Комментарии

3

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Войти

Зарегистрироваться

VladLogin

Я езжу на SsangYong Rexton (4G)

Есть ли у вас мануал на Rexton Y450 (Рестайл 2020 года)? Весь интернет перерыл((

1 месяц

Ponchak

Я езжу на SsangYong Rexton (4G)

А не подскажите, подходят ли диски r16?

3 месяца

Faritulla

Я езжу на SsangYong Rexton Sports

А не подскажете — там где брали мануалы — есть ли там на Рекстон Спортс?

4 месяца

Цены в Корее. Ssangyong Rexton 2018 / Hyundai Veloster / Победитель Samsung S9 plus

2020 New Rexton 2.2L 4WD

SsangYong Rexton. Стоит ли брать? | Подержанные автомобили

Тест на драйве. SsangYong Rexton

Стоит ли Покупать SsangYong Rexton (2001-2012)?

Бюджетный Mercedes ML: SsangYong Rexton II. Обзор и тест-драйв корейского «Бегемота» ???? #KONGBAND

2018, Ssangyong G4 Rexton 4WD

SsangYong Rexton, корейский мерс

Наименование Заправочный объем Спецификации Моторное масло D…

Рекомендуемые жидкости и смазочные материалы

- Изображение

- Текст

Наименование

Заправочный объем

Спецификации

Моторное масло

D20DTR

≒

6 л

Класс качества: оригинальное моторное масло Ssangyong

(соответствует спецификациям MB Sheet 229.51, SAE 5W/30)

D20DT

≒

7,5 л

Класс качества: оригинальное моторное масло Ssangyong l

(отвечающее стандартам MB Sheet 229.1 или 229.3 или 229.31 – для

дизельных/бензиновых двигателей без CDPF) (отвечающее стандартам MB

Sheet 229.31 для дизельных двигателей, оборудованных CDPF)

D27DT/D27DTP

≒

8,5 л

G32D

≒

9 л

Охлаждающая жидкость

D20DTR

8,5 л

Оригинальная охлаждающая жидкость Ssangyong

Антифриз SYC-1025, соотношение антифриза и воды – 50:50

НА ОСНОВЕ ОРГАНИЧЕСКОЙ КИСЛОТЫ, ЦВЕТ: ГОЛУБОЙ

D20DT

10,5–11,0 л

D27DT/D27DTP

11,0–11,5 л

G32D

11,5–12 л

Рабочая жидкость автоматической

коробки передач

5-ступ. АКП

≒

8 л

Оригинальная жидкость Ssangyong (Shell ATF 134 или Fuchs ATF 134)

6-ступ. АКП

≒

9,5 л

Оригинальная рабочая жидкость Ssangyong (FUCHS TITAN ATF 3292)

Масло механической коробки передач

5-ступ. МКП

≒

3,4 л

Оригинальное масло Ssangyong (рабочая жидкость, ATF DEXRON II)

6-ступ. МКП

≒

2,2 л

Оригинальное масло Ssangyong

(HD MTF 75W/85 (SHELL) или HK MTF 75W/85(SK))

Масло раздаточной коробки

AWD

≒

1,1 л

Оригинальная жидкость Ssangyong (ATF DEXRON II или III)

TOD

≒

1,4 л

Part Time

≒

1,4 л

Масло для редукторов

ведущих мостов

Переднего

Без IOP

≒

1,4 л, ≒ 1,5 л

Оригинальное масло Ssangyong (API GL-5 и SAE 80W/90)

IOP

≒

0,78 л

Оригинальное масло Ssangyong (Синтетическое масло Shell GL 75W/90)

Заднего

Неразрезной

≒

2,0 л

Оригинальное масло Ssangyong (API GL-5 и SAE 80W/90)

IRS

≒

1,5 л

Оригинальное масло Ssangyong (Синтетическое масло Shell GL 75W/90)

Рабочая жидкость гидропривода сцепления/тормозной

системы

По мере

необходимости

Оригинальная тормозная жидкость Ssangyong (DOT4)

Жидкость гидроусилителя рулевого управления

≒

1,1 л

Оригинальное масло Ssangyong (PSF-3)

* TOTAL FLUIDE DA (Только при очень низких температурах)

D20DTR: Дизельный двигатель 2,0 л. (Евро 5), D20DT: Дизельный двигатель 2,0 л., D27DTP: Дизельный двигатель 2,7 л. форсированный,

D27DT: Дизельный двигатель 2,7 л., G32D: Бензиновый двигатель

ВНимаНие

y

Используйте только топливо, жидкости и смазочные материалы, рекомендованные Ssangyong.

y

Не смешивайте масла и жидкости различного типа и различных производителей. Это может стать причиной возникновения неисправностей.

y

При замене или проверке поддерживайте указанный уровень масел и рабочих жидкостей.

y

Используйте класс вязкости рабочих жидкостей и смазочных материалов в соответствии со средней сезонной температурой окружающей среды, региона

в котором эксплуатируется автомобиль. За подробной информацией обращайтесь в адрес авторизованных дилерских центров.

Рекомендуемые жидкости и смазочные материалы

ПРеДиСЛОВие

Данное Руководство поможет вам ознакомиться с правилами эксплуатации и технического

обслуживания автомобиля

Rexton W и предоставит важную информацию по безопасности.

Мы настоятельно рекомендуем внимательно его прочитать и выполнять все рекомендации,

чтобы обеспечить наиболее приятную, безопасную и надежную эксплуатацию вашего

автомобиля.

Помните, что в отношении обслуживания ваш дилер

знает автомобиль лучше

сторонних компаний и заинтересован в том, чтобы полностью удовлетворить все ваши

потребности.

Мы хотели бы воспользоваться случаем и поблагодарить вас за выбор автомобиля

Rexton W и заверить вас, что мы по-прежнему внимательно следим за тем, чтобы

автомобиль приносил вам радость и удовлетворение.

Данное Руководство является неотъемлемой составляющей вашего автомобиля и должно

передаваться вместе с автомобилем при смене владельца.

