Сборник руководств на английском языке по техническому обслуживанию и ремонту + схемы электрооборудования автомобиля SsangYong Korando 1996-2006 годов выпуска.

- Автор: —

- Издательство: SsangYong

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 321,6 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту + схемы электрооборудования автомобиля SsangYong Korando с 2010 года выпуска.

- Автор: —

- Издательство: SsangYong

- Год издания: 2010-2013

- Страниц: —

- Формат: PDF

- Размер: 570,0 Mb

Руководство по техническому обслуживанию и ремонту автомобилей SsangYong New Actyon и SsangYong Korando C с 2010 года выпуска с дизельным двигателем объемом 2,0 л.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 347

- Формат: PDF

- Размер: 273,2 Mb

Руководство по техническому обслуживанию и ремонту автомобилей SsangYong New Actyon и SsangYong Korando C с 2010 года выпуска с дизельным двигателем объемом 2,0 л.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 352

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобилей SsangYong New Actyon и SsangYong Korando C с 2010 года выпуска с дизельным двигателем объемом 2,0 л.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 376

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту + каталог расходных запчастей автомобилей SsangYong Actyon и SsangYong Korando с 2011 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: 2015

- Страниц: 491

- Формат: —

- Размер: —

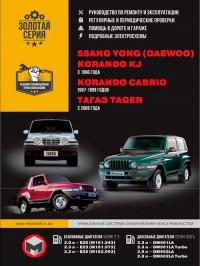

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей автомобилей SsangYong Korando и Tagaz Tager с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 402

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобилей SsangYong Korando с 1996 и Tagaz Tager с 2008 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 402

- Формат: —

- Размер: —

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

FOREWORD

This manual has been prepared to acquaint you with the operation and maintenance of

your new KORANDO and to provide important safety information. We urge you to read

it carefully and follow the recommendations to help assure the most enjoyable, safe,

and trouble-free operation of your vehicle.

When it comes to service, remember that your SSANGYONG dealer knows your ve-

hicle best and is interested in your complete satisfaction.

We would like to take this opportunity to thank you for choosing KORANDO and assure

you of our continuing interest in your motoring pleasure and satisfaction.

This manual should be considered as a permanent part of your vehicle, and must re-

main with the vehicle at the time of resale.

PYUNGTAEK, KOREA

Summary of Contents for SSANGYONG Korando

Эта краткая инструкция разработана Новосибирским Гуру автомобилей SY Korando и Musso Алексеем (MaxAlex Service). Как он сам ее прокомментировал: Данная инструкция составлена в виде авторитарных утверждений, не терпящих обсуждения. Типа «Суй в ж…у помидоры — некогда объяснять»

Вводная

Это не гоночная машина. Максимальная скорость 100 км/час

Это ЗАДНЕПРИВОДНАЯ машина. На полном приводе ездить нельзя. ДА! Нельзя! И особенно в гололед.

Расход солярки по паспорту 10 литров на 100 км. В реальности может доходить до 15 литров. Обусловлено некачественным топливом, городскими условиями и пробками.

Двигатель

О да! Это легенда… Мерседес OM601(2.3л четыре горшка) OM602(2,9л пять горшков) всеядные дизельные моторы с рядным ТНВД BOSCH.

Ресурс мотора 250 — 750 тыс. км. Может доходить до 1500 тыс. км. — все зависит от обслуживания.

Моторы лучше турбированые, т.к. без турбины машина с этим мотором больше похожа на мотоблок для окучивания овощей, чем на автомобиль.

Турбины боятся не надо — ее ресурс 200 — 250 тыс км. Грубая проверка турбины на живучесть производится просто: снимаем впускной патрубок, который идет от воздушного фильтра на турбину. Нежно (как клитор любимой женщины) берем двумя палацами вал турбины и покачиваем. Радиальный люфт вала допустим. Но если присутствует осевой люфт, то пора копить деньги на новую турбину.

Двигатель. Масло

Периодичность смены масла: раз в 5 тыс.км. Масло применять только с допуском MB229.3

Летом 10w40, зимой 5w40.

Объем масла 8 и 9 литров для моторов 2.3 и 2,9 соответственно.

Вместе с маслом рекомендую менять топливные и воздушные фильтра. Цена не большая, зато мотор дольше будет здоровым.

Двигатель. Топливная система

Это то, за что эти двигатели получили статус легендарных. Всеядные… У меня был случай, когда человек ездил неделю на чистом бензине.

В общем пофиг где и на какой заправке заправляться. Этот мотор сожрет все, а вас все равно обманут. Разница лишь в расходе и в тяговитости мотора на данном топливе. Не факт, что если сегодня на заправке вам залили хорошее топливо, то завтра оно будет таким же.

Раз в 50 тыс.км. Требуется замена распылителей. Естественно меняются теплоотводные шайбы под распылителями и шланги обратки. Рекомендую иметь в машине хотя бы 0,5 метров шланга обратки. Бывает эти шланги лопаются в самый неподходящий момент. Шланги обратки весьма специфические, у них внутренний диаметр 3,2 мм. Наша промышленность выпускает шланги начиная с 4 мм. Так что обмануть судьбу не удастся — покупайте дорогие оригинальные шланги.

Если у вас в дороге лопнул шланг обратки — не надо отчаиваться. Корейцы обо всем позаботились. Т.к. мы с вами заглушили клапан ЕГР (см. ниже), то в нашем распоряжении 1,5 метра шикарного вакуумного шланга. Этот шланг идет от стакана масляного фильтра по трубке кондиционера на правый борт капота — отрезаем и пользуемся! Как временное решение (на пару недель) — вполне работоспособно.

Раз в 150 тыс.км. Требуется замена форсунок в сборе.

Фильтр грубой очистки. В схеме питания оригинального мотора Мерседес установлен фильтр грубой очиски топлива. К сожалению на SY такой фильтр зачастую отсутствует, хотя тоже присутствует на картинках. Данную несправедливость нужно испрпвить. Поэтому идем в ближайший магазин и покупаем десяток топливных фильтров грубой очистки для дизеля. Типа BIG GB-612. В отличии от «жигулевского» фильтра, в дизельном фильтре вместо бумажного или поролонового фильтрующего элемента установлена нейлоновая или металлическая сеточка.

Фильтр врезаем в топливный шланг, который идет от металлической трубки топливной магистрали на топливоподкачивающий насос. Топливоподкачивающий насос установлен сбоку на ТНВД. ТНВД установлен с левой стороны двигателя.

Что нам дает фильтр грубой очистки:

Во первых мы визуально можем контролировать степень загрязнения топлива.

Во вторых фильтр отсеивает крупные частички грязи, что продляет жизнь топливоподкачивающему насосу и основному фильтру.

В третьих грубый фильтр хоть немного, но задерживает воду, которая находится в топливе.

В четвертых зимой смерзшийся парафин в первую очередь скапливается в фильтре грубой очистки, а не в основном фильтре.

Выводы из третьего и четвертого утверждения очень пригодятся нам зимой. Т.к. мы купили ни один, а десяток фильтров, то в том случае, когда парафин, либо вода забьет фильтр грубой очистки мы его легко и просто поменяем. Тем самым основной фильтр будет более-менее свободным от воды и замершего парафина. Менять основной фильтр на трассе в сорокаградусный мороз — это то еще удовольствие.

Рекомендую два раза в год (осенью и весной) делать промывку топливной системы специальной жидкостью Wynns Diesel System Purge.

Дополнительные фильтры типа «Сепар» — не нужны:

И подобные им смысла не имеют, а подчас еще и вредны. Посмотрите на нас топливоподкачивающий насос. Да, да, вот этот маленький смешной малыш, который прикреплен сбоку на ТНВД и есть топливоподкачивабщий насос. И уверяю вас, с подачей нужного количества топлива для работы мотора он справляется на «ура». В общем качает он топливо со скоростью примерно литр в минуту. Установив дополнительное сопротивление на пути потока топлива, мы рискуем обеспечить топливное голодание двигателя на больших оборотах и в добавок подсос воздуха в топливную магистраль.

Если проанализируем, то поймем, что «сепар» от слова «сепаратор». А это значит, что топливо в таком фильтре отделяется от вредных примесей благодаря центробежным силам. А что бы создать такие центробежные силу, нужно обеспечить высокубю скорость прокачки. Может быть это и возможно на машинах типа Камаз или огромных тракторах Катерпилер, но для нашего насосика это недостижимо. Поэтому не будем тратить лишние 10 тыс. руб. на эту бессмысленную вещь.

Двигатель. Система охлаждения

Антифриз применять ТОЛЬКО с допуском MB325.0. Данный антифриз может быть либо темно-зеленого, либо желтого цвета. Если в машине залита жидкость другого цвета — срочно под замену. Применение «неродного» антифриза приводит к тому, что через 6 месяцев «сжирает» головку и это требует снятия, шлифовки и вообще денег.

Антифризы между собой НЕ СМЕШИВАЮТСЯ! Вообще! Масла еще можно смешать. Нампример в мотор для экстренной доливки можно долить любое моторное масло, в коробку-автомат — масло уровня Декстрон 2. В мосты все, что угодно уровня GL-5. Антифризы смешивать нельзя. Если у вас появилась срочная потребность в антифризе, то возите с собой тот антифриз, который у вас залит сейчас. Либо просто добавьте дистиллированной воды — так будет намного лучше. Если в магазине продавец вам говорит: «У вас же зеленый антифриз, вот возьмите этот — он тоже зеленый», то плюньте ему в глаза, насрите на прилавок и уходите из этого магазина!

Антифриз меняется вместе с термостатом раз в два года.

1. Сливаем старый антифриз,

2. Меняем термостат (помпу по желанию).

