IM-P343-35 CH Issue 1 1

SP500

Electropneumatic Smart Positioner

Installation and Maintenance Instructions

IM-P343-35

CH Issue 1

3.568.5275.300

1. Index

2. Safetyinformation

3. Technical information

4. Options

5. Installation

6. Electricalconnections

7. Quickstartprocedure

8. Programming

flowchart

9. Programmingand

commissioning

10. Maintenance

11. Defaultvaluesand

programsettings

12. Glossaryof

displaydata

Printed in the UK

© Copyright 2010

Spirax Sarco SP500: Available Instructions

Note for Owners:

Guidesimo.com webproject is not a service center of Spirax Sarco trademark and does not carries out works for diagnosis and repair of faulty Spirax Sarco SP500 equipment. For quality services, please contact an official service center of Spirax Sarco company. On our website you can read and download documentation for your Spirax Sarco SP500 device for free and familiarize yourself with the technical specifications of device.

-

Eaton CGLine+ Touchscreen Controller

CGLine+ Web ControllerManual Betriebsanleitung ManuelTarget group: Skilled electricians Zielgruppe: ElektrofachkraftPublic cible : Électriciens confirmésCGLine+ Touchscreen ControllerEnglish …………………………….. 3Deutsch …………………………. 29Français …………………………. 55 …

CGLine+ Touchscreen Controller Controller, 82

-

EZPull MTX-8

OverviewEZPull MTX-8 is a multi-target controller for use in Five-Stand, FITASC, Super-Sporting andother clay target sports that require multiple traps. EZPull MTX-8 is designed to control up to 8traps. The MTX-8 can be used in manual mode for all multiple traps clay target sports. The MTX-8 also features automatic sequencing from six programmable 5-Stand menus.EEZZPPuullllMMTTXX—88UUsseerrMMaann …

MTX-8 Recording Equipment, 3

-

Sony BDV-E780W

Watch Full HD 1080p Blu-ray Disc™ movies and immerse yourself in powerful 5.1 channel HD surround sound with the integrated Sony® smart 3D Blu-ray Disc™ Home Theater System — BDV-E780W.3 Wirelessly stream movies, TV episodes, music and live sports events from Netix®, YouTube™, HuluPlus™, Pandora®, and more.1 Plus enjoy the convenience of wireless rear speakers, 2 HDMI® inputs, and a …

BDV-E780W Home Theater System, 4

-

Graco Series A

309445Rev. ETo find your local Graco authorized servicecenter: Call us at 1–800–690–2894 Visit our website at www.graco.comINSTRUCTIONS–PARTS LISTImportant Safety Instructions Read all warnings and instructionsin this manual. Save theseinstructions.Pressure Roller with 20” Heavy Duty Extension, EvenFlowt RollerFrame and Contractort Inline Valve– For the rolled application of …

Series A Paint Sprayer, 10

-

HP MSM710

InMSM710 Controller QuickstartThis Quickstart applies to both the MSM710 Access Controller (J9328A) and the MSM710 Mobility Controller (J9325A).This Quickstart introduces the HP ProCurve Networking MSM710 Controller and shows you how to get started using it. After following the directions in this Quickstart, see the MSM7xx Controllers Management and Configuration Guide available at: www.hp.com/go/ …

MSM710 Controller, 6

-

YASKAWA NX100

Part Number: 174074-1CDRevision: 0MANUAL NO. 1HW0482711NX100 OPTIONSINSTRUCTIONSFOR CONVEYOR SYNCHRONIZED FUNCTIONUpon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain for future reference.MOTOMAN INSTRUCTIONSMOTOMAN- INSTRUCTIONSNX100 INSTRUCTIONSNX100 OPERATOR’S MANUALNX100 MAINTENANCE MANUALThe NX100 operator’s manual above corre …

NX100 Controller, 86

-

Eaton RTC-100

Contents1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22. Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . …

RTC-100 Controller, 20

-

Azbil BC-R35 Series

1 ADD FURNACE CO.,LTD. 44 ซอยบรมราชชนนี � …

BC-R35 Series Controller, 17

-

Resol DeltaSol CS/2

Thank you for buying this RESOL product.Please read this manual carefully to get the best performance from this unit. Please keep this manual carefully.Manualwww.resol.com enSolar controllerManual for the specialised craftsmanInstallationOperationFunctions and optionsTroubleshootingVersion 1.11*11204303*11204303DeltaSol® CS/2 …

DeltaSol CS/2 Controller, 32

Popular Controller User Guides:

3.1 Description

The SP500 smart valve positioner is loop powered from a 4 — 20 mA input signal to provide

accurate adaptive positional control of pneumatic actuated linear and quarter turn valves.

Precise control is maintained through valve position feedback that automatically varies the

pneumatic output pressure to overcome the effects of stem friction and flow forces to maintain

desired valve position. Indication of valve position is provided through a continuous digital

display of % travel. Valve position feedback is retrieved by means of a non contact technology

based on Hall effect. The pneumatics are based on piezovalve technology — Therefore, high

resolution, high reliability, vibration insensitivity and extremely low air consumption is

guaranteed at steady state.

The SP500 includes many smart functions that can be fully programmed through menu driven

software using an integral keypad and LCD alphanumeric data. Valve commissioning is

simplified through an autostroke routine and display of programming status, software travel

switch status, mA input signal and valve diagnostics data. Moreover, the absence of

mechanical linkages between valve stem and positioner, drastically simplifies the mounting

procedure and reduces the time required. The SP500 is supplied with a NAMUR standard

mounting kit for attachment to yoke or pillar mounted actuators. For quarter turn valves, a

mounting kit compliant to VDI / VDE 3845 is supplied.

4

12

11

Fig. 1

No. Part

1.

LCD display

2.

Main menu functions with LCD flag indication

3.

Signal pressure to activator

4.

Gland connection for wiring M20

5.

Terminal block

6.

Increase value or toggle value key

7.

Decrease value or toggle value key

8.

Enter key

9.

Supply pressure to positioner

10.

Optional pressure gauge block with gauges

11.

Spare M20 gland connection for wiring a 4-20 mA retransmission or software switches

12.

External earth

13.

Internal earth

4

1

13

5

6

2

7

8

IM-P343-35 CH Issue 1

3

10

9