ПХЁНТХЭК, КОРеЯ

Общие сведения Габаритные размеры ………………………

Страница 4

- Изображение

- Текст

СОДеРЖаНие

00

Общие сведения

Габаритные размеры ……………………….0-2

Идентификационные номера …………..0-7

Переключатели и оборудование

салона ……………………………………….0-8

Моторный отсек ………………………………0-9

Важная информация ……………………..0-13

Защита окружающей среды ……………0-14

01

меры безопасности

Проверка перед началом движения ….1-2

Меры безопасности …………………………1-7

Запуск двигателя и начало движения …1-16

Уход за автомобилем …………………….1-18

Уход за автомобилем при

температуре ниже 0 °C (32 °F) …..1-27

Предупреждения о недопустимости

самостоятельного внесения

изменений в конструкцию …………1-30

Дизельный двигатель

с непосредственным впрыском ……1-33

02

Ключ зажигания и пульт

дистанционного управления

Пульт дистанционного управления*

и ключ зажигания ……………………….2-2

Функции ключа замка зажигания ……..2-4

Отпирание и запирание дверей

при помощи ключа ……………………..2-6

Замена элемента питания

для ключей Rekes ………………………2-7

Система иммобилайзера …………………2-8

Противоугонная система ………………..2-10

03

Двери и окна автомобиля

Механизмы и системы открывания

и закрывания дверей и окон ……….3-2

Двери ……………………………………………..3-4

Окна ……………………………………………….3-6

Верхний люк* …………………………………..3-8

Капот …………………………………………….3-10

Крышка лючка заливной

горловины топливного бака ……… 3-11

Рейлинги ……………………………………….3-13

Дверь багажного отделения

и заднее окно …………………………..3-14

04

Переключатели и органы

управления панели приборов

Переключатели и оборудование

салона ……………………………………….4-2

Комбинированный переключатель

света …………………………………………4-4

Очистители и омыватели стекол ………4-8

Очиститель ветрового стекла

с датчиком дождя* ……………………..4-9

Комбинированный переключатель

очистителей и омывателей стекол …4-10

Переключатель круиз контроля* ……..4-12

Панель переключателей

на водительской двери ……………..4-18

Переключатель электропривода

регулировки наружных зеркал

заднего вида…………………………….4-19

Кнопки дистанционного управления

на рулевом колесе ……………………4-20

Выключатели обогрева стекол………..4-21

Выключатель аварийной

сигнализации ……………………………4-22

Переключатель ESP OFF* ………………4-23

Выключатель системы HDC* ………….4-25

Выключатель системы помощи

при парковке (PAS)* …………………4-27

Переключатели центральной консоли ..4-28

Система полного привода* ……………..4-29

Переключатели потолочной

консоли, переключатели

светильников салона ………………..4-33

05

Комбинация приборов

Комбинация приборов (дизельные

модели) ……………………………………..5-2

Комбинация приборов (модели

с бензиновым двигателем G32D) ..5-4

Индикация давления воздуха

в шинах (автомобили

с системой контроля давления

в шинах (TPMS))* ……………………..5-10

Система контроля давления

воздуха в шинах (TPMS)* …………. 5-11

Контрольные лампы и индикаторы …5-16

Переключение передач и тормозная система Рычаг переключе…

Страница 5

- Изображение

- Текст

06

Переключение передач

и тормозная система

Рычаг переключения передач

(6-ступ. МКП) ……………………………..6-2

Рычаг переключения передач

(5-ступ. МКП) ……………………………..6-3

Рычаг селектора автоматической

коробки передач* ……………………….6-7

Советы по управлению

автомобилем с автоматической

коробкой передач ………………………6-9

Положения рычага селектора ………… 6-11

Зимний (W)/стандартный (S) режим …..6-17

Безопасный режим (автоматическая

коробка передач) ……………………..6-18

Система помощи при парковке (PAS)* ..6-19

Система Bluetooth* ………………………..6-23

Тормозная система ………………………..6-24

Стояночный тормоз ……………………….6-29

07

Сиденья

Устройства, относящиеся к сиденьям …7-2

Водительское сиденье …………………….7-4

Пассажирское сиденье …………………….7-9

Сиденья второго ряда ……………………7-10

Сиденье третьего ряда* …………………7-12

Система обогрева сидений* …………..7-14

08

Ремни и подушки безопасности

Ремни и подушки безопасности ………..8-2

Ремни безопасности ………………………..8-4

Порядок использования трехточечного

ремня безопасности …………………..8-5

Порядок использования ремня

центрального сиденья

второго ряда ………………………………8-6

Порядок использования ремня

(трехточечного) центрального

сиденья второго ряда …………………8-7

Безопасность детей и беременных

женщин ……………………………………..8-9

Указания по использованию ремней

безопасности ……………………………8-17

Подушки безопасности*………………….8-19

Ситуации, при которых подушки

безопасности не срабатывают …..8-23

Указания по использованию системы

подушек безопасности ………………8-27

09

Система вентиляции,

обогрева, кондиционирования

воздуха

Система обогрева/

кондиционирования воздуха ……….9-2

Важные замечания ………………………….9-4

Автоматический обогреватель/

кондиционер ………………………………9-5

Кондиционер воздуха для задних

пассажиров* (двойная система

кондиционирования) ………………… 9-11

Очистка стекол от влаги и наледи …..9-12

Замена фильтрующих элементов

системы кондиционирования …….9-13

Система контроля качества воздуха

(AQS) ……………………………………….9-15

10

Устройства

и приспособления для

обеспечения комфорта

Отделения для хранения вещей и

устройства для обеспечения

комфорта …………………………………10-2

Рулевое колесо и звуковой сигнал ….10-4

Внутреннее зеркало заднего вида ….10-5

Передние подстаканники/

прикуриватель ………………………….10-6

Центральная консоль …………………….10-7

Электрические розетки …………………..10-8

Подсветка перчаточного ящика/

подсветка открытой двери ………..10-9

Задний подстаканник/ящик для

хранения домкрата / отделение

для установки DVD-чейнджера*/

блока системы навигации* ………10-10

Карманы на спинках сидений

и передних дверях …………………. 10-11

Солнцезащитный козырек …………….10-12

Передний светильник салона/

отделение для солнцезащитных

очков ……………………………………..10-13

Центральный светильник салона

и светильник багажного

отделения/поручни …………………10-14

Ящик багажного отделения/

багажная сетка ……………………….10-15

Обогреватель заднего стекла/

съемная пепельница ………………10-17

Рейлинги* ……………………………………10-18

Электронные часы ……………………….10-19

Аудиосистема* …………………………….10-20

11

Действия в экстремальных

ситуациях

Запуск двигателя от внешнего

источника ………………………………… 11-2

Прокол шины во время движения ….. 11-4

Знак аварийной остановки* ……………. 11-5

Возимый комплект инструментов …… 11-6

Снятие запасного колеса ………………. 11-7

Установка запасного колеса ………….. 11-8

Указания по замене колеса ………….. 11-13

Перегрев двигателя …………………….. 11-14

Контрольная лампа наличия воды

в топливном фильтре и контрольная

лампа «Проверь двигатель» …… 11-16

Снятие блокировки рычага селектора

и отмена настроек безопасного

режима ………………………………….. 11-17

Транспортировка неисправного

автомобиля …………………………… 11-18

Аварийная буксировка…………………. 11-19

Буксировка прицепа…………………….. 11-21

Действия в случае аварии

или пожара ……………………………. 11-26

Каталитический нейтрализатор ……. 11-27

12

Техническое обслуживание

и ремонт

Ежедневный технический осмотр ……12-2

Моторный отсек …………………………….12-3

Моторное масло …………………………….12-7

Охлаждающая жидкость ………………12-10

Воздухоочиститель ………………………12-12

Жидкость гидроусилителя рулевого

управления …………………………….12-14

Топливный фильтр и

топливоподкачивающий насос

(без дополнительного

водоотделителя) …………………….12-15

Топливный фильтр и водоотделитель

(с дополнительным

водоотделителем) …………………..12-16

Топливный фильтр ……………………….12-19

Приводной ремень (для бензиновых

моделей)/педаль тормоза

и педаль сцепления ………………..12-20

Стояночный тормоз/каталитический

нейтрализатор ………………………..12-21

Жидкость гидропривода тормозной

системы и сцепления (МКП) ……12-22

Масло раздаточной коробки …………12-23

Жидкость для омывателей стекол…12-24

Аккумуляторная батарея ………………12-25

Свечи зажигания ………………………….12-27

Блок реле и предохранителей ………12-28

Шины …………………………………………..12-30

Замена щеток очистителей стекол ..12-34

Самостоятельное выполнение

технического обслуживания …….12-35

График технического обслуживания (ЕС) –

(дизельные модели) (D20DTR) …..12-36

График технического обслуживания

(другие страны) – (дизельные

модели) (D20DTR) ………………….12-39

График технического обслуживания

(другие страны) – (дизельные

модели) (D27DT/D27DTP) ……….12-42

График технического обслуживания

(бензиновые модели) ……………..12-45

13

Лампы

Технические характеристики

и проверка ламп……………………….13-2

Расположение наружных световых

приборов ………………………………….13-3

Лампы внутренних световых приборов ..13-8

14

Перевод предупреждающих

наклеек автомобиля

15

Алфавитный указатель

Общие

сведения

СОДеРЖаНие

Габаритные размеры ……………………………….0-2

Идентификационные номера …………………..0-7

Переключатели и приборы ……………………….0-8

Моторный отсек ……………………………………….0-9

Важная информация ………………………………0-13

Защита окружающей среды ……………………0-14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

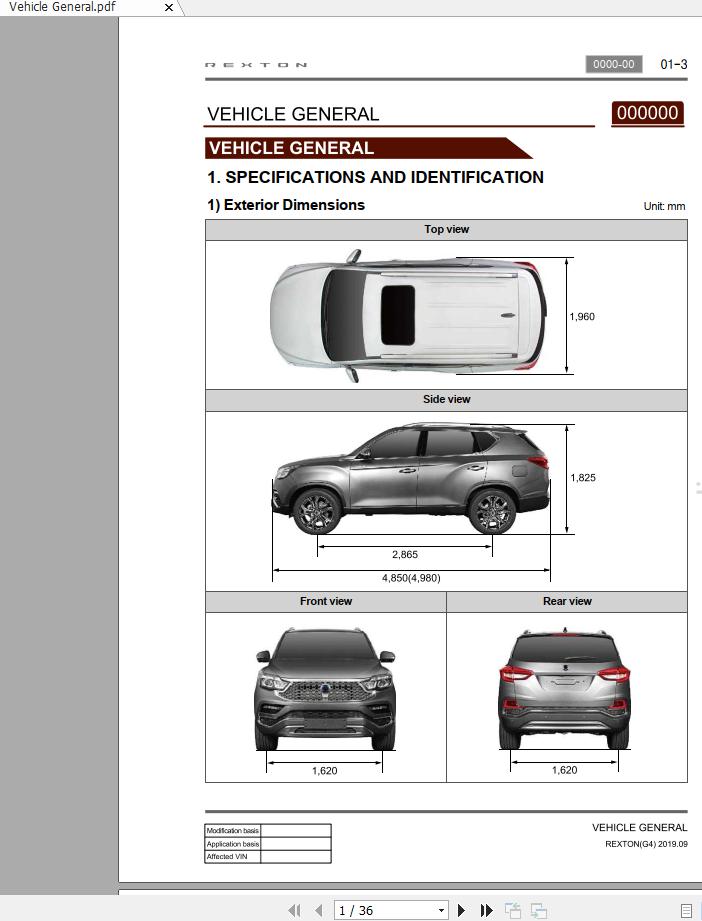

Общие СВеДеНиЯ

0-2

ГабаРиТНые РаЗмеРы

Единицы измерения: мм

1570

2835

4755

1840

1570

1900

Вид сверху

Вид сбоку

Вид спереди

Вид сзади

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Общие СВеДеНиЯ

0-3

Наименование

D20DTR

D27DT

D27DTP

G32D

Общие

Габаритная длина (мм)

4755

←

←

←

Габаритная ширина (мм)

1900

←

←

←

Габаритная высота (мм)

1840

←

←

←

Полная масса автомобиля (кг)

2710 [2650]

2740

←

←

Снаряженная масса

автомобиля (кг)

АКП

1985 (2053)

[1925 (1993)]

2033 (2098)

2008 (2082)

2021 (2095)

МКП

1960 (2020)

[1901 (1960)]

2007 (2072)

_

_

Расход топлива

Дизельный двигатель

←

←

Бензиновый двигатель

Емкость топливного бака (л)

78

←

←

←

Миним. радиус разворота

5,7 м

←

←

←

Двигатель

Количество цилиндров/

степень сжатия

4/6,5:1

5/18:1

(Евро 4 17,5:1)

5/17,5:1

6/10:1

Рабочий объем (куб. см)

1998

2696

←

3199

Тип газораспределительного

механизма

DOHC

←

←

←

Макс. мощность

АКП

<155 л. с.

4000 об/мин>

165 л.с./4000 об./мин.

<161 л.с./4000 об./мин.>

186 л.с./4000 об./мин.

<180 л.с./4000 об./мин.> 220 л.с./6100 об./мин.

МКП

165 PS / 4000 об/мин

_

_

Макс. крутящий

момент

АКП

<360 Нм/

1500–2800 об/мин>

340 Нм/

1800–3250 об/мин

402 Нм/

1600–3000 об/мин

312 Нм/4600 об./мин.

МКП

340 Нм /

1800–3250 об/мин

_

_

Обороты холостого хода

780 ± 50 об/мин

750 ± 20 об/мин

←

700 ± 50 об/мин

Система охлаждения

Жидкостное охлажде-

ние/принудительная

циркуляция

←

←

←

ТеХНиЧеСКие ХаРаКТеРиСТиКи (I)

* ( ): Опционально, [ ]: 2WD, < >: DPF

D20DTR: Дизельный двигатель 2,0 л., D27DT: Дизельный двигатель 2,7 л.,

D27DTP: Дизельный 2,7 л. форсированный, G32D: Бензиновый двигатель

Общие СВеДеНиЯ

0-4

Наименование

D20DTR

D27DT

D27DTP

G32D

Двигатель

Заправочный объем ОЖ (л)

8,5

11.0–11.5

←

11.5–12.0

Система смазки

Шестеренный насос,

принудительная

циркуляция

←

←

←

Макс. объем масла (л)

(при

поставке)

6,0

9,2

←

9,8

Система турбонаддува и тип

охлаждения

Турбонагнетатель,

воздушное

охлаждение

←

←

_

механиче-

ская

коробка пе-

редач

Тип управления

Полудистанционное

управление, напольное

расположение рычага

←

_

_

Передаточное число

1-я

4,489

4,315

_

_

2-я

2,337

2,475

_

_

3-я

1,350

1,536

_

_

4-я

1,000

1,000

_

_

5-я

0,784

0,807

_

_

6-я

0,679

_

_

_

Передача

заднего хода

4,253

3,919

_

_

ТеХНиЧеСКие ХаРаКТеРиСТиКи (II)

* ( ): Опционально

Комментарии

РЕКОМЕНДУЕМЫЕ ЖИДКОСТИ И СМАЗОЧНЫЕ МАТЕРИАЛЫ

РЕКОМЕНДУЕМЫЕ ЖИДКОСТИ И СМАЗОЧНЫЕ МАТЕРИАЛЫ

РЕКОМЕНДУЕМЫЕ ЖИДКОСТИ И СМАЗОЧНЫЕ МАТЕРИАЛЫ

РЕКОМЕНДУЕМЫЕ ЖИДКОСТИ И СМАЗОЧНЫЕ МАТЕРИАЛЫ

РЕКОМЕНДУЕМЫЕ ЖИДКОСТИ И СМАЗОЧНЫЕ МАТЕРИАЛЫ

О п и с а н и я

О п и с а н и я

О п и с а н и я

О п и с а н и я

О п и с а н и я

Спецификации

Спецификации

Спецификации

Спецификации

Спецификации

Емкость

Емкость

Емкость

Емкость

Емкость

Сорт: Оригинальное моторное масло Ssangyong

(Утверждено MB Sheet 229,1, либо 229,3, либо 229,31 для

DSL/GSL ENG áåç CDPF)

(Утверждено MB Sheet 229,31 äëÿ DSL ENG áåç CDPF)

Вязкость: Список MB No. 224,1

Оригинальное масло Ssangyong

Антифриз: SYC-1025

Антифриз : вода = 50:50

Оригинальное масло Ssangyong (Shell AFT 134 èëè Fuchs AFT 134)

Оригинальное масло Ssangyong (ATF DEXRON II)

Оригинальное масло Ssangyong (ATF DEXRON II, III)

Оригинальное масло Ssangyong (SAE 80W/90, API GL-5)

Оригинальное масло Ssangyong

(Синтетическое масло Shell GL75W/90)

Оригинальное масло Ssangyong (SAE 80W/90, API GL-5)