3. наливаем дисцилилованую воду,

4. Прогреваем мотор, что бы термостат открылся.

5. Охлаждаем мотор хотя бв до 50 градусов.

6. Сливаем воду

7. Наливаем новый антифриз.

В среднем, лучшие низкотемпературные характеристики получаются при соотношении 60% антифриза и 40% воды. Чистый антифриз, как это ни странно, замерзает при минус 10 градусах.

Заодно при смене антифриза, имеет смысл отдельно промыть салонную печку. Помпа от газели, две пачки антинакипина на 5 литров воды вам в помощь.

Термостат «родной» из Кореи стоит на 80 градусов. Рекомендую ставить на 85 градусов — зимой теплее, да и на оригинальных немецких моторах стоят именно на 85 градусов.

Помпа, как правило, накрывается на пробеге от 140 до 160 тысяч км. Поэтому если ты только купил машину — имеет смысл помпу поменять.

Двигатель. Навесное оборудование.

Раз в 50 тыс.км. Нужно менять ремень, натяжной ролик, обводной ролик, паразитный ролик, коромысло натяжителя и амортизатор. В общем все под замену.

И мне пофигу, что вам там сказал сосед, мастер с сервиса и прочие клоуны. Есть кадры, которые меняют только ремень, а есть «умные» кадры, которые меняют ремень и еще аж и обводной ролик. Только итог одинаков в обоих случаях — обрыв ремня, поломанное коромысло натяжителя, развалившийся ролик натяжителя. И все это происходит в самый неподходящий для вас момент.

Если на генераторе установлен обычный шкив, а не обгонная муфта, то НУЖНО установить на генератор обгонную муфту. Это намного продляет жизнь ремня и роликов. Хотя есть генераторы с разными резьбами. На какой-то можно накрутить муфту, а какие то имеют бОльший диаметр резьбы.

В любом случае, возите ВСЕГДА с собой запасной ремень, оба ролика и коромысло натяжителя. Хотя бы старые.

Двигатель. Первоочередной Легкий и Нужный Тюнинг.

Самое первое, что надо сделать, купив машину, это заглушить клапан EGR. Клапан находится с правой стороны мотора и представляет собой «грибок», прикрученный двумя болтами (под шестигранник) к впускному тракту. Нужно открутить эти болты, отодвинуть клапан. Вытащить прокладку и по внешней форме прокладки вырезать такой бутерброд: тонкий паронит, жестянка от пивной банки и снова тонкий паронит. «Бутерброд» установить вместо старой прокладки.

Для чего служит клапан ЕГР? На определенных оборотах двигателя клапан открывается и получается что часть выхлопных газов идет во впускной коллектор. Типа для дожига не сгоревшего топлива, что повышает экологию. Все это хорошо на нормальном топливе, однако в нашем типа «топливе» содержание сажи зашкаливает все мыслимые пределы. Эта сажа, смешиваясь с парами масла из сапуна двигателя (да и турбина тоже немного гонит масло) поступают в камеры сгорания. Вся эта гадость откладывается на впускном тракте, впускных клапанах. Следствием этого является зауженное сечение впускного тракта и обширный нагар на клапанах. Нагар задирает маслосъемные колпачки, мешает клапанам плотно прилегать к седлам, что в итоге приводит к низкой компрессии. Более того, впускной тракт построен таким образом, что бОльшая часть абразивной сажи попадает во второй цилиндр. Отсюда задир стенок цилиндра и более низкая компрессия.

Второе, чем надо заняться, это выбить к чертям собачьим катализатор

Может быть катализатор штука хорошая, но тогда, когда он новый. Тем более, как писалось выше, из выхлопной трубы у нас летит сажи в неограниченных количествах (Да здравствует Газпром!). В общем были случаи, что проехав всего лишь 50 км на некачественном топливе, катализатор забивался наглухо. Двигателю просто не было сил преодолевать сопротивление забитого катализатора. Отсюда нестабильная работа и отсутствие тяги. Вспомним еще и турбину, которая крутится в зависимости от скорости и объемов выхлопных газов: нет скорости, нет давления наддува.

В общем снимаем катализатор, берем в руки зубило и лом и выбиваем из него всю дрянь.

Третий акт Марлезонского балета по тюнингу: (а вернее по доведения машины до нормального состояния).

Раз мы выбили катализатор, заглушили ЕГР и заменили распылители, то имеет смысл промыть топливную систему с помощью Wynns Diesel System Purge и продуть впускной тракт препаратом Wynns EGR3.

Двигатель. Глубокий Тюнинг.

Есть всего лишь один относительно дешевый способ добиться прироста мощности и приемистости мотора:

Установить более мощную турбину и добавить соответственно цикловую подачу топлива. Для мотора 2.3 литра идеально подходить турбина от мотора 2.9 литра. Причем что на Муссо, что на Корандо хорошо встает турбина от Муссо, а еще лучше от Муссо-Спорт Евро3).

Второй способ связан с заменой ГБЦ на другую, с бОльшим проходным сечением клапанов, установкой распредвала с другими фазами газораспределения, заменой плунжеров ТНВД на плунжера бОльшего диаметра и т.д. и т.п.

Для примера: в Корее продается набор турбина большей производительности и ГБЦ, которая сможет переварить подачу такого давления воздуха от этой турбины. Прирост мощности примерно 15 — 25 л.с. Цена этого удовольствия в Корее примерно 2,5 тысячи долларов. Цена хорошего мотора 2,9ТД в полной комплектации в Корее 900 долларов.

Двигатель. Зимняя эксплуатация

Правила простые:

1. Осенью в бак добавляйте удалитель влаги из бака.

2. Начиная с октября добавляйте перед заправкой антигель в бак. Рекомендую Ravenol или Wynns. Они в отличии от других, сами по себе не замерзают.

3. Так же зимой имеет смысл добавлять 0,5 литра двухтактного масла на бак. Зимой солярка «сухая», а масло позволяет мягче работать топливной системе.

4. Больше НИЧЕГО не надо добавлять в бак. Все это плохо кончается.

5. Раз в два года необходимо менять свечи накаливания. Использовать только свечи BERU.

6. Очень часто (почти всегда) обгорает силовой провод, который идет на реле свечей. На Муссо этот провод идет от коробочки на АКБ до реле, а на Корандо провод идет от блока предохранителей тоже на реле накала свечей. Т.е. провод внешне выглядит целым, но его сопротивление очень велико и не позволяет как положено нагреться свечам — происходят потери тока. В итоге до минус 20 градусов заводимся нормально, а если температукра падает ниже, то все — приплыли. Решение простое: параллельно родному проводу прокладываем провод примерно на 6кв.мм.

7. Раз уж зашла речь про провода, то перед зимой нужно сделать следующее.: Разобрать клеммы АКБ, зачистить все контакты, смазать медной смазкой ( нет медной, тогда графитовой). Так же зачистить и смазать минусовой контакт на двигателе — он подключается к левой лапе-опоре мотора. Зачистить и смазать плюсовой провод, который идет непосредственно на стартер.

8. Если вашему аккумулятору три года или больше — выкиньте его в помойку. И купите новую батарейку. Да, я вас слышу — вы прошлую зиму отлично ездили, и сейчас хорошо заводитесь. В февральские морозы вернемся к этому спору, если вы еще будете готовы поспорить.

9. На Корандо ставится АКБ максимальной емкости 75 А*ч, на Муссо возможно воткнуть АКБ на 90 А*ч, и то, если разогнуть молотком и пассатижами площадку для установки. Законы физики никто не отменял — нельзя в батарейку размером с «Крону» засунуть атомную электростанцию. Отсюда вывод: если на этикетке АКБ вашего Корандо красуется надпись 85 — 90 А*ч, то поменяйте батарейку. Особенно грешат завышением реальной емкости… блин… да все производители! В общем покупайте либо Варту, либо Баннер.

Коробка Автомат

Как правило (начиная с 1997 года) установлена коробка BTRa M74 . Ресурс коробки 180 — 220 тыс .км.

99% проблем с этой коробкой — это проблемы с потенциометром. Поэтому меняем потенциометр и еще дополнительно возим с собой запасной. Потенциометр установлен на ТНВД.

И один процент связан с датчиком скорости. Установлен на раздатке рядом с фланцем заднего кардана.

Масло в коробку заливается только специальное: Castrol TQ95, Ravenol ATF BTR 95LE. В крайнем случае Liqui Moly Top Tec ATF 1100. Отличие Ravenol ATF BTR 95LE от Castrol TQ95 в том, что первое синтетическое, а значит имеет более низкую точку замерзания. Castrol TQ95 — рекомендуемое корейцами масло, однако является минеральным и в наших зимних условиях непригодно. Да и цена Castrol TQ95 примерно на 30% больше, чем Ravrnol ATF BTR 95LE.

Масло менять каждые 30 тыс.км. Хотя в мануале написано, что замена каждые 60 тыс, но они явно не знали про российский условия эксплуатации.

Емкость коробки 8,5 литров. Для замены требуется примерно 9 литров. Для смены масла обязательно требуется снятие поддона, очистка магнита (заодно и проконтролируете степень износа), замена масляного фильтра и прокладки поддона.

Уровень масла проверяется на теплой коробке, но на заглушенном двигателе. Пробка коробки на «16». Откручивать ТОЛЬКО головкой, иначе можно легко сорвать грани.

Масло меняется в два приема:

1. Снимаем поддон, сливаем масло, сменяем фильтр и прокладку.

2. Очищаем основной магнит от стружки и дополнительно прикрепляем на поддон еще один магнит. Мы используем сверхмощные магниты от сломанных компьютерных жестких дисков. Чем больше стружки (от естественного износа фрикционов) задержится на магнитах, тем здоровей будет наша коробка.