Оригинальное масло Ssangyong

(Синтетическое масло Shell GL75W/90)

Оригинальное масло Ssangyong (DOT4)

Оригинальное масло Ssangyong (ATF DEXRON II, III)

8,5 л

8,5 л

9,0 л

11,0 ~ 11,5 л

11,0 ~ 11,5 л

11,5 ~ 12,0 л

8,0 л

3,4 л

3,6 л

1,1 л

1,4 л

1,4 л

1,4

1,5 л

0,78 л

2,0 л

1,5 л

По мере необходимости

1,0 л

Масло двигателя

Охлаждающая жидкость

Жидкость автоматической коробки передач

Жидкость ручной коробки

передач

Жидкость корпуса

редуктора

Масло моста

Тормозная жидкость/жидкость для сцепления

Жидкость для механизма усилителя рулевого

управления

D27DTP

D27DT

G32D

D27DTP

D27DT

G32D

2WD

4WD

AWD

TOD

Áåç IOP

IOP

Жесткий

IRS

Передний

Задний

2009-02-27, ¿АИД 2:06

Page 2

Parr t — Ti m

e

ë

*TOTAL FLUIDE DA (см. главу 13)

- Manuals

- Brands

- SSANGYONG Manuals

- Automobile

- REXTON 2004.04

- Manual

-

Contents

-

Table of Contents

-

Bookmarks

Related Manuals for SSANGYONG REXTON 2004.04

Summary of Contents for SSANGYONG REXTON 2004.04

-

Page 1

GENERAL INFORMATION 0000-00 GENERAL INFORMATION GENERAL INFORMATION 1. HOW TO READ ELECTRICAL WIRING DIAGRAM………. -

Page 3

— Internal circuit of component (Switch) (Component Name, Terminal Number and Connecting Wiring Circuit) — Lower horizontal line : Ground line ·Ground position (G101 ~ G401) ·B : Body Ground ·Refer to Major Ground Position (Section2) GENERAL INFORMATION REXTON 2004.04… -

Page 4

Battery Voltage (B+) supply in Ignition Switch “ON” and “ACC” Battery Voltage (B+) supply directly regardless of Ignition Switch Ground connected to battery (-) Battery Voltage (B+) supply in Head Lamp Switch 1st and 2nd step (Illumination circuit) GENERAL INFORMATION REXTON 2004.04… -

Page 5

In the locating section, the assignment for part number starts from left bottom and proceeds clockwise. In the fuse and relay box or the instrument panel, the part number is assigned from left top to light bottom. 02 : Part number GENERAL INFORMATION REXTON 2004.04… -

Page 6

0000-00 9) ABBREVIATIONS GENERAL INFORMATION REXTON 2004.04… -

Page 7

0000-00 GENERAL INFORMATION REXTON 2004.04… -

Page 9: Table Of Contents

CONNECTOR/GROUND 6810-00/7410-00/8201-00/8210-00/8210-02/8210-03/8210-08/8210-09/8210-10/ CONNECTOR/GROUND POSITION OF CONNECTOR 8201-00 POSITION OF CONNECTORS AND GROUNDS……CONNECTOR/GROUND 8210-00 W/H ENGINE ROOM….. 8210-02 W/H MAIN……..8210-03 W/H FLOOR(LH)……8210-03 W/H FLOOR(LH)……8210-06 W/H DOOR (LH/RH)…… 8210-08 W/H RR DOOR……6810-00 W/H AIR-CON……. 8210-10 W/H TAIL GATE……8210-09 W/H ROOF……..

-

Page 11: Position Of Connector

8201-00 POSITION OF CONNECTOR POSITION OF CONNECTORS AND GROUNDS 8201-00 2) COMPONENTS LOCATION 1) POSITION OF CONNECTOR, GROUND & SPLICE PACK CONNECTOR/GROUND REXTON 2004.04…

-

Page 12: Connector/Ground

8201-00 3) CONNECTOR, GROUND & SPLICE PACK INFORMATION ▶ CONNECTOR CONNECTOR/GROUND REXTON 2004.04…

-

Page 13

8201-00 ▶ SPLICE PACK ▶ GROUND CONNECTOR/GROUND REXTON 2004.04… -

Page 14

8201-00 4) SPLICE PACK ▶ S203 ▶ S204 ▶ S101 ▶ S102 ▶ S103 ▶ S205 ▶ S206 (1) ~ 2002 MODEL ▶ S202 (CAN) ▶ S207 ▶ S208 CONNECTOR/GROUND REXTON 2004.04… -

Page 15

8201-00 ▶ S204 ▶ S205 ▶ S301 ▶ S302 ▶ S206 ▶ S207 (2) 2003 MODEL ~ ▶ S201 ▶ S202 ▶ S208 ▶ S301 ▶ S203 ▶ S203A ( ): XDi Only CONNECTOR/GROUND REXTON 2004.04… -

Page 16

8201-00 S301A S302 ▶ ▶ CONNECTOR/GROUND REXTON 2004.04… -

Page 17

8201-00 CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION ▶ C101 ~ C115 ▶ C301 ~ C905 ▶ C101 ~ C115 CONNECTOR/GROUND REXTON 2004.04… -

Page 18

0-10 8210-02 ▶ SW (SWITCH) CONTROL UNIT ▶ CONNECTOR/GROUND REXTON 2004.04… -

Page 19

0-11 8201-00 ▶ SENSOR ▶ LAMP ▶ MOTOR ▶ AIR BAG CONNECTOR/GROUND REXTON 2004.04… -

Page 20

0-12 8201-00 ▶ UNIT ▶ COIL/SOLENOID CONNECTOR/GROUND REXTON 2004.04… -

Page 21: 8210-00 W/H Engine Room

0-13 8210-02 CONNECTOR W/H ENGINE ROOM 8210-02 CONNECTOR/GROUND REXTON 2004.04…

-

Page 22: 8210-02 W/H Main

0-14 8210-01 W/H MAIN 8210-01 CONNECTOR/GROUND REXTON 2004.04…

-

Page 23

0-15 8210-01 CONNECTOR/GROUND REXTON 2004.04… -

Page 24: 8210-03 W/H Floor(Lh)

0-16 8210-03 W/H FLOOR (LH) 8210-03 CONNECTOR/GROUND REXTON 2004.04…

-

Page 25: 8210-06 W/H Door (Lh/Rh)

0-17 8210-06 W/H FLOOR (RH) 8210-03 W/H DOOR (LH/RH) 8210-06 CONNECTOR/GROUND REXTON 2004.04…

-

Page 26: 8210-08 W/H Rr Door

0-18 6810-00 W/H AIR-CON W/H RR DOOR 6810-00 8210-08 CONNECTOR/GROUND REXTON 2004.04…

-

Page 27: 8210-10 W/H Tail Gate

0-19 8210-09 W/H TAIL GATE 8210-10 W/H ROOF 8210-09 CONNECTOR/GROUND REXTON 2004.04…

-

Page 28: 7410-00 W/H Seat

0-20 7410-00 W/H SEAT 7410-00 CONNECTOR/GROUND REXTON 2004.04…

-

Page 29

POWER DISTRIBUTION 8410-02/8410-04/8410-06/ POWER DISTRIBUTION FUSE/RELAY 8410-02 ENGINE ROOM FUSE & RELAY BOX ……….8410-04 I.P FUSE & RELAY BOX….. ELECTRICITY DIVIDE 8210-02 POWER WIRING DIAGRAM (DSL)……8410-04 POWER WIRING DIAGRAM (GSL)……8410-06 POWER WIRING DIAGRAM (XDi, 2003 MODEL ~ )…. -

Page 31: Fuse/Relay

8410-02 FUSE & RELAY 8410-02 ENGINE ROOM FUSE & RELAY BOX (3) FRONT (DSL) 1) ~ 2002 MODEL (1) FRONT (4) FRONT (GSL) (2) REAR POWER DISTRIBUTION REXTON 2004.04…

-

Page 32

8410-02 2) 2003 MODEL (W/ XDi) ~ (5) USAGE OF FUSE IN ENGINE ROOM FUSE BOX (1) FRONT (2) REAR (6) CONNECTOR POWER DISTRIBUTION REXTON 2004.04… -

Page 33

8410-04 (3) FRONT (DSL) (5) USAGE OF FUSE IN ENGINE ROOM FUSE BOX (4) FRONT (GSL) (6) CONNECTOR POWER DISTRIBUTION REXTON 2004.04… -

Page 34

8410-06 (7) FRONT (TI) (9) USAGE OF FUSE IN ENGINE ROOM FUSE BOX (8) FRONT (XDi) (10)CONNECTOR POWER DISTRIBUTION REXTON 2004.04… -

Page 35: 8410-04 I.p Fuse & Relay Box

8410-04 8410-04 I.P FUSE & RELAY BOX 1) ~ 2002 MODEL (1) FUSE BOX (3) RELAY (2) POWER SUPPLY POWER DISTRIBUTION REXTON 2004.04…

-

Page 36

8410-04 2) 2003 MODEL ~ 3) TI (1) FUSE BOX (1) FUSE BOX (2) POWER SUPPLY (2) POWER SUPPLY POWER DISTRIBUTION REXTON 2004.04… -

Page 37

8410-04 4) XDi (1) FUSE BOX (3) RELAY (2) POWER SUPPLY POWER DISTRIBUTION REXTON 2004.04… -

Page 38: Electricity Divide

0-10 8410-02 ELECTRICITY DIVIDE POWER WIRING DIAGRAM (DSL) 8210-02 (1) ~ 2002 MODEL POWER DISTRIBUTION REXTON 2004.04…

-

Page 39

0-11 8410-02 POWER DISTRIBUTION REXTON 2004.04… -

Page 40

0-12 8410-02 (2) 2003 MODEL POWER DISTRIBUTION REXTON 2004.04… -

Page 41

0-13 8410-02 POWER DISTRIBUTION REXTON 2004.04… -

Page 42: 8410-04 Power Wiring Diagram (Gsl)

0-14 8410-04 POWER WIRING DIAGRAM (GSL) 8410-04 (1) ~ 2002 MODEL POWER DISTRIBUTION REXTON 2004.04…

-

Page 43

0-15 8410-04 POWER DISTRIBUTION REXTON 2004.04… -

Page 44

0-16 8410-04 (2) 2003 MODEL POWER DISTRIBUTION REXTON 2004.04… -

Page 45

0-17 8410-04 POWER DISTRIBUTION REXTON 2004.04… -

Page 46: 8410-06 Power Wiring Diagram (Xdi, 2003 Model ~ )

0-18 8410-06 POWER WIRING DIAGRAM(XDi, 2003 MODEL ~ 8410-06 1) ENG ROOM & FUSE BOX (1) SB1 ~ SB5 (2) SB6 ~ SB11 POWER DISTRIBUTION REXTON 2004.04…

-

Page 47

0-19 8410-06 (3) Ef1 ~ Ef4 (4) Ef5 ~ Ef9 POWER DISTRIBUTION REXTON 2004.04… -

Page 48

0-20 8410-06 (5) Ef10 ~ Ef14 (6) Ef15 ~ Ef20 POWER DISTRIBUTION REXTON 2004.04… -

Page 49

0-21 8410-06 2) FUSE BOX (7) Ef21 ~ Ef26 (1) F1 ~ F5 POWER DISTRIBUTION REXTON 2004.04… -

Page 50

0-22 8410-06 (2) F6 ~ F15 (3) F16 ~ F21 POWER DISTRIBUTION REXTON 2004.04… -

Page 51

0-23 8410-06 (4) F22 ~ F28 (5) F29 ~ F31 POWER DISTRIBUTION REXTON 2004.04… -

Page 53

CIRCUIT 1491-01/1792-01/2820-01/3110-01/3232-34/3410-01/4610-00/4620-12/4892-01/6810-15/6810-18/6910-01/7010-06/7340-03/ 7410-00/7410-04/7410-32/7632-20/7770-03/7770-08/7830-02/8010-01/8211-01/8310-01/8310-10/8310-23/8320-01/8410-30/ 8511-05/8610-10/8611-09/8710-01/8711-02/8790-01/8810-01/8910-02/8931-01/ CIRCUIT ENGINE ELECTRIC 6810-18 FATC (FULL AUTO 1461-01 STARTING & CHARGING…. 8810-01 AIR BAG & SIDE AIR-BAG 7830-02 REAR GLASS WIPER & 2820-01 PREHEATING CIRCUIT….CIRCUIT……..WASHER CIRCUIT……. TEMPERATURE CONTROL) 1792-01 EGR (EXHAUST GAS 8010-01 CLUSTER……..8610-10 HORN CIRCUIT…… -

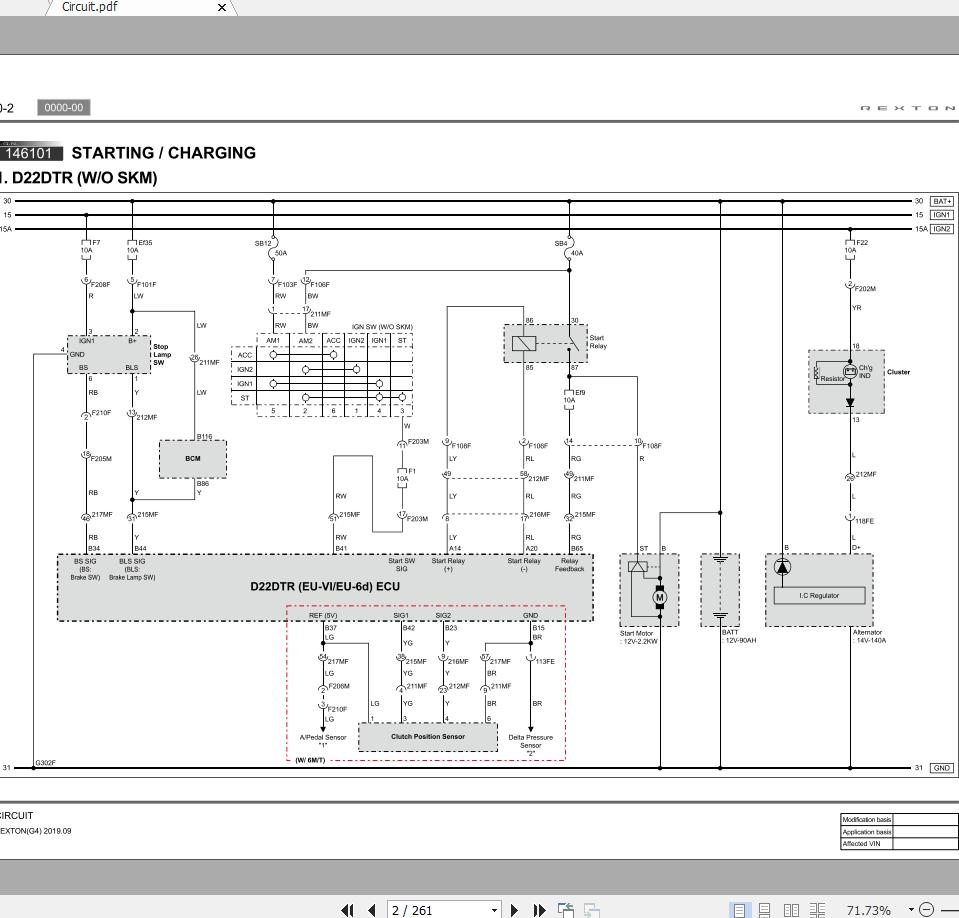

Page 55: Starting & Charging

1461-01 STARTING & CHARGING 1461-01 1) DIESEL (M/T, A/T) ~ 2002 MODEL 2) GASOLINE (M/T, A/T) ~ 2002 MODEL CIRCUIT REXTON 2004.04…

-

Page 56

1461-01 3) DIESEL (M/T, A/T) 2003 MODEL (W/ XDi) ~ 4) GASOLINE (M/T, A/T) 2003 MODEL (W/ XDi) ~ CIRCUIT REXTON 2004.04… -

Page 57

2820-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 58: Preheating Circuit

2820-01 PREHEATING UNIT CIRCUIT 2820-11 1) ~ 2002 MODEL 2) 2003 MODEL ~ CIRCUIT REXTON 2004.04…

-

Page 59

1792-01 3) XDi (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 60: Egr (Exhaust Gas Recirculation) Control Circuit (Dsl)

1792-01 (EXHAUST RECIRCULATION) 1792-01 CONTROL CIRCUIT (DSL) 1) GENERAL ~ 2002 MODEL 2) EURO ~ 2002 MODEL CIRCUIT REXTON 2004.04…

-

Page 61

1491-01 3) HUBER EGR (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 62: Ecu (Electronic Control Unit) (E23)

1491-01 OVPR, FUEL PUMP, CANISTER PURGE VALVE, O2 SENSOR, SPARK PLUG, SENSOR (CAM SHAFT POSITION, MAP, NTC, CRANK SHAFT POSITION,THROTTLE MOTOR, AIR TEMP, PEDAL MODULE CIRCUIT ~ 2002 MODEL KNOCK), CAM SHIFT ACTUATOR CIRCUIT ~ 2002 MODEL CIRCUIT REXTON 2004.04…

-

Page 63

0-11 1491-01 (1) CONNECTOR INFORMATION DIGITAL CLOCK, ENG TEMP SENSOR, IMMOBILIZER CIRCUIT ~ 2002 MODEL (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 64

4) OVPR, FUEL PUMP, CANISTER PURGE VALVE, O2 SENSOR, 5) SPARK PLUG, SENSOR (CAM SHAFT POSITION, MAP, NTC, CRANK SHAFT POSITION, THROTTLE MOTOR, AIR TEMP, KNOCK), CAM PEDAL MODULE CIRCUIT 2003 MODEL ~ SHIFT ACTUATOR CIRCUIT 2003 MODEL ~ CIRCUIT REXTON 2004.04… -

Page 65

0-13 1491-01 6) DIGITAL CLOCK, ENG TEMP SENSOR, IMMOBILIZER CIRCUIT (1) CONNECTOR INFORMATION 2003 MODEL ~ (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 66: Ecu (Electronic Control Unit) (E28, E32)

ECU (ELECTRONIC CONTROL UNIT) (E28, E32) 1491-01 OVPR, FUEL PUMP, CANISTER PURGE VALVE, PEDAL SPARK PLUG, SENSOR (CAM SHAFT POSITION, NTC, CRANK SHAFT POSITION,THROTTLE MOTOR & SENSOR, KNOCK), CAM SHIFT MODULE CIRCUIT ~ 2002 MODEL ACTUATOR, RESONANCE FLAPCIRCUIT ~ 2002 MODEL CIRCUIT REXTON 2004.04…

-

Page 67

0-15 1491-01 DIGITAL CLOCK, ENG TEMP SENSOR, IMMOBILIZER CIRCUIT 4) O2 SENSOR ~ 2002 MODEL ~ 2002 MODEL CIRCUIT REXTON 2004.04… -

Page 68

0-16 1491-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 69

0-17 1491-01 OVPR, FUEL PUMP, CANISTER PURGE VALVE, PEDAL SPARK PLUG, SENSOR(CAM SHAFT POSITION, NTC, CRANK SHAFT POSITION,THROTTLE MOTOR & SENSOR, KNOCK), CAM SHIFT MODULE CIRCUIT 2003 MODEL ~ ACTUATOR, RESONANCE FLAPCIRCUIT 2003 MODEL ~ CIRCUIT REXTON 2004.04… -

Page 70

0-18 1491-01 DIGITAL CLOCK, ENG TEMP SENSOR, IMMOBILIZER CIRCUIT O2 SENSOR 2003 MODEL ~ 2003 MODEL ~ CIRCUIT REXTON 2004.04… -

Page 71

0-19 1491-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 72: Ecu(Xdi)

0-20 1491-01 ECU(XDi) 1491-01 MAIN RLY, PEDAL MODULE, SENSOR, FUEL FILTER WARNING LAMP, IMMOBILIZER, SENSOR(FUEL VALVE(TURBO CHANGER BOOSTER, VACUUM PRESSURE, CAM SHAFT, BOOSTER PRESSURE, CRANK MODULE, INLETMETERING VALVE) SHAFT, KNOCK,WATER PUMP, FUEL TEMP) CIRCUIT REXTON 2004.04…

-

Page 73

0-21 8210-01 3) INJECTOR, CAN LINE (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 74: Diagnosis Circuit

0-22 8210-01 DIAGNOSIS CIRCUIT 8211-01 1) ~ 2002 MODEL 2) 2003~ MODEL CIRCUIT REXTON 2004.04…

-

Page 75

0-23 3110-01 3) XDi (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 76: Tcu(Transmission Control Unit 4-Speed)

0-24 3110-01 TCU(TRANSMISSION CONTROL UNIT 4-SPEED 3110-01 1) DSL ~ 2002 MODEL 2) GSL ~ 2002 MODEL CIRCUIT REXTON 2004.04…

-

Page 77

0-25 3110-01 3) DSL 2003 MODEL ~ 4) GSL 2003 MODEL ~ CIRCUIT REXTON 2004.04… -

Page 78

0-26 3110-01 5) 2004 MODEL (DSL) (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 79: Tcu (5-Speed)

0-27 3110-01 TCU (5-SPEED) 3110-01 1) START MOTOR, A/T LEVER, CAN LINE (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 80

0-28 3410-01 2) SOLENOID OIL TEMP SENSOR, SPEED SENSOR (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 81: Tccu (Transfercase Control Unit)

0-29 3410-01 TCCU (TRANSFERCASE CONTROL UNIT) 3410-01 1) ~ 2002 MODEL 2) 2003 MODEL CIRCUIT REXTON 2004.04…

-

Page 82

0-30 3410-01 3) 2004 MODEL ~ 4) XDi CIRCUIT REXTON 2004.04… -

Page 83

0-31 3232-34 1) CONNECTOR INFORMATION 2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 84: Tod(Torque On Demand)

0-32 3232-34 TOD(TORQUE ON DEMAND) 3232-34 1) ~ 2002 MODEL 2) 2003 MODEL ~ CIRCUIT REXTON 2004.04…

-

Page 85

0-33 4892-01 3) XDi (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 86: Brake System

0-34 4892-01 BRAKE SYSTEM 4892-01 1) ABS & ABS/ABD 5.3 II 2) ABS(TEVES) CIRCUIT REXTON 2004.04…

-

Page 87

0-35 4892-01 3) ABS/ESP(TEVES) (1) WHEEL SPEED SENSOR, STOP LAMP SW, DIAGNOSIS, WARNING LAMP (2) BRAKE PRESSURE SENSOR, SWAS, SENSOR CLUSTER, ESP OFF SW CIRCUIT REXTON 2004.04… -

Page 88

0-36 3110-01 A. CONNECTOR INFORMATION B. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 89: A/T Shift Lock Circuit