3. Наливаем масло.

4. Катаемся примерно 10 км. Это для того, что бы заместить масло в гидротрансформаторе и промыть коробку.

5. Сливаем масло уже из трубки охлаждения. Трубка находится на основном радиаторе с правой стороны.

6. Доливаем масло до уровня.

Как правило замена масла на «аппарате» приводит к большому расходу масла и преждевременной кончине гидроблока.

Если коробка не сразу едет назад, а только после добавления газа, то вариантов два:

1. Неправильно установлен потенциометр. На холостом ходу должно быть 0,5 Вольт. Если напряжение больше 1,0 Вольта, то коробка «дуреет».

2. Коробка требует ремонта. И никакие замены масла и танцы с бубнами здесь уже не помогут.

Если коробка «встала» на третьей скорости (аварийный режим), то не надо впадать в панику. Как правило это обрыв одного или нескольких проводков в косе управления. Нужно внимательно осмотреть все разъемы, подозрительные разобрать и пропаять. Бывает окисляется массовый провод самого блока управления коробкой.

Коробка Механика

Не понимаю, как в 21 веке, когда еще в прошлом веке люди слетали на Луну, а сейчас собираются колонизировать Марс, есть некоторые индивидуумы, которые готовы ездить на «палке».

В общем в этих коробках все просто:

1. Масло примерно 3,5 литра. Рекомендую Castrol TransMax-Z.

2. Обычно протыкается вилка сцепления. Поэтому следим и своевременно меняем. Пр мерно на 100 тыс.км.

Обычно заменить только одну вилку сцепления без снятия коробки не получается. А раз коробку все равно снимать, то уж тогда меняйте вилку, диск сцепления, выжимной подшипник и маленький подшипник, который стоит в коленчатом валу. Почему то про подшипник, который стоит в коленчатом валу все забывают. А ведьт именно на него опирается первичный вал коробки. И подшипник совсем недорогой.

Передний привод

Тесно связан с раздаткой.

Повторюсь: у нас ЗАДНЕПРИВОДНАЯ машина. И те, кто ездит зимой на полном приводе, идут туда, куда укажет им вежливый ГОГА (форумчанин из Новосибирска goga64).

Те, кто ставит механические хабы, имеют право на жизнь, но важно их отключать. Т.е. вам придется перед каждым препятствием выходить из машины, включать хабы, а после преодаления препятствия снова выходить и выключать.

У нас же, как правило, люди включают хабы осенью, а отключают весной. Типа мы ща кнопкой из салона раздатку подключим. Тоже идите по направлению, которое укажет ГОГА.

Те, кто меняют местами в хабах пружинку и шестерню, и тем самым залочивают хабы навсегда, тоже можете строится в затылок с людьми из первого абзаца.

Потом опишу все прелести подробно (что делать, как пользоватся и чем это грозит).

Раздатка

Для приведения переднего привода в движение используется цепь.

Масло примерно 1,5 литра. Менять каждые 25 тыс.км. Рекомендую Castrol TransMax-Z.

Включение 4WD рекомендую производить на скорости не более 10км/час и заранее перед преодолением препятствия.

Включение (и выключение тоже) пониженной передачи 4WD Low — производится на стоящем автомобиле в положении селектора АКПП «нейтраль».

Раздатка настолько проста и до безобразия надежна, что и писать то нечего. Однако бывают проблемы с не включением переднего привода (повышенная и пониженная передачи):

1. Как правило обламываются провода в разъемах. Поэтому проверить, разобрать и пропаять.

2. Второй по распространенностью проблемой является износ позистора в моторчике, который переключает режимы раздатки. Способ решения: Разобрать, почистить, собрать. Если не помогло, то менять моторчик.

3. Не включение пониженной передачи бывает из-за того, что захандрил датчик скорости (не тот, который для коробки и спидометра, а второй). Стоит он так дорого (3800 руб), что проще его заменить простым резистором (5 руб).

Подвеска

Изначально подвеска на наших машинах очень дохлая. Ну потому, что машины лет семь ездили в Корее, а потом и мы их эксплуатируем в хвост и в гриву.

В общем безопасно ездить на такой подвеске нельзя: машина валится в поворотах, «козлит» на кочках и прочие неприятности.

Подвеска. Малый Тюнинг

Что надо сделать (все и сразу):

1. Заменить верхние шаровые опоры. (Верхние шаровые ходят 100 тыс, нижние 200 тыс.)

2. Заменить сайлентблоки верхних рычагов.

3. Заменить стойки стабилизаторов (яйца).

4. Заменить сайлентблоки стабилизаторов

5. Амортизаторы Tokico перед E3708, зад E3496

6. Пружины для Муссо и Корандо KYB RD5081. Для Муссо-Спорт KYB RD5082. (Всех секретов не расскажу все равно).

7. Торсионы рекомендую заменить на усиленные от версий SY с бензиновым мотором 3,2 литра.

Верхние шаровые переставить под рычаг.

Написать про кастор… — будет дололнено

Мосты

Ну здесь все просто.

1. Масло в мостах менять каждые 25 тыс.км. Рекомендую 75w90 уровня GL5. В задний мост 1,9 литра, в передний мост 1,3 литра.

Ступичные подшипники заднего моста ходят примерно 200 тыс.км. При условии смазки каждые 20 тыс км. Во время смазки желательно заменить внутренние сальники моста.

Ступичные подшипники передних колес ходят 100 тыс.км. При условии смазки каждые 20 тыс км. Для смазки требуется заменить сальники ступичных подшипников.

Тормозная система

Если машина оборудована системой TCS, то рекомендую внимательно следить за задними тормозными колодками и своевременно менять их. Понять есть такая система или нет, достаточно просто: надо заглянуть под мост. Если с рамы на мост идут два тормозных шланга, то у вас система TCS. Если один шланг, то у вас стоит простая ABS.

Если сзади обычные барабанные диски, то они почти вечные. Даже не стоит заморачиваться об их замене.

Допустимый износ передних тормозных дисков — 22мм. И если вы думаете, что их можно проточить и продолжать ездить дальше, то идите туда же, куда пошли те, кто постоянно ездит на переднем приводе.

Тормозная система. Периодичность обслуживания.

Тормозные шланги и тормозную жидкость нужно менять раз в два года. Тормозную жидкость использовать уровня DOT-4 (хотя официальный учебник рекомендует DOT-3). Использовать тормозную жидкость желательно фирм Castrol, Bosch, Ravenol, Mannol. Количество тормозной жидкости в системе 1,2 литра.

Отдельно хочу заострить внимание на тормозных шлангах. Бывает что ни грыж, ни подтеков на шлангах вообще не видно. Однако в самый ответственный момент шланги просто мгновенно рвутся. Поэтому меняем раз в два года и все! Это чья то спасенная жизнь.

Тормозная система. Тюнинг.

Передние суппорта и тормозные диски имеет смысл заменить на двухпоршневые суппорта и диски от Рекстона. Эффективность торможения повышается в полтора раза, а это чья то спасенная жизнь.

Колеса.

Ежу понятно, что все четыре колеса должны быть одного размера, одного рисунка и одного производителя.

Зимой использовать только колеса с шипами. Т.к. эту двухтонную дуру остановить очень трудно.

Родные диски имеют вылет 10 — 18 мм. Больше, чем нулевой вылет использовать нельзя, т. к. ухудшается руление автомобилем, широко расставленные колеса забрызгивают грязью кузов, а самое страшное, что очень сильно возрастает нагрузка на ступичные подшипники.

Максимальный размер колес, который можно поставить на машину без особых извражений и «лифтов» (см выше) для Корандо — 31 дюйм, для Муссо 30 дюймов.

Салон

В наших условиях меняйте салонные фильтры каждые 2 тысячи км. Да, они относительно дорогие, но это того стоит. В противном случае вы забьете грязью и пылью радиатор кондиционера и в итоге снизите эффективность работы всей системы отопления зимой.

Те, кто на зиму вообще выкидывают салонные фильтра — идут лесом. Даже объяснять не хочу почему.

Источник: korandovod.ru

- Manuals

- Brands

- SSANGYONG Manuals

- Automobile

- Korando 2013

- Manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Related Manuals for SSANGYONG Korando 2013

Summary of Contents for SSANGYONG Korando 2013

-

Page 149

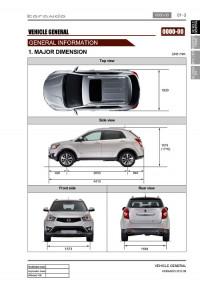

01-3 0000-00 1. MAJOR DIMENSION Unit: mm Top view Side view Front side Rear view… -

Page 150: Vehicle Identification

01-4 2. VEHICLE IDENTIFICATION 1) The engine number (671 950 0 2 5000001) is 2) The chassis number stamped on the lower area of cylinder block in (KPTA0B1SSAP012345) is stamped on the right exhaust manifold side. side in the engine compartment (passenger side).

-

Page 151

01-5 0000-00 ▶ VIN number ▶ Engine number… -

Page 152

01-6 3. SPECIFICATION * ( ) Optional… -

Page 153

01-7 0000-00 * ( ) Optional… -

Page 154

01-8 * ( ) Optional… -

Page 155

01-9 0000-00 4. RECOMMENDED FLUIDS AND LUBRICANTS Use only Ssangyong recommended fluids and lubricants. Do not mix any different types or brands of oils or fluids. This may cause damages. Keep the specified levels when adding or replacing the fluids. -

Page 156

01-10 5. SCHEDULED MAINTENANCE SERVICES 1) Diesel Engine(EU) -

Page 157

01-11 0000-00… -

Page 158

01-12… -

Page 159

01-13 0000-00 2) Diesel Engine(General) -

Page 160

01-14… -

Page 161

01-15 0000-00… -

Page 162

01-16 3) Gasoline Engine… -

Page 163

01-17 0000-00… -

Page 164

01-18… -

Page 168

01-3 0000-00 1. LAYOUT Front view Rear view Right side view Left side view… -

Page 169

01-4 2. MAJOR COMPONENTS ▶ Front View Vacuum pump Oil filter assembly Camshaft position sensor Power steering pump pulley Oil pressure switch Water pump pulley Alternator pulley Idler pulley No. 1 A/C compressor pulley Auto tensioner Idler pulley No. 2 Isolation damper ▶… -

Page 170

01-5 0000-00 ▶ Right side View Wide band oxygen sensor Pre-CDPF pressure port Front exhaust gas temperature sensor Rear exhaust gas temperature sensor CDPF assembly Post-CDPF pressure port Oil drain plug E-VGT turbocharger ▶ Left side View Thermostat assembly Knock sensor 1 connector Oil cooler assembly Variable swirl valve assembly E-EGR valve… -

Page 171

01-6 1. GUIDELINES FOR SERVICE WORKS 1) For Safety To perform the service works easily ans safely, the service technicians must keep the proper working procedures and rules. This manual provides the useful instructions to the service technicians so that they can perform the servive works with standard working process, skills, tips in time. -

Page 172

To improve the efficiency of service work, use only recommended and specified tools. Use only Ssangyong genuine spare parts. Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them with new ones. If reused, normal functions cannot be maintained. -

Page 173

(7) Coolant Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material), and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. (8) Engine drive belt Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if… -

Page 174

01-9 0000-00 5) Guidelines on Engine Service To prevent the personal injuries and vehicle damages that can be caused by mistakes during service and to provide the optimized performance and safety after service works, the service technicials must keep the basic cautions and service guidelines below. These could be easily forgotten during service works. -

Page 175

01-10 (4) Fuel and lubrication system When working with the fuel or oil systems in enclosed area, always keep the working area well- ventilated and never allow anybody to smoke. Gaskets and seals on the fuel and oil systems should be replaced with new ones. All bolts and nuts should be tightened as specified. -

Page 176

01-11 0000-00 2. JACK-UP POINTS ▶ Stand jack-up points and installation status (front side) Jack-up points and setup (front side) Supporting Jack-up points for Jack-up points for 2-post lift 2-post lift Jack-up points and setup (rear side) Supporting… -

Page 177

01-12 3. STANDARD BOLTS SPECIFICATIONS Metric bolt strength is embossed on the head of each bolt. The strength of bolt can be classified as 4T, 7T, 8.8T, 10.9T, 11T and 12.9T in general. Observe standard tightening torque during bolt tightening works and can adjust torque to be proper within 15 % if necessary. -

Page 178

01-13 0000-00 4. CODING 1) Engine Variant Coding Description Selection Coding Additional heater PTC auxiliary heater is the standard equipment in this vehicle. Select «YES». Gear box 5-speed M/T M/T : 6-speed M/T A/T : 6-speed A/T (DSI 6AT) 6-speed M/T 5-speed A/T (DC 5 AT) 7-speed A/T (DC 7 AT) 6-speed A/T (DC 6 AT) -

Page 179

01-14 2) Chassis Variant Coding Description Selection Coding Domestic/Export EU export Select the appropriate system General export EPB application Select the appropriate system Shift lever type Not defined A/T : DURA lever M/T : M/T DC lever DURA lever Electric power Select the appropriate system steering(EPS) Transfer case… -

Page 180

01-15 0000-00 Description Selection Coding TPMS application Select the appropriate system Transmission type Select the appropriate system DC AT DSI AT Vehicle code STAVIC Select : KORANDO (platform) REXTON KORANDO KYRON ACTYON SPORT Not defined ECU coding status ECU not coded Select : ECU coded ECU coded Signal not valid… -

Page 181

02-3 0000-00 1. SPECIFICATION Unit Description Specification Remark Cylinder head Height 131.9 to 132.1mm Flatness below 0.1mm Flatness on Intake manifold 0.1/150mm manifold side Exhaust manifold 0.15mm Mass balance Backlash 0.05 to 0.15mm shaft (MBU) Connecting rod End play 0.05 to 0.31mm Camshaft Axial end play Intake… -

Page 182

02-4 2. MAJOR CHANGES ▶ Oil pressure switch 0000-00 Oil pressure switch — Newly added oil pressure switch (B) instead of oil level switch (A) -

Page 183

02-5 0000-00 ▶ Engine Mount 1900-00 Mounting Assembly RH 2/4WD 1900-00 Front Mounting Assembly 1900-00 Rear Mounting Assembly — Changed appearance of right-hand mounting assembly and its rubber for enhanced NVH performance — Changed appearance and material of front/rear mounting assemblies’ rubbers for enhanced NVH performance * The mounting appearance has been changed, but work procedure is same as the old one. -

Page 184

02-6 3. TIGHTENING TORQUE Tightening torque Remark Component Size Quantity (Nm) (Total torque) 55 ± 5Nm, M12×82 Main bearing cap Not re-usable 180˚ 40 ± 5Nm, M9×52 Connecting rod cap 50~80Nm 90˚ ± 10˚ Crankshaft rear cover M6×20 10 ± 1Nm M8×35 25 ±… -

Page 185

02-7 0000-00 Remark Tightening torque Component Size Quantity (Total torque) (Nm) M6×12 10 ± 1Nm Hot water inlet pipe M10×90 25 ± 2.5Nm Lower Alternator M10×116 46 ± 4.6Nm Upper M8×85 25 ± 2.5Nm A/C compressor M6×25 10 ± 1Nm A/C bracket M8×35 25 ±… -

Page 186

02-8 Remark Tightening torque Component Size Quantity (Total torque) (Nm) Idle pulley/Tensioner 45 ± 4.5Nm pulley 20 ± 2Nm Glow plug 볼트 비고 품명 규격 규정토오크(Nm) M6×25 10 ± 1Nm 수량 (총 토오크) Vacuum pump M6×40 10 ± 1Nm Timing gear case cover M6×45 10 ±… -

Page 187

02-9 0000-00… -

Page 188

02-10… -

Page 189

02-11 0000-00… -

Page 190

02-12… -

Page 191

02-13 0000-00 4. CHECK AND INSPECTION 1) Cylinder (1) Compression pressure test ▶ Specified value Compression ratio 16.5 : 1 at normal operating temperature (80˚C) Test condition Standard 32 bar Compression pressure 18 bar Minimum Maximum 3 bar Differential limit between cylinders The compression pressure test is to check the conditions of internal components (piston, piston ring, intake and exhaust vale, cylinder head gasket). -

Page 192

02-14 (3) Piston protrusion check Measure how the piston is protruded from the upper side of the cylinder block. Specified value 0.475 to 0.745mm Measure it at both end positions in the axial direction of the crankshaft. -

Page 193

02-15 0000-00 2) Cylinder Head (1) Cylinder head mating surface check ▶ Specified value 131.9 to 132.1 mm Total height «A» Minimum height after machining 131.9mm 0.1 / 150 Longitudinal direction Flatness Transverse direction 0.15 below 0.1 mm Parallel deviation of cylinder head Rmax7 Peak-to valley of surface Rz6.3… -

Page 194

02-16 5. GUIDELINES ON ENGINE SERVICE To prevent personal injuries and vehicle damages that can be caused by mistakes during engine and unit inspection/repair and to secure optimum engine performance and safety after service works, basic cautions and service work guidelines that can be easily forgotten during engine service works are described in. -

Page 195

02-17 0000-00 ▶ Fuel and lubrication system Do not allow the fluid and engine oil to make contact with the body paintwork and hoses. If work on the fluid system such as fuel and oil, working area should be well ventilated and smoking should be prohibited. -

Page 196

02-18 1. BELT SYSTEM The belt system is a single belt drive system which uses single belt and has components on the oil filter housing as FEAD (Front End Accessories Drive) type. ▶ Components with HPS (hydraulic power steering) with EPS (electric power steering) Crankshaft pulley (DDU) Auto tensioner Tensioner pulley… -

Page 197: Vacuum Pump

02-19 0000-00 2. VACUUM PUMP Vacuum pump generates the vacuum pressure and supplies it to EGR cooler bypass solenoid. This pump is single vane type and displacement is 210 cc/rev. The lubrication oil is supplied through the hole in hollow shaft. ▶…

-

Page 198

02-20 3. ENGINE MOUNTINGS D20DTF engine mounting is 4-point mounting type and supports the engine and transaxle. Front and rear mountings are rubber type and support the torque reaction. Left and right mountings support the power train rods and torque reaction. Additionally, right mounting is hydraulic type and supports the engine vibration. -

Page 199

02-21 0000-00 4. INTAKE/EXHAUST SYSTEM 1) Intake Manifold Intake manifold is installed on the cylinder head with 8 bolts. The variable swirl valve is introduced to improve the EGR gas mixture and turbulence in combustion chamber and to decrease the exhaust gas. ▶… -

Page 200

02-22 5. CYLINDER HEAD COVER AND OIL SEPARATOR The cylinder head cover is made by high strength plastic to reduce the weight. The multi twist type oil separator improves the oil consumption. ▶ Components PCV valve Oil separator… -

Page 201: Cylinder Head

02-23 0000-00 6. CYLINDER HEAD Cylinder head contains cam position sensor, vacuum pump, intake manifold, exhaust manifold and valve assembly. Vacuum pump and the high pressure (HP) pump are driven by Camshaft and valves are install in vertical direction. This enables the compact layout in cylinder head assembly.