0-37 8810-01 A/T SHIFT LOCK CIRCUIT 3110-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 90: Air Bag & Side Air-Bag Circuit

0-38 8010-01 8810-01 AIR BAG & SIDE AIR-BAG CIRCUIT (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 91: Cluster

0-39 8010-01 CLUSTER 8010-01 1) POWER SUPPLY, GROUND, LAMP (FUEL LOW WARNING, 4H, 2) WARNING LAMP, DEFOGGER CIRCUIT ~ 2002 MODEL 4L) CIRCUI ~ 2002 MODEL CIRCUIT REXTON 2004.04…

-

Page 92

0-40 8010-01 POWER SUPPLY, GROUND, LAMP (FUEL LOW WARNING, 4H, 4) WARNING LAMP, DEFOGGER CIRCUIT 2003 MODEL ~ 4L) CIRCUIT 2003 MODEL ~ CIRCUIT REXTON 2004.04… -

Page 93

0-41 8010-01 3) XDi GAUGE(SPEED, RPM, FUEL, TEMP), WARNING(FUEL, DR OPEN, FUEL WARNING(BAT CHANGE OIL, BRAKE, EGR CHECK, AIR BAG, SSPS, FILTER, ABS/ESP) SEAT BELT), TURNSIGNAL DEFOGGER CIRCUIT REXTON 2004.04… -

Page 94

0-42 8010-01 A. CONNECTOR INFORMATION B. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 95: Multi Meter Circuit

0-43 8611-09 MULTI METER CIRCUIT 8010-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 96: Rain Sensing Wiper Circuit

0-44 8611-09 RAIN SENSING WIPER CIRCUIT 8611-09 1) ~ 2002 MODEL (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 97

0-45 7410-04 2) XDi, 2003 MODEL ~ (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 98: Power Seat Circuit

0-46 7410-32 POWER SEAT CIRCUIT (1) CONNECTOR INFORMATION 7410-04 (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 99: Frt Seat Warmer(W/Omemory)

0-47 8410-30 FRT SEAT WARMER(W/O MEMORY) 7410-32 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 100: Power O/Side Mirror, Defogger Seat Warmer Circuit(W/ Memory)

0-48 8410-30 P OWER O/SIDE MIRROR, DEFOGGER SEAT 8410-30 WARMER CIRCUIT(W/ MEMORY) (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 101: Power O/Side Mirror, Defogger Circuit (W/Omemory)

0-49 8410-30 POWER O/SIDE MIRROR, DEFOGGER CIRCUIT 8410-30 (W/O MEMORY) 1) ~ 2002 MODEL (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 102

0-50 8710-01 2) XDi (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITIO CIRCUIT REXTON 2004.04… -

Page 103: Central Door Locking System

0-51 7410-00 CENTRAL DOOR LOCKING SYSTEM 8710-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 104: Seat Belt, Tension Reducer Circuit (2002 Model Only)

0-52 7410-04 SEAT BELT, TENSION REDUCER CIRCUIT 7410-00 (2002 MODEL ONLY) (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 105: Passenger Power Seat Circuit

0-53 8310-10 PASSENGER POWER SEAT CIRCUIT 7410-04 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 106: Auto Light Control Circuit

0-54 8310-10 AUTO LIGHT CONTROL CIRCUIT 8310-10 1) ~ 2002 MODEL (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 107

0-55 8711-02 2) XDi (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 108: Stics ~ 2002 Model

0-56 8711-02 STICS ~ 2002 MODEL 8711-02 POWER SUPPLY, GND, CHIME BELL, BUZZER, WARNING FRT WIPER, DR SWITCH, LAMP (ROOM, MAP) CIRCUIT LAMP (PARKING BRAKE, SEATBELT) CIRCUIT CIRCUIT REXTON 2004.04…

-

Page 109

0-57 8711-02 DR LOCK, DEFOGGER, POWER WINDOW CIRCUIT (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 110: Stics 2003 Model

0-58 8711-02 STICS 2003 MODEL 8711-02 POWER SUPPLY, GND, CHIME BELL, BUZZER, WARNING 2) FRT WIPER, DR SWITCH, LAMP (ROOM, MAP) CIRCUIT LAMP (PARKING BRAKE, SEATBELT) CIRCUIT CIRCUIT REXTON 2004.04…

-

Page 111

0-59 8711-02 3) DR LOCK, DEFOGGER, POWER WINDOW CIRCUIT (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 112: Stics Xdi

0-60 8711-02 STICS XDi 8711-02 POWER SUPPLY, GND, CHIME BELL, BUZZER, WARNING 2) FRT WIPER, DR SWITCH, LAMP (ROOM, MAP) CIRCUIT LAMP (PARKING BRAKE, SEATBELT) CIRCUIT CIRCUIT REXTON 2004.04…

-

Page 113

0-61 8511-05 3) DR LOCK, DEFOGGER, POWER WINDOW CIRCUIT (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 114: Power Window Circuit

0-62 7830-02 POWER WINDOW CIRCUIT 8511-05 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 115: Rear Glass Wiper & Washer Circuit

0-63 7830-02 7830-02 REAR GLASS WIPER & WASHER CIRCUIT 1) REAR GLASS WIPER & WASHER (W/O FLIP UP GLASS) 2) REAR GLASS DPS WIPER & WASHER (W/ FLIP UP GLASS) CIRCUIT REXTON 2004.04…

-

Page 116

0-64 8610-10 REAR GLASS DPS WIPER & WASHER (W/ FLIP UP GLASS) (XDi) (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 117: Horn Circuit

0-65 7632-20 HORN CIRCUIT 8610-10 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 118: Cigar Lighter Circuit

0-66 8711-02 CIGAR LIGHTER CIRCUIT 7632-20 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 119: Rekes Circuit (~ 2003 Model)

0-67 7340-03 REKES CIRCUIT (~ 2003 MODEL) 8711-02 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 120: Sun Roof Circuit

0-68 8310-01 SUN ROOF CIRCUIT 7340-03 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 121: Head Lamp Circuit

0-69 8310-01 HEAD LAMP CIRCUIT 8310-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 122: Head Lamp Leveling Device Circuit

0-70 8310-01 HEAD LAMP LEVELING DEVICE CIRCUIT 8310-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 123: Drl (Day Time Running Light) Unit (Eu)

0-71 8320-01 DRL (DAY TIME RUNNING LIGHT) UNIT (EU) 8310-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 124: Tail Lamp Circuit

0-72 8320-01 TAIL LAMP CIRCUIT 8320-01 1) ~ 2002 MODEL 2) 2003 MODEL CIRCUIT REXTON 2004.04…

-

Page 125

0-73 8310-01 3) XDi (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 126: Turn Signal & Hazard Lamp Circuit

0-74 8310-01 8310-01 TURN SIGNAL & HAZARD LAMP CIRCUIT 1) ~ 2002 MODEL 2) 2003 MODEL CIRCUIT REXTON 2004.04…

-

Page 127

0-75 8310-23 3) XDi (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 128: Fog Lamp Circuit

0-76 8310-23 FOG LAMP CIRCUIT 8310-23 1) ~ 2002 MODEL (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 129

0-77 8320-01 2) XDi (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 130: Stop & Back Up Lamp Circuit

0-78 7770-08 8320-01 STOP & BACK UP LAMP CIRCUIT (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 131: Interior Lamp Circuit

0-79 7770-03 INTERIOR LAMP CIRCUIT (1) CONNECTOR INFORMATION 7770-08 (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 132: Auto Dimming Room Mirror Circuit

0-80 8910-02 AUTO DIMMING ROOM MIRROR CIRCUIT 7770-03 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 133: Audio, Digital Ciock Circuit

0-81 8931-01 AUDIO, DIGITAL CIOCK CIRCUIT (1) CONNECTOR INFORMATION 8910-02 (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 134: Audio(Multi Vision)

0-82 8931-01 AUDIO(MULTI VISION) 8931-01 1) HEAD UNIT, 2CH EXT AMP, REMOCON, NAVI UNIT, GPS (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 135

0-83 6810-18 2) HEAD UNIT, TUNER UNIT, VCD CHANGER (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 136: Air-Con (Manual, Dsl) ~ 2002 Model

0-84 6810-18 AIR-CON (MANUAL, DSL) ~ 2002 MODEL 6810-18 1) ACTUATOR (MODE, AIR MIX), BLOWER UNIT CIRCUIT 2) INTAKE MOTOR, BLOWER MOTOR CIRCUIT CIRCUIT REXTON 2004.04…

-

Page 137: Air-Con (Manual, Dsl) 2004 Model

0-85 6810-18 AIR-CON (MANUAL, DSL) 2004 MODEL ~ 6810-18 1) ACTUATOR (MODE, AIR MIX), BLOWER UNIT CIRCUIT 2) INTAKE MOTOR, BLOWER MOTOR CIRCUIT CIRCUIT REXTON 2004.04…

-

Page 138: Air-Con (Manual, Dsl) Xdi

0-86 6810-18 AIR-CON (MANUAL, DSL) XDi 6810-18 1) ACTUATOR (MODE, AIR MIX), BLOWER UNIT CIRCUIT 2) INTAKE MOTOR, BLOWER MOTOR CIRCUIT CIRCUIT REXTON 2004.04…

-

Page 139

0-87 6810-18 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 140: Fatc (Full Auto Temperature Control)

0-88 6810-18 FATC (FULL AUTO TEMPERATURE CONTROL) 6810-18 CIRCUIT DIESEL 1) AIR MIX ACTUCTOR, SENSOR (SUN, AMBIENT, INCAR, 2) ACTURATOR (MODE, INTAKE) CIRCUIT WATER TEMP) CIRCUIT CIRCUIT REXTON 2004.04…

-

Page 141: Fatc (Full Auto Temperature Control) Circuit Gasoline & Xdi

0-89 6810-18 FATC (FULL AUTO TEMPERATURE CONTROL) 6810-18 CIRCUIT GASOLINE & XDi AIR MIX ACTUCTOR, SENSOR (SUN, AMBIENT, INCAR, 2) ACTURATOR (MODE, INTAKE) CIRCUIT WATER TEMP) CIRCUIT CIRCUIT REXTON 2004.04…

-

Page 142

0-90 7010-06 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 143: Immobilizer (Dsl)

0-91 8790-01 IMMOBILIZER (DSL) 7010-06 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 144: Parking Aid Circuit

0-92 4610-00 PARKING AID CIRCUIT 8790-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 145: Trailer Connector Circuit

0-93 6810-15 TRAILER CONNECTOR CIRCUIT 4610-00 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 146: Coefficient)

0-94 6910-01 P .T.C HEATER(POSITIVE TEMPERATURE 6810-15 COEFFICIENT) (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 147: Ffh (Fuel Fired Heater)

0-95 4620-12 FFH (FUEL FIRED HEATER) 6910-01 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04…

-

Page 148

0-96 4620-12 S.S.P.S 4620-12 (1) CONNECTOR INFORMATION (2) CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CIRCUIT REXTON 2004.04… -

Page 149

VEHICLE GENERAL 0000-00 VEHICLE GENERAL VEHICLE GENERAL 1. VEHICLE SPECIFICATIONS….2. VEHICLE IDENTIFICATION….3. GUIDELINES FOR SERVICE WORK SAFETY……….4. LIFTING POINTS……..5. TIGHTENING TORQUE OF STANDARD BOLTS……….. 6. CLEANNESS………. -

Page 151: Vehicle Specifications

01-3 0000-00 0000-00 VEHICLE GENERAL GENERAL 1. VEHICLE SPECIFICATIONS 1) Vehicle Dimension VEHICLE GENERAL undefined…

-

Page 152

01-4 0000-00 2) Specifications VEHICLE GENERAL undefined… -

Page 153

01-5 0000-00 ▶Specifications (Cont’d) VEHICLE GENERAL undefined… -

Page 154

01-6 0000-00 3) Maintenance ▶Major Components and Service Interval VEHICLE GENERAL undefined… -

Page 155

01-7 0000-00 ▶Lubrication Chart ※ Please contact Ssangyong Dealer for approved alternative fluid. In only case not available MB 229.1 or 229.3, API or ACEA oil may be accepted, ※※ however it would rather recommend to shorten the change interval around 30%. -

Page 156: Vehicle Identification

Vehicle identification number (VIN) is is on the right front axle upper frame. [KPTPOA19S1P 122357] K.. Nation (K: Korea) P .. Maker Identification (P: Ssangyong Motor Company) T .. Vehicle Type (T: Passenger car — 4WD) P .. Line Models (P: Rexton) O . Body Type (O: 5-door) A..