-

Page 202

02-24 ▶ Components Finger follower & HLA Intake/exhaust Camshafts Camshaft sprocket Cylinder head Camshaft position sensor HP pump drive gear Vacuum pump drive Cylinder head gasket… -

Page 203

02-25 0000-00 7. CHAIN AND GEAR DRIVE SYSTEM D20DTF engine uses single stage chain drive system. Timing chain drives the exhaust side and gear drive the intake side. Timing chain is single bush type. Upper chain drives HP pump connected to intake Camshaft by driving exhaust cam shift sprocke, and lower chain drives oil pump to lubricate the engine. -

Page 204

02-26 ▶ Components Intake/exhaust Camshaft assembly Exhaust HP pump drive gear Connected to Camshaft vacuum pump Intake Camshaft… -

Page 205

02-27 0000-00 Timing gear cover case (TGCC) TGCC Oil seal Screw plug… -

Page 206

02-28 Mass Balance Unit (MBU) Crankshaft MBU drive gear Fuel HP pump HP pump drive gear HP pump gear… -

Page 207: Oil Pan

02-29 0000-00 8. OIL PAN The oil pan in D20DTF engine improves the noise and vibration. Especially, the oil drainage is very easier than before. And, A/C compressor bracket and the oil dipstick tube are mounted on the oil pan. ▶…

-

Page 208

02-30 9. MASS BALANCE SHAFT UNIT (MBU) The balance shaft in MBU (Mass Balance shaft Unit) improves the NVH performance by decreasing the unbalanced force. ▶ Components MBU drive gear Mass balance shaft unit Mass balance shaft unit… -

Page 209

02-31 0000-00 10. FLYWHEEL AND DRIVE PLATE 1) DMF (Dual Mass Flywheel) The dual mass flywheel, or DMF, eliminates excessive transmission gear rattle, reduces gear change/shift effort, and increases fuel economy. There is a friction ring located between the inner and outer flywheel that allows the inner and outer flywheel to slip. -

Page 210

02-32 11. PISTON/CRANKSHAFT/CYLINDER BLOCK This vehicle is FF driving type and the engine is installed in lateral direction. The crankshaft and the cylinder block convert the compression pressure to the rotating energy. ▶ Components Cylinder block Piston Connecting rod Crankshaft… -

Page 211

03-3 0000-00 1. SPECIFICATION Description Specification Fuel Diesel Fuel heater + priming pump + water separator Type integrated type Filter type Changeable filter element type Fuel filter every 40,000 km Change interval every 45,000 km Water accumulating capacity 200 cc Heater capacity 250W 13.5V Injector… -

Page 212

03-4 2. MAJOR CHANGES ▶ Filter Part SGN NO. Sub Sender Filter — Suction port introduced replacing sub sender pre-filter… -

Page 213

03-5 0000-00 3. MAINTENANCE AND INSPECTION 1) Maintenance Procedures for DI Engine Fuel System Always keep the workshop and lift clean (especially, from dust). Always keep the tools clean (from oil or foreign materials). Wear a clean vinyl apron to prevent the fuzz, dust and foreign materials from getting into fuel system. Wash your hands and do not wear working gloves. -

Page 214

03-6 Follow the job procedures. If you find a defective component, replace it with new one. Once disconnected, the fuel pipes between HP pump and fuel rail and between fuel rail and each injector should be replaced with new ones. The pipes should be tightened tospecified tightening torques during installation. -

Page 215

03-7 0000-00 Check the installed components again and connect the negative battery cable. Start the engine and check the operating status. With Scan Tool, check if there are current faults and erase the history faults. -

Page 216

03-8 2) Diagnostic Test for Engine Fuel System (1) Overview If a DTC is displayed on the diagnostic device, check the low pressure- and high pressure fuel systems before removing the components. To run the system properly, the electric system must be intact but for the DI engine, the fuel pressure should be measured also when there is a malfunction even after the diagnostic test with a diagnostic device. -

Page 217

03-9 0000-00 (3) Excessive backleak of injector ▶ Excessive injector backleak Occurs when the injector control valve is not sealed due to the entry of the foreign materials. ▶ Example: Entry of foreign materials Burned out and worn HP pump Mechanical damage inside the injector… -

Page 218

03-10 (4) Loss of pump pressure/flow ▶ Loss of HP pump pressure/flow Faulty fuel supply line, or damaged or worn pump causes the lack of flow pressure and flow volume ▶ Example: Air in fuel supply line Excessive load on fuel supply line (←400 mBar) Burned out and mechanical worn pump High temperature of fuel supply (>… -

Page 219

03-11 0000-00 3) Pressure Test for Fuel System in DI Engine (1) Test device (Tool kit) Tool kit for high pressure line Tool kit for low pressure line (2) Pre-inspection Connections in fuel supply line Fuel level in fuel tank Air in fuel supply line (air bubbles in fuel supply line or fuel) Fuel leaks from fuel supply line (low/high pressure line) Used the specified… -

Page 220

03-12 (3) DTC Check If several DTCs are output simultaneously, check the electric wiring for open or short circuit. Check the low pressure fuel system and fuel filter and confirm that there are no abnormalities. Carry out the high pressure fuel system check. -

Page 221

03-13 0000-00 (4) Fuel System Check Procedure… -

Page 222

03-14 (5) High Pressure System Pressure Test ▶ Fuel rail pressure test Disconnect the fuel rail pressure sensor connector and then IMV connector. Connect the pressure tester to the fuel rail pressure sensor connector. Crank the engine 2 times for 5 seconds. Read the highest pressure value displayed on the tester display. -

Page 223

03-15 0000-00 ▶ How To Use Pressure Tester Press the «TEST» button on the tester to check if the message «TEST?» is displayed. If the button is pressed again at 4 seconds after starting engine cranking, the highest pressure is displayed on the tester. The fuel rail pressure value can be checked using a diagnostic device. -

Page 224

03-16 (6) Low Pressure System Pressure Test ▶ Inspection procedure All wirings/connectors and fuel lines should be connected and the engine should work properly. Prepare a special tool for low pressure test and clean it thoroughly to prevent foreign materials from entering. Disconnect the key connector for fuel filter connection, and connect both connectors to the fuel filter and hose. -

Page 225

03-17 0000-00 ▶ Static test for backleak of injector Disconnect the injector return hose and cover the openings with caps shaped screw (included in the special tool). Connect the hose of the container for measuring backleak to the return nipple of the injector. -

Page 226

03-18 ▶ Dynamic test for backleak of injector Warm up the engine so that the engine coolant temperature be over 80℃ and star the engine again. Disconnect the injector return hose and cover the openings with caps shaped screw (included in the special tool). Connect the hose of the container for measuring backleak to the return nipple of the injector. -

Page 227

03-19 0000-00 ▶ Pressure leak test in fuel system with scan tool When the dynamic test for injector backleak is performed, this test should be done together with it. However, you can check the pressure leak from the fuel system only with this test. To do this test, the coolant temperature should be over 60˚C. -

Page 228

03-20 ▶ HP pump pressure test Prepare a special tool for high pressure test and clean it thoroughly to prevent foreign materials from entering. Disconnect the high pressure fuel supply pipe on the HP pump and install the close rail in the tool kit. -

Page 229

03-21 0000-00 4. CAUTIONS FOR DI ENGINE 1) Cautions for DI Engine This chapter describes the cautions for DI engine equipped vehicle. This includes the water separation from engine, warning lights, symptoms when engine malfunctioning, causes and actions. DI Engine Comparatively conventional diesel engines, DI engine controls the fuel injection and timing electrically, delivers high power and reduces less emission. -

Page 230

03-22 2) Cleanness (1) Cleanness of DI engine fuel system ▶ Cleanness of DI engine fuel system and service procedures The fuel system for DI engine consists of transfer (low pressure) line and high pressure line. Its highest pressure reaches over 1,600 bar. Some components in injector and HP pump are machined at the micrometer 100 μm of preciseness. -

Page 231: Water In Fuel

03-23 0000-00 (2) Di engine and its expected problems and remedies can be caused by water in fuel ▶ System supplement against paraffin separation In case of Diesel fuel, paraffin, one of the elements, can be separated from fuel during winter and then can stick on the fuel filter blocking fuel flow and causing difficult starting finally.

-

Page 232

03-24 1. OVERVIEW The components in the fuel system supply fuel and generate high pressure to inject fuel to each injector. They are controlled by the engine ECU. The common rail fuel injection system consists of fuel tank, fuel line, low pressure line which supplies low pressure fuel to the low pressure pump (includes high pressure pump), high pressure line which connected to the injector and the engine control unit (ECU) which calculates the accelerator pedal position and controls the overall performance of vehicle based on the input signals from various sensors. -

Page 234

03-26 2. SYSTEM LAYOUT AND OPERATION 1) Layout For sensor and actuator control logic, refer to Chapter «ENGINE CONTROL». Fuel supply line Fuel tank Fuel return line Fuel metering by dual sender. Supply the fuel in main fuel tank and sub fuel tank through fuel inlet tube Injector (C3I) Pre-injection, main injection, after-injection by… -

Page 235

03-27 0000-00 High pressure pump Accelerator pedal Fuel filter assembly position sensor Plunger type HP pump (1,800 bar) Vane type transfer pump (6bar) Supply clean fuel/fuel heating/water separation by Generates the high pressurized fuel Detects driver’s intention for priming pump and supply it. -

Page 236

03-28 2) Fuel System Flow Diagram The fuel from the fuel tank is supplied to the fuel heater of fuel filter/priming pump and then low pressure generated by the low pressure pump (built into HP pump) is transmitted to the HP pump. The fuel pressure at the HP pump is controlled by the IMV valve, and the maximum allowed pressure is 1,800 bar. -

Page 237

03-29 0000-00 3) Input/Output devices… -

Page 238

03-30 The engine ECU calculates the accelerator pedal based on the input signals from various sensors, and controls the overall operation of the vehicle. The ECU receives the signals from various sensor through data line, and performs effective air-fuel ratio control based on these signals. -

Page 239

03-31 0000-00 4) Flow Diagram of Fuel Supply System… -

Page 240

03-32 5) Circuit Diagram… -

Page 241

04-3 0000-00 1. SPECIFICATION Component Item Specification Filter type Dry, filter element 0.208 m² Filter area EU: Change every 20,000 km (But, shorten the Air cleaner element service interval under severe conditions) Service interval GEN: Change every 15,000 km (But, shorten the service interval under severe conditions) Weight 1.13 kg… -

Page 242

04-4 2. INSPECTION 1) Troubleshooting ▶ When Abnormal Noises are Heard from the Engine Room For the vehicle equipped with DI engine, if a learning noise occurs in each range or other noises occur, the major cause of it is a faulty turbocharger assembly. But an interference issue, poor tightness or loose in the intake and exhaust system also can cause those noises. -

Page 243

04-5 0000-00 3) Troubleshooting Sequence The basic checks for intake system are as follows: ▶ Basic Checks for Intake System Make sure to replace or clean the air cleaner element periodically. Otherwise, engine will be derated or work abnormally because of low intake air volume. -

Page 244

04-6 1. OVERVIEW The intake system for D20DTF engine is equipped with an electric throttle body which includes a flap. This flap is controlled by an electrical signal to cut off the intake air entering to the engine when the ignition switch is turned off. -

Page 245

04-7 0000-00 2313-15 HFM (Hot Film Air-Mass) sensor HFM sensor, version 6 * For more information, refer to Chapter «Engine Control». 2313-01 Air cleaner assembly and resonator… -

Page 246

04-8 3. INPUT/OUTPUT OF INTAKE SYSTEM… -

Page 247

04-9 0000-00 4. OPERATING PROCESS ▶ Work Flow… -

Page 248

04-10 1) Types of swirl Swirl: One cylinder has two intake air ports, one is set horizontally and the other one is set vertically. Swirl is the horizontal air flows in cylinder due to the horizontal intake air ports. Tumble: Tumble is the vertical air flows in cylinder due to the vertical intake air port Squish: Squish is the air flows due to the piston head. -

Page 249

04-11 0000-00 Load Engine speed Swirl Amount of Remarks valve swirl Low speed, Increased EGR ratio, better air-fuel below 3,000 rpm Closed Heavy Low load mixture (reduce exhaust gas) High speed, Increase charge efficiency, higher over 3,000 rpm Open Light High load engine power The variable swirl valve actuator operates when… -

Page 250

04-12 5. CIRCUIT DIAGRAM… -

Page 251

05-3 0000-00 1. TROUBLESHOOTING 1) Work Flow… -

Page 252

05-4 2. CAUTIONS Do not park the vehicle on flammable materials, such as grass, leaves and carpet. Do not touch the catalyst or the exhaust gas ignition system when the engine is running. If a misfire occurs in the combustion chamber or the emission of pollutant exceeds the specified level, the catalyst can be damaged. -

Page 253

05-5 0000-00 1. OVERVIEW This system purifies the exhaust gas generated by the combustion in the engine to reduce the pollutants and noise during that arise during combustion. 2. COMPONENT Exhaust manifold CDPF assembly Fore details about the CDPF assembly, refer to Chapter «CDPF System». -

Page 254

05-6 3. OPERATING PROCESS 1) Exhaust Gas Flow 2) Input & Output Devices… -

Page 255

06-3 0000-00 1. SPECIFICATION Component Item Specification Max. expansion coefficient Max. turbine speed 215,000 rpm Turbocharger 800 ℃ Max. temperature of turbine housing Weight 7.2 kg E-Actuator Operation duty cycle 300 Hz… -

Page 256

06-4 2. INSPECTION 1) Cautions During Driving The following lists cautions to take during test drive and on the turbocharger vehicle, which must be considered during the operation. It’s important not to drastically increase the engine rpm starting the engine. It could make rotation at excessive speed even before the journal bearing is lubricated and when the turbocharger rotates in poor oil supply condition, it could cause damage of bearing seizure within few seconds. -

Page 257

06-5 0000-00 2) Inspection of Turbocharger When problem occurs with the turbocharger, it could cause engine power decline, excessive discharge of exhaust gas, outbreak of abnormal noise and excessive consumption of oil. On-board Inspection Check the bolts and nuts foe looseness or missing Check the intake and exhaust manifold for looseness or damage Check the oil supply pipe and drain pipe for damages Check the housing for crack and deterioration… -

Page 258

06-6 3) Inspection of Turbine Thoroughly check the followings. Must absolutely not operate the turbocharger with the compressor outlet and inlet opened as it could damage the turbocharger or be hazardous during inspection. Interference: In case where is trace of interference or smallest damage on the compressor wheel means, most of times, that abrasion has occurred on the journal bearing. -

Page 259

06-7 0000-00 4) Possible Causes of Defect The following tries to understand the defects that can occur with vehicle installed with the turbocharger and to manage the reasons of such defects. In case where oil pan/oil pipe has been contaminated, oil filter is defected and where adhesive of gaskets has been contaminated into the oil line. -

Page 260

06-8 Oil Pump Defect: Rapid over-loaded driving after replacing oil filter and oil and clogging of oil line. -

Page 261

06-9 0000-00 Turbine Side: Inflow of foreign materials from engine Compressor Side: such as air filter, muffler and nut… -

Page 262

06-10 Defects caused by reasons other than that of the turbocharger. -

Page 263

06-11 0000-00 3. TROUBLESHOOTING The followings are cautions to take in handling defects of turbocharger, which must be fully aware of. 1) Cautions After stopping the engine, check whether the bolts on pipe connecting section are loose as well as the connecting condition of vacuum port and modulator, which is connected to the actuator. -

Page 264

06-12 2) Work Flow for Troubleshooting… -

Page 265

06-13 0000-00… -

Page 266

06-14… -

Page 267

06-15 0000-00… -

Page 268

06-16… -

Page 269

06-17 0000-00 1. SYSTEM DESCRIPTION OF E-VGT (Electric-Variable Geometry Turbine) A turbocharger is a centrifugal compressor powered by a high speed turbine that is driven by an engine’s exhaust gases. Its benefit lies with the compressor increasing the mass of air entering the engine (forced induction), thereby resulting in greater performance (for either, or both, power and efficiency). -

Page 270

06-18 1) Features (1) Performance (for EURO V) Enhanced emission control: By temperature control with CDPF system Target temperature and airflow control (2) E-Actuator (Electric-Actuator, Rotary type) Optimizes the exhaust gas flow rate by controlling the vanes inside the turbine housing with the E- Actuator. -

Page 271

06-19 0000-00 2. COMPONENTS For more information about control logic, refer to Chapter «Engine Control». E-VGT turbocharger Engine ECU (D20DTF) Accelerator pedal position sensor Atmospheric pressure, RPM signal Transfers accelerating demand to ECU Improves engine power E-VGT duty control T-MAP sensor HFM sensor Coolant temperature sensor Operates the VGT according to… -

Page 272

06-20 3. INPUT/OUTPUT DEVICES… -

Page 273: Operating Principles

06-21 0000-00 4. OPERATING PRINCIPLES The E-VGT is designed to get more improved engine power in all ranges by controlling the turbine as follows: 1) How it Works at Low Speed Normal turbocharger cannot get the turbo effect because the amount of exhaust gas is not enough and the flow speed is slow in a low speed zone, but VGT allows the flow passage of exhaust to narrow, resulting in increasing the flow speed of exhaust gas and running the turbine quickly and powerfully.

-

Page 274

06-22 2) How it Works at High Speed In a high speed zone, the amount of exhaust gas increases and it is accompanied with a great force. Therefore, if the inner diameter of venturi is more widened, the turbine in the turbocharger by the releasing force of abundant exhaust gas can deliver a more increased energy to the compressor. -

Page 275

Type Fulle flow/Paper element Engine oil Specified oil Quality class: Ssangyong genuine engine oil (Total Quartz INEO ECS 5W 30, SK ZIC SY 5W 30 or oil Approved by MB 229. 51) SAE 5W30 Capacity Min.: 4.5 L / Max.: 6.0 L… -

Page 276

07-4 2. MAJOR CHANGES ▶ Oil pressure switch 0000-00 Oil pressure switch — Newly added oil pressure switch (B) instead of oil level switch (A) -

Page 277

Recheck the oil level after 5 minutes. Regularly check the engine oil level and add Ssangyong genuine engine oil if necessary. Clean the dipstick with clean cloth so that any foreign materials cannot get into the engine. -

Page 278

07-6 1. SYSTEM DESCRIPTION 1) Overview The lubrication system supplies oil to each lubrication section to prevent friction and wear and to remove heat from the friction part. As the engine runs, frictional heat is generated on each lubrication section. If this condition persists, the bearing can be burned and stuck. -

Page 279

07-7 0000-00 3) Oil Filter Module The oil filter module consists of lubrication system, cooling system and some mechanical devices as below. System Components Supplementary devices Power steering pump (HPS), Alternator, A/C compressor Belt drive Belt tensioner, Idle pulley Cooling Water pump, Thermostat, Cooler housing and Pipes Lubrication Oil filter, Oil cooler (except coolant pipes) -