-

Page 157

01-9 0000-00 3) Engine Serial Number The engine serial number is stamped on the lower area of cylinder block in exhaust manifold side. 4) Manual Transmission Number The transmission label is affixed on the upper area of clutch housing. 5) Automatic Transmission Number The transmisson label is affixed on the right area of transmission housing. -

Page 158: Guidelines For Service Work Safety

01-10 0000-00 3. GUIDELINES FOR SERVICE WORK SAFETY 1) General To maintain and operate the vehicle under optimum state by performing safe service works, the service works should be done following correct methods procedures. Accordingly, the purpose of this manual is to prevent differences that can be caused by personal working method, skill, ways and service procedures and to allow…

-

Page 159

01-11 0000-00 2) Cautions on Inspection/Service During service works, be sure to observe below general items for your safety. For service works, be sure to disconnect battery negative (-) terminal if not starting and · inspection. · While inspecting vehicle and replacing various consumable parts, be sure to take caution not to damage vehicle and injure people. -

Page 160

01-12 0000-00 3) Guidelines on Engine Service To prevent personal injuries and vehicle damages that can be caused by mistakes during engine and unit inspection/ repair and to secure optimum engine performance and safety after service works, basic cautions and service work guidelines that can be easily forgotten during engine service works are described in. -

Page 161

01-13 0000-00 ▶ Fuel and lubrication system Painted surface of the body can be damaged or rubber products (hoes) can be corroded if engine oil and fuel are spilled over. If spilled over engine, foreign materials in air can be accumulated on the engine damaging fuel system. -

Page 162

01-14 0000-00 4) During Service Work — Inspection Before lifting up the vehicle with lift, correctly support the lifting points and lift When using a jack, park the vehicle on the level ground and block front and rear wheels. Position the jack under the frame and lift up the vehicle and then support with chassis stand before service work. -

Page 163

01-15 0000-00 Never reuse cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them with new. If reused, normal functions cannot be maintained. Align the disassembled parts in clean according to disassembling order and group for easy assembling. According to installing positions, the bolts and nuts have different hardness and design. -

Page 164

01-16 0000-00 5) During Service Work for Electric Devices Be careful not to modify or alter electrical system and electrical device. Or there can be vehicle fire or serious damage. Be sure to disconnect battery negative (- ) terminal during every service work. Before disconnecting battery negative (-) terminal, turn off ignition key. -

Page 165: Lifting Points

01-17 0000-00 4. LIFTING POINTS 1) Lifting Positions ▶4-post lift As illustrated, position the vehicle on the 4-post lift securely and block the front and rear of each tire not to move during working. During lifting, be sure to check whether vehicle is empty Board-on lift connection device installed in front of vehicle should be positioned in front of ·…

-

Page 166: Tightening Torque Of Standard Bolts

01-18 0000-00 5. TIGHTENING TORQUE OF STANDARD BOLTS Tightening Torque By Bolt Specification ▶ Metric bolt strength is embossed on the Determine extra proper tightening torque head of each bolt. The strength of bolt if tightens with washer or packing. can be classified as 4T, 7T, 8.8T, 10.9T, If tightens bolts on the below materials, 11T and 12.9T in general.

-

Page 167: Cleanness

01-19 0000-00 6. CLEANNESS 1) Cleanness of Engine Fuel System and Service Procedures The fuel system for DI engine consists of transfer (low pressure) line and high pressure line. Its highest pressure reaches over 1600 mbar. Some components in injector and HP pump are machined with 100 μm of preciseness.

-

Page 168

01-20 0000-00 2) Job procedures Always keep the workshop and lift clean (especially, from dust). Always keep the tools clean (from oil or foreign materials). Wear a clean vinyl apron to prevent the fuzz, dust and foreign materials from getting into fuel system. -

Page 169

01-21 0000-00 Follow the job procedures. If you find a defective component, replace it with new one. Disconnect the negative battery cable. Use special tools and torque wrench to perform the correct works. Once disconnected, the fuel pipes between HP pump and fuel rail and between fuel rail and each injector should be replaced with new ones. -

Page 170

01-22 0000-00 Plug the removed components with clean and undamaged sealing caps and store it into the box to keep the conditions when it was installed. Clear the high pressure offset value from scan tool after replacing the high pressure pump. To supply the fuel to transfer line of HP pump press the priming pump until it becomes hard. -

Page 171

01-23 0000-00 3) DI Engine and Its Expected Problems and Remedies Can be Caused by Water in Fuel (1) SYSTEM SUPPLEMENT AGAINST PARAFFIN SEPARATION. In case of Diesel fuel, paraffin, one of the elements, can be separated from fuel during winter and then can stick on the fuel filter blocking fuel flow and causing difficult starting finally. -

Page 173

01-3 0000-00 1113-01 ENGINE ASSEMBLY GENERAL 1. SPECIFICATIONS 1) Fastener Tightening Specifications ENGINE ASSEMBLY undefined… -

Page 174

01-4 0000-00 ▶ Fastener Tightening Specifications (Cont’d) ENGINE ASSEMBLY undefined… -

Page 175

02-3 0000-00 2211-06 FUEL SYSTEM GENERAL 1. FUEL SYSTEM SPECIFICATION ▶ Use Only Unleaded Fuel Rated at 89 Octane or Higher Fuel quality and additives contained in fuel have a significant effect on power output, drivability, and life of the engine. Fuel with too low an octane number can cause engine knock. -

Page 176

02-4 0000-00 ▶ Temperature VS Resistance FUEL SYSTEM undefined… -

Page 177

02-5 0000-00 CONFIGURATION AND PROCESS 1. FUEL SYSTEM The function of the fuel metering system is to deliver the correct amount of fuel to the engine under all operating conditions. The fuel is delivered to the engine by the individual fuel injectors mounted into the intake manifold near each cylinder. -

Page 178

02-6 0000-00 1) Starting Mode When the ignition is turned ON, the ECM turns the fuel pump relay on for 1 second. The fuel pump then builds fuel pressure. The ECM also checks the Engine Coolant Temperature (ECT) sensor and the Throttle Position (TP) sensor and determines the proper air/fuel ratio for starting the engine. -

Page 179

02-7 0000-00 7) Battery Voltage Correction Mode When battery voltage is low, the ECM can compensate for a weak spark delivered by the ignition module by using the following methods: Increasing the fuel injector pulse width. Increasing the idle speed rpm. Increasing the ignition dwell time. -

Page 182

04-3 0000-00 2411-01 EXHAUST SYSTEM OVERVIEW AND OPERATION PROCESS 1. CRANKCASE VENTILATION SYSTEM 1) Operation at Idling and Mid- Load 1 HFM Sensor 12 Crank Chamber 2 Cylinder Head Cover 13 Oil Return Pipe 3 Oil Spearation Chamber (Full-Load or Over Mid- Load) 14 Oil Pan 4 Intake Air Duct (Cross Pipe) 15 Timing Gear Case Cover… -

Page 183

04-4 0000-00 ▶ Operation at Idling and Mid- Load The throttle valve (6) is closed or very partially opened, and the vacuum pressure in intake manifold is high. The blow-by gas and the fresh air that is additionally supplied through the vent connection (D) in the crank-case in partial load gets supplied to the combustion chamber from the crank chamber (12) through the oil separation chamber (11), airconditioner bracket (10), vent line (9), and restrictor (7) mounted to the cylinder head. -

Page 184

04-5 0000-00 2) Operation When Full- Load at Partial Load 1 HFM Sensor 12 Crank Chamber 2 Cylinder Head Cover 13 Oil Return Pipe 3 Oil Spearation Chamber (Full-Load or Over Mid-Load) 14 Oil Pan 4 Intake Air Duct (Cross Pipe) 15 Timing Gear Case Cover 5 Vent Line (Full-Load or Over Mid-Load) 16 Crankcase… -

Page 185

04-6 0000-00 ▶ Operation When Full- Load at Partial Load The throttle valve (6) is partially opened or fully opened. The air flows very rapidly through the vent line (5) s connection (D) and the intake air duct when full load at partial load. Consequently, most of the low-by gases are supplied to the combustion chamber through the timing gear case cover (15), chain housing (17), oil separation chamber (3), vent line (5), throttle valve (6), and intake manifold (8). -

Page 186

05-3 0000-00 1532-24 LUBRICATION SYSTEM OVERVIEW AND OPERATION PROCESS 1. OIL CIRCULATION 1 Oil Strainer 16 Oil Supply (To Chain Tensioner) 2 Oil Pump 17 Camshaft 3 Oil Pan 18 Cam Bearing 4 Oil Non-Return Valve 19 Valve 5 Oil Filter 20 Oil Gallery (Supply Oil to Intake Tappet) 6 Oil Filter Bypass Valve 21 Oil Gallery (Supply Oil to Exhaust Tappet) -

Page 187

06-3 0000-00 1441-01 ENGINE ELECTRICAL OVERVIEW AND OPERATION PROCESS 1. IGNITION SYSTEM This ignition system does not use a conventional distributor and coil. It uses a crankshaft position sensor input to the Engine Control Module (ECM). The ECM then determines Electronic Spark Timing (EST) and triggers the electronic ignition system ignition coil. -

Page 188

NO DATA… -

Page 189

08-3 0000-00 1430-01 ENGINE CONTROLS GENERAL 1. ENGINE AND ECM PROBLEM CHECK REPORT 1) Vehicle and Customer Information 2) MIL Information 3) Problem Description ENGINE CONTROLS undefined… -

Page 190

08-4 0000-00 4) Condition When Problem Occurs ENGINE CONTROLS undefined… -

Page 191

08-5 0000-00 2. SPECIFICATIONS 1) Engine Data Display Table Condition : Warmed up, idle, P/N or neutral ENGINE CONTROLS undefined… -

Page 192

08-6 0000-00 2) Fastener Tightening Specifications ENGINE CONTROLS undefined… -

Page 193

08-7 0000-00 OVERVIEW AND OPERATION PROCESS 1. SCHEMATIC AND ROUTING DIAGRAMS 1) ECM Wiring Diagram (2.3L DOHC — 1 of 7) (MSE 3.53D) ENGINE CONTROLS undefined… -

Page 194

08-8 0000-00 2) ECM Wiring Diagram (2.3L DOHC — 2 of 7) (MSE 3.53D) ENGINE CONTROLS undefined… -

Page 195

08-9 0000-00 3) ECM Wiring Diagram (2.3L DOHC — 3 of 7) (MSE 3. 53D) ENGINE CONTROLS undefined… -