Page 280

07-8 2. OPERATING PROCESS 1) Operation Flow… -

Page 281

07-9 0000-00 3. LUBRICATION 1)Anti-friction The oil makes a thin film on the surface of sliding components to reduce the wear due to friction. 2)Cooling The friction makes the heat on the components. The oil absorbs the heat and radiates it or cools it down. 3) Sealing The piston ring on the piston seals the cylinder. -

Page 282

08-3 0000-00 1. SPECIFICATION Description Specification Cooling system Type Water cooling, forced circulation Coolant Capacity Approx. 8.5 liter 740W X 380H X 27t (over 281,200㎣) Core size Radiator Flow type Cross flow Min. cooling capacity over 68,000kcal/h Type Long life coolant (SYC 1025) Antifreeze Mixing ratio 50 : 50… -

Page 283

08-4 2. INSPECTION Possible Cause Action Coolant level — Leak from the radiator — Replace the radiator is too low — Leak from the auxiliary reservoir — Replace the auxiliary reservoir — Leak from the heater core — Replace the heater — Leak from the coolant hose connections — Reconnect the hose or replace — Damaged coolant hose… -

Page 284

08-5 0000-00 1) Coolant Level Check Park the vehicle on level ground and apply the parking brake. Stop the engine and wait until it is cooled down. The coolant level should be between the MAX and MIN mark on the coolant reservoir. Check the coolant level. -

Page 285

08-6 2) Leak Test Release the pressure in the system by loosening the pressure cap of the coolant reservoir slightly. Then, remove the pressure cap completely. Never open the cap until the coolant temperature becomes under 90℃ to prevent any burn. Add the coolant so that the coolant level is between MAX and MIN mark on the coolant auxiliary tank. -

Page 286

08-7 0000-00 3. CAUTIONS If 100% of anti-freeze is added, the water pump vane can be damaged and thermal conductivity can be decreased resulting in poor circulation in the cooling system which leads to overheated engine. Use of non-recommended coolant could cause damage to the cooling system and overheating of the engine. -

Page 287

08-8 1. SYSTEM DESCRIPTION 1) Overview Coolant reservoir Long life coolant is used. Water pump Sealing Oil filter module Water pump pulley Impeller vane The water pump is driven by the engine drive belt and supplies the coolant to each area of the engine. Thermostat When the engine coolant reaches 90℃, the thermostat… -

Page 288

08-9 0000-00 Coolant temperature sensor Measures the coolant temperature and sends the result to the engine ECU. Electric fan Circulates the fresh air forcibly to exchange heat with the radiator core fin. Radiator Releases heat through fins and cools down the hot coolant as the coolant passes through the tube of the radiator core. -

Page 289

08-10 3) System Layout… -

Page 290

08-11 0000-00… -

Page 291

09-3 0000-00 1. SPECIFICATION Specification Alternator Crankshaft pulley : Alternator Pulley 1 : 2.94 Normal output (idling/2200 rpm) 70/120 A 70/140A ← Regulator voltage 14.6 V ← Brush Length 12.5 mm ← Wear limit 7 mm ← Battery Type ← Capacity 90AH… -

Page 292

09-4 2. INSPECTION 1) Alternator Output Test Item How to check DTC set value / Action Disconnect the cable connected to the B Pass: If the measured current is 45 A terminal on the alternator. Connect one end or higher. of the ammeter to the B terminal and the Fail: If the measured current is less other end to the cable connected to the B… -

Page 293

09-5 0000-00 2) Troubleshooting for Alternator Item Cause Action Overcharged battery Defective alternator voltage regulator Replace defective alternator detection wiring Repair or replace Discharged battery Loose alternator drive belt Adjust the belt tension or replace Poor connection of related circuit or Retighten the loose connection or open circuit repair open circuit… -

Page 294

09-6 3) Checking Battery… -

Page 295

09-7 0000-00 (1) Checking ▶ Using battery tester PASS (11.0 V or more): Explain to the customer that the battery is reusable. Need to be charged (9.0 to 11.0 V): Charge the battery with a charger and reinstall it. Explain it to the customer. -

Page 296

09-8 (3) Starting with jumper cable If the battery is weak or terminated, the battery from another vehicle can be used with jumper cables to start the engine. ▶ Connecting order The positive (+) terminal of the discharged battery The positive (+) terminal of the booster battery The negative (-) terminal of the booster battery Connect one end of the other jumper cable to the body of the discharged vehicle, such as the engine block or a front towing hook. -

Page 297

09-9 0000-00 (4) Maintenance If the charge warning lamp ( ) on the instrument cluster comes on while driving, there is a malfunction in the charge system including the battery. Therefore, carrying out the system check is needed. Make sure that the battery cables are firmly connected. If the terminals are corroded, clean them with a wire brush or sandpapers. -

Page 298

09-10 1. SYSTEM DESCRIPTION 1) Overview The charge system is designed to supply electrical energy to the vehicle while driving, and supplies a constant direct current voltage by converting mechanical rotational movement to electrical energy. The voltage regulator on the back of the alternator controls the generated voltage in all rotating ranges and adjusts the system voltage according to the electric load and ambient temperature change. -

Page 299

09-11 0000-00 3) Charging The alternator uses a new regulator which has three diodes. It consists of the delta stator, rectifier bridge, slip ring and brush. ▶ Charging time according to vehicle conditions and environment Specification: Charging a fully depleted high- capacity battery takes twice or more as long as charging a fully depleted battery for small vehicles. -

Page 300

09-12 2. CHARGING OPERATION 1) With Smart Key System… -

Page 301

09-13 0000-00 2) Without SMART Key System… -

Page 302

09-14 3. CIRCUIT DIAGRAM… -

Page 303

09-15 0000-00… -

Page 304

10-3 1413-00 1. SPECIFICATION Description Specification Glow plug Rated voltage 4.4 V 1100°C Maximum temperature 1080 to 1100°C Operating temperature Glow plug control unit EMS operating voltage 6 to 16 V -40°C to 110°C Operating temperature Dark current Max. 1 mA… -

Page 305

10-4 2. TIGHTENING TORQUE Glow plug GCU (Glow plug Control Unit) Name Tightening torque 15 ± 1.5 Nm Glow plug 10 ± 1.0 Nm Glow plug control unit bolt… -

Page 306

10-5 1413-00 1. OVERVIEW The pre-heating system for D20DTF engine has the glow plug to the cylinder head (combustion chamber), and improves the cold start performance and reduces the emission level. The pre-heating resistor (air heater) is used to heat the intake air. This enables the diesel fuel to be ignited in low temperature condition. -

Page 307

10-6 2. SYSTEM OPERATION 1) Input/Output Diagram of Glow Plug Control Unit 2) System Diagram… -

Page 309

10-8 3) Circuit Diagram… -

Page 310

10-9 1413-00… -

Page 311

10-10 4) System Operation Glow plug is installed in the cylinder head. It enhances the cold starting performance and reduces the exhaust gas during cold starting. ECU receives the various signals such as engine rpm, coolant temperature and vehicle speed through CAN communication lines. -

Page 312

10-11 1413-00 (3) Operating Steps ▶ Pre-Glow: Step 1 If normal communication with the ECU is established 2 seconds after the power is supplied to the IGN terminal from the battery, the GCU supplies the battery power to raise the temperature of the glow plug to 1000℃… -

Page 313

10-12 ▶ During cranking: Step 2 and step 3 Step 2: If the ECU receives the cranking signal after pre-heating (step 1), the GCU supplies the voltage of 6.8 V for 1 sec to raise the temperature to 1,100℃. Step 3: The GCU supplies the voltage of 5.1 V to keep the temperature at 1,000°C. Under fixed temperature: The AQGS unit supplies power for 30 seconds (Step 1 + Step 3) if no cranking signal is received after the step 1. -

Page 314

10-13 1413-00 ▶ Normal operating mode This shows the components of preheating system in the pre-heating and the post-heating steps. -

Page 315

10-14 ▶ When there is no engine cranking signal after turning the ignition key ON… -

Page 316

11-3 1461-00 1. SPECIFICATION Capacity 12V 2.3kW Engagement Meshed type Rotating direction Clockwise Pinion gear manufacturing Cooled forging Solenoid operating voltage Max. 8 V Weight 2.5 kg Bracket manufacturing Aluminum die casting… -

Page 317

11-4 2. TROUBLESHOOTING Possible Cause Problem Action Low battery voltage Charge or replace Loose, corroded or damaged battery cable Repair or replace Engine will not crank Faulty starter or open circuit Faulty ignition switch or blown fuse Repair or replace Poor engine ground Repair Low battery voltage… -

Page 318

11-5 1461-00 1. SYSTEM DESCRIPTION The starter (start motor) starts the engine with rotational power by converting the electric energy to the mechanical energy. When the engine is cranking, the pinion gear meshes with the ring gear. If the ring gear overruns, the pinion gear clutch overruns to protect the pinion gear. -

Page 319

11-6 2. OPERATING PROCESS 1) System Layout (1) Engine start SKM performs the authentication process for the SMART key and sends the engine start request to EMS if there is a normally coded SMART key when pressing the Engine Start/Stop button with the brake pedal depressed and gear shift lever in “P”… -

Page 320

11-7 1461-00 (2) With SMART key system… -

Page 321

11-8 (3) Without SMART key system… -

Page 323

11-10 2) Circuit Diagram (1) With SMART key system… -

Page 324

11-11 1461-00… -

Page 325

11-12 (2) Without SMART key system… -

Page 326

11-13 1461-00… -

Page 327

12-3 8530-00 1. OVERVIEW 1) System Description Auto cruise operated ECO cruise operated The cruise control is an automatic speed control system that maintains a desired driving speed without using the accelerator pedal. The cruise control switch is under the right side of steering wheel and ‘ECO”… -