Page 196

08-10 0000-00 4) ECM Wiring Diagram (2.3L DOHC — 4 of 7) (MSE 3.53D) ENGINE CONTROLS undefined… -

Page 197

08-11 0000-00 5) ECM Wiring Diagram (2.3L DOHC — 5 of 7) (MSE 3.53D) ENGINE CONTROLS undefined… -

Page 198

08-12 0000-00 6) ECM Wiring Diagram (2.3L DOHC — 6 of 7) (MSE 3.53D) ENGINE CONTROLS undefined… -

Page 199

08-13 0000-00 7) ECM Wiring Diagram (2.3L DOHC — 7 of 7) (MSE 3.53D) ENGINE CONTROLS undefined… -

Page 200

08-47 0000-00 ENGINE CONTROL MODULE 1491-01 Disconnect the negative battery cable. Remove cowl side trim form passenger side. Re-er to Section 9G, Interior trim. Remove the four securing nuts for the Engine Control Module (ECM) from the mounting bracket. 10 Nm (89 lb-in) Pull out the ECM from the bracket. -

Page 201

09-3 8510-23 8510-23 CRUISE CONTROL SYSTEM OVERVIEW AND OPERATION PROCESS 1. CRUISE CONTROL SWITCH The purpose of the cruise control system is to automatically maintain a vehicle speed set by the driver, without depressing the accelerator pedal. The cruise control switch is located under the right side of the steering wheel, and when this switch is operating «AUTO CRUISE»… -

Page 202

09-4 8510-23 1) When To Use Use the cruise control system only when (a) the traffic is not jammed, (b) driving on motorways or highways where there is no sudden change in the driving condition due to traffic lights, pedestrian, etc. Use the cruise control system only when driving on motorways or highways. -

Page 203

09-5 8510-23 2. CIRCUIT DIAGRAM 1) Configuration CRUISE CONTROL SYSTEM undefined… -

Page 204

09-6 8510-23 3. HOW TO OPERATE CRUISE CONTROL SWITCH 1) How To Set Speed To operate the cruise control system, accelerate the vehicle to the speed within the specified range below with depressing the accelerator pedal. — Cruise control operating range: between 36 km/h (22.37 mph) and 150 km/h (93.207 mph) When the desired speed is reached, which should be within the above range, push up the cruise control switch lever to ACCEL side (upwards arrow), or push down the switch lever to DECEL side (downwards arrow). -

Page 205

09-7 8510-23 2) Accelerating with the Cruise Control System (1) While the cruise control system is running To increase the set speed, push up the cruise control switch lever to ACCEL side and hold it until the desired speed is reached without depressing the accelerator pedal. When the desired speed is set, release the switch lever. -

Page 206

09-8 8510-23 3) Decelerating with the Cruise Control System (1) While the cruise control system is running To decrease the set speed, push down the cruise control switch lever to DECEL side and hold it until the desired speed is reached without depressing the brake pedal. But the cruise control system cannot maintain the cruise function at less than 34 km/h (21.13 mph). -

Page 207

09-9 8510-23 4) Recovery of Set Speed (RESUME) Even if the cruise control is cancelled, the previous set cruise speed can be recovered by operating the cruise control switch lever like below: — Pull the switch lever in the arrow direction shown in the illustration. This RESUME function works only when the vehicle speed is more than 36 km/h (22.37 mph) without using the accelerator or brake pedal. -

Page 208

09-10 8510-23 5) Normal Cancellation of the Cruise Control (OFF ↔ ON) The cruise control system will be cancelled when the button on the side of the switch is pressed, or when one of the following conditions is met: When the brake pedal is depressed or ESP is activated. When the vehicle speed is less than 34 km/h (21.13 mph). -

Page 209

01-3 0000-00 1113-01 ENGINE ASSEMBLY GENERAL 1. SPECIFICATIONS 1) Fastener Tightening Specifications ENGINE ASSEMBLY undefined… -

Page 210

01-4 0000-00 ▶ Fastener Tightening Specifications (Cont’d) ENGINE ASSEMBLY undefined… -

Page 211

02-3 0000-00 2211-06 FUEL SYSTEM GENERAL 1. FUEL SYSTEM SPECIFICATION ▶ Use Only Unleaded Fuel Rated at 89 Octane or Higher Fuel quality and additives contained in fuel have a significant effect on power output, drivability, and life of theengine. Fuel with too low an octane number can cause engine knock. -

Page 212

02-4 0000-00 ▶ Temperature VS Resistance FUEL SYSTEM REXTON 2004.12… -

Page 213

02-5 0000-00 OVERVIEW AND OPERATION PROCESS 1. FUEL SYSTEM The function of the fuel metering system is to deliver the correct amount of fuel to the engine under all operating conditions. The fuel is delivered to the engine by the individual fuel injectors mounted into the intake manifold near each cylinder. -

Page 214

02-6 0000-00 ▶ Run Mode The run mode has two conditions called »open loop» and »closed loop». Open Loop ▶ When the engine is first started and it is above 690 rpm, the system goes into «open loop» operation. In «open loop», the ECM ignores the signal from the O2S and calculates the air/fuel ratio based on inputs from the ECT sensor and the MAF sensor. -

Page 215

NO DATA… -

Page 216

NO DATA… -

Page 217

05-3 0000-00 1542-07 LUBRICATION SYSTEM GENERAL 1. ENGINE OIL SPECIFICATION 1 Drain Plug …….. 25 Nm (18 lb-ft) 2 Oil Filter 3 Engine Oil Filler Cap 4 Dipstick Gauge ▶ Specifications LUBRICATION SYSTEM undefined… -

Page 218

05-4 0000-00 OVERVIEW AND OPERATION PROCESS 1. OIL CIRCULATION 1 Oil Pump 20 Oil Supply (To Exhaust Camshaft Bearing) 2 Oil Gallery (to oil filter) 21 Oil Supply (To Intake Camshaft Bearing) 3 Oil Filter 22 Oil Gallery (Oil Supply to Exhaust Valve Tappet) 4 Oil Pressure Switch 23 Oil Gallery (Oil Supply to Intake Valve Tappet) 5 Main Oil Gallery… -

Page 219

06-3 0000-00 1441-01 ENGINE ELECTRICAL OVERVIEW AND OPERATIONPROCESS 1. IGNITION SYSTEM This ignition system does not use a conventional distributor and coil. It uses a crankshaft position sensor input to the Engine Control Module (ECM). The ECM then determines Electronic Spark Timing (EST) and triggers the electronic ignition system ignition coil. This type of distributorless ignition system uses a »waste spark»… -

Page 220

NO DATA… -

Page 221

08-3 0000-00 1430-01 ENGINE CONTROLS GENERAL 1. SPECIFICATIONS 1) Engine Data Display Table ENGINE CONTROLS undefined… -

Page 222

08-4 0000-00 2) Fastener Tightening Specifications ENGINE CONTROLS undefined… -

Page 223

08-5 0000-00 OVERVIEW AND OPERATION PROCESS 1. SCHEMATIC AND ROUTING DIAGRAMS 1) ECM Wiring Diagram (3.2L DOHC — 1 of 7) (MSE 3.63D) ENGINE CONTROLS undefined… -

Page 224

08-6 0000-00 2) ECM Wiring Diagram (3.2L DOHC — 2 of 7) (MSE 3.63D) ENGINE CONTROLS undefined… -

Page 225

08-7 0000-00 3) ECM Wiring Diagram (3.2L DOHC — 3 of 7) (MSE 3.63D) ENGINE CONTROLS undefined… -

Page 226

08-8 0000-00 4) ECM Wiring Diagram (3.2L DOHC — 4 of 7) (MSE 3.63D) ENGINE CONTROLS undefined… -

Page 227

08-9 0000-00 5) ECM Wiring Diagram (3.2L DOHC — 5 of 7) (MSE 3.63D) ENGINE CONTROLS undefined… -

Page 228

08-10 0000-00 6) ECM Wiring Diagram (3.2L DOHC — 6 of 7) (MSE 3.63D) ENGINE CONTROLS undefined… -

Page 229

08-11 0000-00 7) ECM Wiring Diagram (3.2L DOHC — 7 of 7) (MSE 3.63D) ENGINE CONTROLS undefined… -

Page 230

09-3 8510-23 8510-23 CRUISE CONTROL SYSTEM OVERVIEW AND OPERATION PROCESS 1. CRUISE CONTROL SWITCH The purpose of the cruise control system is to automatically maintain a vehicle speed set by the driver, without depressing the accelerator pedal. The cruise control switch is located under the right side of the steering wheel, and when this switch is operating «AUTO CRUISE»… -

Page 231

09-4 8510-23 1) When To Use Use the cruise control system only when (a) the traffic is not jammed, (b) driving on motorways or highways where there is no sudden change in the driving condition due to traffic lights, pedestrian, etc. Use the cruise control system only when driving on motorways or highways. -

Page 232

09-5 8510-23 2. CIRCUIT DIAGRAM 1) Configuration CRUISE CONTROL SYSTEM undefined… -

Page 233

09-6 8510-23 3. HOW TO OPERATE CRUISE CONTROL SWITCH 1) How To Set Speed To operate the cruise control system, accelerate the vehicle to the speed within the specified range below with depressing the accelerator pedal. — Cruise control operating range: between 36 km/h (22.37 mph) and 150 km/h (93.207 mph) When the desired speed is reached, which should be within the above range, push up the cruise control switch lever to ACCEL side (upwards arrow), or push down the switch lever to DECEL side (downwards arrow). -

Page 234

09-7 8510-23 2) Accelerating with the Cruise Control System (1) While the cruise control system is running To increase the set speed, push up the cruise control switch lever to ACCEL side and hold it until the desired speed is reached without depressing the accelerator pedal. When the desired speed is set, release the switch lever. -

Page 235

09-8 8510-23 3) Decelerating with the Cruise Control System (1) While the cruise control system is running To decrease the set speed, push down the cruise control switch lever to DECEL side and hold it until the desired speed is reached without depressing the brake pedal. But the cruise control system cannot maintain the cruise function at less than 34 km/h (21.13 mph). -

Page 236

09-9 8510-23 4) Recovery of Set Speed (RESUME) Even if the cruise control is cancelled, the previous set cruise speed can be recovered by operating the cruise control switch lever like below: — Pull the switch lever in the arrow direction shown in the illustration. This RESUME function works only when the vehicle speed is more than 36 km/h (22.37 mph) without using the accelerator or brake pedal. -

Page 237

09-10 8510-23 5) Normal Cancellation of the Cruise Control (OFF ↔ ON) The cruise control system will be cancelled when the button on the side of the switch is pressed, or when one of the following conditions is met: When the brake pedal is depressed or ESP is activated. When the vehicle speed is less than 34 km/h (21.13 mph). -

Page 238

ENGINE GENERAL 0000-00 ENGINE GENERAL GENERAL 1. STRUCTURE………. OVERVIEW AND OPERATION PROCESS 1. ENGINE CONTROLS COMPONENTS..2. INTAKE SYSTEM COMPONENTS..3. EXHAUST SYSTEM COMPONENTS..4. LUBRICATION SYSTEM COMPONENTS……..5. COOLING SYSTEM COMPONENTS..6. FUEL SYSTEM COMPONENTS….. -

Page 240: General

01-3 0000-00 0000-00 ENGINE GENERAL GENERAL 1. STRUCTURE ▶ Front view ▶ Rear view TVD (Torsional Vibration Cooling fan pulley Oil filter Damper) Aut tensioner pulley Vacuum pump Air conditioner compressor Auto tensioner Crank position sensor Power steering pump pulley Poly-groove belt EGR valve Idle pulley…

-

Page 241

01-4 0000-00 ▶ Top view Cylinder head cover Fuel pipe Booster pressure sensor Intake manifold Injector Oil separator Water outlet port Fuel return line Oil dipstic Common rail Oil filler cap EGR center pipe Fuel pressure sensor Glow plug ENGINE GENERAL undefined… -

Page 242

01-5 0000-00 ▶ Left side view ▶ Right side view Cylinder head EGR — RH (#3) pipe Turbocharger vacuum modulator Cylinder block Oil separator EGR valve vacuum modulator Oil dipstic EGR valve Drain plug HP pump Exhaust manifold Turbocharger ENGINE GENERAL undefined… -

Page 243: Overview And Operation Process

01-6 0000-00 OVERVIEW AND OPERATION PROCESS 1. ENGINE CONTROLS COMPONENTS 1) ECU Related Components ENGINE GENERAL undefined…

-

Page 244

01-7 0000-00 2) Engine And Sensors ENGINE GENERAL undefined… -

Page 245

01-8 0000-00 3) Electrical Components And Pre Heating System ENGINE GENERAL undefined… -

Page 246: Intake System Components

01-9 0000-00 2. INTAKE SYSTEM COMPONENTS ENGINE GENERAL undefined…

-

Page 247

01-10 0000-00 ▶ Intake Air Flow Chart ENGINE GENERAL undefined… -

Page 248: Exhaust System Components

01-11 0000-00 3. EXHAUST SYSTEM COMPONENTS ENGINE GENERAL undefined…

-

Page 249

01-12 0000-00 ▶ Exhaust Air Flow Chart ENGINE GENERAL undefined… -

Page 250: Lubrication System Components

01-13 0000-00 4. LUBRICATION SYSTEM COMPONENTS ENGINE GENERAL undefined…

-

Page 251

01-14 0000-00 ▶ Lubrication Flow Chart Oil pump Oil restriction (inner — φ 4 mm) Oil gallery (to oil filter) Oil supply (to exhaust camshaft) Oil filter Oil supply (to intake camshaft) Oil pressure switch Oil supply (to exhaust camshaft bearing) Main oil gallery Oil supply (to intake camshaft bearing) Oil gallery (chain tensioner side) -

Page 252: Cooling System Components

01-15 0000-00 5. COOLING SYSTEM COMPONENTS ENGINE GENERAL undefined…

-

Page 253

01-16 0000-00 ▶ Coolant Flow Chart ENGINE GENERAL undefined… -

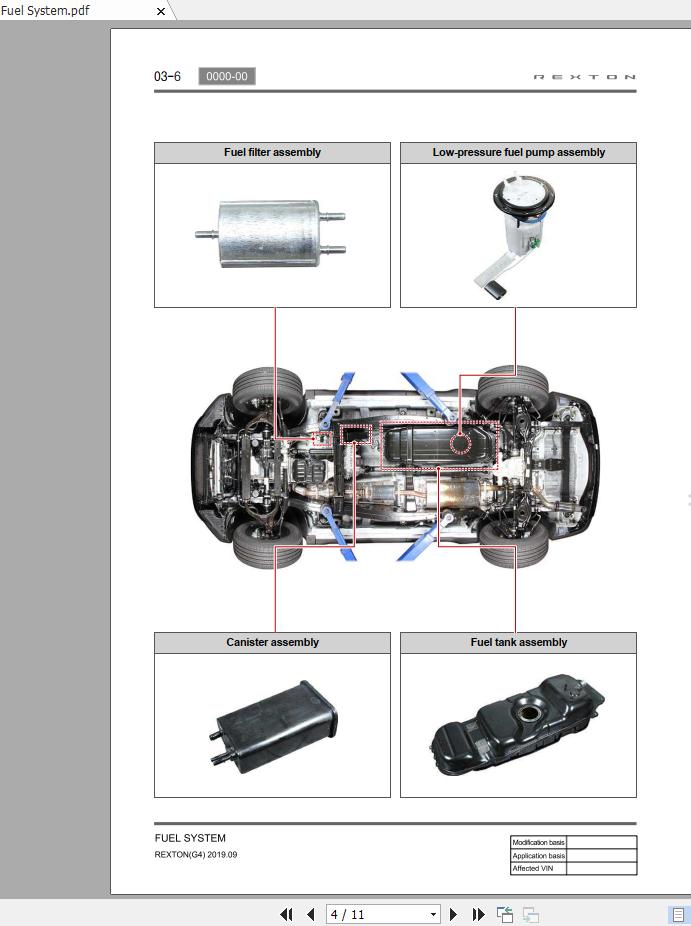

Page 254: Fuel System Components

01-17 0000-00 6. FUEL SYSTEM COMPONENTS ENGINE GENERAL undefined…

-

Page 255

01-18 0000-00 ▶ Fuel Supply System According to input signals from various sensors, engine ECU calculates driver’s demand (position of the accelerator pedal) and then controls overall operating performance of engine and vehicle on that time. ECU receives signals from sensors via data line and then performs effective engine air-fuel ratio controls based on those signals. -

Page 256

02-3 1212-01 1212-01 ENGINE ASSEMBLY GENERAL 1. D27DT ENGINE STRUCTURE 1) Major Components in Engine and Engine Compartment The advanced electronically controlled D27DT engine that has high pressure fuel system has been introduced to this vehicle. It satisfies the strict emission regulation and provides improved output and maximum torque. -

Page 257

02-4 1212-01 2) Engine Structure Front View Rear View 1. TVD (Torsional Vibration Damper) 7. Viscos fan clutch 13. Oil filter 2. Air conditioner compressor 8. Auto tensioner pulley 14. Vacuum pump 3. Power steering pump pulley 9. Auto tensioner 15. -

Page 258

02-5 1212-01 Top View 19. Cylinder head cover 24. Fuel pipe 29. Booster pressure sensor 20. Intake manifold 25. Injector 30. PCV valve and oil separator 21. Water outlet port 26. Fuel return line 31. Oil dipstick 22. Common rail 27. -

Page 259

02-6 1212-01 Left Side View Right Side View 33. Cylinder head 38. EGR-RH (#3) pipe 42. Turbo charger booster vacuum 34. Cylinder block 39. PCV valve and oil separator modulator 35. Oil pan 40. Oil dipstick 43. EGR valve vacuum modulator 36. -

Page 260

02-7 1212-01 2. SPECIFICATIONS ENGINE ASSEMBLY undefined… -

Page 261

02-8 1212-01 3. ENGINE PERFORMANCE CURVE ▶Output and Torque ENGINE ASSEMBLY undefined… -

Page 262

02-9 1212-01 ▶Oil Temperature/Pressure and Boost Pressure ENGINE ASSEMBLY undefined… -

Page 263

02-10 1212-01 4. TIGHTENING TORQUE ENGINE ASSEMBLY undefined… -

Page 264

02-11 1212-01 ENGINE ASSEMBLY undefined… -

Page 265

02-12 1212-01 ENGINE ASSEMBLY undefined… -

Page 266

03-3 1881-01 1881-01 ENGINE FUEL SYSTEM GENERAL 1. CAUTIONS FOR DI ENGINE This chapter describes the cautions for DI engine equipped vehicle. This includes the water separation from engine, warning lights, symptoms when engine malfunctioning, causes and actions. DI Engine ▶… -

Page 267

03-4 1881-01 ▶ Priming Pump The priming pump installed in fuel pump is the device to fill the fuel into the fuel filter. When the vehicle is under the conditions as below, press the priming pump until it becomes rigid before starting the engine. -

Page 268

03-5 1881-01 ▶ Draining the Water From Fuel Filter 1. Place the water container under the fuel filter. Turn the drain plug (2) to «A» direction to drain the water. Wait until a certain amount of fuel gets out from the port, then turn the drain plug to «B»… -

Page 269

03-6 1881-01 OVERVIEW AND OPERATION PROCESS 1. FUEL INJECTION SYSTEM 1) Electronic Control of Fuel System According to input signals from various sensors, engine ECU calculates driver’s demand (position of the accelerator pedal) and then controls overall operating performance of engine and vehicle on that time. -

Page 270

03-7 1881-01 2) Composition of Fuel System Components in fuel system are designed to generate and distribute high pressure, and they are controlled electronically by engine ECU. Accordingly, fuel system is completely different from injection pump type fuel supply system on the conventional Diesel engine. The fuel injection system in common rail engine is composed of transfer pressure section that transfers fuel in low pressure, high pressure section that transfers fuel in high pressure and ECU control section. -

Page 271

03-8 1881-01 3) Hydraulic Cycle in Fuel Line (Transfer and High Pressure Line) ENGINE FUEL SYSTEM undefined… -

Page 272

03-9 1881-01 4) Components of Low Pressure Transfer Line Low pressure stage is to supply sufficient fuel to high pressure section and components are as below. Fuel tank (including strainer) Hand priming pump Fuel filter Transfer pump Other low pressure fuel hoses (1) Fuel tank Fuel tank is made of anti-corrosion material and its allowable pressure is 2 times of… -

Page 273

03-10 1881-01 (3) Fuel filter It requires more purified fuel supply than conventional diesel engine. If there are foreign materials in the fuel, fuel system including pump components, delivery valve and injector nozzles may be damaged. Fuel filter purifies fuel before it reaches to high pressure pump… -

Page 274

03-11 1881-01 5) Components of High Pressure Transfer Line In the high pressure section, sufficient fuel pressure that injectors requires will be generated and stored. The components are as below: High pressure pump Rail pressure sensor Pressure limit valve Common rail High pressure pipe Injector Fuel pressure regulating valve (IMV) -

Page 275

03-12 1881-01 (3) High pressure pipe (fuel pipe) Fuel line transfers high pressure fuel. Accordingly, it is made of steel to endure intermittent high frequency pressure changes that occur under maximum system pressure and injection stops. Injection lines between rail and injectors are all in the same length;… -

Page 276

03-13 1881-01 6) Electrical Wiring Diagram ENGINE FUEL SYSTEM undefined… -

Page 277

04-3 2313-01 2313-01 ENGINE INTAKE SYSTEM OVERVIEW AND OPERATION PROCESS 1. COMPONENTS LOCATOR ENGINE INTAKE SYSTEM undefined… -

Page 278

04-4 2313-01 2. AIR FLOWS ▶ Work Flow of Intake System ENGINE INTAKE SYSTEM undefined… -

Page 279

05-3 0000-00 0000-00 ENGINE EXHAUST SYSTEM OVERVIEW AND OPERATION PROCESS 1. COMPONENTS LOCATOR ENGINE EXHAUST SYSTEM undefined… -

Page 280

05-4 0000-00 2. EXHAUST GAS FLOWS ENGINE EXHAUST SYSTEM undefined… -

Page 281

06-3 1533-01 1533-01 ENGINE LUBRICATION SYSTEM GENERAL 1. SPECIFICATIONS ※ Severe condition: When most trips include extended idling and/or frequent low-speed operation as in stop- and-go traffic. When most trips are less than 6 km (Operating when outside temperatures remain below freezing and when most trips are less than 16 km) When operating in dusty, sandy and salty areas In hilly or moutainous terrain… -

Page 282

06-4 1533-01 OVERVIEW AND OPERATION PROCESS 1. COMPONENTS LOCATOR ENGINE LUBRICATION SYSTEM undefined… -

Page 283