Page 328

12-4 2) Traffic Conditions for Using Cruise Control Use the cruise control system only when the traffic is not jammed, driving on motorways or highways where there is no sudden change in the driving condition due to traffic lights, pedestrian, etc. Improper use of the cruise control could be dangerous. -

Page 329

12-5 8530-00 2. CONFIGURATION 1) Circuit Diagram The engine ECU detects the operating conditions of cruise control system, and monitors the braking performance, vehicle speed, road conditions and ESP system operation. If the engine ECU determines that there are not any problem to drive in cruise control mode, the vehicle can be operated by cruise switch signals (decelerating, accelerating, cruising). -

Page 330

12-6 2) Components Test voltage(VCC 5V) FUNCTION KEY VOLUE REMARK MAIN 0.15 ~ 0.55V DECEL 0.7 ~ 1.1V ACCEL 1.6 ~ 2.0V RESUME 2.52 ~ 2.92V 4.22 ~ 4.82V… -

Page 331

12-7 8530-00 3. OPERATION 1) Setting a Desired Speed To operate the cruise control, accelerate to the desired speed, which must be more than 38 km/h (24 MPH) and less than 150 km/h (90 MPH). In the vehicle equipped with manual transaxle, the gear shift lever should be in 3rd (GSL: 2nd) or higher gear position. -

Page 332

12-8 2) Accelerating with the Cruise Control System (1) While the cruise control system is running Push up the ACCEL switch of the cruise control lever and hold it until the desired speed is reached without an accelerator pedal intervention. When the desired speed is reached, release the lever. -

Page 333

12-9 8530-00 3) Decelerating with the Cruise Control System (1) While the cruise control system is running Push down the DECEL switch of the cruise control lever and hold it until the desired speed is reached without a brake pedal intervention. But the cruise control system cannot maintain the cruise function at less than 38 km/h. -

Page 334

12-10 4) Recovery of Set Speed (RESUME) Even if the cruise control is cancelled, the previous set cruise speed can be recovered by pulling up the cruise control lever when the current vehicle speed is over 38 km/h without an acceleration intervention. But if you turn off the ignition switch, the memorized set speed is cleared and you cannot recover the previous set speed. -

Page 335

12-11 8530-00 5) ECO Cruise Control ECO cruise is ready and ECO cruise indicator on the instrument cluster comes on when pushing down the cruise control lever. To activate the ECO cruise mode, push down the cruise control lever again. To cancel the ECO cruise mode while in operation, push down the cruise control lever again. -

Page 336

12-12 6) Normal Cancellation of the Cruise Control The cruise control system will be canceled when one or more items of the following conditions are applied; When the brake pedal is depressed. When the cruising speed is decreased less than 38 km/h. When pushing the ON-OFF switch of the cruise control lever. -

Page 337

But if the cruise control system isn’t recovered, you should contact a Ssangyong Dealer for diagnosis of the cruise control system. Abnormal changes of the gear selector lever can damage the yyengine. Do not move the gear shift lever to Neutral while driving at the set speed. -

Page 338

13-3 1793-01 1. SPECIFICATION Item E-EGR valve Motor EGR response time 50 mS Driven by DC motor Valve EGR gas flow rate 120 Kg/h Position sensor Sensing type Hall sensor 5V ± 10% Supply voltage Signal range 5% ~ 95% <15mA Max. -

Page 339

13-4 1. SYSTEM DESCRIPTION 1) Overview The EGR (Electric-Exhaust Gas Recirculation) valve reduces the NOx emission level by recirculating some of the exhaust gas to the intake system. To meet Euro-V regulation, the capacity and response rate of E-EGR valve in D20DTF engine have been greatly improved. -

Page 340

13-5 1793-01 2) Location and Components E-EGR cooler and bypass valve HFM sensor EGR cooler EGR bypass Used as a main map value to control the EGR. The cooler lowers the high temperature of the The coolant temperature, engine rpm, engine exhaust gas and the bypass valve directly load, intake air temperature (HFM: decreased at 60˚C or more), atmospheric pressure… -

Page 341

13-6 2. OPERATING PROCESS 1) Schematic Diagram… -

Page 342

13-7 1793-01 2) Input/Output Devices 3) Control Logic The EGR system controls the EGR amount based on the map values shown below: ※ Main map value: Intake air volume ※ Auxiliary map value: Compensation by the coolant temperature Compensation by the atmospheric pressure: Altitude compensation Compensation by the boost pressure deviation (the difference between the requested value and the measured value of boost pressure) Compensation by the engine load: During sudden acceleration… -

Page 343

14-3 1114-00 1. SPECIFICATION Emission Regulation Euro-V Front Area 182.41cm 124 X 158 X 78L Size 124 X 158 X 194L Shell SUS430J1L X 1.5t CDPF Canister End Cone SUS430J1L X 2.0t (Single) Catalyst Capacity 4.2L CDPF Material of Filter AT (Aluminum-Titanium Alloy) -

Page 344

14-4 2. CAUTIONS ▶ Standard pattern of soot accumulation (1) Abnormal Soot Accumulation (2) Normal Soot Combustion ▶ Cautions to protect the catalyst filter Use the designated fuel only. Observe the recommended service intervals of engine oil. Check the engine oil level frequently and add if necessary. Do not idle the vehicle unnecessarily. -

Page 345

14-5 1114-00 (3) Warning Lamp Related to CDPF ▶ CDPF regeneration process (warning lamp NOT illuminated) The CDPF system enters the regeneration mode when the driving distance becomes approx. 600 to 1,200 km (may differ by the driving condition and driving style). Then, the engine ECU performs the CDPF regeneration operation. -

Page 346

14-6 ▶ Excessive overload of CDPF (warning lamp illuminated) If the vehicle is driven at a speed of 5 to 10 km/h for an extended period of time, the soot accumulated in the CDPF cannot be burned as the CDPF cannot reach the regeneration temperature. -

Page 347

14-7 1114-00 1. OVERVIEW The DOC (Diesel Oxidation Catalyst) generates CO2 and H2O which are harmless through the oxidation process of CO and HC. And the DPF (Diesel Particulate Filter) collects PM (Particle Matter) and is regenerated to reduce the quantity of particulates, HC and CO. But there is a limitation in reducing the emission of exhaust gas for each system, so the CDPF which combines these two system is applied. -

Page 348

14-8 2. COMPONENT Rear temperature CDPF Oxygen Front temperature sensor (DOC + DPF) sensor sensor Measures the Protects the temperature of fuel turbocharger. combustion. Engine ECU (D20DTF) Differential pressure sensor Electric throttle body Calculates the amount of PM collected by reading the pressure Regulates the rate of air difference between before and intake. -

Page 349

14-9 1114-00 3. INPUT/OUTPUT DEVICES Front temperature sensor: This sensor is installed at the inlet of DOC and detects whether the DOC can burn (oxidize) the post-injected fuel or not. Rear temperature sensor: This sensor is installed at the inlet of DPF and monitors that the temperature of the exhaust gas is kept at 600℃. -

Page 350

14-10 4. POST-INJECTION AND AIR MASS CONTROL A DPS (Differential Pressure Sensor) measures the pressure difference between before and after the CDPF and detects whether the soot is collected in the CDPF or not. If PM is collected in the CDPF (In this case the pressure difference between before and after the CDPF exceeds the specified value. -

Page 351

14-11 1114-00 Front EGT sensor Rear EGT sensor HFM sensor Intake air volume ECU (DCM 3.7) Measures the temperature of Measures the temperature of DOC. DPF. The DOC performs the redox The DPF burns the soot with reaction at between 300 and hot exhaust gases 500℃… -

Page 352

14-12 5. OPERATING PROCESS [Configuration and principle of operation] Collecting PM Oxidation (DOC) → Regeneration The exhaust gas When the exhaust gas enters The engine ECU detects the into the CDPF assembly, its amount of PM collected by the passed through the CO, HC and PM are reduced information from the exhaust manifold… -

Page 353

14-13 1114-00 6. OPERATING TEMPERATURE… -

Page 354

14-14 7. ELECTRIC CIRCUIT DIAGRAM… -

Page 355

14-15 1114-00 8. CAUTIONS 1) Designated Engine Oil for CDPF (Low Ash Oil) Need to use the designated engine oil for CDPF The smoke from the vehicle may generate the particle material in the ambient air. CDPF is the device to reduce the smoke by collecting and recycling it. To ensure the performance of CDPF, the designated engine oil should be used. -

Page 356

14-16 9. DESCRIPTION ON CDPF REGENERATION Sensor item Data Unit Description Driven distance from last Driven distance from last generation up to CDPF regeneration CDPF regeneration history Display regeneration history (distance/time) (distance/time) Index stored until now in figure, Index ([0] ~ [4]) Driven distance between The regeneration distance/time is stored up CDPF regenerations[0]… -

Page 357

14-17 1114-00 Sensor item Data Unit Unit Times of CDPF regeneration The ECU calculates the soot mass from start (soot mass from engine) engine in consideration of the engine RPM, based on the ECU base MAP. The ECU regenerates the CDPF automatically when it determines that the accumulated soot is about 36 g or greater. -

Page 358

15-3 0000-00 1. ENGINE DATA LIST Data Unit Value ℃ 0.436 V (130℃) to 4.896 V (-40℃) Coolant temperature ℃ -40 to 130℃ (varies by ambient air Intake air temperature temperature or engine mode) 780 ± 20 Idle speed 750 ± 20 Engine load 18~25% Mass air flow… -

Page 359